You must be logged in to rate content!

7 minute(s) of a 205 minute read

3-16-2011

Got most of the old flange chopped off. that sht was a good 1/2 lb of metal. Prob gonna take it to a machine shop to have it angle cut, unless I can find someone local with a big enough bandsaw.

I need the flange to be sitting at a 35deg. forward tilted angle. This is what I meant by leaning the hotside back. It'll allow the flange to "center" the turbine housing, rather than have it underneath.

Basically I'm making the turbo more "compact". It'll be easier to work with instead of going crazy and lowering the motor, cutting the rain-tray etc.. once angled I'll be able to fit the turbo in there without any further modification necessary. After much thought and staring at the thing with a protractor and tape measure for hours..I have a fairly good game plan.

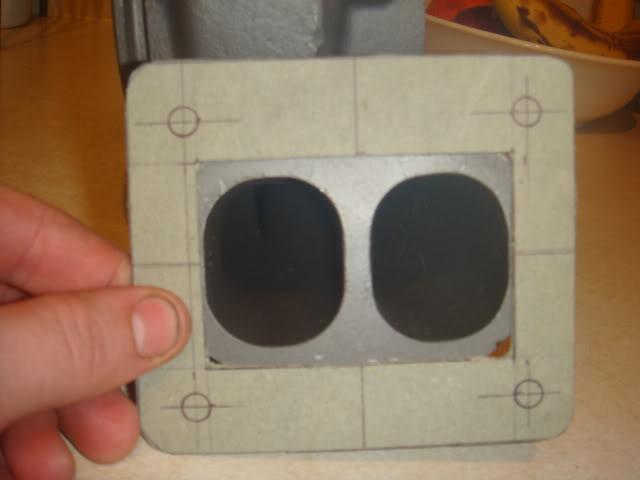

My cardboard T4 flange helped a lot.

Heres roughly the angle it will be sitting at:

3/18/11

The turbo officially fits in its "home" behind the motor. I don't have to modify anything which is awesome. no cutting! Its close, damn close, but it'll work out.

Got all my measurements locked in and ready to cut tomorrow. If my flanges n sht don't come in, I'll start mocking up all the bracing. Its gonna need a lot. I want to take almost all load off the point where the t4 flange meets the turbine housing, that way I won't have to worry about it cracking in the future. Gotta make some kind of turbo brace too. Pics tomorrow.

Got it pretty damn straight.

3/20/11

fw/pp back from machine shop. All nice n balanced out.

Added one more thing to my to do list:

Crankcase evacuation. I will be doing it with a modified LT1 or VW smog pump. looked into The exhaust evac setup..not really a big fan. I'd rather do it with an electric pump set on a boost activated switch. I was never really happy with the open catch can setup, its messy and smells terrible. I WILL have the most efficient, oem motor, high boost vrt there ever was.

Just fabbed/painted a turbo inlet pipe for a fellow C owner. Figure I'd pic whore Came out pretty sweet.

3/24/11

I have some pics for today. Been busy so I haven't had much time to put in the C, but I got the t4 flange tacked on and test fitted the turbo as it will sit. It fits, but the motor is tilted, so with the motor sitting upright it hits the firewall slightly. I need to move the entire unit in about 3/8".

I may cut a small section of firewall out and make a new, slightly concave piece out of sheet metal, or maybe just cut back the hotside a little more if it allows. when I get more time I'll figure out something, but for the moment I am happy to say my hx52 "bolts on".

Firewall clearance

Tomorrow I'm going to get a quote from a local machine shop, to take 1/8" off the atp mani (both block & turbo sides) and t4 flange. Total 3/8" will be plenty of clearance. I can't cut the turbine housing down anymore.

My last resort is firewall modification. If I have to do it, then so be it. Im not worried about cutting into my car.. the trunk floor is missing, the bay has holes in it from a previous SC etc..Its not exactly a prime example of an OEM spotless car, nor do I care about leaving it perfectly as VW intended. At least if I go that route, it'll serve a purpose. Hey, its no worse than all these "shaved bays" lol people modify their bays to be pretty, I chop mine up for function.

4/3/11

Got the manifold Jig made up today. Off to the fabricator on Mon.

4/8/11

4/9/11

UPDATE!!

4/12/11

Have a small update n some pics tonight. decided to pull the motor after an incident with me falling down hugging an 02m.

Pics: Didnt get much done, but I did the crankshaft seal, mounted the FW/clutch setup..attempted to to the trans on the lift (that was a ****in joke lol) then just pulled the motor. The 02m is way to big to wedge in there with the motor still in. Thanks to Nick and Naz for the help today

Wow this is great! Funny assistant you’ve got there ???? #furryfriend

Posted by Diggymart on 5/8/19 @ 2:36:22 PM