You must be logged in to rate content!

26 minute(s) of a 54 minute read

12-31-2020

4th Gen BBC Project

Compliments of ulakovic22 @ www.ls1tech.com

Figured I would finally post my project car since it's about to be finished. I still have a lot of work to do, but most of the parts have been bought and are just waiting to go on. Here is the car.....

Here it is after I painted the engine bay

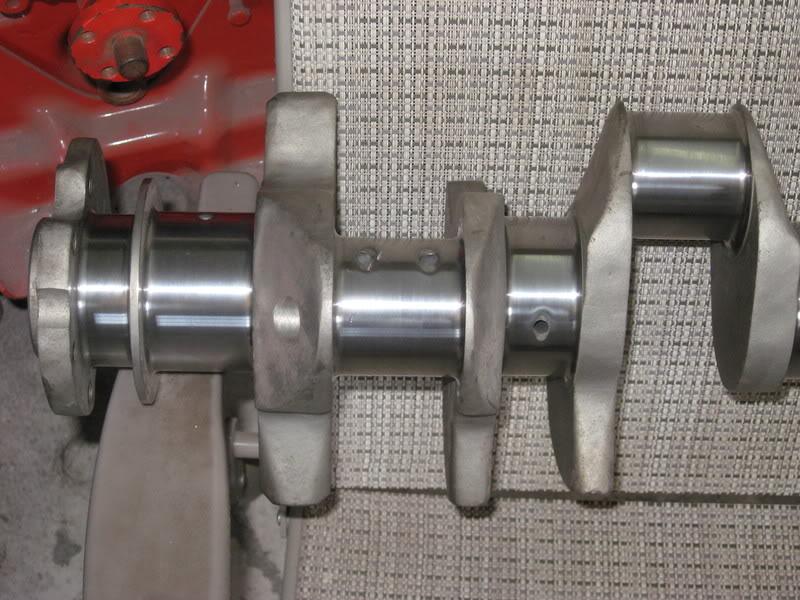

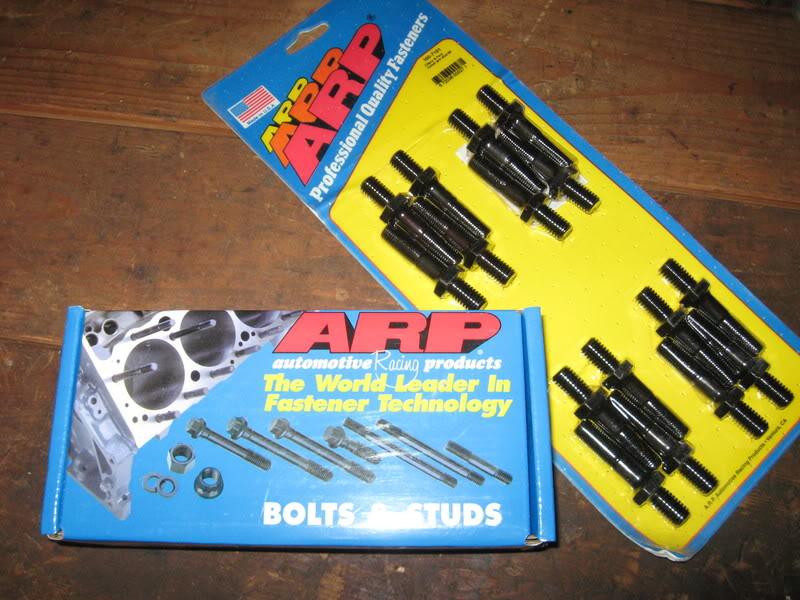

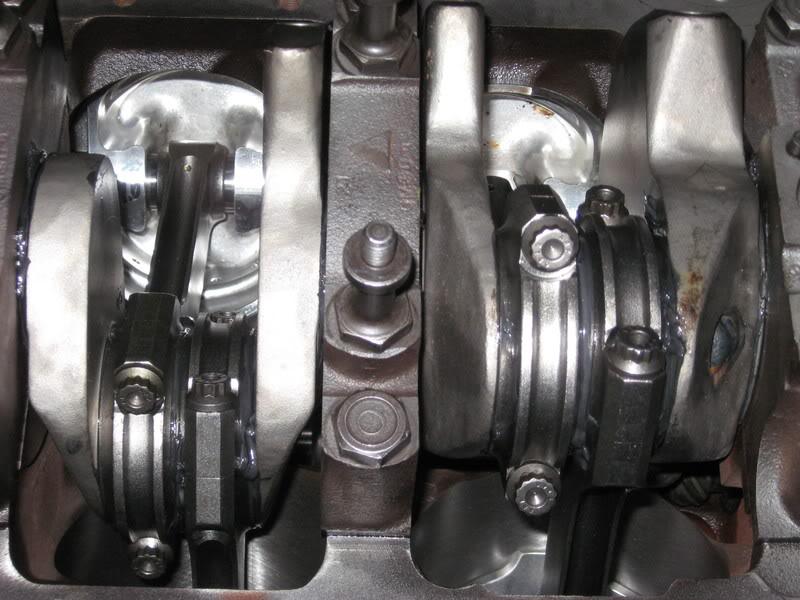

All the motor stuff....Gen V 502 bored .100, 4.25 Eagle crank, Crower SPS +.250 rods, Wiseco Low Dome Pistons netting 11.1 CR, Comp Endurex SR lifters, Comp 1.7 Pro Mags, Bret Baur SR cam, misc hardware.

3/22/2008

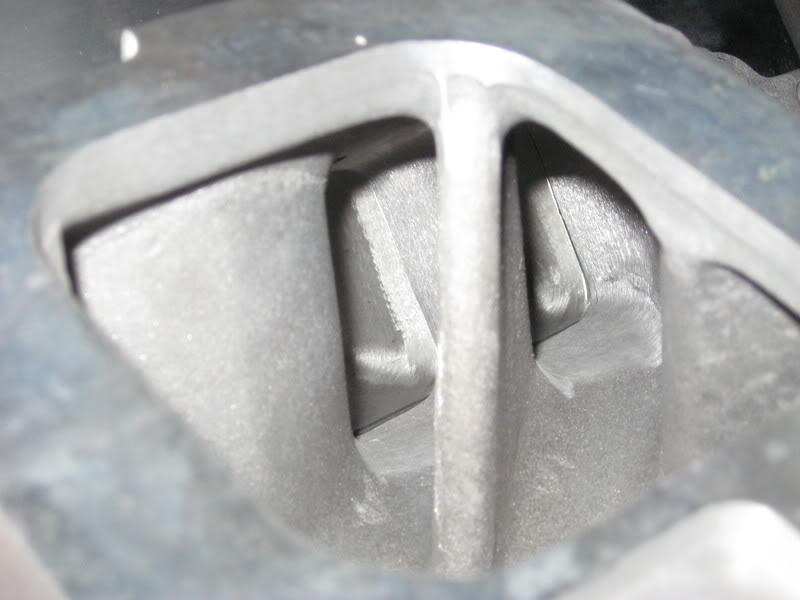

RHS 320cc heads touched up by Lloyd Elliot, they flow a little over 400 cfm on a 4.310 bore, mine is a 4.56 bore so they might flow a little more.....pics are as cast, don't have any after the port work. Manley valves 2.25/1.88, PAC springs, BRE lightweight steel retainers, 10* locks.

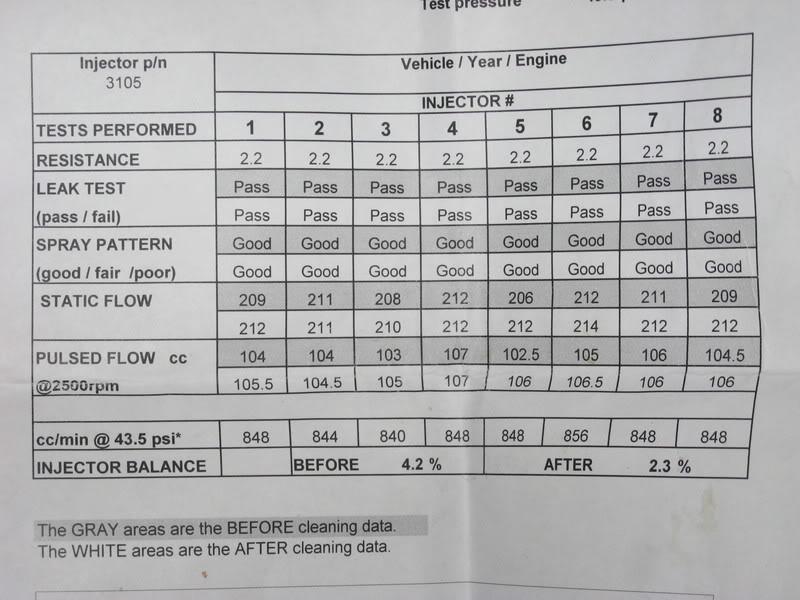

Seimens Deka 79lb/hr injectors, I'm pretty sure that they should work, if not then I can always bump up the fuel pressure to get the needed flow. I'm only expecting around 825 fwhp so I think the stock lines and walbro should be fine until I start spraying.

Finally the brains of the operation, and a big thanks go to Brady for hooking me up with BS3/DAI. Once my Autometer gauges come in I'll post those up too.

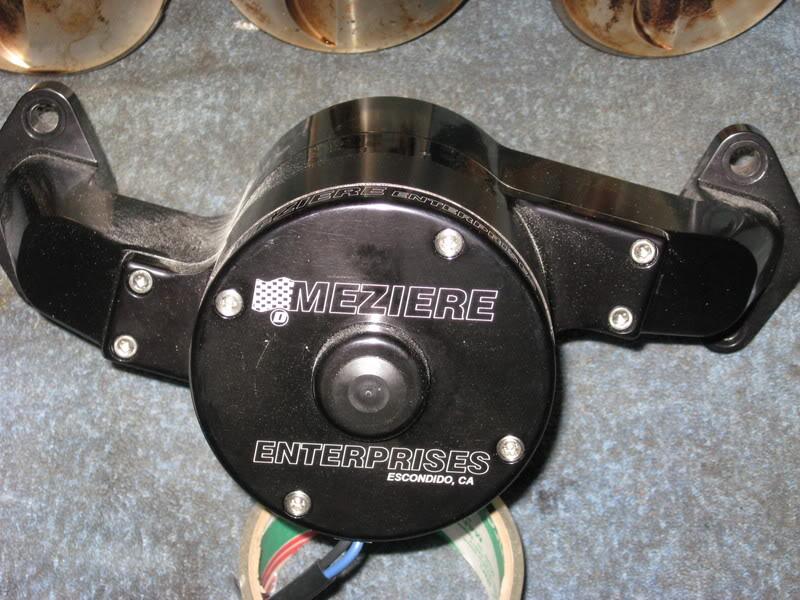

All in all I think this will be a pretty cool project. When I get new batteries in the camera I'll get pics of the other stuff like TB, Victor Jr 454R manifold, Meziere Elec. w/p, etc.

Here is my post on CamaroZ28 when I first got them and had the work done. I haven't measured them, taken pics etc. since I got them back. Just been sitting in the boxes at the shop.

Quote:

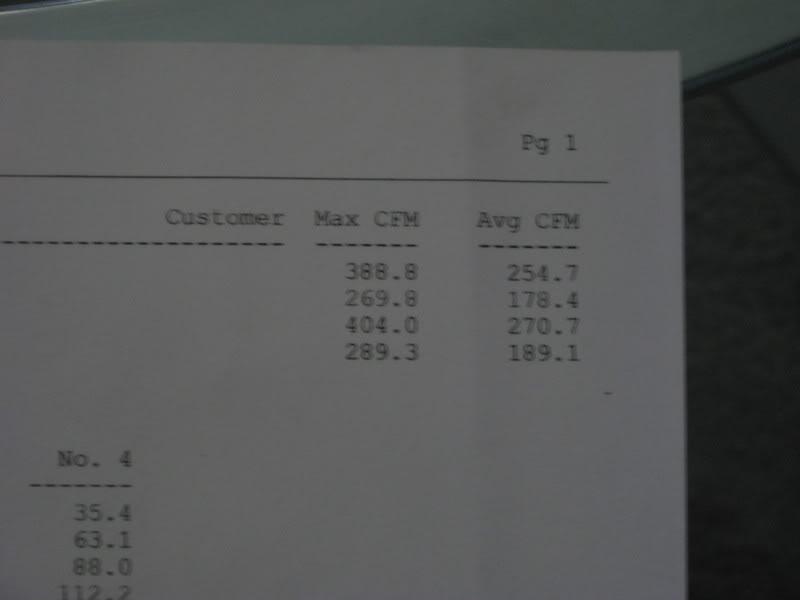

Finally was able to drop the intake and heads off at Lloyds place yesterday and he was nice enough to take a break and flow the heads right there in front of me. It was really cool seeing how it all worked. Here are the "before" numbers and I'll update with the "after" numbers once I get them back in a couple of weeks.

Flowed @ 28" on a 4.310 bore fixture with 2.25/1.88 Manley Severe Duty Valves

.100 80/ ?

.200 142/106

.300 203/145

.400 259/184

.500 310/218

.600 353/241

.700 380/259

.800 388/269

For comparisons sake here are the advertised numbers from the RHS website.

.100 75/62

.200 166/110

.300 246/160

.400 309/195

.500 340/229

.600 360/248

.700 375/265

The peak numbers are pretty close, but you can see the low lift numbers are a little off. RHS supplied no information on how the test was performed other than @ 28", so I don't know how much of an apples to apples comparison it is in regards to bore fixture size, radius inlet, exhaust pipe, etc.

More pics:

Here is the flow sheet, end runner on a 4.310 bore fixture and yes they are the 320cc version:

Headers are Hooker 2455's. They were 150 a set and I have cut the #7 primary so I can loop it and then go straight down to clear the firewall. I will have to bend them to get more clearance around the k-member, but they are a nice alternative I'm willing to work with in the beginning rather than buying a $1,200 set of headers. BTW they are 2" primaries, but I'm thinking on my next set I'll get 2 1/4".

The idea was to make the car appear stock so basically the car is stock. Uses stock hood, stock airbox, it has a T56, but it will be built later on after I find out what I'm looking at. Basically along with everything else I don't want to over build and get a Viper tranny for $2,500 to handle some pretty small numbers that a $1,500 or so tranny would handle just fine. I do have the McLeod Steel Street Twin already so I'm good there.

Rear end is a little different, I would rather have confidence that I can launch hard so I'm getting a Midwest 9", I just have to decide what width I want. I would like to go 3" shortened with 15x10 with 5" backspace, I think that would be awesome, but I'm not sure if I want to do that or get a stock width rear and run 15x10 with 8" backspace so I can still run the stock WS6 wheels when I'm not racing so I can have once again that stock appearance and then just slap on the drag wheels when I go to the track.

I like the second option because it fits the theme, but the look of the first option is soooooooo nice.

3/27/2008

Just talked to the builder on the phone and was shooting the **** and while I don't have the balance card obviously he told me the rod weight was 885g and the Pistons/Pins/Rings were 778g. Total bobweight was 2,489g, which he said was fairly light. I don't have a lot of experience with rotating weights so I take his word for it, but wondered what you guys thought.

I'm running 2" primaries and 3.5" X pipe exhaust.

Yeah the less cubic inches is a small problem, but when comparing a 355 to a 383, which has a higher CID variance, most of the time they make close to the same peak power but the 383 has more area under the curve which I understand will probably be the case here.

I'm excited to have it all come together too so I can keep moving and get everything finished. I had the project stall for a long time waiting on Wiseco to come out with their low dome pistons. Now I'm waiting on McLeod to ship out the freakin' flywheel/clutch assembly so I can get the RA balanced. Once that's done I should hopefully get things moving again with the fuel system, gauges and wiring while I wait for the intake to be ported.

3/28/2008

Fabbing up a fuel system this weekend so I'll have more pictures hopefully next week of a twin walbro setup, fuel lines, rails, regulator, etc.

Going to have to take a break for a while and switch my attention over to my motorcycle. I got tagged this morning by a 5 gallon bucket blowing across the freeway. Have to buy new bodywork now, but at least I can try out a new paint scheme

4/13/2008

Past couple of weeks have been busy, got the twin disk in so I can finally get the engine balanced and also got my dual walbro setup put together thanks to Mighty Mouse. Pulled the rear end out, sanded and painted it. Still have to touch it up and I'm painting the diff cover black with the LG logo in silver. Hopefully everything will be back in the car within the next couple weeks so I can start wiring everything up and finally get it started.

5/14/2008

Got some more work done on the car over the past couple of weeks and it should be going into the car this weekend after I get some new head gaskets. Anyway here is where I'm at right now.

5/25/2008

Someone was asking about carb pad to cowl clearance so here ya go. This is without an intake gasket, I had it all together to mark the intake ports and took this picture after I took it apart to ship off. Took some other random pictures.

I found out with the Griffin radiator I'm running I can't use the stock plastic support so I need some universal radiator mounts. Anyone sell some or do people just fabricate their own?

It's a standard deck BBC (9.8), not a tall deck (10.2). That's actually why I didn't put a Pontiac (10.25 IIRC) motor in there. You're right, the motor doesn't even look to be shoehorned in there, but there still isn't much room. The whole plan was to take a LT1 car and swap a BBC in there. Mechanically without the A/C everything has been a direct bolt in with no issues other than the driveshaft. The big expense comes from the motor itself and then upgrading the other components to match. Anyway here are a couple of the mock up pictures showing the headers and shaft.

6/8/2008

Made a bone head move and forgot to install the oil pump driveshaft, so I had to drop the pan and pump to put that on. Got lucky and the tall valve covers fit, but just barely. Still need to figure out what I'm going to do for a radiator support. Ordering pushrods and new link bars, Comp supplied std. link bars instead of offset ones. Headers going on next weekend and should have the intake manifold back from getting ported in a couple weeks. Then comes fuel lines, brake lines and electrical.

6/12/2008

Waiting on the intake to get back from porting and I'm measuring for pushrods again this weekend to make sure I get the right length. After that the motor can be button'd up. Then it's headers and exhaust followed up by a lot of electrical work. I have to rewire the whole car including gauges and the BS3. I would say I have at least until the end of July since I only work on it during the weekend. That's also only if my parents don't have a list of stuff that needs fixing when I go out there. Last weekend I had to put my Dad's riding lawnmower back together before I started working on my car, lol.

7/27/2008

Ok been a while since I posted. Got the intake manifold back, ordered pushrods after measuring and new link bars for the lifters. Come to find out as I was putting everything together that one of the lifters at the base of the cutaway was bent and when put together with the link bar wouldn't slide into the lifter bore so I have to get a new one from Comp. Pictures below show the bend and also you can see the crack on one side of it. In the blurry picture you can kind of see the highlighted cracks on both the top and bottom.

Still working on the headers. They no longer bolt up with the RHS heads like they did when I mocked up with the stock 990's. Hitting the k-member really bad so I'll have to relief cut them and bend them up so they will fit. I'm so glad they were only $150, lol. Eventually I'll get a set made, but I'm not at the point yet where I say screw it and buy a $1300 set of headers.

8/6/2008

To minimize down time I ordered a single lifter from Jegs and then when Comp sends the replacement I would just return that to Jegs. Well today I got the replacement and well I'm just kinda ticked. I ordered an 888-1 which should be a single lifter of the 888-16 set I had ordered. Instead I got this, the lifter on the left. I'm not sure exactly what happened but obviously the lifter on the left isn't a HIPPO lifter like the other 15 I have. Guess I have to wait another week or so for Comp to get back with me about the cracked one I sent back to them cause these lifters are still on back order everywhere.

8/19/2008

I got further on the project this weekend. I got the valvetrain in and lash set at .020 cold. I'm hoping that .020 cold translates to .015 hot but of course I'll check it after I get it broken in.

Installed the balancer, crank trigger and spaced out the alternator bracket so the pulley lines up.

Got the manifold on there with gaskets (dry) so I can mock up the throttle body again and make a template. I used an old one I made and it was really close so I think I'm good to go, just a few minor adjustments. I left it dry so I can pull it back off and prime the engine right before I start it instead of priming it and then letting it sit for a long time.

Anyway here are some random pics of stuff. Notice on the manifold how well the ports all line up. Yes I'm proud of how well I marked the intake

11/3/2008

Wow, glad to see some guys are still checking up on this thread. Sorry for not updating it in so long. I got the intake elbow done and am wiring it up right now with sensors. I totally suck at wiring and I don't spend too much time working on it anymore, at least not like I used to.

As far as throwing on a 4 hole I did think about it because it would be very easy, but then I would lose the windsheild wipers and wouldn't be able to run any kind of air cleaner. This way I can run pretty much all the stock components like CAI, wipers, hood, etc.

Yeah, I knew they were, but I didn't think it would cause the headers to kick out like they did.

I've also decided that I'm going to run the fuel system in series instead of parallel, there just isn't enough room at the back of the motor and it will look like crap with fuel lines running everywhere. Probably run a regulator on the passenger side rail. I need to order a lokar throttle cable since the LTx cable won't work. Still need to do something about the exhaust, but I haven't physically worked on it in months.

2/10/2009

Mocking up the fuel system, will actually put it together and finish next week while I'm off work. Pumps and tank are in and I'm wiring up the relays. FPR is going on the front pass. rail and the drivers will crossover to it. The two lines running on the valley are the feed lines to the back of the rails. Feed is -8 and return is -6.

3/26/2009

Little by little I'm getting it done. Luckily between two projects I'm staying pretty busy and can bounce back and forth between them and don't sweat the little stuff. A few more pics of progress.

8/11/2009

Figured I would drop in for an update.

The car is very close to starting. I've got all the powertrain wiring done (fuel pumps, fans, w/p, BS3, ignition box, alt, starter, etc.) and I was able to finally get the rotor phasing done on the cam sync last night. I need to get spark plugs and cut a set of custom wires, check fluids and then see if she'll start. Hopefully all this will be done by the end of August and she'll be getting the final touches at a local shop.

Not sure how much invested, but I started from scratch so investment includes the purchase of the car (roller), trans, complete engine and suspension needed for the swap, plus the other stuff needed to get it to run like BS3, MSD box, electric w/p, alt, distributor, Painless relay kits and misc. wiring accessories. If I had to guess it's in the $10-12K range.

9/17/2009

Little update. The car is together and I was trying to get it to start before I send it off to get tuned so I at least know that everything works. The problem is that I can't get the dang thing to start. I have fuel pressure and spark but I guess the base tune the BS3 came with is way off.

Next, I've decided to go ahead and can this project. After getting it all together this thing is a HUGE PITA to work on and when it's all said and done it will still just be an old Trans Am. I'm still going to get it started and get some numbers out of it since I've put all the work into it, esp. wiring everything up and then I'll pull the motor/trans and put it in my 67 C10.

I'm going to pull the LT1 out of the C10 and either try to sell it all together or make it into a road race car or something. Not sure yet. I also just moved and I don't have internet yet so once I get it hooked up I'll post pics of the T/A almost done and the truck it's going into.

9/21/2009

Ok, here are some cell phone pics from this weekend. It's all I got since I don't have internet at home.

Here are the pics of my old truck that it's going into once it's been tuned.

A lot more room

Here are pictures of the pan and motor mounts with no cradle, but there is no clearance issues with the pan. The steering rack is the closest thing to the pan, which is about a 1/4 away.

5/18/2010

Update for those subscribed. I got the car towed back from the shop after sitting for 9 months. Car was left outside and broken into, but nothing was taken since it appears to be a gutted stock car.

I pulled the engine out Sunday and cleaned it up as best I could. I'm going to pull the intake and heads just because of all the water stains, oxidation and leaves that were laying on the intake and in the engine bay. There are some other things I'm going to clean up and make sure al alright before I drop it in the truck.

I already have another 6 speed so both the WS6 and C10 will be 6 speeds. The WS6 is getting my old LT1 on the tubular k-member I already have since I can use the SBC/BBC mounts on the LT1. With the added clearance of the tubular k-member I'm looking into going TT.

BBC is going in the truck now and with the added room it will be N/A for a long time until I can afford to swap pistons to lower the compression. Truck will be kept in street trim and since the WS6 is already gutted it will be a drag car and sold eventually.

Great build

Posted by Diggymart on 3/31/20 @ 6:33:10 PM