You must be logged in to rate content!

7 minute(s) of a 209 minute read

12-20-2011

Decided to try and make a flange that goes around the cut out above the rearend, without removing the rearend.

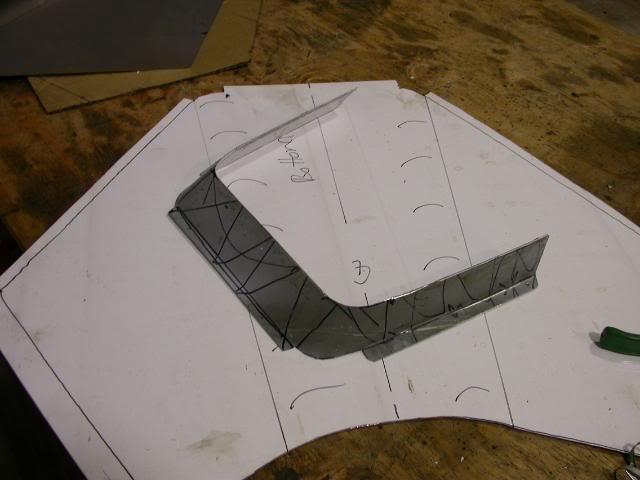

I made a pattern to fit the removable driveline tunnel.

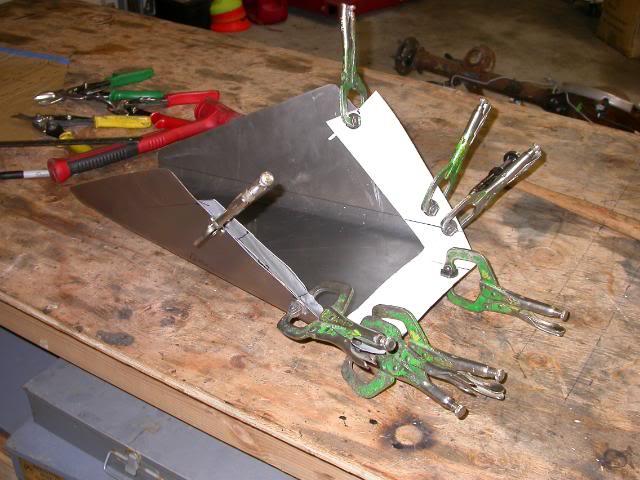

Calculated my flanges and and notched the radius because I can't bend a flange on it.

Flanges turned up.

Here is the formed part.

From the bottom of the car.

Need to decide on what fasteners to to use to hold the cover on, Duz or quickcert.

12/20/2011

Here is a 40 series Flowmaster. Not tucked up into place, but you get an idea what it would look like.

12/21/2011

On the down hill side of the tunnel modification.

Floor panels are welded in. Pictures from the bottom of the car.

Right side:

Decided to remove the rearend to make things easier.

Left side:

One more piece to go. Going to try and get finished up tonight.

12/22/2011

A candy bar and cup of coffee later, I am fired up. All parts are welded in. On my last weld pass doing the passenger side radius I blew a 3/8" hole  and had to fix.

and had to fix.

Next , clean up, decide on fastener to hold cover on, paint and seam seal.

The primer sealer has been put on. Going to have to wait till spring to apply the paint, warmer weather. Ordered white seam sealer to match what is inside the car.

Decided to use Nutcerts to hold the cover on.

12/23/2011

Picked up a nutcert gun this afternoon, so tomorrow I should have the cover mounted.

I cut out the bump stop mounts and while I was in there, I was looking at the fenderwells where alot of people have to clearance front inside of the fenderwell for tire clearance. Being in the cut and weld mode, I pulled out the sawzall and went to town.

First I decided how far forward to go. Looking into the fenderwell from the side, I sighted staight back to the inner fenderwell and determaned the starting point. Tire is not going to be any farther forward than that point.

I wanted to try and follow the contour of the inner fenderwell. Decided to start cutting and made a pattern that follwed a the contour I was looking for.

Looking from the back of the car:

Side

Cleaned the seam sealer from behind the areas to be welded. The brace on the inside of car is still in place. Just cut away the bottom flange in the area of the brace where the new piece of sheetmetal was going to be added.

Cleaned up the welded area and sprayed with some self etching primer. once the primer dried, applied a light coat of undercoat.

Tunnel is done. White seam sealer came today.

Just need to paint and seam seal to be complete.

Next, will be finishing the fenderwell modification to the right side.

12/24/2011

Been working on the right fenderwell modification. Tacked in and will finish in the morning.

Looking from the back of the car: