You must be logged in to rate content!

7 minute(s) of a 390 minute read

12-2-2007

I've heard two different, very reputable LSX engine builders mention these lobes in passing, and finally looked them up:

Comp Cams : XTREME MARINEâ„¢ HYDRAULIC ROLLERS - HIGH LIFT

These have the same ramp designs as the lower lift Xtreme Marineâ„¢ designs but have higher lift to enhance power

output with cylinder head and engine modifications.

LOBE RATED DURATION IN LOBE TAPPET LIFT @ THEORETICAL VALVE LIFT

NUMBER DURATION DEGREES LIFT TDC @ “0â€Â LASH ROCKER ARM RATIO

CAMSHAFT TYPE

.050 .200 106° 110° 1.5 1.6 1.7

3473 290 234 152 .360 .081 .068 .540 .576 .612

3474 292 236 154 .360 .085 .071 .540 .576 .612

3410 294 238 154 .350 .088 .075 .525 .560 .595

3475 294 238 156 .360 .088 .075 .540 .576 .612

3376 296 240 157 .360 .092 .078 .540 .576 .612

3411 300 244 159 .350 .099 .085 .525 .560 .595

3370 304 248 167 .380 .107 .092 .570 .608 .646

3377 306 250 166 .360 .111 .096 .540 .576 .612

3371 308 254 171 .380 .119 .103 .570 .608 .646

3372 314 258 175 .380 .126 .111 .570 .608 .646

3373 318 262 179 .380 .134 .118 .570 .608 .646

3374 322 266 182 .380 .142 .126 .570 .608 .646

3375 326 270 186 .380 .149 .134 .570 .608 .646

3447 330 274 190 .380 .157 .141 .570 .608 .646

also from the 2007 comp cams catalogue it says:

"These profiles use the same design techniques of the baseline Xtreme Energy

â„¢ Hydraulic Rollers but have been optimized

to increase power and durability when run at steady rpm for extended periods of time. Specifically designed

for big blocks with heavier valve train components."

I'm only interested in the intake at 244 @ .05", but its advertised duration (or duration at .006" lift) is 300, vs the 293 of the origianl lobes I was going to use. These lobes sound great, they are designed for big ass heavy big block valves, which is exactly what I'm running with my 2.200" stainless intake valves. I don't need these lasier lobes on the exhaust because they are a more standard (and lighter) 1.600". The larger advertised duration (at the same .500" lift) will also allow me to run a little more advance and still have a lower DCR. At 8.6 I was pushing it a bit before.

I'll call comps help line before making any final decisions, but here's some food for thought.

Who would have thought, Marine Lobes in a road racer?!

12/12/07

I'm not saying that anyone would be disappointed if they went with a set up from vengence. 575 hp at the crank is pretty impressive! But I'm confident that my set up will do better. Also the trick flow heads are not as good as a ported LS7 head on a large bore block; if you care, look up the dyno graps of cars equipped with both on ls1tech.coms dyno comparison forum, then look up both of their dry flows from the published flow bench results, you'll see I'm right. And regarding the "vindicator" cam: It's traditional split is too narrow for the heavily biased intake (or you cold say relatively poor flowing exhaust) on the LS7 heads. It's overlap is also much more narrow than the cam I'm proposing, which will cost power for the sake of driveability. And finally, it's smaller, which is fine for the 364 ci that it was designed for, but on my 392 will cost power again. I appreciate peeps throwing out suggestions, but before you reccomend that I scrap all of my parts and ideas for something else, I'm just asking that you do a minimum of research, or actually come from a place of knowlege before you post....in the mean time some cool pics of the halibrands and 275mm falken 615s.

1/1/08

I wasn't being defensive. I just get a little frustrated on this forum sometimes. I post up technical questions about camshaft design, and instead of replys, I get peoples' opinions on what sounds cool, and "vindicator ftw".You're right though, long tubes do sound nastier. The only reason I havn't mentioned them much before is that I was waiting to see what my final exhaust valve size was going to be, what the cam specs were going to end up at, the final bore and strokea, etc. Once that info and more is locked in there will be some serious posts on calculating header diameter, triY design, step location, blah blah. There' some serious power to be had with the right pipes!I just got my LS7 heads back from West Coast racing heads, and I've got to go pull my LS1 heads to see if the exhaust ports and header bolt location are the same. I hope they are because I'd rather use my scabby LS1 heads for the custom header mock up.And yeah those are halibrand cobra IIIs that were originally designed for ac cobra replicas. At first I was all excited to have original halibrands, but later found out that right before these models were made halibrand stopped being a US designed and made. All four wheels were slightly out of round (have sinces been fixed at Pico tire and wheel just North of LA) and the backs (17x10.5) were only made for a very short period of time and are a slightly different color than the fronts (17x9 without the deep dish for extra caliper clearance).

1/12/08

Halibrands definitely tickle my pickle!

And the progress is slow but steady.

...but it's about to come to a screaming halt for the next three months.

I have to move to Trenton NJ for a surgical clerkship, and I'm going to have to take call, overnight every fourth night. Then I'll have to move again.

Went over to my old stomping grounds TTP in Passaic NJ and media blasted my valve covers. Worked out great. Then I used a dremel with a 80 grit roll to remove the casting marks. I think I'm going to try and polish 'em.

Took these pics for another thread to show how this bad boy is mid engine:

If you look close you can see the make-shift pendulum line that goes to the center of my front wheel. The car is level. And I think it's safe to say that this is a mid-engine car!

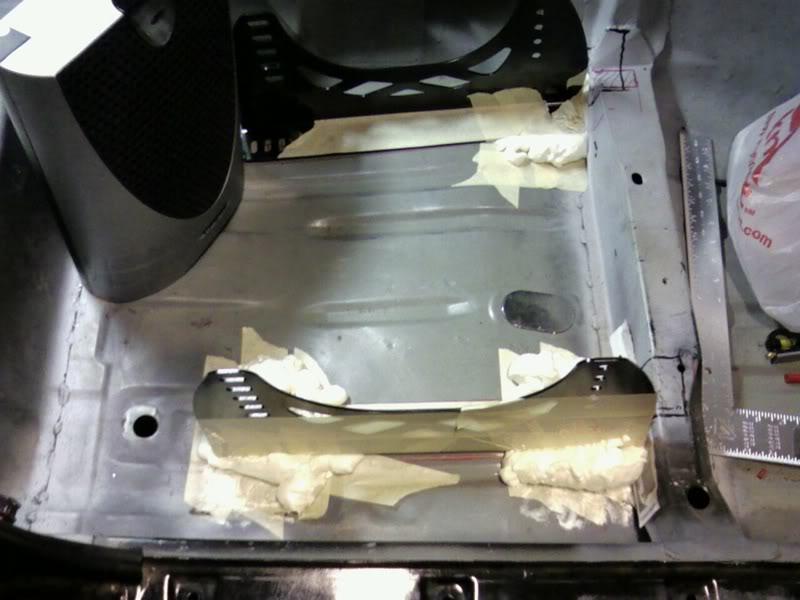

I've also been working hard on the seat mounts, because A: I want them low, and B: I want the seats in their final position before I weld in the harness bar.

First I removed the mini pilar that holds up the outer/rear stock seat mounting point, and then masked off everything. In order to make a template for the odd shaped floor, I bolted down my OMP seat mounts and injected some insulating foam. Cardboard templates may have been easier, but it was a fun experiment, and it worked out perfectly.

Notice the heater sitting in the car so that the foam would cure in my F'n freezing garage!

Good Nissan read!

Posted by Diggymart on 11/1/21 @ 12:53:02 PM