You must be logged in to rate content!

5 minute(s) of a 22 minute read

5-13-2009

I did sand, file and clean all of them however a few are to the point they are close to being even with the plate, so they are all but gone. A few are like new.

This car has a little over 9K miles as it was used at Bucknell Collage by the security department so it has a lot of stop & go cycles. I shifted point sets around where possible keeping them grouped since the forward contacts are used more than the reverse ones. I will try and take a picture of the points this weekend.

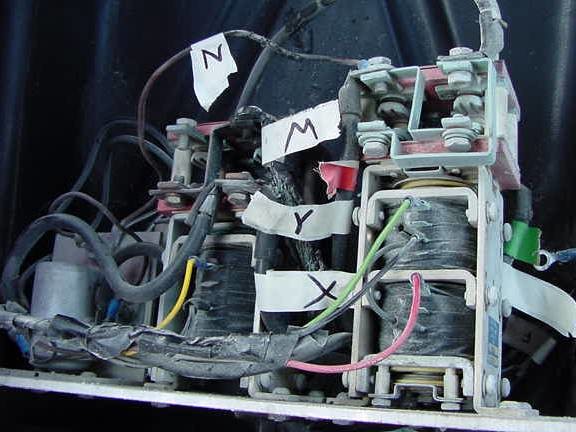

Here is a picture of a well used contactor that I downloaded from the internet.

On the tall tower to the right, on the top, you will see 2 ribbed shaped points (left one is easier to see). This has a point attached to it along with a point attached to a plate directly above it. Unsure how I would attach a new point to these different style mating surfaces? Possibly drill a hole smaller than the new point and braze it in from the back side?

Thanks for the input. You are correct silver solder would be better than brazing. This is good to know as I can't weld or braze worth a $#%. I may have some silver dimes here somewhere. There is rumor that 2 of these critters are sitting in a junkyard an hour from here so I may make a trip and buy up their contactors if there in ok shape. I may also shake down some electrical friends that are hoarding some silver contacts.

5-14-2009

Barry, the tall contactor is forward / reverse (up reverse & down forward). Factory originally had them operating the other way but found there was less wear going forward if coil pulled down. The other contactor in called the speed controller (SP-1). The 8 batteries are wired in parallel and in series and divided into two packs of four, providing 24 volts in each pack. The car uses 24 volts from each pack in parallel for the first two speeds and 48 volts in series for the top speed. The speeds are changed by changing the voltage through the use of an accelerator's three micro switches.

As the accelerator is depressed, current will flow from the two packs of batteries wired in parallel which produce 24 volts. In the first speed the current passes through a nichrome ribbon resister (under the car in rear) which cuts the amperage load and permits a fairly smooth take off. The first position has a top speed of 11 mph. Depressing the accelerator further will activate a solenoid in the contactor box which bypasses the resistor and increases the speed 23 mph. The car remains in a parallel circuit mode using 24 volts from each pack of batteries. The third speed changes the current from 24 volts in a parallel circuit to 48 volts in a series circuit. To reverse the car a toggle switch on the dash is used to change the current flow to the opposite direction.

Here is a picture of the point set up I pulled from the internet.

Larry there are no dumb questions. The entire body including the top is made out of a material called "Cycolac", which is an extremely thin type of plastic (not fiberglass). It will crack simply by looking at the Citicar the wrong way. They have also been known to crack at the windshield pillars if loading onto a trailer. S

Since the vehicle is riveted together stress cracks tend to show up. I countered this by drilling the rivet holes a whisker larger to allow for a tiny amount of play and expansion (not loose though). Riveting this vehicle together was like building an experimental airplane. Even the taillight chrome housing, rocker moldings, etc were riveted. I had to buy a pneumatic rivet gun as my right hand was starting to look like Hulk Hogans. I beefed up the areas prone to cracking with fiberglass underneath prior to painting.

No range between speeds and it is jerky at best, even though the owners manual says you will become an expert at controlling these miro switches.

At the end of production they came out with a different style of controller that eliminated these switches and provided for a variable type speed control. I have this set up but requires a total rewire of everything that controls the motor. I will wait to work the bugs out of everything than tear this portion apart and redo. This will drive the wife nuts as she is ready to drive this thing.

Interesting car! you don't see these every day!

Posted by MPower on 10/12/20 @ 1:49:44 PM