You must be logged in to rate content!

9 minute(s) of a 536 minute read

4-3-2010

not much going on right now , i took the center console , shifter mechanisim , and E-brake cable all out , i also took out the stero and cd changer , and the climate control unit , and i'm in the process of removing the dash in anticipation for the new pedal assembly ( it comes as a whole peice connected to the bracing behind the dash .

the headers also should be here today and that (along with getting the stock exhaust ,,,, which i did not )should get me rolling again on mounting the engine.

i was also contacted by LAdismantlers sayign all my parts are ready

http://www.ladismantler.com/index.ph...em&inv_id=2263

they should ship out monday or tuesday !

so , next up on the list

- remove dash (tons of fun right there )

- mount headers and mock engine in and finalize both engine cradle designs

- seperate the wires i need from the porsche wiring harness.

- figure out what else i need to do

04.07.10

well finally some progress to report

i finally got the damn dash out ! man is that thing a pin in the rear ! 10 gazzilion screws and then some !

also vette shorty headers cam in today ! and might i add they are blingy :

i put them on the mockup engine and started thinking about crossmember placement and exhaust routing . the headers fit nicly and clear everthing around them using this cradle .

the plan is to run them so they face towards the back of the car like so :

and have a 45deg. elbow right after the flange so the exhaust becomes horizontal , then it makes a 180 deg. u turn towards the front of the car into a 10" muffler or bullet (wich will be horizontal too), after that the exhaust exits the muffler and makes an upwards sweeping uturn into another bullet or muffler that will be 17" long and sits right above the other muffler/bullet. after that the exhaust can either go straight out to the tips or i can run it into the stock muffler for more noise reduction .

another thing i noticed is that with this cradle i have no clearance issues between the motor mounting plate and the header, but if i go with the other design cradle (using the F-body motor mount ) it might touch or be too close to the header. so the solution would be to use the vette style aluminum pedestal and doughnut mount for a clean and nice fit.

i should have the welder back in a few days , so i can finish up this cradle and start mocking the engine and exhaust on the other cradle too ( don't ask me why i'm doing things twice , i don't know )

on a side note, all the trans stuff should be shipping out tomorow !

so , next up is :

- order mufflers and u bends for exhaust system

- weld up first virsion of cradle to make it officially finished

- strart tacking together the second cradle and see how everything fits

- remove pedal assembly

- figure something else to do while i'm there

04.12.10

well a minor setback but not major i guess;

in my infinite wisdom i welded the engine pedestals to the hoop i made without double cheking pan clearance ( i went off the side of the block ) . i later noticed that the oil filter kicks out a bit and it would not clear the pass. side engine mount .

so to cure this i had to cut and grind the welds i made the engine mount plates ( the "L" ) and reweld them at an angle - basically a few inches away from where they were before . this was the best way to do it since it still gives me the room i want to run the exhaust .

and to further clear things up , i can not use the F-body mounts with the vette headers ( they touch ) , so if i am to go with the other design , i have to get some vette mounts and pedestals .

so i guess now i just have to wait for the trans and exhaust bends and stuff to show up so i can finish the bottom part of the car ( i know i 've been saying that for a month now )

04.21.10

well i have some good news and some bad news,,,,

the good news is that the transmission and other things needed for converting the car from an auto to a manual showed up ! :

,,,, the bad news is that my worries about not being able to push the transmission further towards the front of the car became true.

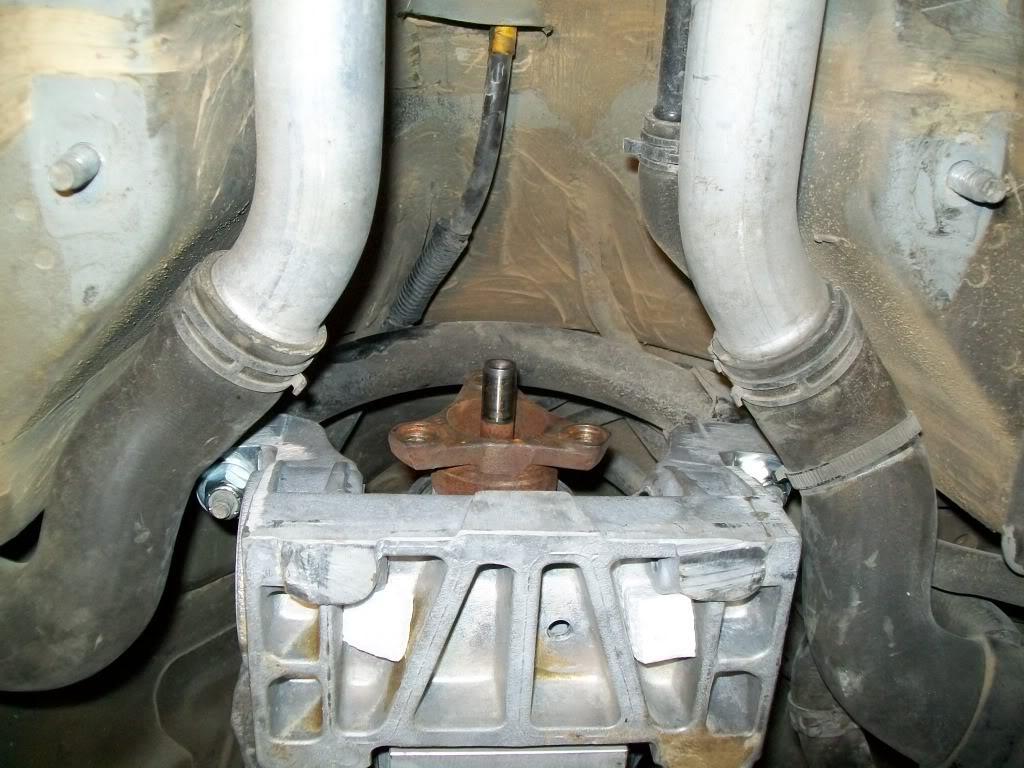

it is so cramped where the transmission mount is that is almost impossible to push the tranny forward more than where it is stockbecause of how the coolant pipes are routed.

now i didn't think of this option last night when i was under the car , but i might be able to relocate the transmission mount further if i notch the floor pan and push the hoses into the recess therby clearing some room to relocate the trans mount . but that has to wait till i go back there.

any how , its a good thing i didn't weld up the mounts according to the measurments i had before . and guess what !!!??? i have to redo the cradle again !!

the reason for redoing it is that the oil pan will hit the bar if i use the stock trans location. here's what i mean :

so ,,, the new mounts will be much simpler , i just have to get some 90 deg. bent tubes today and start chopping away .

after that is done and i'm happy with where the engine sits i will have to start looking into where i have to notch the rear brace ; the engine will be moved so far back that in order to run a water pump and power steering i have to clerace the brace a bit to make them fit . here is how the engine should sit compared to the brace when done :

(don't mind my "air gap" oil pan )

the brace should be notched to about where the spot welds are in the bottom pic or where the latch starts in the top pic. , offcourse after notching it i have to run a brace ( most likely a tubelar one ) from one side to the other to maintain the integrity of the body.

and in another moment of "DOH!" i noticed that the AC compressor and mount i had on the real engine ( which i was using for measurements for accessory drives) was of an F-body ,,,, and the bracket and AC i am intending to use are off an LS3 ,,,,, which means the engine is going to be overall narrower than what i had annticipated,,, which means i can't cut the brace till i get an accurate measurement .... (man this measure twice, cut once stuff is killing me ! )

i should have the tranny in the car by tonight , and i will know then if i can relocate the coolant hoses or not. i decided to try and focus on the bottom side of the car first and leave the top part ( interior, dash ,wiring , etc.) for later till i can get the car off the lift . that way i can roll it out somewhere whare i can have more working room next to the car.

04.25.10

One small step for man , one giant leap for sam-kind

Trans finally in the car, and like I said before moving it forward is almost impossible ,,,, if i use the stock transmission mount

I’ve been messing with an idea of another trans mount (fabricated) that would get me those precious inches of clearance, but more on that later ( I just started thinking about it and I have no idea if it would work or not , I have to go back to the garage and physically check it). here is how the original trans mount looks like :

now,, i said before that i might have to redo the cradle because of interfernce between the cradle and oil pan , but now that i'm thinking about it , why not just notch the pan abit ( all i need is about 1"-1.5" of clearance) , or get a custom pan made that would be a bit shallower than this one (all this assuming the trans stays in place).

i guess now i have to start messing with the trans mount and see what i can do there. after that is done i can focus on the engine compartment again and locating the engine in there. ( guess no new cradle for now )

Nice details ????

Posted by Diggymart on 5/1/19 @ 2:11:40 PM