You must be logged in to rate content!

8 minute(s) of a 264 minute read

8-30-2016

As usual there have been delays but now they're 99% done and just about to put it in the crate to ship down to us. Going to be stupidly tight (time / money) to get it ready for this year's WTAC and I was really close to withdrawing. However the cams finally came through although the head needed to be further modified to allow the intake cam to turn.

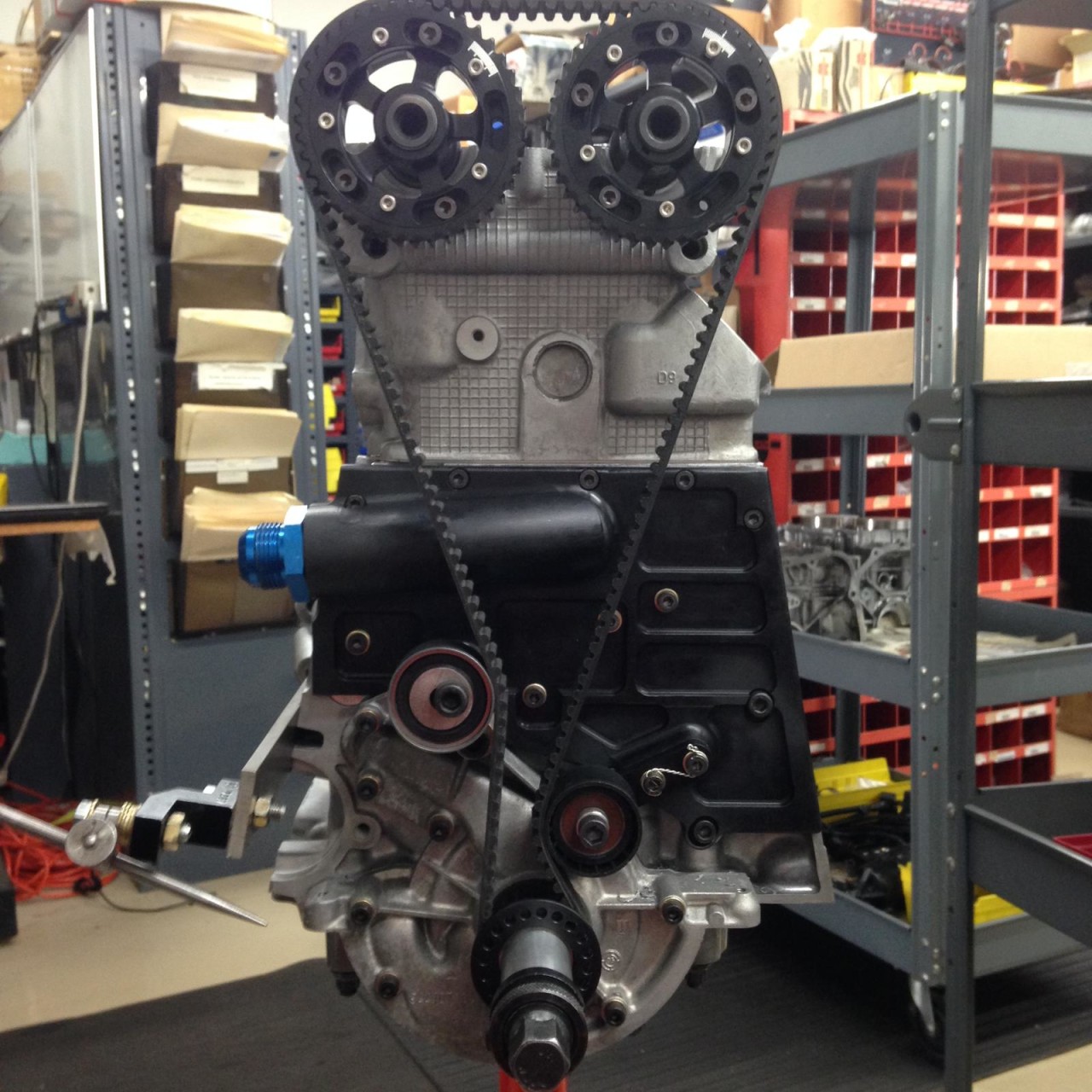

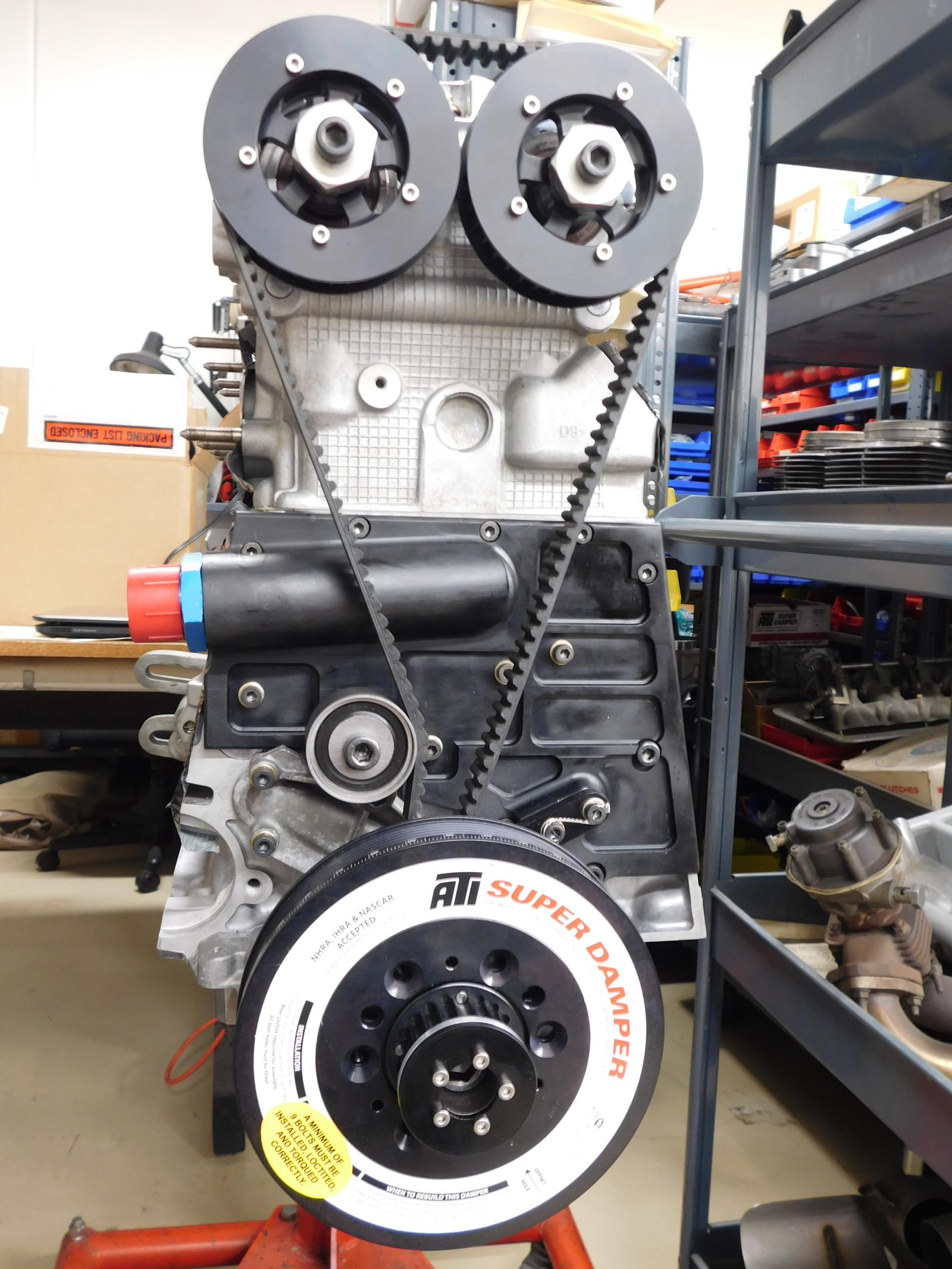

To package the adj cam wheels means that the crank pulley is small. An extra tensioner has been established to maximise belt wrap. Concern is how the belt is going react at over 8000rpm. Assuming Michael Mount has run his n/a motors to similar rpms I am hopeful that we have also taken every precaution here.

The next question was what housing to run with the turbo. As we're sticking with the GTX3582r we have the choice of the .82, 1.06 or even the .63 (won't be using this). Speaking with Gustaf he is quite sure that the 1.06 is the way to go and I'm inclined to believe his real world testing. Others, such as the engine builder seem to think that the .82 should be sufficient. The compromise is between driveability/spool and backpressure/strangulation. While the motor has been built to spin out to about 8800rpm we need to maximise mid range rather than top end with the H pattern gearbox. With the 94mm stroker crank I don't know how this is going to affect the motor in the upper rpms either. Having said that, the rods are actually longer than stock by 2mm by designing the pin location in the piston to assist. Don't know the actual rod/piston ratio yet but not as bad as I first thought.

Another thing is the intake. Again, as we need early to mid range tq, I'm not so sure if we'll go with a short runner intake like Gustaf's. Our memories are fresher with the 2.5 8v racemotor which was a bit laggy, so we need to allow for the extra 700cc's and stroker crank plus all the modifications to allow the motor to rev quickly. So I'm caught between smaller housing/longer runners or just trust the motor and go with the larger housing and shorter runners to allow the motor to breath more efficiently at the top end.

Any turbo plotting experts are free to chime in. :-)

Basic specs so far are:

Intake runners: Approx 280mm - 50mm OD.

Head: Pretty high lift / short duration cams high flow head

Valves: 41mm int / 35mm ex

Exhaust is 3650mm / 143" from turbo back. 3" in diameter.

The Crossover is 880mm / 34.6" from collector to turbo. 2.25" in diameter.

Headers are all different. They average 685mm / 27" to collector. 1.75"

diameter.

Collector is 125mm / 4.9" long.

Turbo: GTX3582r

Compressor wheel specs

62.5mm inducer

82.5mm exducer

Turbine wheel specs

68mm 84 Trim

8-31-2016

Thanks guys. Last little bits being finished off today. Maybe in crate tomorrow. Once I have the engine build sheet I'll post info.

Won't be quite bolt in but not too many surprises I hope. Having said that, there's always something that comes up. Then run the cams in for 20 mins and off to dyno not much after that. I don't think it's very practical to try and swap over the housings on the dyno but that may be an option. I'm not totally thrilled with a 3" exhaust either.

9-8-2016

Just about to go into crate. All the last little bits have been zipped up. Cams are adjustable. Covers have been made up to minimise any chance of belthop.

9-26-2016

Finally made it....just.

It was picked up over a week ago. Then it lay in a depot for a couple of days before being finally loaded onto a plane. All sorts of emails back and forth between various parties but it was finally here about 5 days ago. Then more crap having to go through Quarantine. Finally late last Friday someone says it looks like it's clear to leave. I'll get it out to you on Monday (today). I phoned them mid morning to check progress and remind them that we only have access to a forklift until 4pm as we have to borrow it from another shop in the building. No sign of it by 2pm. I call them again. They say, yep it looks like he is about to pick it up shortly. Getting a little anxious as time is running out for today and really don't want it to go back to base again. Finally Paul text me to say the driver called him and said he's 5 mins away. Awesome. 45 mins later Paul texts again saying no sign of the truck. I call the shippers again and get put on hold. She comes back. "It's been delivered 1/2 an hour ago signed by Harry". Harry...half an hour ago?? Now I'm starting to imagine it is lost and someone shifty called Harry will disappear never to be seen again. Called Paul and he walked downstairs to see a crate sitting in someone else's dock. Phew!! It's been a long time coming. Now onto seeing if we can make it to the event this year. We'll put a solid week of work into it and decide.

Yes, no time / $$ to make any changes like turbo etc. From what I understand the head on the 16v comes across the same distance on the exhaust side. So hoping that the headers/X-over all fit (once we convert the headers to 16v flanges). Then we will have to see what we've got on the intake side as far as room goes for the intake / runners etc. Don't mind if we shorten them a little anyway. Mounting and plumbing the EWP will take a bit of doing. Once it is all done we will run the cams in and then check the lash for any change. Then hopefully off to the dyno. Belt is pretty long but Neil has done what he can to keep it on. Will video it on the dyno.

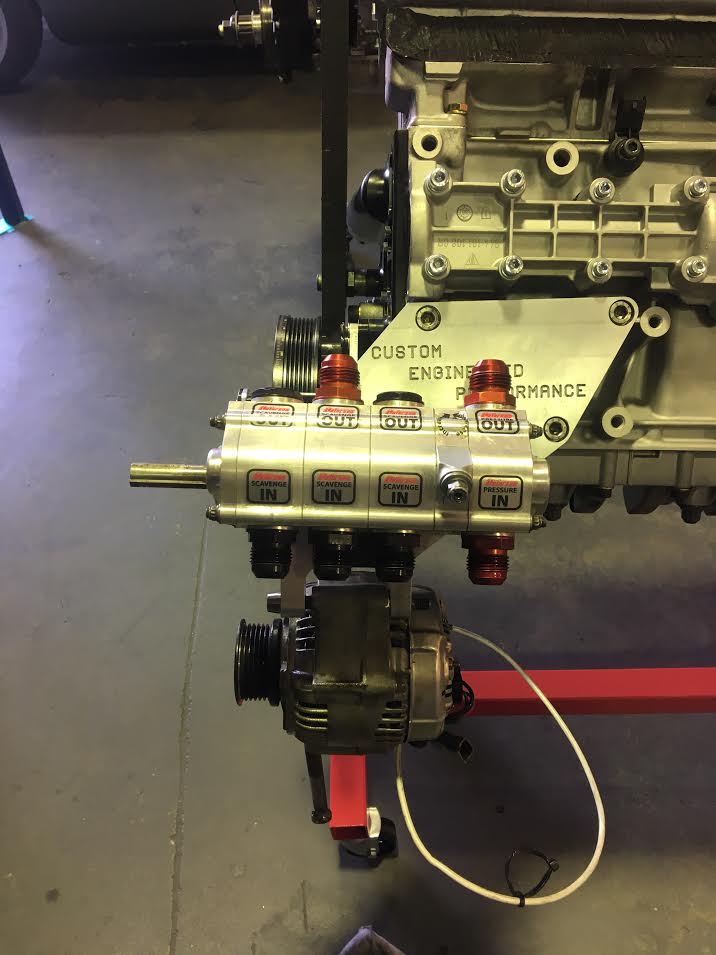

Interesting picture which highlights some of the efforts that have gone into the build. See how much closer to the motor the belts will run. Minimising the extent of parts hanging off the nose of the crank to reduce crank whip and harmonic imbalances. Downside, we have to remove the CEP billet bracket and make up something quick-smart! More notes from the builder.

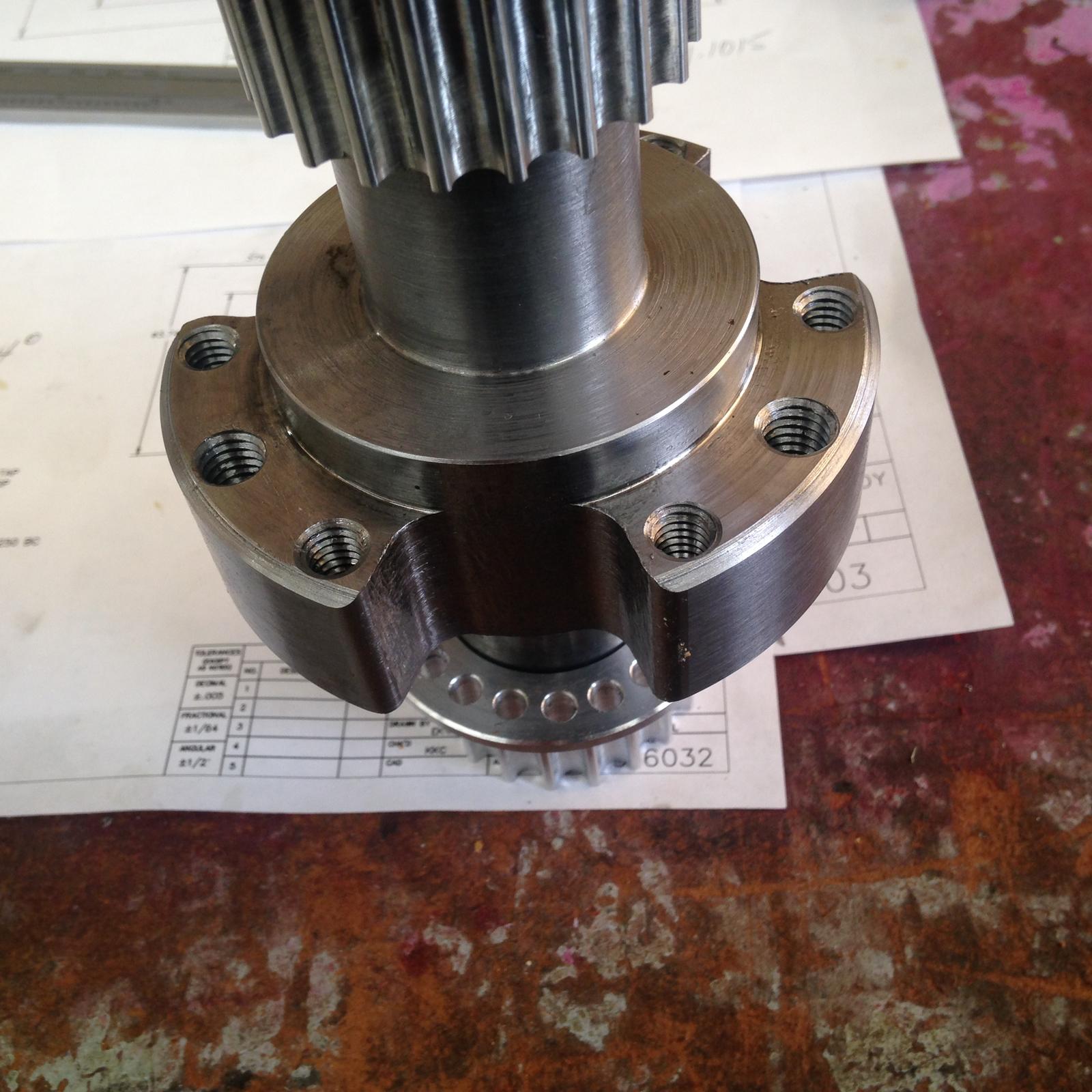

"After hearing of the previous issues on the 3.1ltr motor, we scrapped what we had and completely redesigned the front drive system. This required the cam gears to change as well. The whole assy is mounted on the hub that is pressed onto the crank. There is an interference of approx 0.0004" between the hub and the crank. You will need a puller to remove it. The cam and Oil pump gears are a slip fit onto the hub and are driven by 4 drive pins each.

These cannot come out as the diameter in the hub is bigger than the holes in the gears."

Bit of a can of worms in terms of getting a full understanding of the task at hand. Thing that we didn't think about is the different fuel rails and fixtures. My CEP billet rail also doesn't fit the 968 head so we can either adapt it or chase a stock 968 rail for the meantime. Picking where to spend time/money is the task. The turbo didn't fit with the exhaust side b/shaft cover. So we had to take that off and also grind down the CEP turbo mount. Even then it's tight with the new rear housing!

Wow great build!

Posted by Diggymart on 12/28/20 @ 2:54:22 PM