You must be logged in to rate content!

9 minute(s) of a 390 minute read

10-11-2012

Got inspired by a DIY FLCA and tension rod thread on NRR. So I ordered some 5/8 heims and 14mm high misalignment spacers from the UK.

When the spacers showed up they were upto 0.010" undersized. The summit 5/8 id, 3/4 -16 thread SUM-XMAXL10T Rod ends were dead on at 0.624-0.625" bore. I tried to find some 3/4" to 14mm spacers but couldn't find any.

Should I be concerned about this? The whole point of adding the heims is to get rid of deflection...

Here's a 20 second video of the play.

IMG 1458 - YouTube

the goal

I still need to buy an SAE tap and die set that goes upto 5/8"

I boutgh a cheap metric set at harbor freight and it's horrible. The threads are always loose. I want to pony up for a quality SAE tap and die set. Any reccomendations?

11/23/12

I ordered 5 of the walbro fuel pick-ups: 4x MP-12, and 1x MP-16. None of these have bleed holes, so if the tank ever truely runs dry I might have to take off a fuel line to relieve the vacuum, but APE assured me this was a better idea than providing a bleed hole that might allow air to get sucked into the fuel lines. Originally I intended to put the MP-16 (right angle pass through pick up) in the ATL sump, and send all four of the other pick ups to pass through the last MP-16. But when the pick-ups got here, those 5/16 barb inlet/outlets looked really small. I re-read APEs website,

"A single pickup can flow 40 gal per hour, so they work well with high-performance applications, too."

Auto Performance Engineering - Walbro fuel pick-ups

To put that into perspective a single Bosch 044 flows 53 gal per hour. So is 40 GPH of flow enough?

For Return-Style regulators:

Multiply maximum horsepower by .17 to calculate minimum pump size in "free flow" GPH.

Example: 400 HP x .17 = 68 GPH "free flow"

A single walbro pick-up shouldn't be a restriction until 235 hp (40 GPM/0.17)...

Maybe that's "high-performance" for a snowmobile...

So I'm probably going to need to use some sort of fuel block to run 2 or 3 lines from the pick ups to before the -8 AN OUT on the fuel cell. You really have to be careful with restrictions between fuel pick ups and fuel pump. Both restrictions and high fuel pump mounting placement lead to vapor lock fast.

-12 AN is the standard line used with dry sump set ups. It's damn big and hard to work with. But I read that some Nascar teams run -16 AN to pick up a small amount of horsepower. It makes sense. All automotive oil pumps are crank driven, and pushing oil around under pressure aint easy. For the straigh section of piping under the car (close to 12 feet) I'm planning on using -16 solid stainless line, and then stepping down to -12 for the flexible line.

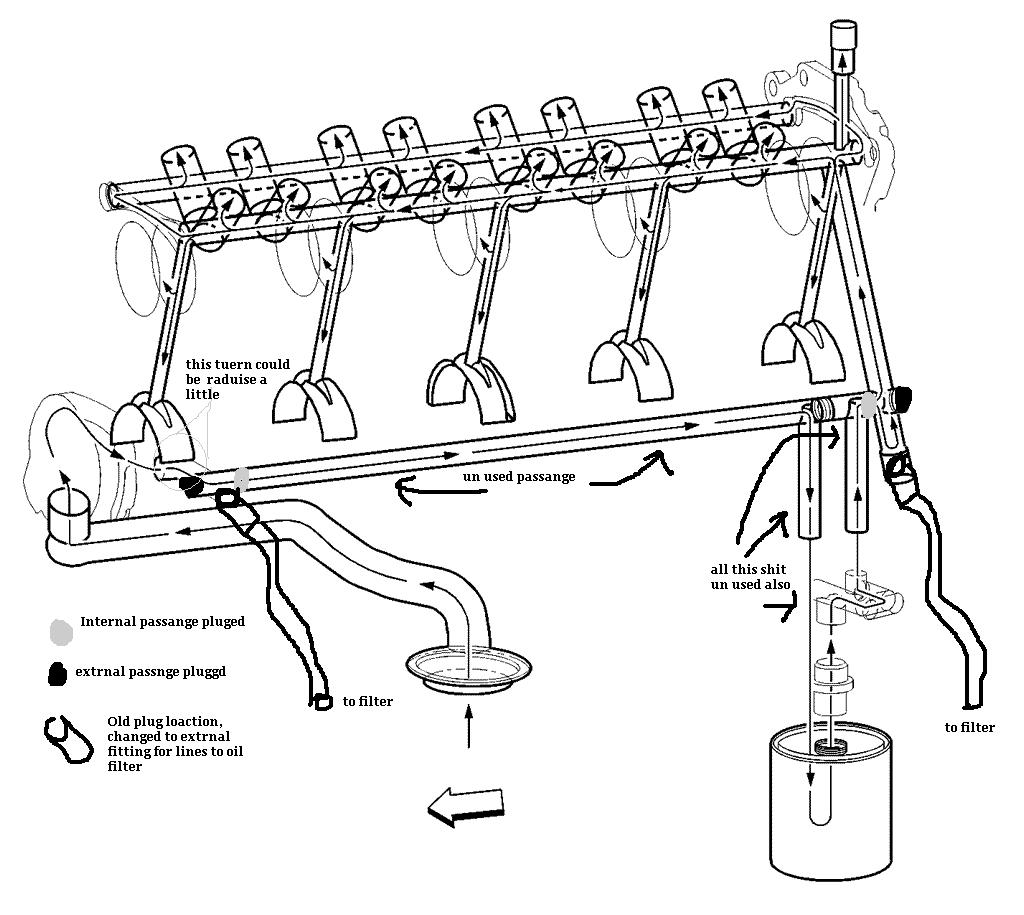

But if stepping from huge -12 line to even more rediculous -16 is worth some horsepower (and probably better oil pressure) imagine what removing some very sharp 90 degree bends would do. I have to get the oil out of the block and back for both the oil cooler and filter.

Count the number of 90 degree bends the oil has to take inside the block and stock fuel filter to get from the output of the LS1 oil pump to the back main galley...

I count 10!

The internal oil galleys of the LS1 are created by drilling out the block. Most of the bores go all the way through the block, and then the access sites are blocked with screw in plugs. Here's a pic of the two bore sites for the main galleys (at the corner of the block). The front bore gets blocked by the timing chain cover, but the threaded galley port (on the driver side of the block) gets a 16mmx1.5 plug that should probaby have a crush washer under it.

Kurt Urban makes an adapter to tap into the block, here's a pick of it in place of the semi-verticle galley plug at the driver side rear of the block. It has the weird 16mmx1.5mm thread on one end and a -10 AN on the other, custom machined from stainless (but it's $100)

There's also this

Summit Racing Part Number:FRA-460616

Fitting Size 1:-6 AN

Fitting Size 2:16mm x 1.5

(only $3.95)

But here's my problem with both of them.

Internal Oil galley ID: 0.571"mm

Fragola -6 ID: 0.375"

16mmx1.5mm thread minor diameter: 0.577"

EDIT:

I got an email from Todd Brandon (Manager at Kurt Urban) and the bore for their -10 AN adapter is 0.450" all the way through. So that's a minimum wall thickness of (0.577-0.450)/2 = 0.0635" where the threads are.

I really don't want to add another restriction. I consider the internal oil galley diameter to be a minimum.

It's a little scary, but right now I'm planning on drilling the two plug ports in the block for a 1/2" NPT fitting. 1/2" NPT female threads first require drilling a 23/32 bore (0.71875"), and then tapping 0.5337" deep for thread engagement.

In Hot Rod's September 2012 issue they did a comparison of -6 AN fittings(0.375 OD), and the inner bores varied from 0.220" to 0.270". Hopefully this means a -12 AN to 1/2" NPT fitting will have an ID somewhere around 0.595" (finally bigger than the stock oil galley dimensions. Here's such a part from Earls

I've looked the block over pretty carefully and I think there is plenty of meat for the boring and tapping of the 1/2" NPT. Maybe it would be easier to weld a fitting onto the block, but I worry about messing up any heat treating that was done.

With this external oil routing, I count 10x 90 degree turns that I get to eliminate between the stock LS1 oil pump and the main verticle oil galley at the back of the block! I'll probably introduce 3 or 4 of my own (externally), but all of mine will be WAY more gentle, and that's still a hell of an improvement. Less pressure loss should mean that I can run thinner oil. 0w-20 here I come.

12/4/12

I've been trying to find a source other than Accel for aluminum wiring. Most modern airliners use it at least on their larger generator wires. But the new Airbus uses it all the way down to 22 gauge. Its only 67% as conductive as copper, but since it weighs 1/3 as much it ends up requiring a gauge size two larger for the same resistance compared to copper and still weighs half as much!

"Sigh. It appears that some posting on here never read the old threads on the Airbus "aluminium" wiring, or did not understand what was written.

A380 Not State Of The Art-Due 2 Aluminum Wiring? (by Coelacanth Oct 22 2006 in Civil Aviation)?threadid=3056107&searchid=3062099&s=ElGr eco#ID3062099

This is not the post I was looking for, but it will suffice I think.

ElGreco From France, joined exactly 6 years ago today! , 164 posts, RR: 1

Reply 7, posted Mon Oct 23 2006 12:11:22 your local time (5 years 2 weeks 1 day 12 hours ago) and read 10683 times:

Good afternoon everybody,

I had already answer few times about these questions on aluminium cable technology on A380, but I will do it again with pleasure.

1) few pure aluminium cables are used by Airbus, Boeing, Bombardier,... for years on feeders for power cables to save weight (from A320 for Airbus).

2) A380 is the first plane in the world to use that technology for smaller cables (e.i.: up to #22 contact with #24 cables) but we used aluminium/cooper cable with nickel plated, and not pure aluminium cable (e.i.: each wire is aluminium with 10µ of cooper around and 2µ of nickel deposit).

3) contacts are in copper with nickel and gold plating (as for copper technology) but with longer design to be crimped on the cable and on the insulation cable as well. Furthermore, a ferule is installed in the contact as interface between cable and contact.

4) this technology is based on patent made in 1965, and we are working on that technology from 1967, as many others companies).

5) This technology have been choose in 2002 by Airbus and qualify in 2003. Weight saving is closed from 500kg per A380, it's used on A400M and it will be use as well on A350XWB.

In conclusion don't worry be happy.

El Greco

IIRC El Greco had something to do with making/designing the wiring. Somewhere I think you will find he told us that the Al and Cu are co-extruded and then Ni Plated.

If you want to think that Al with copper, nickel and gold plating is vanilla style Aluminium, well that is fine, but it aint."

Good Nissan read!

Posted by Diggymart on 11/1/21 @ 12:53:02 PM