You must be logged in to rate content!

9 minute read

Outer Axle boot DIY

Compliments of DubbinChris @ www.vwvortex.com

I have a garage to park my car in but it has no opener so I have get out each and every time to open and close the door. Getting out the other day I saw a small spot of grease on the outside of my drivers front wheel. I cranked the wheel fully to the left and with a flash light saw what I suspected I might see....

Well I was on the computer an hour later ordering a boot kit from GAP...

http://www.germanautoparts.com.../34/1

I then waited a few days for it to come in the mail before getting started...

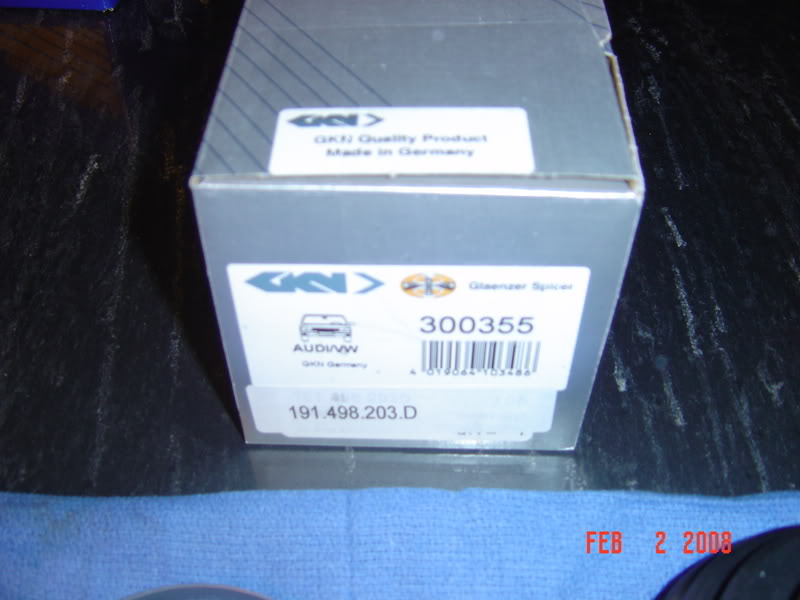

"Made in Germany" pleases me!

What's inside...

I didn't take pictures of it, but obviously the first thing I did was to remove the axle from the car. Even though the Bentley says I need to, it was not necessary for me to disconnect the ball joint to get it out. Just the 6 bolts at the trans and the 30mm axle nut.

Put the axle in the vise...

Cut outer clamp with a good pair of cutters...

And remove...

Slide boot down to expose joint...

Cut the inboard boot clamp...

And remove....

My favorite way to remove the boot....

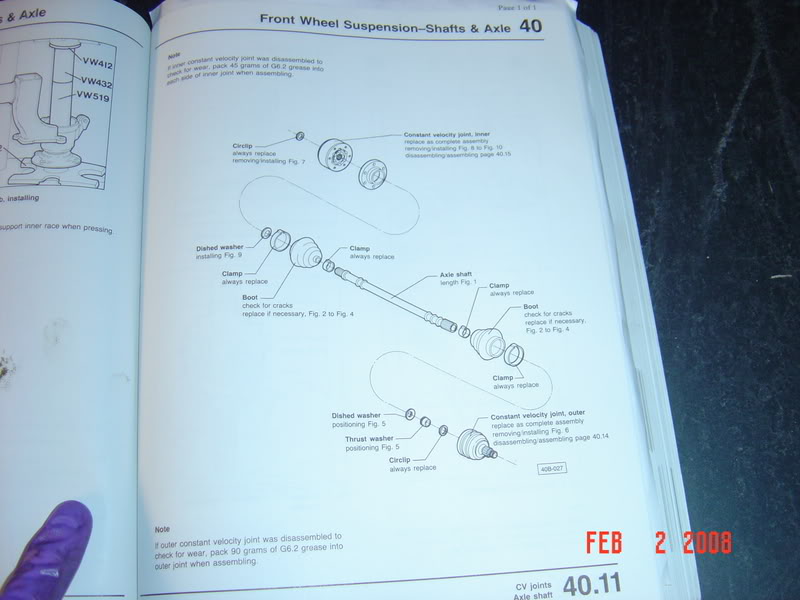

Diagram if anybody is interested...

Using a dead blow hammer is best but this is all I had. Hit joint to remove from axle shaft splines....

Remove plastic "race" and thrust washer...

Use snap ring pliers to remove this...

Tilt cage at various angles to remove balls noting that one hole is bigger than all the others. That is the key to getting the cage out later....

Now clean your balls.....

ONE!

TWO!!

Three???!!!

Ok bad joke above. Anyway get all six cleaned and inspected....

Then rotate cage all the way to the side and utilizing the largest hole it will come out of the joint housing. Get it nice and clean too...

Now clean out the inside of the joint housing. Inspecting it also. I did find some scoring on 5 out of 6 of the bearing races. Hopefully you can see them in the pics. I suspect these may cause the joint to essentially fail sooner than later.

The unscored one...

Now all clean and waiting....

Put 1/2of the supplied grease into the joint housing....

Put this back in the same way you took it out....

Tilt it around to put each large bearing back in...

Now put axle back into the vice and slide the new boot on...

Slide on the thrust washer...

And the a new plastic bearing race...

Install the new snap ring that came with the kit...

Put the joint back onto the shaft....

Tap to get past snap ring and seated...

Slide boot up towards joint...

Put remaining grease into boot...

Slide boot over joint housing, being sure to get seated all the way around...

Put outer clamp around and latch...

You'll need one of these special band crimping tools to use....

Now burp!!!

Then the inner clamp. Same process....

Now reinstall axle. Hopefully my little DIY will help some folks out there. Let me know if I should add or change anything. I took the pictures and wrote this up quick.

One thing that I didn't do but should have. Before removing the cage from the the joint housing you should mark both so that the cage is installed in exactly the same position as it was removed. Robert Bentley say so!!!!

Thanks for watching.

Thanks for sharing!

Posted by Diggymart on 9/16/19 @ 1:29:38 PM