You must be logged in to rate content!

98 minute(s) of a 205 minute read

1-8-2021

Das $build thread$

Compliments of dasbeast3.0 @ www.vwvortex.com

10/21/09

Well..its come time. I need to fix my c, the trans is shot and since I hate o2a's Im getting rid of it. Hopefully I dont run out of $. For now I just want a solid platform to build upon for f/i. Ill keep this updated as I move along. As of right now I am waiting on parts. Ill get a few last drives in while its running, then pull it apart. I'm all about practicality, my build will be practical, functional and to the point. I dont care about flashy b/s or the latest trends. Clean and simple ftw. This is gonna be a sloooow build because work is slooooowww. Soon enough things will pick up and I'll get moving on it.

The stretch:

O2m 6 speed

peloquin

driveshaft shop axles

wire tuck

clean up and repaint the bay

abs delete

do chains ( possibly rebuild motor)

pull fenders

borrow $

spend $.

try to have fun w/o getting pissed off.

sell my other car to fund this sht.

You all know my sled:

10/22/09

O2m mount:

Not a bad daily for 1k :

Started on the bumper for the 93 Beast today:

Stripped the snowflakes for the daily:

Just getting Misc. sht out of the way to make time/room for the bramble.

11/7/09

Here's a nice fu ckin update

The whole god damn car needs to be stripped and painted. Whoever did it better not let me find out..thats all I have to say.

11/8/09

Started prepping for paint today but ran out of sandpaper :

11/9/09

What scratches?

12/3/09

Here's an update..not much of one tho

Plans changed. Entire f/i setup is on its way.

12/31/09

Back from the m-effin dead bizatches.

Paint is done (finally). still gotta wetsand and buff etc.. Bringing it to the garage this weekend, pulling the trans and getting some work done. Picking up new, big gear 02a shortly. New clutch, headgasket w/ spacer ( 8.5:1 comp.) and some minty timing chains...progress is in sight for once. Also got all the parts to fab up my downpipe so that'll be happening as well.

enjoy (or not) some shtty pics.

1/5/10

Back in business.

hours and hours of sanding/buffing.

1/9/10

Did work today. Parts are in the mail.

Backwoods motor mount..timber edition.

Finally got this dump out.

1/10/10

Picked up the 3" system today courtesy of VW Sporting. For a mk3 Jetta but I'll put my mig to work and make it fit the C Noooooo prob. Also scored a nice atp v band catch can the other day.

1/14/10

Head spacer is in w/ new mk4 gasket, head cleaned up all nice, motor is timed, new headbolts all torqued down...mmmm progress. I'll get pics up asap. Waiting on delivery from 034 and MJM..lots of fresh parts. Nice new ss exh. mani. bolts are coming as well. I had a hell of a time getting the old studs out. 2 snapped right off the bat. I was able to weld on some bolt heads and pop em out... thank god they broke with 1/8" sticking out. Old 02a is apart. Pinion bearings are toast.

1/21/10

I am so sick of wiring. Removing old wrapping, splitting the harnesses, re-routing, the re wrapping. Such a pain in the ass. Other than that, still waiting on parts.. trans should be done within a week er so. Stripped the undercoating and Por-15'd the inner fender wells as well.

Anyone have an obd2 upper timing chain cover? I stripped out one of the lower bolt ports.

1/22/10

Wiring has only been pulled apart and re routed so far. Gonna re-wrap and semi-tuck this coming week. Still gotta order flex braid from jegs for a ridiculous 200 bucks.

As for today: Finally got my stainless exhaust mani studs, turbo mani studs, new loknutz, gaskets etc..

Hit up Lowes and got some welding wire, butane, and more friction tape. Lots of wiring left. Gonna strength weld/paint the subframe tonight also. I'd like to get some wiring done but it's Friday..Traditionally I get quite drunk on Fridays. Eh..I'll see how things go.

My dog came for a ride to Lowes..he looks pretty aggravated. lol I though it was a funny pic.

2/1/10

Update: Trans is done and installed, wiring is 99% finished. I had a setback w/ a bad set of headbolts..not fun. Arp studs and new headgasket on the way. Pics will be up shortly. Btw, if anyone wants to help fund my build, buy my V1 charger setup!!

2/3/10

New pics up:

Spacer cleaned and copper sprayed (again)

Block cleaned and ready 2 go

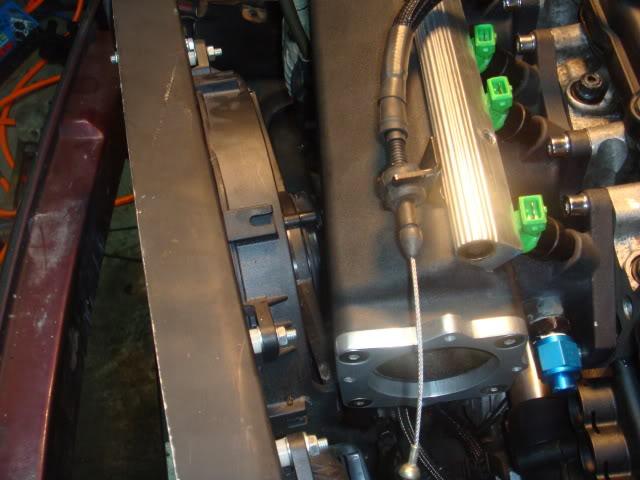

Started test fitting the ic while i wait for the arp studs

2/6/10

New parts arrived today.

2/13/10

Update: got things done!

2/18/10

Did lots of work this week but keep forgetting my camera. lol I'm retarded.

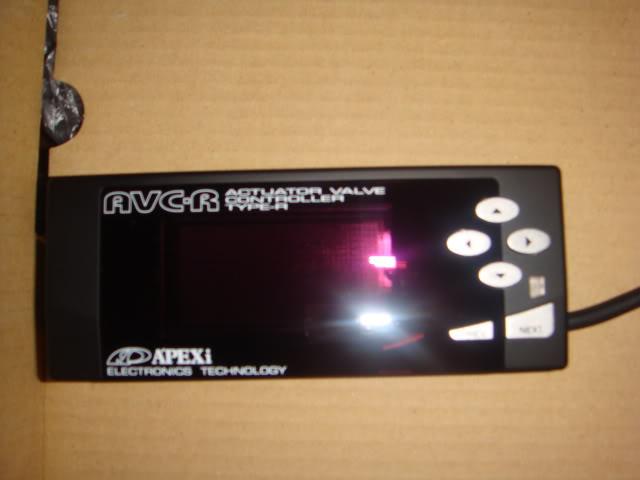

Anyhow..wiring is done and heatwrapped, brackets are all made and painted, cv's repacked and installed w/ new hardware, new timing cover installed, piping is near done, fueling is done w/ new -6 lines and reg. Oil cooler relocated, I/c is installed etc.. Got a shipment of parts in as well: wideband 02 (Aem), oil feed T, catchcan fittings/hose, and lots of other stuff. Just ordered an Apexi avcr black boost controller (gear based boost ftmfw!!) since Benzi convinced me to go big or go home. Almost ready to put back on the ground! If I don't have to work tomorrow I'll get some pics. Just gotta fab up the exhaust and downpipe then I should be almost ready to fire it up. Also got a new turbo blanket and pipe wrap. Now, I gotta decide on a water/meth setup and get some new spark plugs. I'm thinking snow perf. for the meth..

2/19/10

Just ordered up one of these bad boys since the plastic oem trash is cracked.

2/20/10

Ok first downpipe config..b4 I decided to recirc the wastegate:

again:

After wastegate piped in:

Eff you d/p.

Fueling

I/c:

Relocated oil cooler:

D/p

Catch can mounted:

More:

Wideband came in today.

2/22/10

So I got the elbow today. Fans clear which is good... but the msd bracket doesnt, and my piping from the i/c to the throttle body needs to be re-fabbed. Its in the complete wrong place. bummer. Gotta cut the bracket to fit, then make a new section of pipe unfortunately. I suppose i'll go buy some tri mix tomorrow. I'll get some pics shortly.

2/23/10

Got the pass. side fender prepped, primed and ready to spray tomorrow. There was a spot where the paint cracked, and the edges were pretty beat on the rolled part of the fender. New paint never hurts. Also gonna respray the door that got keyed.. Its not up to my standards, so I'm just gonna strip and re shoot it. Hopefully I have enough paint left to spray the abt rep. sides as well. Avcr came in today too !! I'll have more pics shortly.

Avcr:

Black is where its at, not a fan of the cheesy silver version.

I miss driving my car.

2/26/10

Off topic but BAAAD News. The building where I work collapsed under the 2 feet of snow this morning. My damn fender, paint, tools were in there. Not to mention a vette, jeep, and trailblazer. What an effin day. Anyone care to donate a vr fender? Lol

2/27/10

The c didnt get damaged I checked it out today.. a few light scratches but nothing that won't buff out. My brother thankfully put a blanket over the roof of the C before the sht fell down. Most of it hit the windshield and was pretty soggy. Finally good fkn news! Next week I obviously wont be working, so i'll have some time to work on the C. I was gonna take a break but fk it, I have nothing else to do, might as well get some sht done!

Got some nice shots of the carnage ! Destruction ftw..It was pretty fun smashing windows n stuff in.

somehow the front stayed up. The small window to the right is where i crawled in and scooped my fender/tools/ paint!

No, that is not a reflection Thats looking through the shop door!

No progress on the C, but who doesn't like destruction? I know I do!

Just ordered the rest of my boost piping, couplers and t bolts. Got the V bands in to finish up the exhaust. Just a matter of getting there and doing work now. I might get stuck doing some demo work w/ the shop all week which would blow. I'll find out tomorrow. Gonna keep my fingers crossed lol.. a whole week of working on the C would be Tiiiiiiittiez.

3/1/10

Small update:

Took out and unwrapped the d/p, ground down welds and (re)strength welded it, coated it w/ 2000 Deg. paint. Welded in the v band flange and o2 bung also. Tomorrow I'll wrap her up and call it done. I feel much better about it now Also got the Gruven bracket installed.

Tomorrow I'm hoping to get the exhaust done. I got lucky and have most of the week off. We demolished the building Sunday and scrapped it today. Also squared out the damaged ceiling in the garage so we can replace the rock :

rock covered C:

elbow fitment:

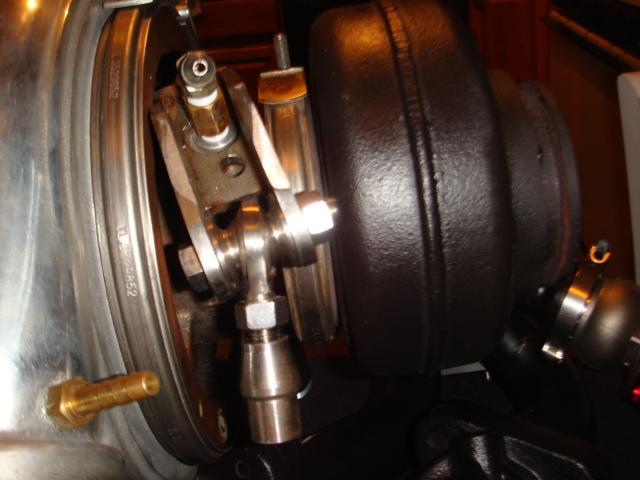

Gruven bracket:

3/2/10

Ok, Finally finished the nemesis of a downpipe lol wrapped it up and got it installed, not coming back out till it rots away. The damn w/g was binding up on it and not letting the pipe sit flush against the exhaust housing, I had to coax it with a hammer...just had to whack a small flat spot into the d/p and she's golden. Also got the oil return to clear the axle...had to turn a 90 deg fitting into a 120 deg., Fits perfect now. Filled her up w/ oil and had a pinhole leak around the weld bung so had to drain and weld it shut. Trimmed the msd bracket and got the t/b to fit properly, then trimmed the charge piping to fit correctly..my hood now closes!!! Mostly b/s stuff today but progress regardless! Didn't get to the exhaust like I wanted to. Tomorrow is another day.

Adjusted the shift linkage w/ the new gruven bracket..that thing makes quite a difference in throw/feel. def. tightens it up a good bit.

Pics:

Piping trimmed

msd bracket and icm housing trimmed:

oil return:

Dp DONE!

The beast chillin out :

3/3/10

More things:

Solenoid for EBC:

Pressure sensor for EBC:

CV's torqued up to drive flanges and wheels back on:

Started fitting the 3" system. Need 3 more V-bands... I got most of it trimmed and ready to go. Test pipe is done also.

B4 trimming:

Cleaned some of the sheetrock out of the rain tray area:

Top shots:

3/11/10

Ok, I have a fairly decent update. She Runs... very well. lol Tomorrow the exhaust will be done, got my plugs and gapped them, ignition is done, etc. Just waiting on t bolt clamps. I use some worm clamps for now to fire it up. Sounds mean as hell! Still have a ways to go but turning the key and hearing it start/ drive is an amazing feeling. Got a Vid below.

http://s384.photobucket.com/user/rad...02883.flv.html

Exh. parts drying:

Test pipe w/ 02 simulator, No cel

3/17/10

trimmed everything to fit Sleeper status:

3/20/10

Having some ideas to change up the front end. Zip. Not sold yet but its def different.. This below minus the 3 bar, replaced with a badgeless. Flame away boys

4/3/10

Round 2. Came out much (100x) better.

4/6/10

Got the breather port relocated away from the i/c piping that was kinda crushing it.

4/23/10

Been a while since I've updated so I figuredI;d post something up. The Corrado is running perfect on the new 42# tune ( C2's latest 42# software is excellent). Paint is wetsanded and buffed out = DONE. Never again. I drove it for a total of 30 miles to drop some parts off...she felt great besides the horrible mis-alignment, seized wheel bearings, and blown tie rod end. lol

I got the front end pulled apart for new brakes, tie rods, ends, wheel bearings, and ball-joints. Should be finished up by the weekend, then off to Rapid-Parts for an alignment on Monday. I also have a mk4 valve cover slammed on there, courtesy of Benzi. Plus... and a big PLUSSSSS, I picked up some kinda motor inside cleaner thing..Devils own ftmfw. My goal of 400whp (reliably) is looking much better

Got the false trunk floor almost finished up today also

9/8/10

Been a long time since I updated anything, the car hasn't sold so I might as well keep going with it.

A/W system is going in shorty, Still gathering parts. The small a/a sucks and its making me pull timing like crazy on hot days, Don't wanna chop up my bumper for a big a/a so the only feasible option is a/w.

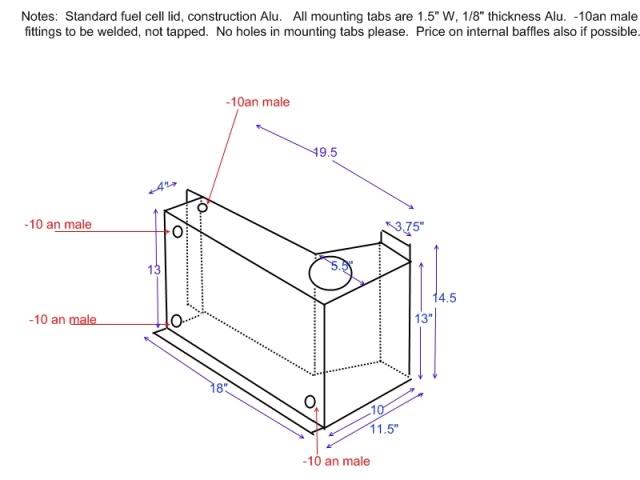

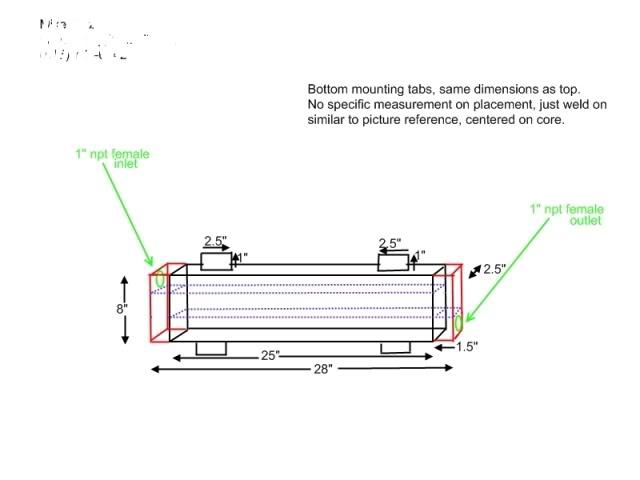

So far I got the precision 1000hp i/c and I designed a custom water tank for my trunk, which should be here in a few weeks, its still being fabbed up. Im going to grab a Meziere 55 gph pump, and Ford Cobra "lfp" heat exchanger which is huge but fits perfect. also a set of small Spal fans for the h/e will be coming. All my lines and fittings are going to be 1" npt for nice flow, no 90's etc.

Heres the water box design: its made to hug the pass. side strut tower.

I changed all the -10's to 1" npt, lol disregard that.

9/9/10

I changed up my pump choice to the Stewart 55gpm inline. It has a supposed 10,000 hour lifespan. Anyone use one b4?

10/1/10

Well..rebuilding things on the car this coming winter. Heres the new list:

Pull head, deck, port and rebuild it.

Build the block if I can swing it.

AWIC (in the werrrrkkks)

Porsche Boxster 4 pot front calipers, 12.3 tt rotors, and pure motorsport brackets.

Precision 6262

Redo the front subframe n get rid of the solid metal mount.

cooling system overhaul x2.

If im feeling froggy I may just paint the bay also.

Ill get moving once the colder weather comes:

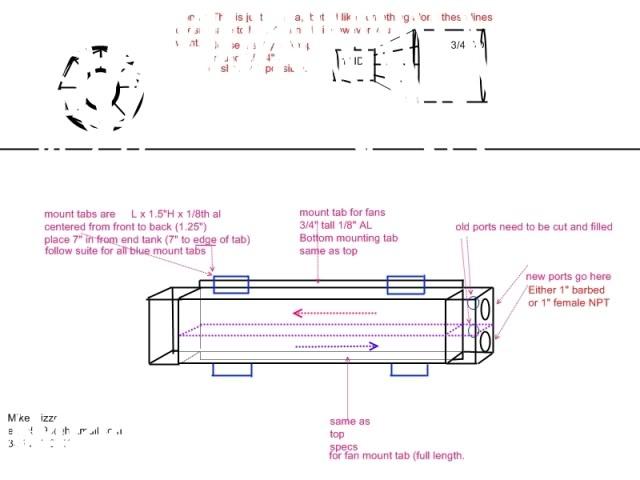

As for now I have most of the parts for the awic. I had the trunk mount box made to my design, I am having a 3 pass heat exchanger fabricated also... I designed my own since I couldnt find anything to my liking, Precision 1000hp core is here, and I wound up getting the Stewart pump w/ -16 an reduction fittings. After running that thing in the tub, holy sht does it push some water. 55gph is retarded and prob way overkill, but overkill is where its at.

Tank almost done:

Just got a quote on my custom heat exchanger..$650 plus shipping. That's not happening.

Next two choices are making it myself (Still gotta learn to weld AL. ) or a ford Cobra dual pass setup with the ends chopped out and 1" npt fittings welded in. It might be a little big tho, Its 30 x 8 x 2.5. I can make room I guess.

10/2/10

I have my doubts about china made cores. They have a low fin count and thick wall design which hinders heat transfer. Don't get me wrong, they are sweet for the price, but I'm shooting for max heat transfer. Look at an oem radiator design and fin count per inch (or better yet a factory cobra or lightning heat exchanger), then check out a chinese or other aftermarket core (same as frozen boost or cx racing etc.) The don't cool nearly as well, Somewhere around a 35% loss in efficiency. Ive been doing a ton of research on it, looking for the most efficient core. Im sure the frozenboost core will work fine, but I already went pretty balls out with the rest of the system, I might as well keep pace.

My thinking is this: A low pressure, super high flow system.. No 90's, no restriction other than the H/X and IC. All piping and fittings are 1" ID. I want the water cooled as low and fast as physically possible, Which i don't think will happen without a good quality core. I'm limited on core size to around 30L x 2.5W X 8H which is fairly small, so I'm using 2 spal fans on the exchanger to keep air moving continuously. Maybe I'm wrong and totally over-thinking it, but every time I cheap out on something it bites me in the ass and I wind up redoing it.

10/3/10

My dented I/C :

Pump all set minus good clamps:

10/12/10

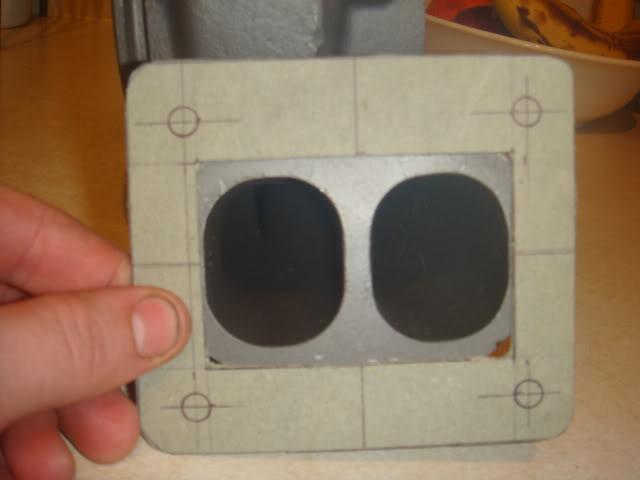

Revised heat exchanger for better flow, Work being done by Mr. Donny Bailey. I should have it ready in a week or two Basically an upgraded Mustang Cobra Heat exchanger modified to my needs. Now I gotta buy a set of Spals to mount up.

10/14/10

So yea, some jackass broke into my C tonight. They stole my radio faceplate (no, not the whole radio, just the faceplate) My Gps, a beach towel and a fu cking bag of opened sunflower seeds. My girl's truck also got broken into.. took her broken umbrella, near empty bottle of dolce/gabbana perfume and a half bottle of hand sanitizer.

What the f uckin f uck is this world coming to? U gotta be one dumb/homeless bastard to take that type of sht. Didn't touch my tools in the trunk or the avcr etc. Its so stupid, I'm not even mad, I just kinda want my faceplate back. I'd be happier if they took the whole radio.

2 weeks ago someone robbed my weedwacker, empty propane tank, empty gas can and a pair of jack stands. Theres gotta be a new bum in town er something. Im gonna find that dick and take all my useless shtty items back.

The stupid sht never fails, I swear. I really gotta look for another place to live. I had to post this b/c its just so damn retarded. Maybe I'll set a trap with a half eaten cupcake and a warm beer. Guaranteed bum lure.

Anyway, my box came in today. I have a day off finally so I gave it a quick test fit:

Just gotta trim one mounting tab slightly and she'll fit perfect. The quality of work is Spot on. Fkn guy welds like a robot. Every bead is dead symmetrical / perfect. I'm very happy with the part. I highly recommend Donny if anyone ever needs something fabbed up.

10/15/10

Slow progress: filled my tank today. She holds just shy of 6 gallons. I'm thinking a total system capacity of 7-8 gals which is sweet.

10/25/10

I want to run the oem FW but need a capable clutch and pp. So far Spec is the only one I found that mates up a high tq clutch to a dual mass FW..and I don't want to use a Spec clutch, they suck. Worst case scenario is I run a single mass and southbend setup. Which cost roughly 1 arm and 1 testicle.

Once I tear the car down I'll have lots of pics of the a/w stuff going in. Tomorrow my 93 officially leaves the garage to make room for the Bramble, so ill get workin shortly.

As for my plan of attack:

-Wavetrack diff. and complete rebuild by Mr. HGB (Im hoping he can fix the common shift fork issue),

-Clutch/FW/ PP

-Lastly I'll grab some DSS axles.

After that, I'll mock up all the brackets n stuff for the heat exchanger and start routing/test fitting my feed n returns. Then, find a pump location, Make some (hidden)bracketry to brace the IC core, Weld up new charge piping etc. I have a long way to go. At least the parts are all starting to arrive

I may just do the FST 16.5 lb steel FW and Clutchnet stg 3 organic disk and call it a day. The whole setup is about $1k. Even to retain the dual mass, the clutch and pp kits alone are right up there in price, not to mention having the OEM FW resurfaced. I have some time to sort it out tho..right now I'm concerned with buying a diff and having the trans rebuilt.

11/6/10

Got the HX in finally:

11/12/10

Dropped the 02m off tonight with Mr. HGB. I wound up going with a Peloquin diff since I'm too impatient to wait for the Wavetrac to get off back order. I'm sure it'll do the job just fine. I'm having the shift forks modded so the rivets don't pop out on me, and the trans is getting a full rebuild. I should see it in about 2 weeks. I just gotta order a clutch, Flywheel and PP then I can get my ass in gear. (literally)

Someone buy my axles or 02a dammit! New, prices: $1350 trans $615 axles.

11/17/10

Sold my 02a finally, so now its time to buy a clutch/PP After some heavy debating and a conversation with a friend (the one and only guy who's opinion I give a sht about), I'll be staying with the Factory dual mass FW and going with a southbend stg3 PP with the stg3 OFE clutch disk. I know my back and forth decisions may seem trivial, but my car will be the one driving home when other people's sht is broken.

If anyone is curious why I chose this option, Its b/c going down to a single mass/lightweight FW. Will chatter something ugly. Plus it will most likely be the cause of an early death of my trans. Single mass, especially LW cannot soak up harmonic vibrations for sht, even with a sprung disk. Those vibrations, over time (especially on a daily driven vrt) will contribute to wearing the gearbox much faster than I care to replace them. Dual mass is heavy, but it idles well and is a safer option IMO. Doing research, I came upon a lot of horror stories with 02m's and single mass LW FW's. No thanks.

I'll have pics up soon, Thursday the work begins.

11/18/10

It has begun.

11/20/10

Basically the connections on the slave have to be reversed so the bleeder valve can seal correctly in the slave, then the fitting that the USP line plugs into needs to be modified.

The fitting plugs in and seals fine, but it is made of solid metal. The oem part is plastic with 4 relief cuts in it, allowing it to compress to fit the retaining clip in. The clip does not fit over the metal USP fitting once plugged in, and there will be nothing to hold it in w/o it. Sooo, All you have to do is take a dremel with a really small/thin diamond bit and channel out the slots on both the top and bottom of the oem black female fitting, to allow the clip room to expand over the USP male fitting. I circled in red where the clip sits. I tried everything before the dremel, even making my own clip, bending the oem one etc.. the slots are just too small to work with.

11/22/10

started test fitting the piping:

Ok finally I got this clutch line figured out lol. There was a rubber bushing/seal stuck in there that I didn't see. My T is the same part # so I knew I had to be doing something wrong. She plugs right in now.

11/24/10

Slow progress: Today I smoothed the I/C and got it in primer, and cut/ welded the diverter valve flange on the charge pipe to face the correct way. Kind of a tossup on I/C color. Black, urban gray met. or bright silver met. I was thinking of maybe a camo between the 3 plus some white. IDK....camo is a little out there for my taste tho.

11/25/10

11/29/10

Test fitted the heat exchanger today. She sits perfect in there with plenty of room for 2 fans.

I see next week as a "good progress" week. Trans will be here, Shawn so kindly has shipped out the Jig for me, and the a/w stuff is just about ready to go in. I think Im gonna be pulling, cleaning and painting a lot of stuff this time around. Subframe, misc brackets, rad shroud etc. I didn't care what it looked like before, but now I want everything looking fresh n clean.

12/3/10

Didnt get to weld the cup on, it got too damn cold out.

12/8/10

Got the cup welded on tonight The infamous Jig fit perfectly I welded 2 small reinforcement plates where the gap was a little large, rather than just glopping a ton of weld in there. Im sure its overkill but it will never break. I got about 85% of the circumference welded which is plenty strong. There is a small section in back I couldn't get to, but I'm not worried about it. It would require dropping the k frame and taking a bunch of sht apart, which I really didn't feel like doing for such a small piece.

plates (hard to see after welding since they were pretty small.)

1/6/11

Got the Pro-M setup and installed the clutch line form USP to the 02a Master. I'll have some pics and progress up soon hopefully. Been working on the 93 Beast while I wait for my trans

1/9/11

No turbulence issues, the Maf is designed to have the filter mounted right on it, there are 3 bolts holding it on.. (you cannot modify it to work any different) Its got a big bell mouth as wide as the filter that tapers down to 80mm. Most turbulence comes from having the maf too close to the turbo anyhow.

The Pro Maf works differently than oem, It has nothing sticking into the air path, so even if it was close to the turbo it uses 360deg. sampling, which wouldn't really be affected much by turbulence. Its a pretty bad ass part. Basically, as good as it gets without going standalone. Its tunable by fuel pressure and Maf calibration, which is pretty cool. I should be able to get the most out of my setup..prob picking up a good bit of power with less boost..I can finally lower f/p effectively to work with meth. The 42# software responds like sht to f/p changes.

More parts: Ordered up the non-abs stuff finally.

Also, after speaking with my trans guy the 02m should be done in 1.5 weeks. *crossing fingers*

1/20/11

Finished restoring my non abs stuff...well almost, gotta repaint the brake res. it came out chalky.

Ld3x platinum metallic!

1/23/11

Finally got my flywheel in, had to special order it through Eurospec. Tracking down a single mass oem weight steel FW seemed useless.... I emailed every company I could think of inquiring about it. Finally Eurospec came through, and it was priced really good.

I'm gonna send it to a machine shop to shave off a few lbs and balance it with the clutch and PP as one unit. Unfortunately no one produces a 20lb FW for the VR6/02m which is really what I was looking for. Oem is 26lbs.. I think knocking it down to about 20-22lbs should let it rev similar to stock w/ an 02a, yet not allow the gear lash of a standard LWFW at 16.5lbs.

Yes, I am picky

1/24/11

FINALLY: bit the bullet and ordered a clutch/pp. I'm sure most you don't care, but for me its been a relentless pain in the ass deciding wtf clutch to use. I wanted to go with Southbend, but after speaking with the company..their SS pressure plate is basically identical to Clutchnet's 2x.

The SB stg 5 feramic kit is $1050.00. The Clutchnet setup has the same clamp load PP and copper feramic full face disk..totalling out to $524.00 As for power holding capability they are both identical. I know SB is top of the line, but I feel like you pay for the name.. Who knows maybe Im wrong. Clutchnet offers the same exact setup for half the price. I guess I'll see how it holds up, Ive had great luck w/ Clutchnet products so far. With the extra savings I'll pick up a set of cams

2/1/11

Got the clutch/pp in finally should be good for 450-500 fwtq:

Single mass FW: only one of these around biatches!

The 8 foot long ice-sickle, lol coulnt even get it all in one pic. it attaches from my drain to the ground. we've been diligently waiting for it to touch the ground for 2 weeks. Lol

3/3/11

Small update: abs is gone, starting to unwrap all the wiring and get rid of the abs harness.

New turbo is on the way too: Holset HX52. the thing is a monster. Gonna be making my own hotside out of a 11cm t3 divided, weird flanged housing. Im going to make it into an undivided (small) t4 housing. The plan is to cut it open, get rid of the center divider and flange, then start measuring/cutting/ welding. I'll get some pics up soon.

3/5/11

almost done:

3/6/11

Picked up the trans tonight, Hank did a great job like always, very happy with it. I just need to grab a slave cylinder and new FW/PP bolts then I can get working. I have pics of the modded shift forks and some other stuff, just have to figure out how to get them from my phone to the internet lol.

3/7/11

Shift fork mod:

3/8/11

Got the trans almost ready. stripped the paint of the flanges and trans mating surfaces, retapped all holes & got the 30lbs of powercoat/ paint out of the flange bolt threads lol Also made sure my clutch fits the shaft correctly, and straightened the trans spacer. Bolts/slave are on the way here so work will be coming soon.

I stripped and painted the trans mount too, I'll get a pic later.

3/9/11

Ok, T60-1 is on its way to Russia, and the hx52 is on its way to me (not from Russia lol)

Specs:

Brand new, Billet wheel Holset HX52

69mm compressor wheel

70.5mm exhaust wheel

11cm T3 exhaust housing (roughly equates to .81 t3)

Placed an order with 034motorsport for: T4 undivided flange, t4 gasket, 3" V-band for exhaust housing, SS flex pipe and 38mm WG flange for new routing of WG to downpipe, all new silicon boost/vac lines, oil feed / drain gaskets, 1/4" barb to tap into comp. housing n some other stuff.

This should be a pretty cool project

Hx52 is on the left. (not my specific turbo, but just a reference to show size etc.) The other 2 turbos are about the size of a t60-1 or gt35r..yes, the 52 is a monster.

3/11/11

Non abs is done, just need some wrap for the brake lines:

3/14/11

Hmm plans have to change with the Holset. It arrived today, and its not a t3..Sooo I guess that's a good thing, being that I won't have to cut the housing open now. Its a divided t4, the seller was a retard. I'll just knife edge the divider and call it a day.

Fitment however is going to be an issue. the thing is ****ing massive. I still need to cut off the oem Holset flange, and adapt my T4 to it. The flange will have to be on an angle, as the turbo sits about 2" too high, and will hit the hood w/ the atp mani. Basically I gotta lean the turbo back. I'll get pics up of what I mean soon. Other than that, I,m prob going to lower the motor 1/2" and cut a small section of the rain tray out. The atp mani may need some trimming as well.

on to the pics!

The last pic makes it look deceivingly large, but it actually does fit back there in the space allotted. I wanted to get a pic of the turbo shaft, but I don't want to take it apart and have to re-balance it. Ive heard of them snapping on holsets.. but no way.... the thing looks like 1/2" steel dowel, shts huge.

3/16/11

Got most of the old flange chopped off. that sht was a good 1/2 lb of metal. Prob gonna take it to a machine shop to have it angle cut, unless I can find someone local with a big enough bandsaw.

I need the flange to be sitting at a 35deg. forward tilted angle. This is what I meant by leaning the hotside back. It'll allow the flange to "center" the turbine housing, rather than have it underneath.

Basically I'm making the turbo more "compact". It'll be easier to work with instead of going crazy and lowering the motor, cutting the rain-tray etc.. once angled I'll be able to fit the turbo in there without any further modification necessary. After much thought and staring at the thing with a protractor and tape measure for hours..I have a fairly good game plan.

My cardboard T4 flange helped a lot.

Heres roughly the angle it will be sitting at:

3/18/11

The turbo officially fits in its "home" behind the motor. I don't have to modify anything which is awesome. no cutting! Its close, damn close, but it'll work out.

Got all my measurements locked in and ready to cut tomorrow. If my flanges n sht don't come in, I'll start mocking up all the bracing. Its gonna need a lot. I want to take almost all load off the point where the t4 flange meets the turbine housing, that way I won't have to worry about it cracking in the future. Gotta make some kind of turbo brace too. Pics tomorrow.

Got it pretty damn straight.

3/20/11

fw/pp back from machine shop. All nice n balanced out.

Added one more thing to my to do list:

Crankcase evacuation. I will be doing it with a modified LT1 or VW smog pump. looked into The exhaust evac setup..not really a big fan. I'd rather do it with an electric pump set on a boost activated switch. I was never really happy with the open catch can setup, its messy and smells terrible. I WILL have the most efficient, oem motor, high boost vrt there ever was.

Just fabbed/painted a turbo inlet pipe for a fellow C owner. Figure I'd pic whore Came out pretty sweet.

3/24/11

I have some pics for today. Been busy so I haven't had much time to put in the C, but I got the t4 flange tacked on and test fitted the turbo as it will sit. It fits, but the motor is tilted, so with the motor sitting upright it hits the firewall slightly. I need to move the entire unit in about 3/8".

I may cut a small section of firewall out and make a new, slightly concave piece out of sheet metal, or maybe just cut back the hotside a little more if it allows. when I get more time I'll figure out something, but for the moment I am happy to say my hx52 "bolts on".

Firewall clearance

Tomorrow I'm going to get a quote from a local machine shop, to take 1/8" off the atp mani (both block & turbo sides) and t4 flange. Total 3/8" will be plenty of clearance. I can't cut the turbine housing down anymore.

My last resort is firewall modification. If I have to do it, then so be it. Im not worried about cutting into my car.. the trunk floor is missing, the bay has holes in it from a previous SC etc..Its not exactly a prime example of an OEM spotless car, nor do I care about leaving it perfectly as VW intended. At least if I go that route, it'll serve a purpose. Hey, its no worse than all these "shaved bays" lol people modify their bays to be pretty, I chop mine up for function.

4/3/11

Got the manifold Jig made up today. Off to the fabricator on Mon.

4/8/11

4/9/11

UPDATE!!

4/12/11

Have a small update n some pics tonight. decided to pull the motor after an incident with me falling down hugging an 02m.

Pics: Didnt get much done, but I did the crankshaft seal, mounted the FW/clutch setup..attempted to to the trans on the lift (that was a ****in joke lol) then just pulled the motor. The 02m is way to big to wedge in there with the motor still in. Thanks to Nick and Naz for the help today

4/13/11

im gonna clean the bay. not getting stupid with painting everything, but i'll make it look presentable. the only "while its out" thing to do is the motor itself. I already replaced everything else.

and yes Shawn he 02m is stupid big. I was trying to rest for a sec when it slipped out, I caught it, then fell down with it in my arms. no ****in way was I gonna let the trans drop from 6 feet up onto concrete. lol it didnt hurt yesterday, but I def. feel it today. Corrado:1 , Mike:0

4/18/11

Back in. Gotta get better pics, but I got the bay all cleaned up pretty. The 02m fits in there nice n snug. I went through the gears quick on the shifter and it feels awesome. I now have a 6 speed in my C

the 24v tstat housing is a no go with the Schimmel manifold, the barb for the upper rad hose will hit the TB. I'll have to use the 12v one and make some custom rad hoses. Still have a long way to go, but it should be fairly smooth sailing from here.

This weekend im gonna grab the manifold from Dave then get started on the turbo/downpipe/wastegate fabrication, since that's the next biggest obstacle. After the turbo side of things is buttoned up I can make pretty quick progress on finishing the car 100%.

4/19/11

did more work today. Not much to show, But I did a lot of little sht that needed attention.

Re-tapped stripped bolt hole for the therm housing

replaced all gaskets

Figured out how to route rad hose without interfering with shift linkage

re-did fueling setup

made up brake booster line

fixed oil leak from oil cooler (pushlock hose split)

cleaned up a lot of parts that were caked with nasty

replaced a ton of old ****ty bolts

new o-rings for injectors

some other sht

I had to cut the therm housing outlet pretty short in order for 5th gear to engage (linkage would hit the barb) but theres enough material poking out to where the hose can't pop off. I test fit a spare rad hose with clamp and went through the gears, it was fine. I have about 1/4" clearance now. I thought it would be more of a bitch to get it all to work, but once again the sawzall got the job done.

tomorrow Im gonna start fitting some of the A/W stuff. I have the whole week off so I might as well make good use of it.

Brake booster (check valve from audi a4) mated to -6 pushlock:

Fueling:

Overall mess:

Cut barb for linkage clearance:

4/20/11

Ya so It looks like ill be doing the smart thing and modifying the shift lever. I have a few more pics from today. I started mocking up some of the A/W stuff.

4/22/11

Did work for a little bit today. I put the spare therm housing on, and modified the shift lever.

I didnt want to tap a hole in a different spot, so I cut the original mounting barb off, then ground about 1/8" off the lever, the entire length of the left side, lowering where the cable end sits (also allowing the spring/cable clamp to move without binding on the shift lever) The barb base then fell right out.

I drilled and tapped that hole, then found a perfect fitting bolt (you'll see in the pics) and ground the head down for clearance, then just cut it to length. I have about 1/2" clearance to the therm housing now, and a nice solid shift cable end. I'll have pics up tomorrow.

Heres the pics. They are bit blurry, but you can see what I did. The bolt is smooth right until it hits the lever, where it becomes threaded. Thats what I mean its the perfect bolt! lol No threads to wear out the plastic bushings on the shifter ends. Other than that, I was figuring placement for the awic.

4/24/11

****ty phone pics but it fits real nice:

4/25/11

Im running 2x 38mm Tials. I just fabbed up the DP today so once I get the vbands in for the turbo, I can start welding the wastegate piping. They are being recirc'd so things stay nice n quiet. Prob have it done later this week. Tomorrow morning I pick up tri-mix to keep everything SS.

I had to make a lot of bends to clear the shifter cables, manifold and brake lines. Came out pretty good. My fab skills have improved slightly lol. Got it all tacked up ready for welding tomorrow:

4/26/11

Nothing great but it came out ok

4/28/11

Got the turbine housing welded up today. Came out decent, got some pretty good welds on it. The stupid t4 flange warped a bit so I gotta have a machine shop flatten it back out. No big deal tho. Other than that I just need to clean up some of the spatter and port the inside of the housing where it was welded, then I can call it done.

I pre heated the housing a good bit with a blow torch then slowly let it cool after I was done. I welded it really hot, so I figured it would warp a little. I'd rather have the weld penetrate as much as possible so I don't have to worry about breakage or cracking. Got it done with 309SS

These welds came out a little better than the DP:

4/29/11

Dropped the hotside and twinscroll off at the machine shop today to get milled down flat. I'll have both back either today or tomorrow. From there I'll clean up the hotside so it looks presentable, then this project will be almost done. I started stripping down the compressor housing for polishing, i think it'll add a nice touch to the bay

4/30/11

Half ass polished the turbine housing. Needs more sanding/ polish work, but its good enough for now. I need to get this bomb running asap.

5/3/11

Some more pics, getting ready to fab the wastegate setup tomorrow. I marked everything exactly how it sits on the C ride and reassembled off the vehicle. Getting closer!

Got my wastegates almost done. I have to finish welding the far one tomorrow, gonna hard pipe it and use a smaller flex section, im glad to say the major pain in the ass is over with tho! It all fits and bolts up perfectly.

5/5/11

Maybe someone knows a trick to this or has good advice: I'm having a lot of trouble getting the shifter to go smoothly into all gears, I tried everything. I did the procedure VW states, lock the trans and put a pin in the shift box for placement, to align the cables. no dice.

I tried it with my own adjustments as well, I messed with it for about 4 hours and it WILL NOT adjust properly.

There's a good bit of play in the shifter, as if maybe the bushings are shot. IDK I cant seem to get it on point. I did it when the trans was on the ground, took 10 mins and it shifted smooth, no probs. once installed is when I'm having the probs. the cables seem to be about 1/2" too long, they fit but are a bit tight. they don't feel like they are binding at all though. Im hoping its just bad bushings. its the euro polo box.

I can get it to go in all gears, but if 1-4 go in smooth, 5-6 and reverse crunch. then if 5,6 are smooth, 1-4 crunch.

Got it all bolted in. Fits real tight, but it goes together pretty easily. I gotta clean everything again since its all covered in grease n dirt. and no, the oem manifolds will not be seen. I made the atp heat shield work. Drilled 2 holes where the manifolds protrude, I need to retain those 2 posts since I'll be making a turbo brace to bolt there.

6/4/11

It lives. Still a lot of work to do but im really happy to hear it run. No problems beside me forgetting to tighten a fuel fitting, I had a bad leak when i first tried to start it. Snugged it up, and she fired on the 2nd crank. It runs great though, the Holset sounds baaad.

From the drivers seat you can hear a low whistle at idle... I ****in love it.

The vid sucks and my engine bay is a mess, but ya..here it is (and yes I tripped over the car cover lol) :

http://s384.photobucket.com/user/rad...movie.mp4.html

6/5/11

The cooling system needs a ton of fab work yet. I have to make 2 "y" fittings to retain the factory overflow tank. Instead of getting crazy with t's and 25 an fittings I just ordered some SS in different sizes and am gonna weld it up. I need one Y to have 1", 5/8", and 1/2" branches, then the other needs to be 90deg. 1.25" on 2 ends with 1/4" branch in the center. Its a pain in the ass since everything is really tight as far as coolant hoses, but they gotta be there

Other than that, I need to make a new test pipe to mate my new DP to the old exhaust, install my harness for the IC water pump, mount the IC reserve tank solid to the trunk, get a new wideband sensor, clean up the bay, make a bracket for the intercooler, lots of turbo bracing, make random brackets for the i/c hoses, get axles, do wheel bearings..and lots more little ****.

6/10/11

Well, Yet again my bad luck strikes. Or, the Corrado could just possibly be cursed. Idk what it is, but the blows keep coming.

I was at work, but apparently a hailstorm came through my area and destroyed my car. My neighbor said golfball sized chunks were coming down and demolishing vehicles. All his customers cars got damaged as well. The C was covered but not thick enough to stop damage, so I have about 100 dings all over the body. The roof isnt too bad somehow, but the 1/4's, fenders, doors, and hood are pretty rough.

I called my insurance company and they will be out on Tuesday. I will get a large check and fix the car to showroom condition (possibly with a built motor). At least I get to paint it the way I always wanted to. Just gonna suck straightening all those dings, I don't wanna use filler so im gonna tap as many out as I can. Im gonna do pretty much a full resto on the body, strip it to metal, pull all glass etc. Only thing I'm not doing is the bay, I'll do that next time I pull the motor.

No I am not shaving anything, its not really my style. Only thing different that I considered was pulling the fenders, but its not very likely..I like the factory arches.

All in all.... Sweet Jesus today was brutal.

6/19/11

On a better note, body work starts this upcoming week. Insurance wants me to prove I am not going to just pocket the $, so I need to show them work being performed. No big deal tho.

FINALLY ordered DSS axles, and got my coolant system done.

Still need to work out 100 minor issues tho. My wastegate flanges warped a bit from welding, not bad, but it will be an issue down the road. I stacked a few gaskets to get a decent seal but I'm not sure how long it'll hold up. I hate doing half ass stuff but time is limited so I'll have to take a gamble on this one. If it doesn't work.. then off to the machine shop again

Also, I really need to brace the turbo somehow. Its only a matter of time b4 the manifold cracks without support. This stupid **** takes a ton of time, but I AM making progress! Axles were a major thing, at least the turd will move under its own power.

I'll have to get my ass moving and make the I/C functional...kinda need that for boost.

6/26/11

Round 3. LOTS of sanding left to do.

7/17/11

Bought all the paint yesterday so I will be making progress shortly. Other than body work I've had trouble with cracking wheel bearings in half due to bad hub/spindles. The car sat w/ no axles all winter so I killed my hubs spindles and bearings. It all got tweaked way out of spec. I got aggravated with it and ordered everything new. Oh yea LK4Z is some damn expensive base

For anyone who gives a ****, I decided to use all PPG paint. Deltron base, primer & sealer, PPG 2021 clear. Its what I always use and am pretty comfortable with it.. i know I'll be able to get a damn good looking paint job with minimal sanding/buffing.

7/20/11

Porsche goodness:

Many $ worth of liquid:

7/26/11

Brakes are done, minus banjo bolts that are in the mail. 4mm spacers arrived and give me perfect clearance to the calipers. I have about 2mm of play now. DSS axles are a perfect fit and everything bolted together very nicely. Body work is moving along, almost got one fender 100% down to metal. I was gonna take it to factory primer but there was a lot more paint than I expected on the fenders. 6 coats including factory! lol I don't have the time to sand it so I hit it w/ the ol' aircraft stripper and got most of it loose.

Other than that I had a bad t-stat so I had to undo the housing and replace it. New wideband is in and the car mechanically is coming to an end. I just need to install the harness I made for the intercooler pump then it will be boost-able. Also ordered some SS rod to make some turbo bracing, so I dont crack my manifold from the weight/movement.

And this guy is keeping the C company for a while:

7/29/11

Bodywork. A lot of it.

Stripped both fenders to bare metal. Bumped the dings out and got a light skim coat over them. one is in primer the other one needs to be re-shaped slightly around the arch due to a building falling on it last year.

Next in line: Hood. Its gonna be a chore straightening out 30 dings using little, if any plastic. My plan is to strip to metal, guidecoat/ sand the metal to see all the dings (guidecoat will sit in all my low spots) bump them flush (the ones I can get to) and give the bad ones a skim if i have to. I'll prime 2 or 3 coats and block it out nice n smooth.

7/31/11

I drove it.

lol hood came up and smashed the windshield in.

8/1/11

I tried to get a video but my damn camera memory was full. You guys have to hear the way this **** sounds lol. I got the i/c working and fixed my coolant problem.

Took a healthy run down the road at 25psi. The car is insane. Much MUCH faster than before at the same boost. The 6speed clicks gently into gear, very tight /responsive. I haven't gotten past 3rd gear but I was already approaching 100mph. The way the turbo spools is perfect. Exactly what I wanted. Builds boost at 3k full at 4k, but the onset of power is very gradual which is awesome for traction.

Here is the shorter vid. Not too great, the other one is better.

http://s384.photobucket.com/albums/o...t=MOV04809.mp4

Vid# 2: 2/3 gear pull.

http://s384.photobucket.com/albums/o...t=MOV04808.mp4

Yes the windshield is trashed. lol

As for that bolt, I just grabbed one that fit. (your talking about the small one on the side of the mount right? ) Pretty sure its an m8 but I don't know offhand. There is plenty of room for the motor and trans to move, I have almost 1" of clearance to the cup.

8/6/11

I cant find a local clean hood so i am fixing the og one. I previously was going to scrap it, and cut a chunk out to patch rust on a buddies car..sooo I decided to do something a little different and keep the hood. Im sure some will hate it, but it is very necessary being that my bay gets stupid hot. It will look clean and simple when done.

chunk cut:

Little skim and thats as far as I got b4 rain:

8/9/11

Few more. Stripped to hood to metal finally, its pretty hammered so it def needs some love. theres a pretty ugly gash in it that was previously fixed kinda ****ty, gotta hammer it out a little. other than that I got it sanded to 220, gonna do my bodywork then epoxy prime, surfacer and block.

8/16/11

epoxy primed hood and fender. Moving along.

9/3/11

Finally got a day to myself, so I shut the phone off and got **** done. I skipped out on a weekend trip to work on the C, my girl is angry but she'll get over it.

I had all the glass pulled out on friday, theres a good amount of rust under the front windshield, the hatch has some rot holes and the side glass had a bit of rust too. gotta cut/weld metal in the hatch but the rest i was able to grind away. Gonna treat the window channels with Por15 then prime and paint so they cannot rust out again. Im hoping i can get this thing in the booth by next weekend, then i can have the glass put back in and actually make it to h20 with the car.

cant see it in my ****ty pics but I smoothed the rockers, looks soooo much better. Its a real pain in the ass getting all the chip guard off.

9/4/11

Got the rest of the car stripped down. Also blocked out the drivers side. I need to get more epoxy primer, there is a lot of bare metal n I ran out, so I couldnt finish priming it today. Def moving along. damn good chance that I can paint it by the weekend. I put a solid 24hours in and intend to put every spare second into the car this week.

A buddy also gave me some hood hinges today, so a huge thanks to him. now i can paint the hood on the car.

9/8/11

Picked these up:

No, not resizing the rods (not really nec. imo). Just changing bolts.

Continuing on with the bodywork. Gonna sand/ prime the rest of car tomorrow, block out/paint prep on Sat, and hoping to get it in the booth on Sunday.

Also found more damage on the pass side rocker, I pulled it out since it was just filler stuck in it. Got that done and all bodywork done. No more hail damage and the car is dead straight.

9/12/11

Did more work, got the entire car primed. I blocked out 60% of it today, ill finish tomorrow. Then gonna wetsand with 600 and she is ready for the booth. And yes I and going to prime / paint the rest of the hatch, I didnt get a chance to strip all the glue n sht off where the plate holder sits, so I masked it.

Btw, I am in love with PPG's V-prime.. sht is awesome. Block sand dry with 400, no clogging.

On to the pics.

My state of the art paint booth:

9/18/11

The C is officially ready for paint. Here are the last primer pics anyone will see.

9/21/11

The car is purple again. It came out pretty good, def needs wetsanding. Not perfect but overall I can live with it. There is a lot of dust in the clear from our wonderful booth, i laid the clear on heavy so most will sand out. I'll have better pics up soon

9/29/11

cut and polished one fender so far

10/4/11

Going to respray the roof and hood this Sat. I got a little solvent pop from rushing that last coat of clear. most of it sanded out but wasnt perfect so I just wanna reshoot it. Im going to spray the bumpers and other misc little stuff anyway so i might as well get it all done in one shot. Other than that the car looks mint tho, I started wetsanding/polishing the rest of the body.

Windows will go back in next week, and ill start reassembly of all moldings etc.

10/8/11

bumpers are done and hood/roof were resprayed. Came out real nice, hopefully my blend looks good after polishing.

10/9/11

The blended area came out good, i was a bit worried but it polished up to where you cant notice it. Started wetsanding and buffing also. roof and hood look ridiculous, so do the fenders and bumpers. Just have to finish sanding the rest of the car and spray misc stuff like mirrors etc. I def. put some hours in this weekend.

10/23/11

Just bought Spoonfed lower windshield trim, and rain tray... finally. Rain tray will be "trim" black for an oem look. I ALMOST did carbon kevlar but couldn't pull the trigger lol.

Still contemplating what i wanna do with the rear plate tub. so many options but i need it to look "right". I love the mattig delete I have now but its wavy, and it drives me nuts looking at it. its too thin and weird shaped to do any straightening or body work which is unfortunate.

I got things done today, fixed the massive coolant leak with a nice SS part I made, and cleaned the hell out of the interior. Painted some misc stuff too.

Interior looking tight yo

Old piece of crap coolant T:

Painted things:

11/15/11

Motor is being built:

Pauter rods

83mm JE 8.5:1 pistons

Billet mains

Main/block girdle

Undercut, knife edge, balanced and micro polished crank.

Some other ****.

Block goes to the machine shop in 2 weeks, Crankshaft is getting dropped off Thursday. this is the last part of this damn build..finally.

2/22/12

Getting this piece of shat done for dyno day. This is more of a reminder for myself of what i have to finish than an "update" I always write things down and lose the paper, here i wont forget.

Mechanical:

-manifold reinforced/tig welded

-pipe new wg's to DP

-injector o rings

-finish turbo brace 1

finish turbo brace 2

finish turbo brace 3 and 4

-new 02 sensor

-rewire i/c pump

-redo charge piping to fit around turbo braces

-new home for avcr

-brake light switch

-i/c core bracket

-fix relay box top

Paint:

-rockers

-door jambs

-Hatch

-hatch underside

-gas door

-spoiler

-wetsand/buff

-Install window scrapers

-new window molding (DR.)

-find all the parts i lost

3/5/12

sorry pics suck but here is some work done.

Started on turbo bracing, just waiting on my welding gas to arrive this week so i can get it done. also need to weld the new wastegate piping, but im gonna have that tig welded once i get it tacked together, the stupid mig gun doesnt fit in those tight spots. I got rid of the 38mm flange style wg's. they sucked. replacing with mvs v-band jobs.

Other than that, my list on the last page got shorter. I finished all the i/c water lines and wrapped them in some fancy sleeving. **** looks awesome. Made all SS brackets to hold lines away from axles and exhaust since they are routed underneath the car. I moved the oil cooler in front of the rad as well, new location has much better airflow. Also ordered up everything to change my oil return to -12an with no bends (prev. -10 /90deg.). I got rid of the .065 restrictor on the oil feed , the Holset needs a lot more oil to stay happy. It'll run cooler too which is good.

What else ..... brakes and clutch were re-bled, i started prepping a lot of small parts for paint, front window is back in, rewired meth setup w/ weatherpack connectors the tow guy ripped it all out w/ his foot on accident. prob more stuff i dont remember

works been slow and i got a burst of motivation to get this dump finished.

3/13/12

had the day off so i did some ****.

Resprayed mirror, gas door and spoiler.

Welded the WG inlets, ported out then smoothed the welds to look pretty.

-12 oil drain got here too, gonna start prepping that for install tomorrow.

3/29/12

80% done with the mechanical portion of this thing....which means i will definitely make it to dyno day. I put some serious time in the turbo setup this week and its really coming together nice. It fits 10000x better than it did before, and I wont have to worry about longevity now. Time was an issue so I had a local guy tig weld the wg piping for me, then I did the rest with some ss wire and my mig.

I made some bad ass braces for the manifold/turbo. all done with 3/4" .65 wall ss tubing, 1/2" 316SS solid round tube and some really expensive hi-temp heim joints, which are made from 316 Stainless center bearing, races and housings. Also got the top brace nearly done (for turbo) which bolts over the oil feed port and will then form some sort of triangle, braced to the ex. manifold. Prob finish that up on saturday.

Other than that, I hard piped a -12 oil drain, which extends past the mani. so I dont melt my drain line. Just hogged out a -10 garret drain to 7/8" ID, section of 1" id pipe and AL weld fitting, welded it all up and worked out perfect.

With that said...my goal is to have it running by Sunday.

Brace on bottom of manifold:

oil drain:

top brace:

nice welding

4/3/12

Got some **** done today. Dropped the oil pan, cut off old -10 fitting cleaned up the pan a bit and welded on the -12 port. Cut the drain hose to length also, perfect 45deg. sweep, so it should flow very nice. I made a foot for the bottom manifold brace and finished the entire bottom support system. Also installed manifold, wastegates, turbo etc.

The one thing I did which some will disagree with, swapped out rod bolts w/ arp. I know you are supposed to resize, but I am not pulling everything apart to get the pistons out right now, dont have the time to do it. I Plan on running 28-30lbs and don't wanna put a hole in the block when the factory bolts let go. Def pushing the limits here, but I have a spare block im building so it only needs to hold up for a few months.

I have heard of guys running w/o resizing for years w/ no problems. I guess ill see how it goes

4/11/12

My stupid camera is broken and wont adjust so pics r bad. Wetsanded and buffed, por15 some areas, CLEANED. Paint looks awesome. Few areas I gotta touch up yet, but overall its purple and shiny so that makes me happy for now. typical corrado, it started pissing oil like crazy also. Oil cooler hose split, stupid pushlock is only good for a few years then it dry-rots and cracks. other than that, i just have a lot of reassembly to do.

5/22/12

Just checking in since its been a while. Ordered the rest of my old rotted /ripped moldings from Zeb, and I'm tracking down a brand new OE hood since I've lost interest in the scoop already. lol other than that stuff the car has been running great.

I had a bad boost control issue that i finally ironed out (stuck at 28psi). I semi-fixed a few weeks ago but something wasnt right still. I thought my manifold design was promoting horrible boost creep, I had 1bar springs in the wg's and ran 28psi off the springs..so doubling spring pressure is pretty bad. Turns out in the rush to get the C finished for dyno day, I forgot to put the damn port plugs in one of the wastegates..long story short I was running off one wastegate and had a nasty boost/vac leak in the other. Which explains the mildly stumbling idle and boost creep. Stupid, but at least its not expensive! lol I found 3 plugs still new in the package on my toolbox and a ****ing light bulb came on. Anyhow, I swapped the springs to 10lb and am going to reassemble tomorrow. im sure ill still have mild creep but nothing like before. if i can keep it around 13lbs off the springs ill be happy.

Ill get some good pics of the completed car here shortly and that will be the end of my build for now. Ill let everyone know how a stock 12v holds up at 500+whp. its staying in till it gives up. After I get wife'd up next year ill finish the "real" motor and check back in this place with some new plans.

7/2/12

Parting the car back to stock.

12/20/12

The car is still alive, not sold and in one piece (unfortunately). however for those wondering, a stock vr6 w/ 100k, arp and proper cooling/detonation control has no problem at all being beat on at 36psi which is over the 600 mark. Been hammering on it since I built it. Built motors for 600whp and under are a 100% waste of $. Proven fact. Other than that, the hx52 ****ing looooovveeesss cold weather. I've come to terms that the car will never sell, and I have zero time to part it out, as much as I'd love to have it back to stock. Gonna put in a 4puck come springtime and take it from there. Dont waste $ on building motors my friends.

3/18/13

Just want to say IM OUT . lol the car is parted and will be sold off as OEM soon. Good meeting a lot of you and giving/getting help over the years. def made some good friends. Been an awesome experience and i regret nothing. I had an absolute blast with the big turbo! if anyone is in need of parts, give me a shout i have it everything except 6 speed swap and turbo /manifold/dp. not parting the car, just the build so no stupid requests pls.

Wow this is great! Funny assistant you’ve got there ???? #furryfriend

Posted by Diggymart on 5/8/19 @ 2:36:22 PM