You must be logged in to rate content!

8 minute(s) of a 548 minute read

4-1-2013

The State Government has recently disclosed that some 200 dead Crows had been found on a road near the township of Castlemaine, in North Central Victoria. Local Wildlife Officers were alarmed that these deaths may have signalled an outbreak of avian influenza.

The Government Department for the Environment and Conservation then hired an Ornithological Behavioural expert who over the ensuing six to eight weeks examined a random sample of the remains and determined that the birds had actually died from vehicular impact.

After an even more extensive and exhaustive study he also determined that 98 per cent of the deceased Crows had been killed after being hit by trucks while only 2 per cent were killed by cars.

After researching into why the results are so disproportionate and following several more weeks of investigation his report finally arrived back at the Relevant Ministers Office.

''When Crows eat road kill, they always set up a lookout Crow in a nearby tree to warn of impending danger. But while the lookout Crow could warn the other Crows with a cry of 'Cah' it had

not yet learnt to call out 'Truck'!

4-4-2013

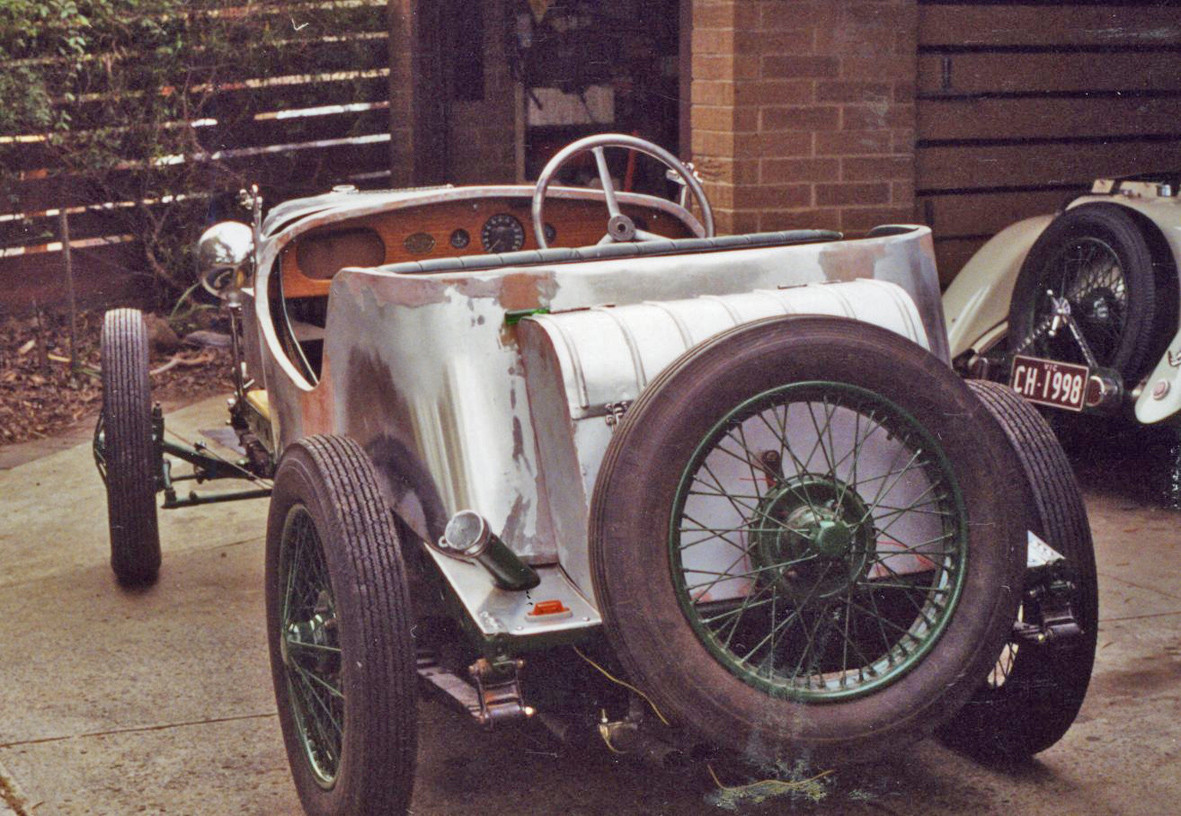

Moving forward with the review of some of my earlier restorations. This time the first of a series of Dodge Fours, this one according to the present owner a 1919 would be the earliest. I sold it almost finished but waiting the installation of the motor & gearbox and a set of tyres. The new owner completed the car fitting the fenders and the wire spoke wheels. He took it to the Lake Gardner Speed Trials (a salt lake in South Australia) where it was electronically timed at over 80 mph for the flying mile.

4-5-2013

Hello Roger

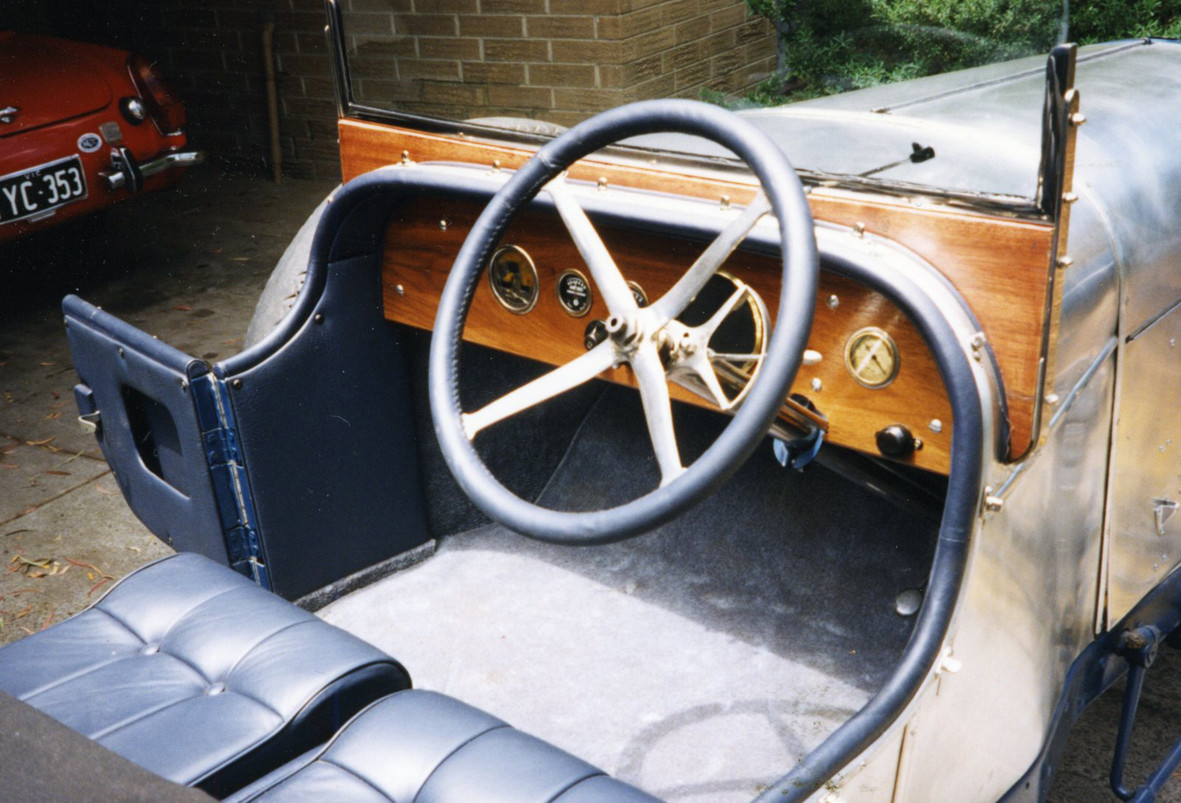

Yes the panels are all aluminium. I like working with Aluminium for body panels, It is light and comparatively easy to work. My first choice when selecting a new project is that it comes from the late teens or early twenties. Having made something of a study of the bodies on these cars it appears that most body builders did not own an "English Wheel" and compound curves were avoided wherever possible. I have found that I can build acceptable bodies in aluminium using simple curves only. By carefully planing how each panel is cut out, joins can be kept to a minimum. Judicious use of "crescent moulding" is regarded as being normal. Some amateur body builders do use it excessively which to me is just not acceptable. The Dodge Speedster body is an example. Including the door and luggage "boot" lid there are just six pieces of aluminium sheet plus the two infill panels each side of the tail. These were formed out of the piece cut out for the luggage "boot" opening. There are six pieces of Crescent mould. One each side of the tail following the outline, One piece around the cowl one piece along the top of the door and another piece covering the join each side of the cowl.The one on the passenger side is hidden by the spare wheel.

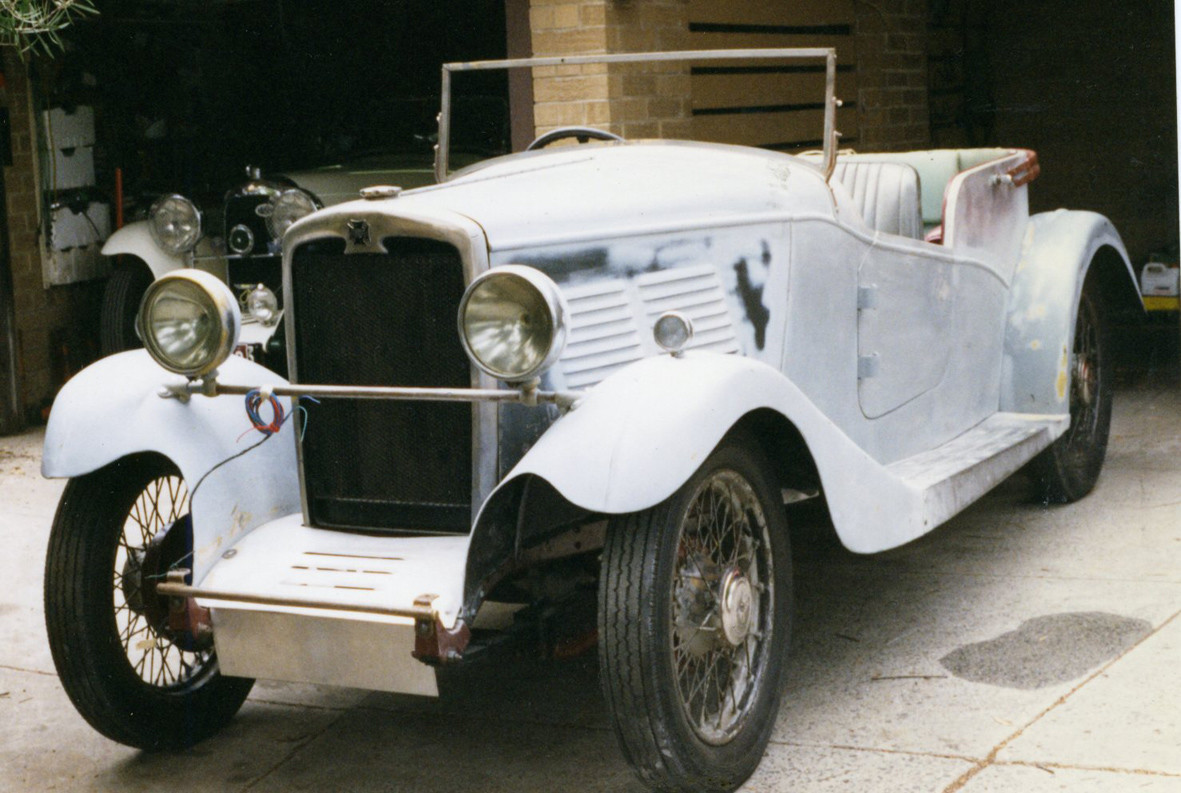

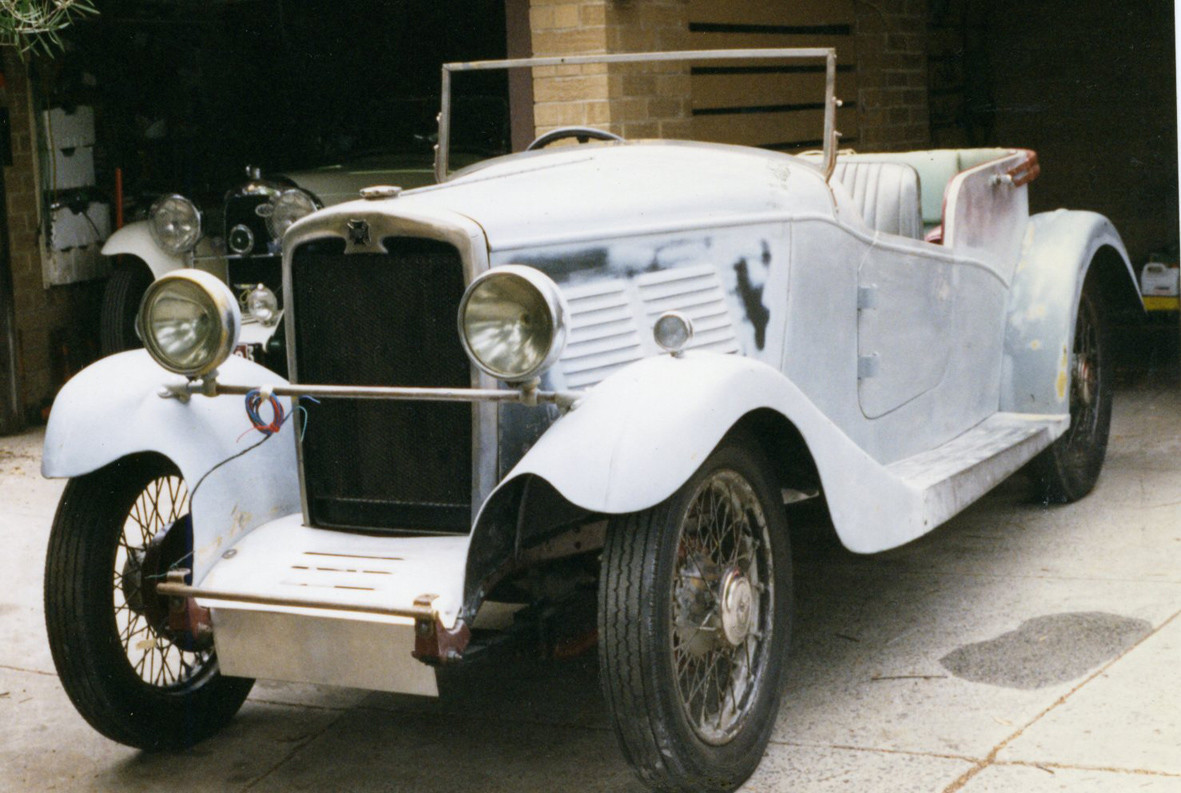

This principal can just as easily be applied to small English sporting cars of the 1930s. The attached photographs of the little 1932 Crossley 10hp is a classic example. Most of the saloon body had evacuated out the back of my trailer by the time it had travelled approximately 150 miles on country roads. Shown also is my patent "two bow" steel tube and strip top frame.

Roger can you tell me the number of individual pieces of Aluminium used in this body?

All my restorations including building the bodies are done single handed, in the same commodious one car garage and the car-port, open to all weather. This of course using only the most basic of hand tools. An electric drill, a angle grinder and an antique gas welding kit are my most sophisticated pieces of equipment.

Perhaps this explains why I have so very little tolerance for "poseurs" who cannot start their "restoration" until they have finished building and equipping their fully air conditioned home away from home. I would expect that a power operated recliner chair is the first piece of equipment purchased. An absolute must for fully technicolor dreams!

4-6-2013

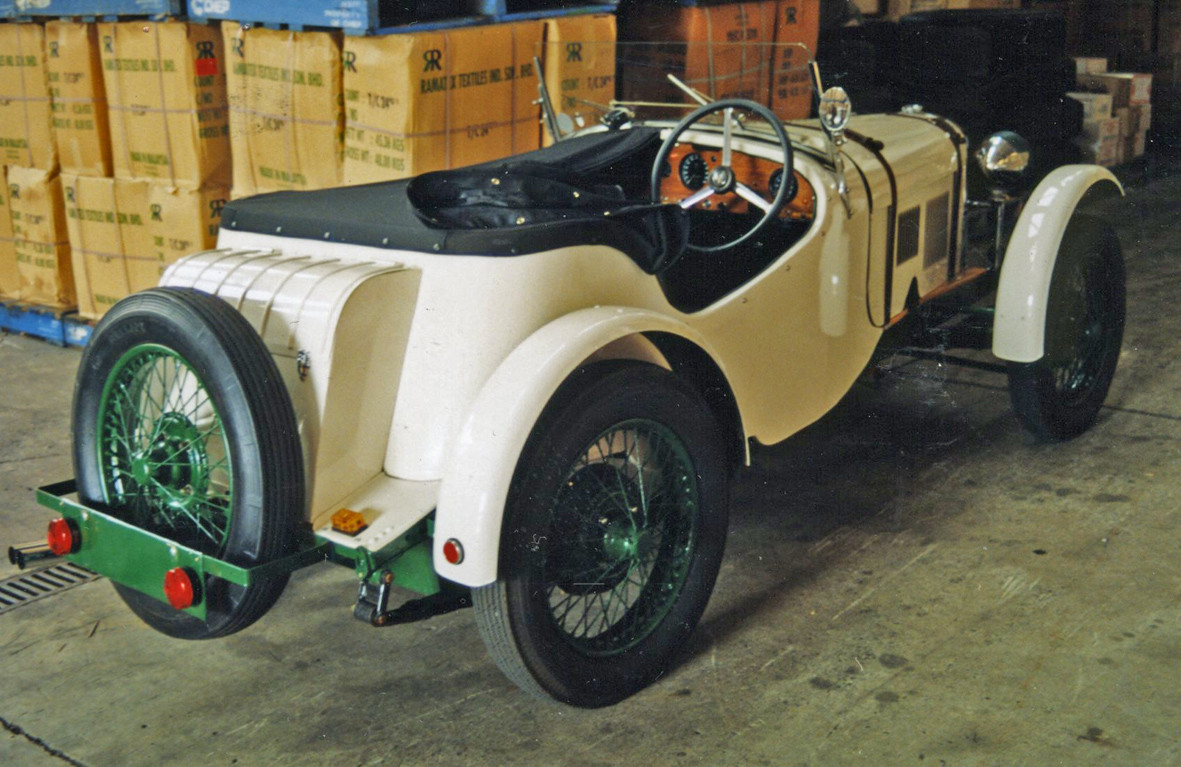

The same principle was applied for building the 1930 Austin 12/Six Sports, This one the chassis was shortened to the same wheel base as the 1930s Six cylinder MGs. It had a 1500cc six cylinder engine with three SU carburettors. It now lives in Switzerland not far from you Roger. It has been repainted black as it is now used for "Historic" Ice and Snow Racing. I probably enjoy these little sporting car restorations more than the huge and exacting project that the Packard became. In retrospect I would probably been far better served to simply dispose of the original body and built a "Cheap and Cheerful" speedster. It would have cost a whole lot less and would have been sold by now allowing me to move on to my next project.

Hello Pat

Crescent moulding is an extruded aluminium strip with an end section in the shape of a crescent. Domed on the outside radius and concave on the inside. It is commonly used as a cover strip. It usually comes in a variety of widths from 1/4 inch up to 1 1/2 inch. The one I normally use is 1/2 inch. It must be annealed to bend it horizontally. It is very useful for covering either butt or lapped panel joints.

Keep on keeping on

Hello Roger

I was referring to the actual body not the entire car. There is one piece for the top of the cowl, two pieces for each side, two for the doors, one for the rear, the trunk has two sides, and a back. then there are the two little aprons covering the gap between the rear fenders and the trunk. 12 pieces in all. It all comes out of a single sheet of aluminium. The fenders are, as is the hood, the original that came with the car. Access to the trunk is via the rear seat.

Keep on keeping on

4-7-2013

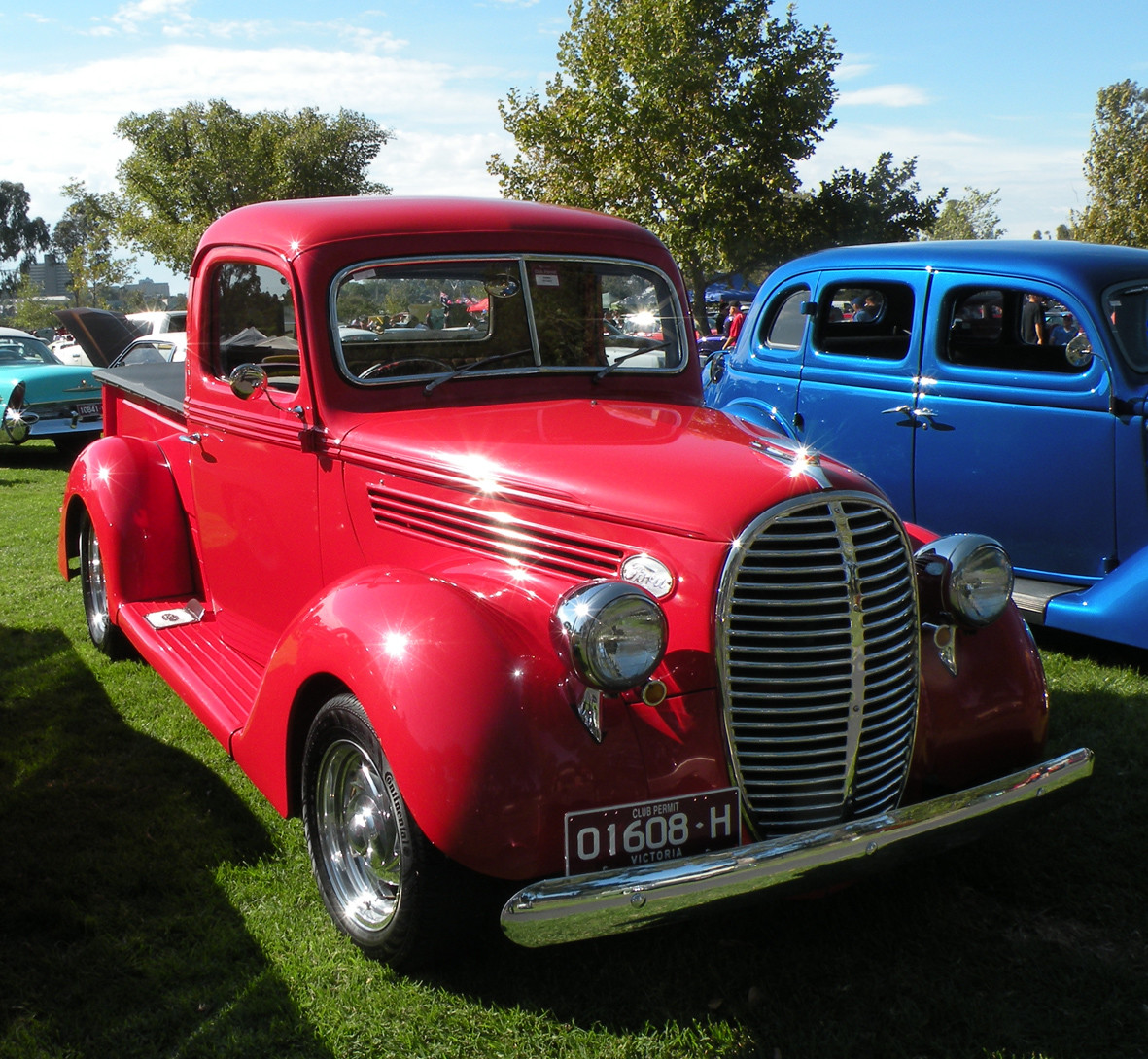

Yesterday we braved the Freeway traffic to DRIVE the Packard to the "All American Motoring Show"

Just a random sample of the almost 2,000 cars present. You could count the trailers on the fingers of one hand!

bravo!

Posted by CCmyVW on 1/26/20 @ 5:30:36 PM