You must be logged in to rate content!

5 minute read

16v Distributor Seal Replacement

Compliments of JonnyPhenomenon @ http://forums.vwvortex.com

November 10, 2007

as usual, my 16v distributor is leaking oil. its leaking all over my transmission, making a mess of my engine bay.

I got the proper seals ordered and did the rebuild this morning.

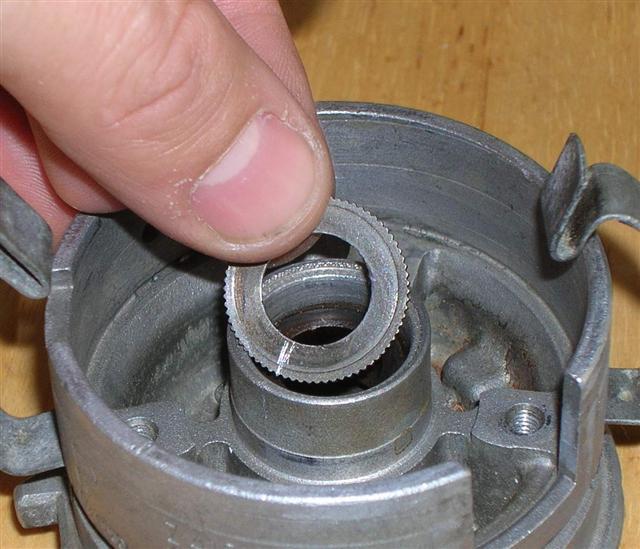

first of all, the big O ring that goes on the distributor body is available at the dealership for 3$ a pop. I bought two because I had two dizzy's to rebuild. The other seal is a 12mm by 19mm by 5mm OIL seal available almost anywhere if you know how to ask. I got mine at napa. the trick is to ask someone to look up METRIC OIL seals by size. they have a book they look through. the company they order it from is CR, and the part number is 4072. if they look it up in there computer they wont find it so be sure to tell them to find it in the book.

this site here looks promising, (thanks to widebodymk2 for the link)

http://www.rocketseals.com/catalog/o...iameter?page=5

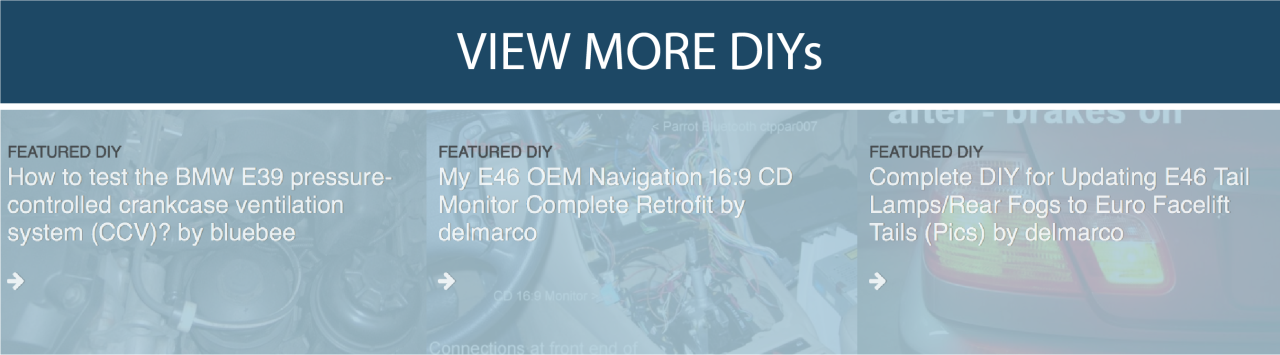

I didnt take any pics of the disassembly this time. this distributor was a real breeze to get apart and it was over so quick I didnt have time to take pics. but basically you gotta take the spring thing off, pound out the drift pin and pry off the funny toothed washer but that is pressed into the dizzy's body. usualy this means you beat the heck out of the washer to do it, but if you are lucky it comes out clean.

I have done these before and had chunks of metal break off the body when I was doing it.

next pull out the old seal; and press in the new one. press the washer back in and reassemble the unit. good to go.

sorry, I would be more descriptive but I am falling asleep...

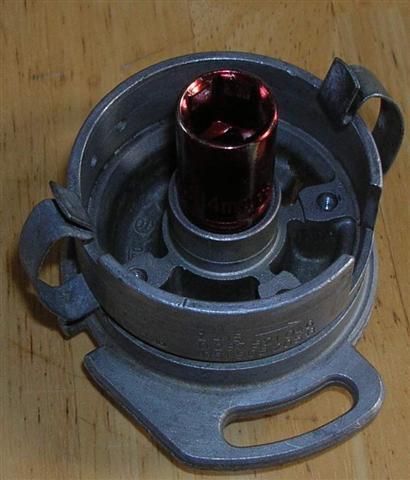

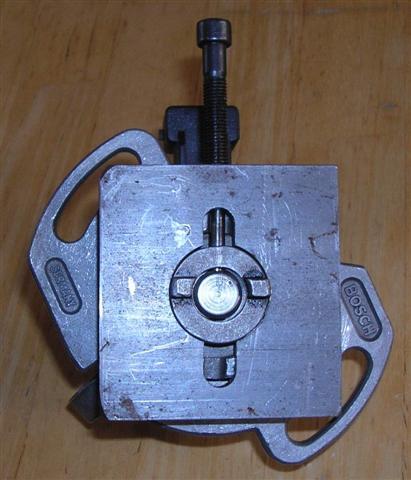

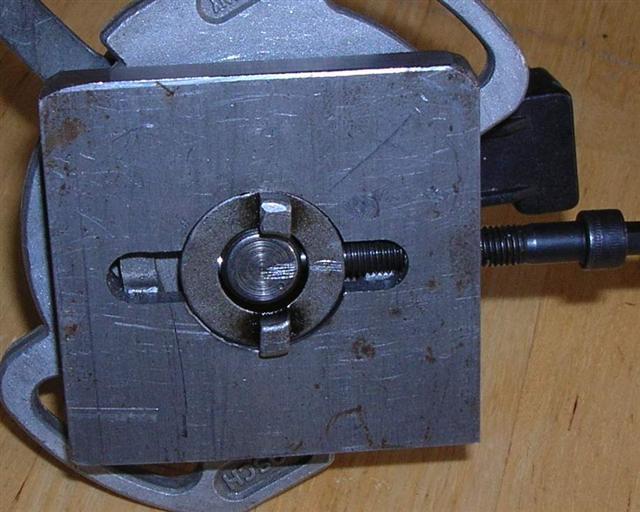

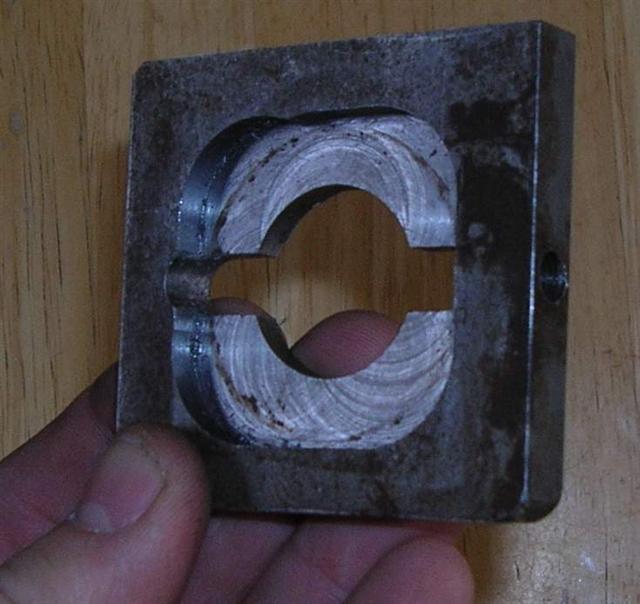

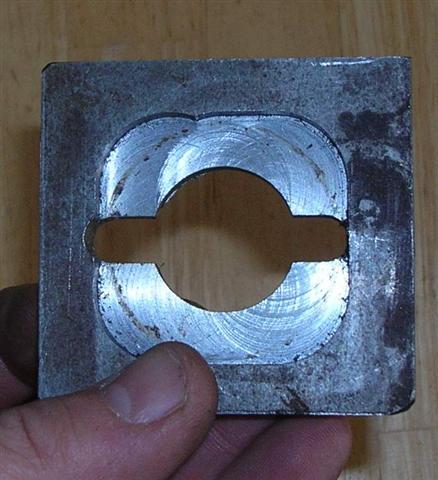

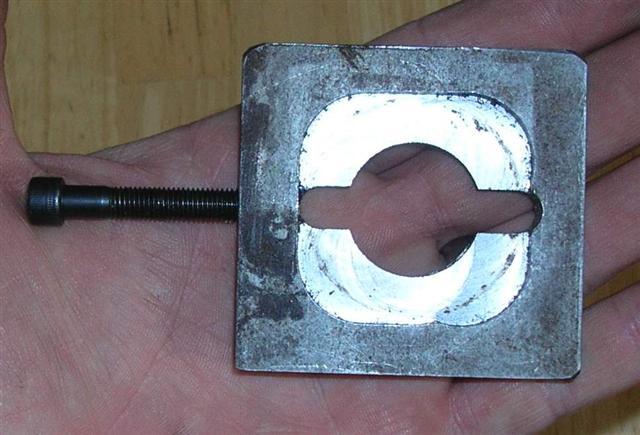

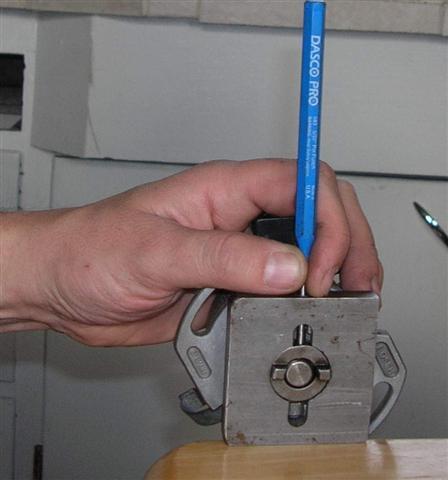

one advantage I have for doing these is a little Jig I made on my end mill. it holds the diz body and stuff steady and takes the force off of the soft metal parts so you dont ruin them when you are trying to pound out the stupid pin.

Ill include pics of that at the end.

here are pics:

I should sketch up a cad drawing of the jig.

I made it because the last dizzy I fixed had a really hard to remove drift pin, and I ended up hammering on it for so long that I flattened out that little 'gear' thing that the pin is holding in place.

but the jig holdes the whole thing in place and spreads out all the force evenly. it also makes it so I can just turn a screw to get the new pin in, thereby avoiding a lot more of the blunt force trauma that the dizzy would otherwise suffer.