You must be logged in to rate content!

5 minute read

Tremec, TKO Girdle support

Compliments of 92rohcp @ www.corral.net

For anyone who is running big HP on their TKO500/600 a transmission girdle is smart investment but it doesn't have to be costly. There are other upgrades to strengthen the transmission like Liberty threaded front bearing support Explained below.

**Liberty's Exclusive Threaded Front Cluster Bearing Support eliminates oil leakage from the front cap and more importantly it supports the front cluster bearing preventing the cluster shaft from improper movement. Since the stock cap is only held in place by the o-ring, it can allow the cluster shaft to move and alter shimming. This movement decreases the overall integrity of the transmission. Liberty's Exclusive Threaded Front Cluster Bearing Support corrects all of the problems associated with the stock cap.

However the TKO case becomes the weak point where the front of the case meats the bell under heavy load the case can flex allowing the main shaft and counter shaft gears to separate causing gear carnage and sometimes the case can even crack.

Swarr auto came up with a solution called the Trans Girdle, Swarr Girdle like a clam shell it bolts between the Bell and the transmission front case supporting the transmission alum case from flexing. These sell for $185 from Swarr or

Pro Motion and Pro Motion says is a must for 650hp or above.

Here are some images and what gave me the idea to make my own.

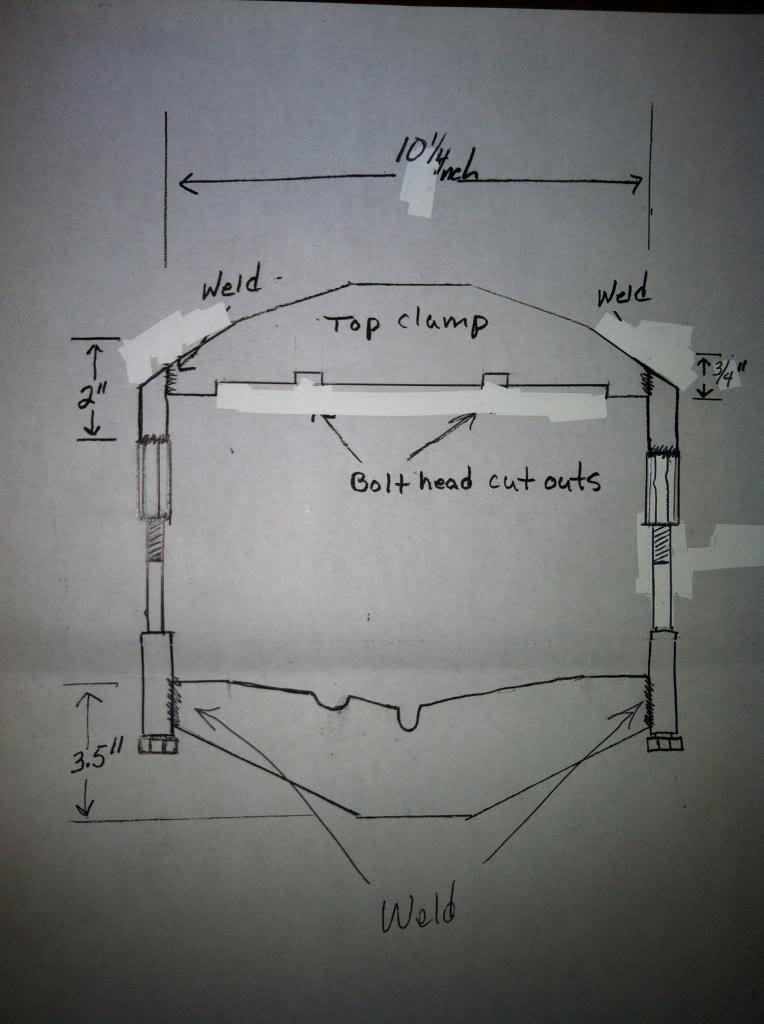

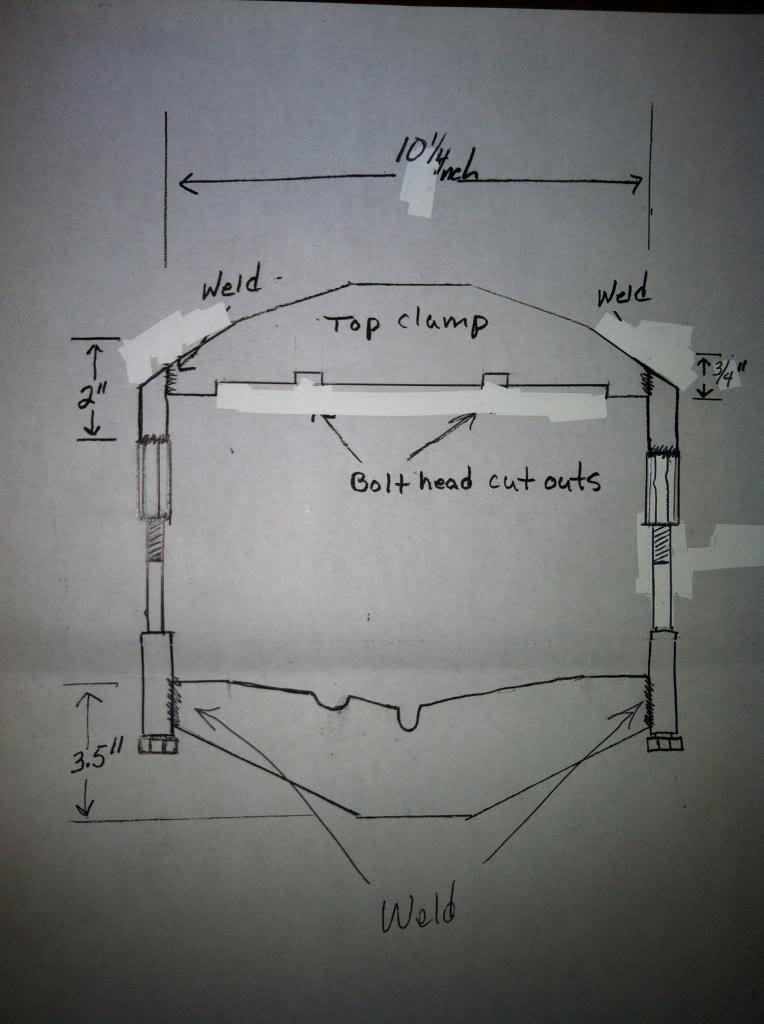

I used .25 inch steel plate 10.25" long to clear the transmission bolt ears, this leaves room to weld on the round bolt guides where the bolt goes through to clamp the 2 halves together. The top plate or clamp is 2" wide and I went with 3.5" for the bottom as it has more room and needs the added with due to the cutouts needed to contour the bottom of the trans case.

I used the steel plates to scribe on by putting them right up against the front of the case upper and lower then tracing with a pencil so I new what to cut out.

With a metal cutting blade on my trusty old chop saw and a hand grinder I shaped both plates to contour the very leading edge of the case so it supports the front aluminum plate that holds the main and counter shaft.

Here is the drawing of my design with measurements. I was able to build this for under $10 using some of my stuff and buying one steel plate 11"x 3.5" and the long threaded nut. Beats paying $185 plus I had fun making it. Also used my trusty old Harbor Freight 90 amp Flux core MIG welder to weld the round bolt guides to the steel plate. I'll post up some more pics of the the actual girdle soon.

It's finished now and I did have to make some changes to my original design. As you can see from my drawing above the changes have been made so you can go by those numbers. The plates were made shorter 10.25" and then the tubes welded on I also had to cut the top piece down so it could fit inside the tunnel. Also I cut and recessed the top piece so it could fit lower over the transmissions top plate. It's dam near the same as the Swarr girdle now.