You must be logged in to rate content!

8 minute(s) of a 175 minute read

6-30-2008

so , i got some stuff in today , mainly the alternator relocation bracket , k&n filter , and other assorted doodads.

i also got the tensioner back from the machine shop, and now its adjustable

the new bracket and brace should be done tomorow. i also had them make new spacers to go inplace of the alternator in its bracket. ( so the bracket won't break)

funny thing happened when i was removing the alternator, i tried to spin it but it was seized! i couldn't figure out why it was like that , but when i tryed to twist it with a bit of force it made some grinding noises and a buttload of sand came pouring out . so i took out the alt. and blew air through it and cleaned it . now it spins freely ! ( stupid sand storm  )

)

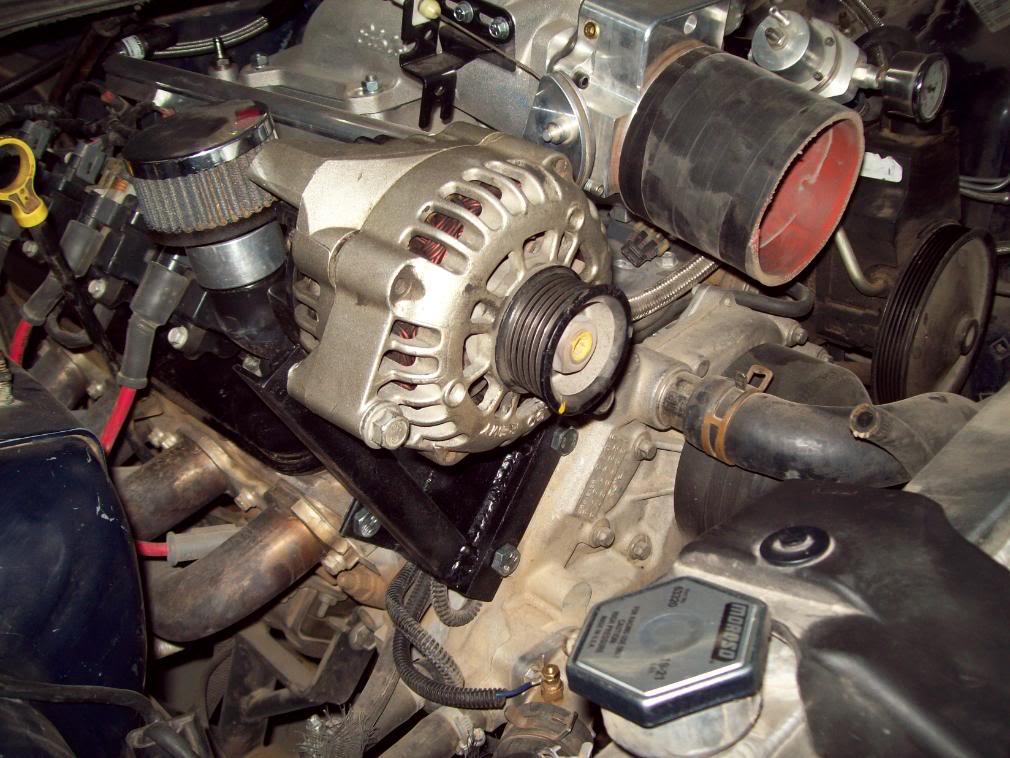

i also installed the smokn' hawk alternator relocation bracket loosely to test fit the alternator ( i need to get new bolts and a tensioner - mine is a billet non-sprung one).

happy to report it clears the fuel rail . i used another ls1 alternator to test fit , but i will check final fitment tomorow with the f-body one to make 100% sure.

i also ended up rerouting the alternator wires , which came out quite neat in my opinion

the biggest bummer of the day is that i finally got the super pulley back from the machine shop ( after narrowing it down by 12 mm ), and when i take the F2 out to put the superpulley on it , i find out i was sent the wrong shaft diameter pulley !! the pulley is for the large shaft blower , while mine is the small one - like the F1-r and D1-sc.

the good news is that i will take it to the machine shop tomorow to have them make an adapter if you may call it that . i already talked to the guy there and he said no problem  they do this kind of stuff all the time.

they do this kind of stuff all the time.

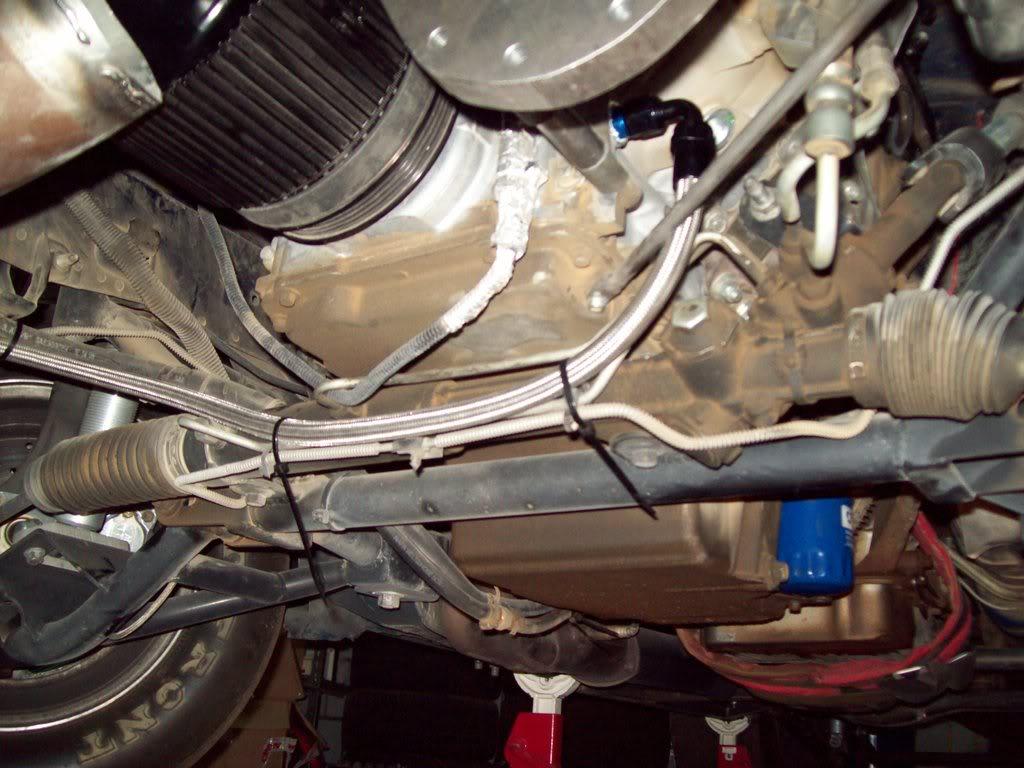

another no go was my plan on running a sump in the rear plastic tank. i was hoping it would have a flat enough spot to cut a hole big enough for the sump and epoxy it in place. i checked and it seems like it wouldnot work. guess i will just stick with what i have now: a bulk head fitting in the bottom of the tank with a -10 hose connected to it . i'm also planning on drilling another hole somewhere in the corner of the tank and install another bulkhead connector and cap to work as a drain for when ever i need to drain my tank.

what i have planned for tomorow :

- drop off the pulley and have the machine shop make an adapter.

- pick up the new blower bracket and alternator spacers

- install vacuum block and route vacuum hoses

- install the alternator and its bracket

- install the blower bracket and tensioner

- most likely buy a battery for putting in the rear.

on a side note, i just ordered an intercooler for the stang ,, which should be here in a couple of weeks ,which means all my parts will be accounted for and then , the stang build thread commences

7/5/2008

time for some updates:

the super pulley is a no go  - just ordered a new one , but i will try another machine shop !)

- just ordered a new one , but i will try another machine shop !)

got a battery ( yay!  )

)

finished wiring the fans , they now come on with the ignition on , and i have a swith to kill them if i need to .

i also finally finished all the vaccum lines , i used a vacuum block i took off my stang a while back ( who said fords are useless  ) and routed the main line from the manifolt to it , then from the block to various other thingys :

) and routed the main line from the manifolt to it , then from the block to various other thingys :

got the alternator and tensioner mounted for the last time :

also got the alternator bracket spacers done and installed :the brace (the bar sticking diagonally ) is the old one , i didn't like how the new one turned out , so i'm building a totally "redesigned" brace . the tensioner now clears the crank cog and has sufficient travel::

here is a side by side shot showing how i notched the new bracket :

also almost finished the tube going from the intercooler to the TB, i welded a bung on it to thread in the IAT sensor, and will be welding two nuts to hold the methanol nozzles on there too.

so , up next is the following:

-label the switches on the dash ( just two labels  )

)

-plumb the oil accumulator from the block to the canister.

-remove the passenger side header extension to weld the crankcase evac. thingy

-travel limiter

-put driver side header back on

-remove tranny for rebuild and maybe , just maybe , swap out the oil pan gasket .

-wire the alternator light and the AFR warning light from the dynojet commander

7/9/2008

i got some stuff done in the last few days. i also managed to get a new fiberglass hood for my stang and this lightweight seat ( also fiberglass), all i need to it is upholster it and fabricate a mounting bracket/ base for it.:

also managed to finish up plubming the oil accumilator:

i finally got around to installing a drain on the gas tank, it basically a bulkhead fitting with a cap.

( what do you do when you need some one to hold a wrench on one side of the car while you are on the other side, but no one is around??? )

according to my all knowing excell sheet, i finished 40% of the items on my list

so hopefully tomorrow i will finish cleaning the inside of the tank and button it up.

i should have the methanol injection nozzle bungs welded in on my intake tube , i already welded the AIT sensor bung on there. i might even paint the tube black.

and from the list i posted in the post above, i will be putting the header back in so i can fire the car up to see if there are any leaks and what not.

after that , the tranny comes out and we see what kind of damage we have