You must be logged in to rate content!

7 minute(s) of a 209 minute read

12-26-2011

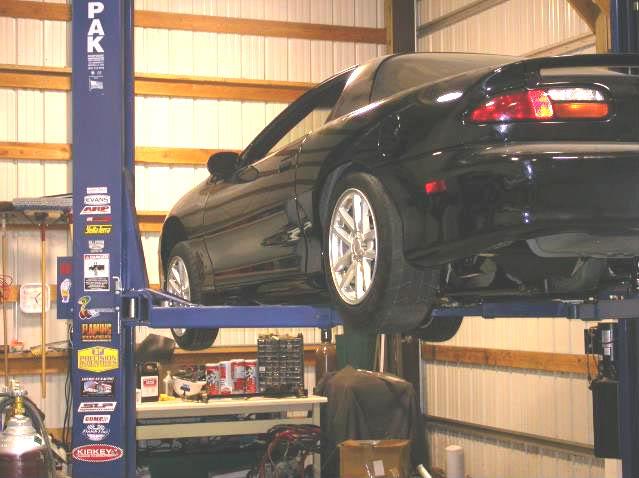

Put the rearend back in the car today to see how much more clearance I have. The car is set at an approximate ride height for the rear and the LCAs set at 19.50".

I was not able to get the torque arm level with the bottom of the the car before the modification.

The front inner fenderwell modification for tire clearance.

12/29/2011

Quote:

How much do thouse bump stopes weight?

2lbs each, including 2 bolts and rubber stop. Also rounded to make up for lost material from hole saw.

Quote:

Are you glad you cut them out, still think its strong

There is a 90 degree flange down, on the inside of the stock spring bucket, I cut right up to it. In my thinking, this will help keep the structural integerity of the sheetmetal supporting the rear frame rail.

Drivers side

Passenger

1/3/2012

Decided to remove the rear coilover and put the spring in the stock location. Spent some time over the holiday designing an in car ride height adjuster set-up and incorperated the roll bar pad area.

Time to cut and see what I find.

Right rear, inside car, over stock spring bucket area.

This area needed some structural help if I was going to incorperate it into the rollcage. I plated 3 sides. The area to the front of the car (shock area)appears to be 16 or 18 guage, should be strong enough.

Waiting for the jack bolts to get here so I can keep going.

1/6/2012

Last night, I needed to get something done, so I removed the ebrake handle and cable.

Purchased a 4" holesaw this morning and removed the stock upper spring locators.

Located a 10" spring for testing and built a temporary spring locator that bolts to the housing.

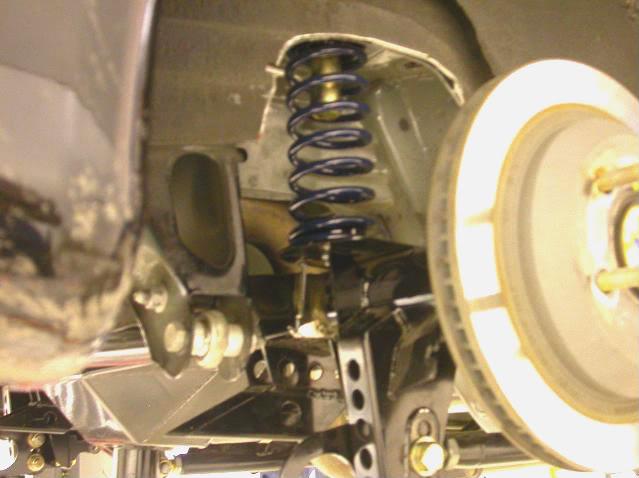

Installed the spring, raised the rearend till tension is on the spring and 90 degrees to the spring pad.

Looking up into the stock upper spring bucket, the coil spring is going to be positioned back from the stock location.

1/7/2012

The new 10" springs came in. Waiting for several parts to arrive to complete the project. The prep work is done and ready for welding once the rest of the parts arrive.

Made plates to be welded in on the bottom side of the spring bucket. Held them on with tech screws until welded. By doing this they will locate the same every time.

Installed my temporary spring locators on the rearend, both springs and raised the rearend to ride height while springs were pressing against the plates. Took a torpedo level, squared the springs front to back and side to side. With a Sharpie, traced around the outside of the spring where it contacts the plate.

Removed the spring and plate. To make it simple to locate center, I made a template. Center punched center and used a hole saw to cut the hole for the tubing.

Inserted the tubing and installed the plates back in the car. The tubing is pressed in, don't want to weld in until the rest of the parts arrive.

Passenger

Driver

1/8/2012

Fabbed up some spring perches for the rearend. Made bolt on style because holes were aleady in place on the housing. Painted them with POR15.

1/11/2012

Still waiting on jack screws, should be here friday. Getting the top plates fitted and ready for welding once the jack screws arrive.

Finished cutting and fitting the roll bar mounting pads for welding. Once the rest of the parts arrive, it will take no time to finish this project.