You must be logged in to rate content!

6 minute(s) of a 264 minute read

1-31-2015

So we've decided to build up an 8v motor to run until the 16v one is done. Due to the high level of customisation on the 16v the timeline on that is somewhat unknown.

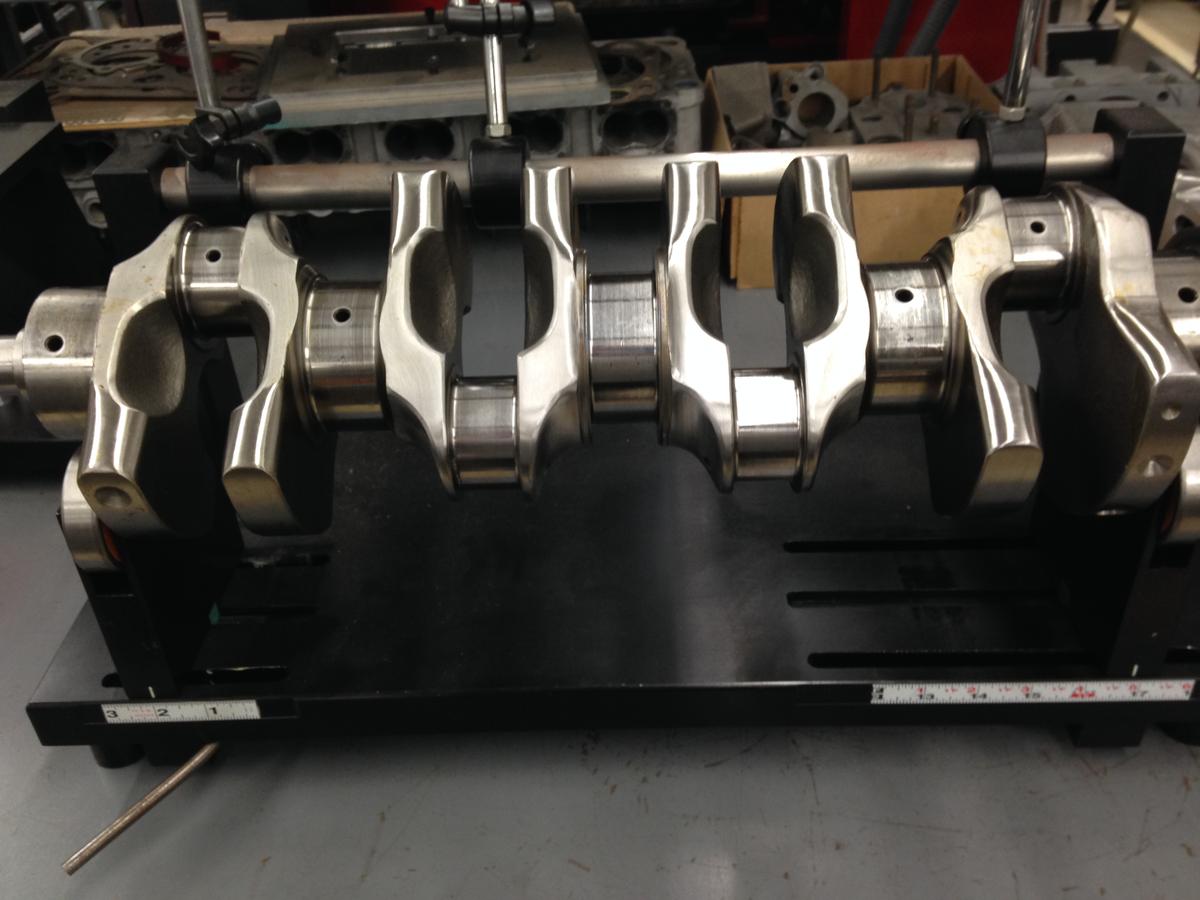

We were going to 'throw together' an 8v from bits and pieces just to circulate, but it turns out that this little motor should be quite interesting in it's own right. We've just decided to order some non stock length rods which will allow us to run some nicer forgings offered from CP. The rods will be Carillo. Both these brands are under the one 'Pankl' roof. The pistons will be lighter and have a smaller pin plus located higher up in the piston. Less likely for the piston to 'fall over' at the top of the stroke. The crank is a modified stock unit but certainly not knife edged. (It has been cleaned up since this pic) We feel that the knife crank was one of the main reasons for our previous engine's disintegration. The builder (Neil Harvey of Performance Developments) also has strong feelings against X drilling. The head has massive intake ports and larger valves. It will be flowed later this week along with the worked 16v head we already have. Should be very interesting. Has a very high lift cam in it and solid tappets. We should be able to rev and continue to make power beyond 7500rpm.

What I am somewhat curious about is the size of the intake runners on our current version and if they will be too small for the head? I don't have the i.d. of those runners to hand but they will be significantly smaller than the ports.

So, will this just create some RAM effect and be fine or will it present a blockage or choke point? Should we open up the intake now and make changes or just suck it and see. ID of Bellmouths are 50mm so you can make guess on runners. I'll know next week.

2-1-2015

Yes, it will be interesting to see what results you and Sid come up with Eric? Remind me what intake you're going to be using...runner size etc??

Ours are about 41.3mm i.d.

2-1-2015

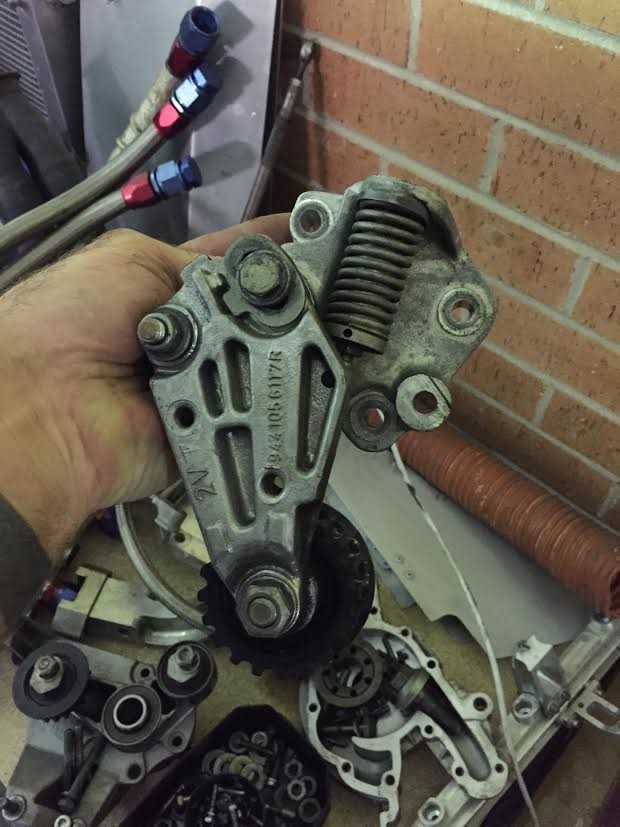

Can someone confirm if this is an early or late version tensioner? I think late.

2-4-2015

Yep, ours is a later model, thanks all.

So we've ordered the new pistons and rods. Neil has designed these so they have a relatively stock stroke but will be quite a bit lighter and have better weight distribution with a smaller pin and raised higher in the piston which will have shorter skirts. He feels that this motor will rev out to 8000rpm and that the intake will be the limiting factor. So we're going to make a new intake or perhaps use one that is being built for Gustaf's car. Once we finish the 16v motor we might put this one up for sale or keep it as a spare. I am looking forward to seeing how different this 8v motor will be compared to the last one. It will be only about 2.5ltr though with the 102mm pistons. We are going to try Neil's 'sealing system' too. Sort of similar to ours but the O rings are in the head, not sleeves.

2-18-2015

So we've had a bit more progress on the 8v motor. Rods have arrived and pistons not too far away. Compression ratio will be 9:1 which is the highest I've heard on a 8v motor. Only running E85 race grade fuel so I feel fine with this. Should be interesting. Going down in CC from 3.1ltr to 2.5ltr with a motor targeting 8000rpm cut out would suggest that we will lose out on some early to mid range tq. However I'm thinking that the c/r will make up some response out of corners.

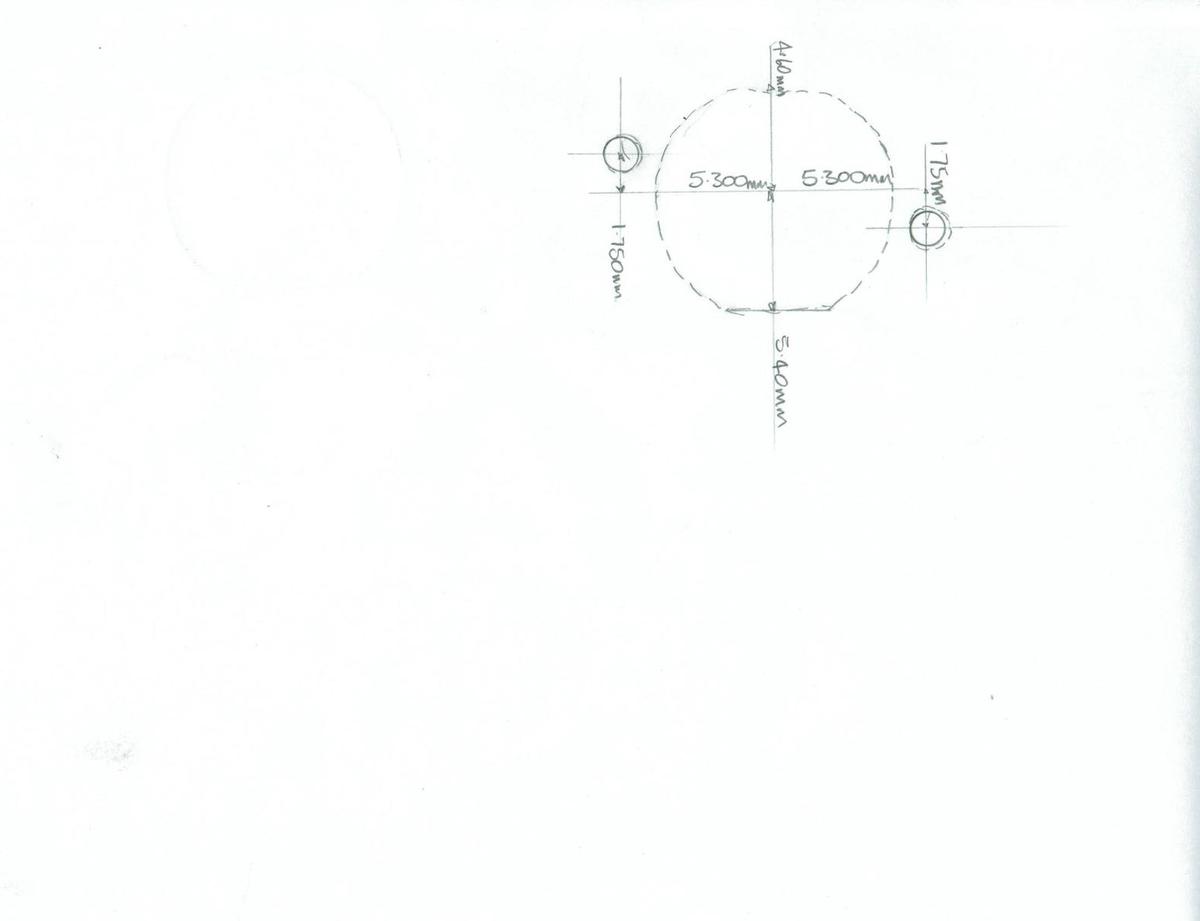

I've also been in discussing with someone else about making an intake for this motor and his assessment is that with the head being such a good flowing one we won't hit a choke point on this and his feeling is that we can go with a longer than expected runner which will also help with lower down tq. He's working on the length of the runners in harmonic values with all the data I've given him.

Really should be an interesting 8v motor.

NA Block

Doweled Girdle

Line bore checked

Polished internally

Deck plate fitted

Steel liners fitted and honed to 102.00mm

Race prepped Bearings

Bull nosed Crankshaft with narrowed journals, balanced to new Piston and Rod weights

Carrillo Rods, increased CCL to suit shorter Piston Comp height

CP lightweight boxed strutted Pistons with DLC pins, gas ported for low tension ring set

Piston Oiling Valves fitted

9/16” ARP head studs with 12 point nuts

Updated for late tensioner assy

NA 2V Cylinder head

Ported both sides

49.00mm x 5/16” Intake Valves

43.500mm x 5/16” Exhaust Valves

Ampco 45 valve seats

Ampco 45 valve guides

PD race valve springs

PD Titanium Valve Spring Retainers

PD Titanium Valve Locks

Stainless Exhaust studs

Machined for stepped head washers

PD stepped head washers

Arrow solid Cam Followers

PD Camshaft

Modified cam housing

At 28" test pressure

Intake Exhaust

0.050 47 26

0.100 82.5 59

0.150 114 92

0.200 141 111

0.250 163 133

0.300 187 151

0.350 212 171

0.400 235 182

0.450 257 192

0.500 265 200

0.550 273 206

0.600 279 211

"This head keeps flowing. The cam lifts are 0.595 and 0.526". So disregard

the flow numbers above these lifts. But it shows this head does not go into

choke even up to 0.600" lift. The exhaust goes sonic even on the bench so I

know the velocity is high. You can hear it crack!"

Wow great build!

Posted by Diggymart on 12/28/20 @ 2:54:22 PM