You must be logged in to rate content!

4 minute(s) of a 731 minute read

3-26-2020

I like that idea. I'm super fortunate to have a private office; but my area still gets a fair amount of foot traffic. I moved my visitor chairs to the corner so there won't be any temptation to come visit. Thanks for the tip. Usually when things get tough, manufacturing is the last place someone would want to be. We are fortunate to have a diverse customer base, some of which includes priority government work.

Wednesday is usually a guaranteed 1 hour in the garage; because apparently I married a Survivor fan. I had no idea. She watches her guilty pleasure and the baby, and I get to go wrench.

I believe I mentioned in my last post that the new timing belt is on. I took a few minutes to disassemble my CAS and hit it with a wire wheel since it was covered in 20 or so years of grime. I was slightly tempted to take the mounting bracket into work and get it powdercoated black; but I think a somewhat clean aluminum bracket would match my car more than a brand new shiny black paint job.

I should probably hit the plenum again with the same wire wheel.

Pretty much my only goal this evening was to get the condenser installed and vacuum out the AC system so I could let it sit overnight and know how I stand. I pulled the condenser back out and made a small adjustment to the port that was giving me trouble. You can see in the pic below how close I was, and even that small amount of misalignment was preventing the threads from engaging. Thankfully it only took one try and I was good to go. I reinstalled my almost brand new dryer on the other side of the condenser, replaced a few o-rings that had gone missing somehow; and fired up the vacuum pump. From lights on in the garage to pulling vacuum was less than 30 minutes. I love when a workday goes right!

Minute misalignment makes me mad

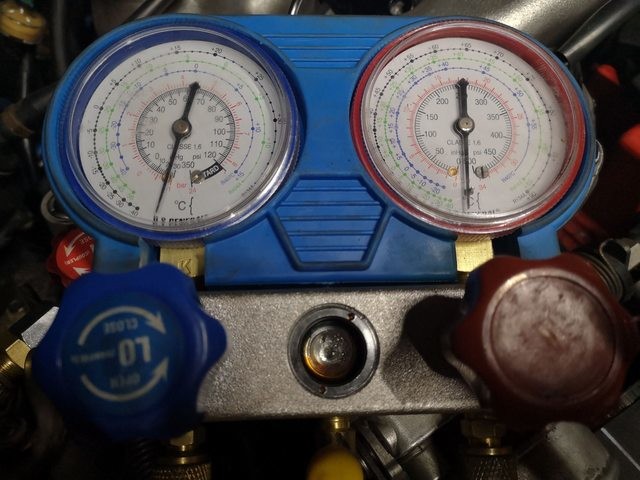

Manifold hooked up and pump going! H/L ports are easy to access. I used a generic R12/R134a retrofit kit.

Manifold hooked up and pump going! H/L ports are easy to access. I used a generic R12/R134a retrofit kit.

I let the vacuum pump run for a little over an hour just to be safe. I closed the valves on the manifold and shut the pump off at 9:35PM. I called my work night quits as soon as I did my initial leak check. When I saw I didn't have a catastrophic leak I elected to get out while I was ahead and celebrate with an old-fashioned.

Manifold reading at 9:57PM. Right before bed. No big leaks!

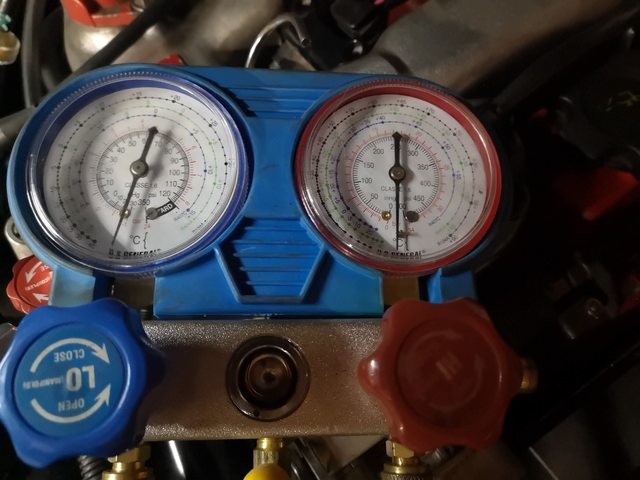

Manifold reading at 7:16AM on my way to work.

Manifold reading at 7:16AM on my way to work.

After roughly 10 hours; the needles have not moved whatsoever. I. Am. Ecstatic. Assuming the compressor works; I might be in business!

If I'm lucky I'll get an hour or two in the garage this weekend and I can do my bi-annual hose clamp and bolt check. I can't reassemble much else at the moment as I am waiting for more permatex blue to be delivered. The water pipes and thermostat housing don't use a paper gasket; and my current supply of permatex blue has solidified in the tube. As soon as that comes in; I'll be about 45 minutes of reassembly away from a test drive. I can't wait to get this thing fired up, charged, and driven! It's raining all week; so the roads should be clean to my satisfaction by the time I'm done. Yehaw!