You must be logged in to rate content!

12 minute(s) of a 44 minute read

9-7-2012

These Corbeau seats are vinyl (or leather if you choose) so that (to me anyway) would detract somewhat from the "cushiony" feeling.

They are mostly foam and are low profile - less springy.

If you were to just plop down in them from standing, you would probably NOT bounce - but just land like a thump.

When I first got them and sat in them, they felt to firm - I didnt "sink in" & the cushion didnt conform much at all so to speak. I was a little concerend that they would not be comfortable on long cruises & stuff - to much like a racing seat or something - more of a firm foam feeling than a springy feeling - they are very low profile seats - great for headroom & they had the right look.

As I moved forward with building the car, I had it all mocked up with complete interior for about 4 months as I worked on other parts of the car.

I would just sit in the car in the garage, almost every day after work & on the weekends - sometimes for hours at a time looking & studying all the interior details & making all my re-design notes & plans, etc... Getting the feel for the car before I took it all apart again.

Anyway, the firmness of the seats never came into question again, they ended up being quite comfortable - just firmer then a regular car seat. Maybe they started to conform to me after sitting in them so much, or maybe I just got used to them, but I like them. They sit different than a regular "new" car but in a way they add to the feeling that your not in grandma's new cushy cadillac but that you in a 60's muscle car ready to rip it up!

They keep you in place & althoe I have not driven in them yet, I believe they will provide a level of performance above a standard car seat & still provide comfort for long cruises.

9/8/12

Installing Autometer Pro Comp II LED Gauges in a 67 Mustang gauge panel

The idea here was to make the gauge panel a self contained unit with just a couple plugs. No cables or oil lines, all electric, for easy removal. Some friends said electric gauges suck compared to the accuracy of mechanical, but all new cars use electric gauges, and they are accurate enough for me.

If my oil psi or water temp is of by a couple psi or degrees, it isn't gonna hurt anything - this car is for cruising.

The gauges I used are Autometer Sport Comp II, electric, full sweep, Black face, LED gauges.

Sizes I used are:

- Speed & Tach: 5"

- Oil Psi, Water Tmp, Fuel: 2 5/8"

- Oil Temp, Trans Temp, Volt: 2 1/16" (for the radio bezel)

They fit perfectly into a 67/68 gauge panel!

These gauges are very cool. They light up like the gauges in new cars - LED light through the gauge, not a rimlight, so the numbers & stuff are all very clear & bright.

I would have preferred a Speedo that went to only 120mph & a tach that went to 8,000 rpm instead of 180mph & 10k for racing applications - but its a minor complaint & in the end didn't bother me at all.

I also used the dimmer by Autometer because the Ford Headlight switch dimmer wont dim the LED's.

They are expensive because they are Electronic and LED - set me back about $1,200 for all 8 gauges & dimmer - from Summit.

Tech notes:

- Fuel gauge:

Autometer reads 10 ohm FULL, 73 ohm EMPTY (OEM ford sender for 1969 20 gal gas tank reads 7.9ohm FULL & 92ohm Empty as I measures it stop to stop - I connected the sender to the gauge and it reads well, the gauge will stay on FULL for the first inch or so of movement on the sender, then start registering. The gauge will show EMPTY a little before the stop. Should be OK.

- Power for Dimmer:

Autometer advertises that you can dim up to 6 gauges with the dimmer.

I called Autometer because I want to dim 8 gauges plus the Lokar LED shift indicator. The tech guy said the Max load the LED Dimmer can handle is just over 1 amp (1,120 ma). Nothing bad will happen if you draw to much, it just wont dim well. The 5" gauges draw @ 140ma, The 2 5/8 Gauges draw @ 100 ma, and the 2 1/6 Draw @ 85ma plus the Lokar shift indicator at @ 150ma. All total should be around 980 - 1,000 ma (about 1 amp.)

INSTALLATION:

There are many ways to do this Im sure, but I wanted it to look like OEM with the gauges mounted behind the bezel, not stuffed in through the front. To mount the gauges behind I had to remove the bezel on the AM gauges. There are companies on the net that will build one for you to the tune of about $1,400 or so - and they only use a couple style of the regular mechanical gauges, not the electric LED.

First you have to remove the Aluminum bezel from the gauge. NOTE - start with the cheapest gauge (Volt) to get the hang of it - its a little unsettling to start tearing apart a $250 gauge right off the bat.

I used a small screwdriver to start bending up the lip, then used a paint can opener & just worked my way around the gauge. Just bend a little at a time & go around several times - Be careful of the plastic lens as you can scratch the outer edges of it as the bezel gets loose. I scratch the edges of the Speedo gauge before I realized it. I called AM to buy a replacement lens, they would not sell me one. Fortunately once installed behind the Ford Bezel, the scratches are hidden because the gauge opening on the bezel is smaller than the AM bezel that scratched it.

On these Sport Comp II gauges, the lens is not attached to the housing. see the expanded view.

To keep everything aligned, I used green tape to attach the lens to the housing so it doesn't slide around & keeps dirt & stuff from getting inside on the face.

TAKE APART THE FORD CLUSTER:

I had two old ones to choose from.

NOTE: Label the cardboard light sleeves & index them with a line so you get the right ones back in the right place - makes it easier. Also, when final assembling, I used a bit of tape to hold them in place.

I used the OEM metal back plate to hold the gauges & to mount the bezel to the dash using all 7 screws and a new reproduction plastic bezel - standard black camera case finish.

Some aftermarket conversion kits will only use 5 out of the 7 attachment points - eliminating the two lower mounting points under the 5" gauges. Its my opinion that you need these two mounting points to really secure the cluster in place, if not, the two points on each side of the cluster are all that keeps the panel from "swinging" out & bouncing around - the top 3 mounting points can act like a "hinge" if not secured at the bottom. Also, most kits dont have a good solution for the wiper switch & mounting the turn signal lights & stuff that I want to keep connected.

TRIM THE BEZEL:

With the bezel upside-down, place the gauges on top of the correct opening (I labeled mine on the back because the positioning of the gauges is reversed when its upside down) You will see where to cut the plastic to get the gauge to sit nice & flat on the opening. You will also have to snap of the little alignment "nubs" on the plastic bezel. If you have an old bezel, practice on that first - I did, and that gave me a good template for the final trimming on the new bezel.

Once the gauges lay flat on the openings, I indexed them so they were straight. I labeled the gauges on the back with "TOP" on the top.

Then I cut notches where the OEM screws mounted the OEM gauges. I screwed in sheet metal screws at an angle because the AM gauges are bigger. This holds the gauge in place & indexed while you drop on the back plate. I dont think its secure enough to hold them for actual use.

TRIM THE METAL BACK PLATE:

Position the gauges on the metal back & you will see where you need to cut it - be sure to leave as much meat as you can on the back plate - specially on the top & bottom of the outside two gauges.

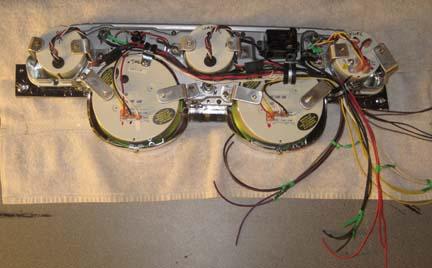

Mine looked like this when I was finished.

Once the back plate is on & secured with gauges in place, I made brackets to hold the gauges more securely - specially since the Speedo, Oil Psi & Water Tmp gauges have buttons you push & I didnt want to end up pushing the gauges through once installed.

I used some aluminum bar, cut & bent to lake brackets & the screwed them right to the back plate & used the AM thumbscrews to push out on the brackets (opposite how you normally install gauges). This made the very tight.

I added 3 reinforcement mounting points on the bottom of back plate to the bezel with some plumbers strap. Because I cut off the two lower mounting points attached to the OEM Speedo & Tach.

Then I took it all apart, painted the back plate & assembled it all one last time.

Note - paint the inside of the back plate - the area around where the wiper switch goes - flat black. It blacks out silver & stuff behind the switch when its all finished - looks cleaner.

WIRE IT UP:

Some gauges used push on tabs, some had pigtails & plugs. I wanted to keep the gauges as is, so if I had to change one out, it would be a simple swap.

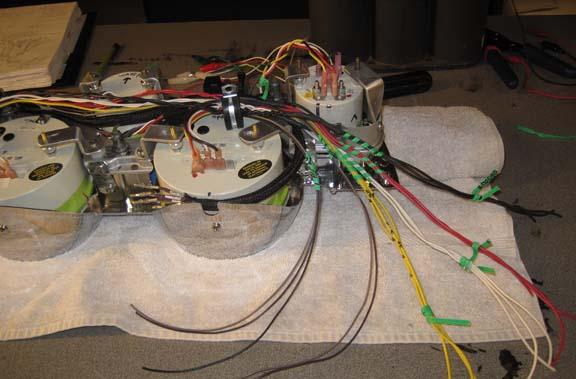

I made two harnesses - one for the car stuff (5 pins - turn sig, brake, Hibeam) and one for the gauge LED & signals (11 pin). I kept the Wiper harness as is.

I combines common wires (ground, LED, 12v Power, etc... ) into one wire for making the plugs easier.

At the wire ends, I labeled them so I could identify easier later on - I printed up little labels, slid on a piece of clear shrink tube on the wire, then slid the label into the clear shrink tube & hit it with some heat - easy to read & wont rub off.

Turn Signal, Hi Beam & Brake wiring

Wire Labels

Gauge wiring

All wrapped up with plugs attached

LED lighting - hard to get a good pic

Took a weekend to make up & it looks really cool!

Nice Mustang! I like what you did with the gauges!

Posted by miatamatt on 3/16/21 @ 8:54:42 PM