You must be logged in to rate content!

12 minute(s) of a 390 minute read

9-18-2008

Thanks for the props guys!

I've been having a lot of fun getting into the nitty gritty of suspension design and engine building with this project.

As much as finishing the project is a major goal, so is learing as much as I can. Someday I'd like to take what I've learned hear and build a one-off, half ton, single seat commuter car. One thing at a time.

I've been following dent sport's build for a long time. I'd like to do a lot of the same type of events as he's doing. Like time attacks and hill climbs. I've printed out red lines rules regarding cage design and other things, as well as nasa's, and while I was at it the NHRAs (all though it seems they will allow most things if they were built to the rules of another sanctioning body).

Check out dent sport's build here

DSG 240RS Updates...still a ways to go

And something else that I would love to do is buy a rally computer and go do a targa with my pops. Oh and Bonneville has always been a dream, maybe the silverstate classic, or maxton here on the east coast. My grandfather used to race a model A at the dry lakes is CA when he was younger than I am, I'd love to do that too. I just want to go have fun and have the fastest car I can build. I've got a lot of dreams!

check out targa Newfoundland here:

Targa Newfoundland - It's About the Drive

-=Peace and Tire Smoke=-

9/19/08

David Vizard had a hand at MTI in the development of their LS7 head porting program. He wrote a short article about it here:

7 Liter Corvette Heads - can they be improved upon? - GoFastNews.com - All Racing News All the Time!

They obviously removed the little pad above the spark plug! If it works for David Vizard...

Also, after not calling me back I called Ohlins again the other day. They don't think that they are going to be able to hook me up with a 300zx style rear-bottom mount even though I need entirely new shock bodies back there! I'm about to change my avatar.

I found my radiator on ebay, although monster motorsports is a good source also. Mine was custom built for Hendricks motorsports for a nascar qualifying car, but never used. Scored it for $260 (they are about $1300 custom/new)... twice because the first one I found UPS threw over my fence and destroyed it. There's only 26-27" between the frame rail which is much more narrow than 90% of the nascar radiators. But we have more room verticly. Also beware of the built in oil to water oil coolers because they will prevent you from putting any angle/v-mount because of frame rail clearance issues. The welds on the C&R are amazing. But beware of superspeedway radiators with >15 fins/sq.in. they may be a little too dense for street use. Mine is 15. Also don't go too thick if you don't need it. 5" thick radiators get pretty heavy once they are full of water.

9/20/08

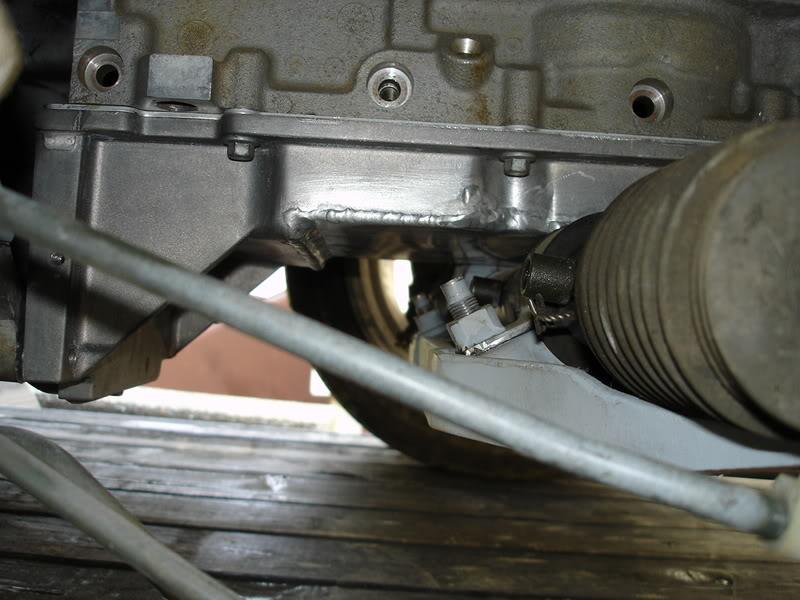

My garage isn't at my house so it might be a while. But there's a reason for all of the kits sitting so hi. The GTO pan forces the block up, and the tunnel forces the engine/bellhousing forward. Banging is a severe understatement regarding what I did to the trans tunnel to get the engine back, and then I strapped my GTO oil pan down to the mill and took a lot of material out.

it's also subtle to see, but I cut out the ENTIRE center section of the crossmember and reinforced it underneath the steering rack.

The only kit out there that I see right now addressing the oil pan problem is Sikky.

For those interested in N/A power, I asked Brian Nutter of Wiseco Pistons to check out my thread on my latest piston dome idea and here's his response from over on LS1tech.

The soft head concept is valid, but there are some things you need to consider. Larry Widmer is a good friend of mine and a good customer. We do the pistons for his 420+ crank horsepower naturally aspirated Honda 4 cylinders. At the same time, you've got to look at Cup and Pro stock engines today for the most advanced 2v technology. These are the people who know the most, but they aren't going to talk about it on a forum. I've seen the CFD combustion analysis they do and it's incredible. Efficiencies well beyond F1 due to them developing against a standard that remains in place for longer than a couple years. Larry certainly stands as a person that got many of these people to start Studying and Thinking about the art.

Most of the present high end N/A engines do not enhance swirl in the intake port. In general, we don't want swirl at the expense of flow and tumble designs are better. To this end, Larry has some interesting features in the Venturi area that act as a vortex generator and induces the air to stick around the short turn of the intake runner.

Where swirl can be accomplished without hurting flow is in the combustion chamber. A Pro Stock engine COULD use a smaller chamber and get a flat top to net the needed compression, but they don't. What does that tell you about mixture motion? We build up dome around the intake side without shrouding the valve (made easier by the cant of the intake valve used on those heads, and the exhaust side of the dome is smaller-but still above the deck a fair amount. I'd say this area is "funnel like" in the chamber and the dome that matches it.

For guys that are truly gluttons for punishment, we've built pistons that had a dome on the intake side and a Reverse dome on the exhaust. It was a nightmare to engineer, machine, and I hope the customer had an easier time of getting it into the engine than we did building them. The pistons were VERY heavy because of the Mass could not be removed underneath the intake side, yet the crown had to be thick enough under the reverse dome side. All in all, it's an excellent exercise, but the heads and pistons almost need to be designed around each other from the start to not shrowd the valves.

So what's a guy to do?: You'll find the easiest way to get good results is to mill the heads enough that a small reverse dome is necessary. Be careful because you CAN hurt flow and that almost always hurts more than the enhanced combustion helps. Speak to your cylinder head manufacturer as the best have flowed the heads at different chamber volumes. Back to the reverse dome- The wall created with this reverse image actually reflects the combustion back to the center of the cylinder for a split second longer resulting in a more complete burn. I have seen this in CFD and in burn patterns on pistons. As always, there are other things that can offset the gains...deep valve pockets may require lowering the top ring and creating more crevice area. Where does it stop! It doesn't!

Our three part numbers k462,k463, and k464 use something we call the Wiseco flow dome. When we went to a multifit pocket to accomodate different heads, it made it hard to hit the negative -3cc volume necessary for many applications. We designed a nifty little dome that mirrored the face of the valves on the intake and exhaust...this left a natural flame slot around the plug area. In theory, it may promote flow around the valves when the piston is around tdc. Because the intake dome is larger than the exhaust, it could promote movement toward the exhaust side, but the PERFECT combination would require a cylinderhead and dome be built in conjuction....literally minimal piston to valve clearance and the chamber sized to net the compression ratio in conjuction with the dome. We have some visuals of this if you want to email me at [email protected] . Larry and I have spoken about him doing flow testing with the piston under the cylinder head in the bore fixture and the valves opened up as they would be around tdc with typical camshafts. For now though, it's unproven to help or hurt. Some day I'll retire and mess with this stuff every day. Until then, take anything I say with a grain of salt.

The SBC has a lower deck height than an LS1. The LS1 also has much deeper skirt. And I built my pan with enough clearance for a 4.125" stroke. Most SBCs are only running a 3.5" stroke I believe. So of course they can have the bottom of the pan sitting that much closer to the block, thus allowing the entire engine to sit that much lower.

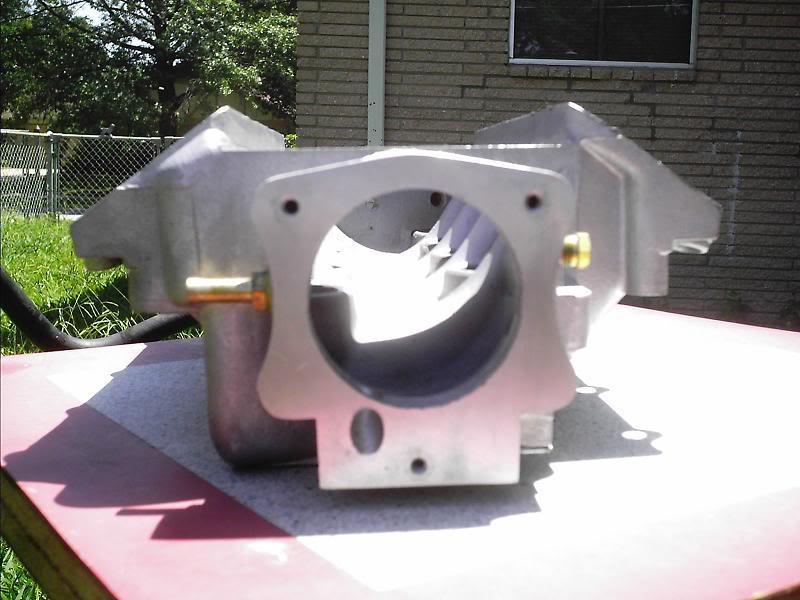

Even with this relatively tall single plane on an LS1 (I'd bet you're intake isn't this tall) you'll notice that the carb base is not taller than the fuel rails.

Also the LSx style plenum under runner intakes aren't as low as you might think. Here's the Al BBK intake for the LS1

These 4 things together, incrementally, make the LS1 look quite a bit taller than a SBC.

And regarding the fire wall. I really did want to cut it, but that would relegate me to a different class in nasa time trials among others. I believe it also forces you to have a heavier cage in other sanctioning bodies.

11/7/08

I couldn't take driving just the explorer anymore and just bought a '95 miata. Don't worry, though, the LS7 nissan is still the priority. I've been going back and forth with both Katech and Oliver Rods, trying to decide between lube tubes or piston squirters. I got worried about small end lubrication with my dry sump cranking at 15" of vacuum. I'll let you all know which way I go.

I take my last exam for a while next week, and started organizing my new garage yesterday so that I can actually move through it without killing myself. I also couldn't take driving just the explorer anymore and bought a '95 miata. It's equipped with pretty much the entire flyin' miata catalog including the Corky Bell designed whipple "Ubercharger U3". It's currently at 9 lbs and is a lot of fun. I called BEGi last week to ask about upping the boost and how to calculate a projected boost level based upon pulley drive ratio. I ended up speaking to Corky directly for about an hour! It was a real treat. I've read his book "Maximum Boost: Designing, Testing, and Installing Turbocharger Systems" cover-to-cover more than once. He was extremely helpful. He walked me through what turned out to be pretty simple math, and we talked about screw supercharges, and improvements he's thinking about/working on for my kit. It turns out that for a relatively narrow range (that I happen to be operating in), the pressure ratio (aka boost) = the pulley ratio. Flyin' miata reccomends not going over 12 psi on a stock 95 1.8L motor, but Corky said 14-15 is in the range of doable with 93 octane and an excellent tune. To that end Flyin' Miata sold me a very small supercharger pulley (67mm) that they had left over (the stoped selling the kit) at an excellent price because the didn't sell many because they don't recommend them. I also installed an LC1 wide band from innovative motorsports. I plan on polishing up the tune before I swap pulleys. The LC1 and new Link Ecu have not been fun to learn. But I shall overcome, and study, and practice until I am of EFI guru status! Once the street tune is done I'll head over to my old shop in New Jersey, TTP for some dyno sessions and precision alignment. They just moved into a bigger/nicer facility in Little Falls and are having a grand opening BBQ tomarrow, if I can pry myself away from this computer, deny the urge to go play with the link ecu, and get enough studying done tonight I might stop by.

Basically Oliver only makes thick I-beam billet rods. The thickness allows them to use some fancy laser to bore two holes inside the rod lengthwise. The holes supply the small end with oil from the mains. Just like with piston squirters, more oil pressure/volume is probably a good thing.

When running a high vacuum sump pump there is no oil being splashed around lubricating the small end of the rod, and failures sometimes occur.

http://www.flatlanderracing.com/olivertubes.html

Good Nissan read!

Posted by Diggymart on 11/1/21 @ 12:53:02 PM