You must be logged in to rate content!

11 minute(s) of a 68 minute read

8-29-2010

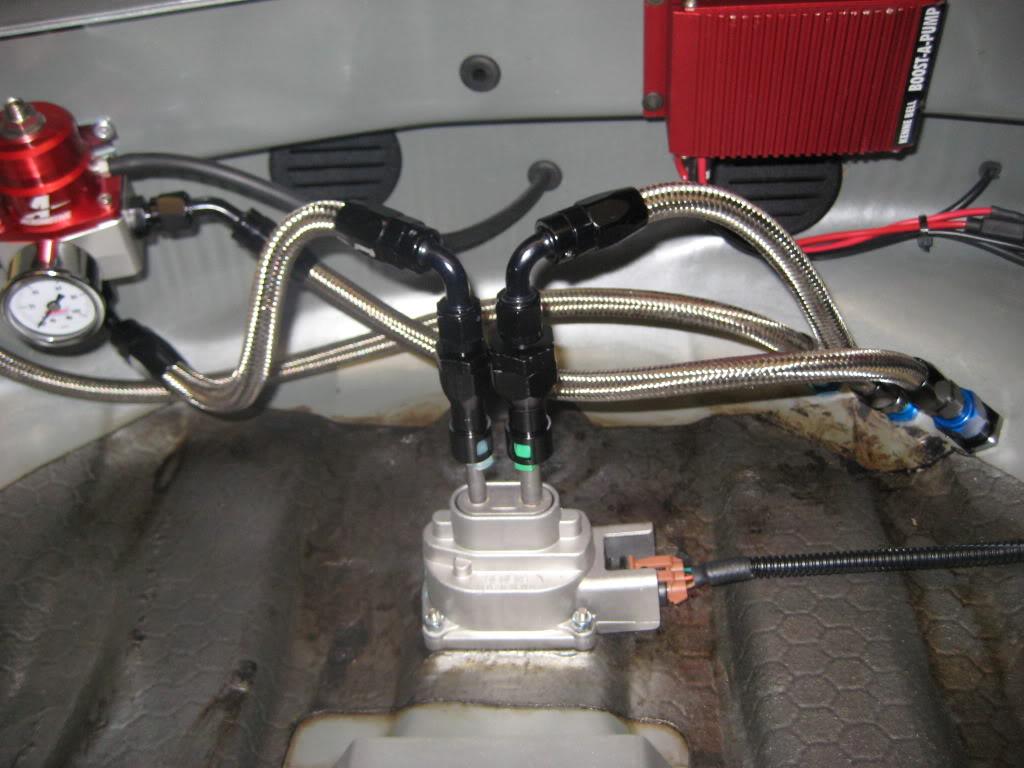

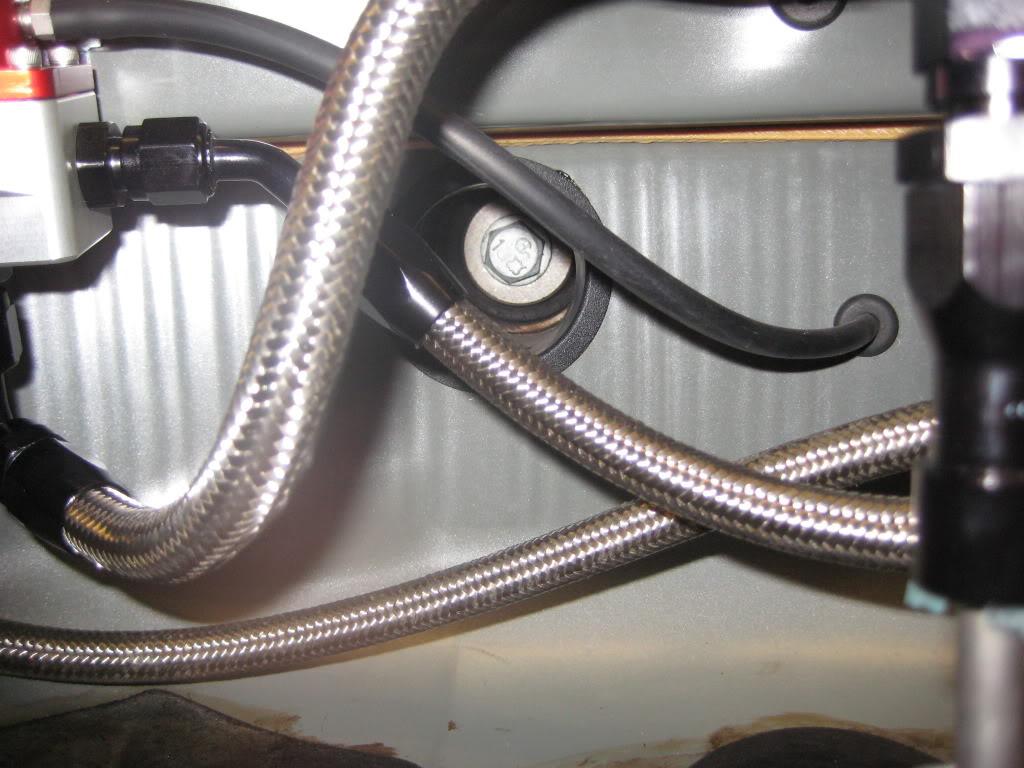

Braided hose and billet fittings aren't cheep....but to have great fuel flow is worth the effort and $

- Boost Ref. FPR $140.00

- 20' -8 Braided Line $100.00

- 15' - 6 Braided Line $60.00

- (2) 90 Deg -8 AN female to -8 AN Hose $50.00

- -8 AN Bulkhead fitting, Nut, Gasket Washers $20.00

- (3) -6 An Bulkhead Fittings, Nuts, GAsket Washers $36.00

- (5) 90 Deg -6 AN Female to -6 AN Hose $75.00

- (1) 45 deg -6 AN Female to -6 An Hose $14.00

- (3) Straight -6 An Female to -6 AN Hose $16.00

- (3) -6 AN Oring to -6 AN Male $24.00

- -8 An to -6 AN Reducer Fitting $20.00

- -6 AN to -8 AN Expander Fitting $13.00

Endless Fuel Capacity................PRICELSS!

KB BAP? Well, My first install of the blower....I used the KB bap thru tuning and final tunes as well as 1/4 times. I installed to Inline Sensors at my fuel rails so I could monitor and Data Log Fuel Pressures thru my Zietronix....as I continue to Mod. No one was doing anything with fuel delivery yet. Later...I swaped to the Arrington Fuel Bucket and loaned my BAP out to a buddy while he worked thru some of his issues N/A. All was good with the Fuel Bucket till I Up'ed the boost....reading 10-12 PSI Boost and lossing 13 PSI Fuel Pressure. I was looking to see how far I could take the Techco Injectors as well as have room to grow! My Buddy was done with my BAP.....So I reinstalled it and played with the voltage settings while logging FP....pretty cool! After figuring out just how much fuel PSI I could get with the BAP....If I ever needed it....I mapped out my fuel Line and FPR mod's to make it soild without the BAP. So, here I am now.....all the fuel I need off the pumps....with my BAP back up. As it stands right now...I wont need the BAP....But its there and ready with just a flip of the switch!

Wireing? Still running the factory harness. No Issues and No Power spikes.

10/2/10

4450 Lbs, 92 Octane, 20" wheels all the way around with 20" Dr's, No meth and 8 PSI

Well, finally made it to the track....and the weather was dry!! I'm still leaving a bit at the table with my tuning (Russ is keeping it quite safe)...all my tuning has been done on the streets, I'm doing all the data aquisition and Russ Anema down in cali is dialing it in. I still have some timing I can add, but I want to get some more hardware to monitor knock first.

I'm guesing I'm gona have to give up on the 20" Dr's!!They worked killer thru my 5 PSI set-up but I never got them to hook in the 4 runs I got this friday. Also, Due to the lack of ROLL BAR.....I had to hit the brakes and coasted at the 1/8 mark. I was a bit bummed....but it was awesome killing all the rides next to me....up intill the 1/8 mile mark!!!

Best Run Of The Day:

1/8 Mile 6.658 @ 103.47 MPH Hit the brakes and coasted to a 1/4 mile of 11.499 @ 86.22 MPH

Starting plan B for traction....and hope to hit an event in Oregon soon!

10/31/10

Ok,

Here's the break down of build vers's E/T. I'm still lacking HP numbers for the Blower install and boost levels....I'll get that soon! My 10 PSI E/T is off by 4-6 tenths.....Traction issues.....But I'll have the firmly planted by next year and I'll come back and Update this entry! I'd like to Thanks a very good Buddy of mine for truly being the best friend you can imagine....Always there with a helping hand....and when Funds were running short....He cracked his own wallet to help me finish what I had on the drawing Board!!!

I thank you Greatly.......Allen Hess!!

You'll be seeing lots of his car in 2011!!!

2008 Challenger SRT8 Car #4501 Build Versus ¼ Times.

Full Show Weight 4400#, 92 Octane, 20â€Â FR SRT8 Wheels With Nitto NT555Rs & NT05R Drs

Initial Base Line ¼ times was 13.200 @ 112.00 MPH All N/A 6.1L (2008)

Dyno = 0 (No Data)

Zoomers Cat Back and X pipe

Stage #1 ¼ Mile Time was 12.319 @ 111.74 with 1.739 60 All N/A 6.1L (2009 LX Football)

Dyno = 430 RWHP and 434 RWTQ

- Factory SRT8 Shorties

- Zoomers X thru to tips

- 170 Deg T-Stat

- Mopar Muscle T-Body 83-85mm

- Mopar CAI

- Diablo Running 93 Octane

- Edge 3000 TC

- Rear End swap to '09 Getrag with 3.73 Gear

Stage # 2 ¼ Mile Time Was 11.865 @ 114.86 With 1.705 60 All N/A 6.1L (2009 LX football)

Dyno = 480 RWHP and 470 RWTQ

- Factory SRT8 Shorties

- Zoomers X thru to tips

- 170 Deg T-Stat

- Mopar Muscle T-Body 83-85mm

- Mopar CAI

- Intertia MotorSport CRM Tune

- Edge 3000 TC

- Rear End swap to '09 Getrag with 3.73 Gear

- Inertia Motor Sports Premium Heads CNC Ported 2.10/1.60

- Inertia Motor Sports SRT Max Cam 218/223 112 LSA .556/.566

- Inertia Motor Sports Ported Intake

- Magnflo Hi-Flow Cat'ed Midpipes

- Paramount Performance Stage II V-Body

- Paramount Performance Hennesey TCM

Stage # 3 ¼ Mile Time Was 11.444 @ 119.45 With 1.596 60 392 Stroker 4 PSI (2010)

Dyno = ? RWHP and ? RWTQ All Tuning Done On the Streets Via E-mail

- Factory SRT8 Shorties

- Zoomers X thru to tips

- Magnflo Hi-Flow Cat'ed Midpipes

- 170 Deg T-Stat

- 3.0L Techco Twin Screw SC Pushing 4 PSI (3.125 UPR and 5Â LWR)

- Arrington 90 MM T-Body #0065

- KB Boosta Pump and -6 Main Fuel Feed Line

- RDP Thru Fender CAI

- CMR Tune From Russ Anema

- Edge 3000 TC

- Rear End swap to '09 Getrag with 3.73 Gear 226 MM LSD Unit and Axles

- Paramount Performance Stage II Valve -Body

- Paramount Performance High Torque Drive Line Assy

- Paramount Performance Hennesey TCM

- P/ N P5153604 Crate Engine, 392 Hemi, 540 Horsepower, 490 ft.-lbs. Torque

Specifications As Ordered and Changes:

- Factory 6.1L Deep-Skirted Cast Iron Block with Cross-Bolted Mains (#314-1-622)

- Mopar Performance Heads (P/N L- P5153349, R- P5153350) AT Cylinder Heads

- CNC Ported Aluminum Twin-Plug Cylinder Heads New Castings

- Stainless Steel 2.100" Intake and 1.600" Exhaust Valves Rev (Reworked Inertia)

- Ovate Wire (Beehive) Competition Valve Springs Comp Cam 26918-16Â (Reworked Inertia)

- Viton Competition Valve Stem Seals

- Titanium, 7° valve spring retainers

- Machined, 7° round groove valve locks

- High-temperature Viton valve seals, bronze alloy valve guides

- Hardened, custom valve seats

- Premium "five-angle" CNC-machined valve job

- Mopar Performance Head ID Info:

- R/H Head = 05037448AA

= 175610061

Intake = 6170064911

- L/H Head = 05037449AA

= 067620235

Intake = 6058014811

- Mopar Performance Push Rods (P/N P5153629) Comp Cam

- Competition chrome Moly steel Pushrod set features 6.675" and 7.875"

length,.080 Wall and 5/16" diameter

- Mopar Performance Cam (P/N P5153691) Comp Cams

279°/285° (duration @ .006") Hydraulic Roller Camshaft

0.584" Intake and 0.552" Exhaust Lift @ 110 LSA (Swapped For HHP Blower CAM Below)

- Mopar Performance Pistons (P/N P5153635) Diamond Pistons

- Forged Pistons (4.055" Bore)

- 10.5:1 Compression Ratio

- Top Notched .080 Intake and .100 Exhaust

- 0.927 Pins

- Mopar Performance Proprietary Crank (P/N P5153578) Scat ForgedÂ

4140 Forged Steel Crankshaft - 3.795" Stroke and 2.100 Journals

- Mopar Performance Rods (P/N P5153635) Scat Forged

4130 Forged Steel I-Beam Connecting Rods - 6.200" Length

- Premium Tri-Metal Performance Engine Bearings

- Precision Balanced Rotating Assembly

- Distributor less Coil-On-Plug (COP) Ignition System

- Special Grind SC CAM From HHP- HHP Stage 4 / Stroker Blower Cam

.273/.285 Duration @ .006

.547/.556 Lift

119+2 LSA

Stage # ¼ Mile Time Was 11.066 @ 136 With 1.875 60 392 Stroker 10 PSI (2010)

Dyno = ? RWHP and ? RWTQ All Tuning Done on The Streets Via E-mail

- Factory SRT8 Shorties

- Zoomers X thru to tips

- Magnflo Hi-Flow Cat'ed Midpipes

- 170 Deg T-Stat

- 3.0L Techco Twin Screw SC Pushing 10 PSI (2.71Â UPR and 6.5Â LWR)

- Arrington 90 MM T-Body #0065

- Arrington Twin 255 LPH Walbro Fuel Bucket

- Aeromotive Boost Ref. Fuel Pressure Regulator and -6 and -8 Braided Lines

- RDP Thru Fender CAI

- CMR Tune From Russ Anema

- Paramount Performance 4K Billet Stator TC

- Rear End swap to '09 Getrag with 3.73 Gear 226 MM LSD Unit and Axles

- Paramount Performance Hi-Torque NAG1 Tranny

- Paramount Performance High Torque Drive Line Assy

- Paramount Performance Hennesey TCM

- P/ N P5153604 Crate Engine, 392 Hemi, 540 Horsepower, 490 ft.-lbs. Torque

Specifications As Ordered and Changes:

- Factory 6.1L Deep-Skirted Cast Iron Block with Cross-Bolted Mains (#314-1-622)

- Mopar Performance Heads (P/N L- P5153349, R- P5153350) AT Cylinder Heads

- CNC Ported Aluminum Twin-Plug Cylinder Heads New Castings

- Stainless Steel 2.100" Intake and 1.600" Exhaust Valves Rev (Reworked Inertia)

- Ovate Wire (Beehive) Competition Valve Springs Comp Cam 26918-16Â (Reworked Inertia)

- Viton Competition Valve Stem Seals

- Titanium, 7° valve spring retainers

- Machined, 7° round groove valve locks

- High-temperature Viton valve seals, bronze alloy valve guides

- Hardened, custom valve seats

- Premium "five-angle" CNC-machined valve job

- Mopar Performance Head ID Info:

- R/H Head = 05037448AA

= 175610061

Intake = 6170064911

- L/H Head = 05037449AA

= 067620235

Intake = 6058014811

- Mopar Performance Push Rods (P/N P5153629) Comp Cam

- Competition chrome Moly steel Pushrod set features 6.675" and 7.875"

length,.080 Wall and 5/16" diameter

- Mopar Performance Cam (P/N P5153691) Comp Cams

279°/285° (duration @ .006") Hydraulic Roller Camshaft

0.584" Intake and 0.552" Exhaust Lift @ 110 LSA (Swapped For HHP Blower CAM Below)

- Mopar Performance Pistons (P/N P5153635) Diamond Pistonsâ

- Forged Pistons (4.055" Bore)

- 10.5:1 Compression Ratio

- Top Notched .080 Intake and .100 Exhaust

- 0.927 Pins

- Mopar Performance Proprietary Crank (P/N P5153578) Scat Forged

4140 Forged Steel Crankshaft - 3.795" Stroke and 2.100 Journals

- Mopar Performance Rods (P/N P5153635) Scat Forged

4130 Forged Steel I-Beam Connecting Rods - 6.200" Length

- Premium Tri-Metal Performance Engine Bearings

- Precision Balanced Rotating Assembly

- Distributor less Coil-On-Plug (COP) Ignition System

- Special Grind SC CAM From HHP- HHP Stage 4 / Stroker Blower Cam

.273/.285 Duration @ .006

.547/.556 Lift

119+2 LSA

12/7/10

Well,

I just started my winter Mods for the 2011 season. The first mod was injector swap to meet my new base fuel needs. I ran the Kit Techco's (G302's) all the way up thru 10 PSI with the aid of the Boost Ref Fuel Pressure Reg. There was still enough headroom to run it up to 12 PSI on 92 octane.

I'm swapping out for some Ford Lu80's and to do so...I needed to mod my fuel rail stands to allow for the .500" longer length!! Here's some pics for all the Techco boys!

Upper:

-Kit Techco Rail Stand

Lower:

- Modified Techco Stand

Finished Stand ready for Lu80 Injectors:

12/24/10

Just a little update,

Russ nailed the the tunning first time out!! I swapped my G302 injectors pushing 10 PSI on the blower....for some Lu80's and the starter tune he scaled was nuts on....I mean perfect!!! I have a little driving around to do (Get about 200 Miles) on the tune and then I'll grab some more data to make sure its perfect for 92 octane.

Russ also sent me (2) Ethanol starter tunes (e75 and e85). Once I get my ethanol contect sensor installed......It will be time to gather some data and perfect my alternative fuel (Flex Fuel) tunes. With the sensor in place....I can manually mix my own Ethanol percentages.....say e95 if I wish.....I'm pretty stoked!!!

Here's a few pics of my fuel stuff and my new Track Wheels!! Thanks Charles....Love the wheels!!

G.

12/31/10

Well,

Finally got to installing the Zeitronix e85 Content sensor and the readout gauge. I installed the gauge in the glove box....you only need to check it after a fill up or if you're adding some ethanol to the mix....to bring the E content % up.

I also wanted to add some vents to the trunk area as well as make getting to the (2) dif bolts that are a PITA to get to.....muche easier!! I located (2) 2.5" removeable vents...inline with the dif bolts.

Glove Box Gauge