You must be logged in to rate content!

16 minute read

383 build

Compliments of bjautos7 @ http://www.hotrodders.com

3-1-2013

hi , have started my engine build , here same photo's of what i have done so far.

started wth the block frist. cleaned all casting around the block just to make it look nicer.

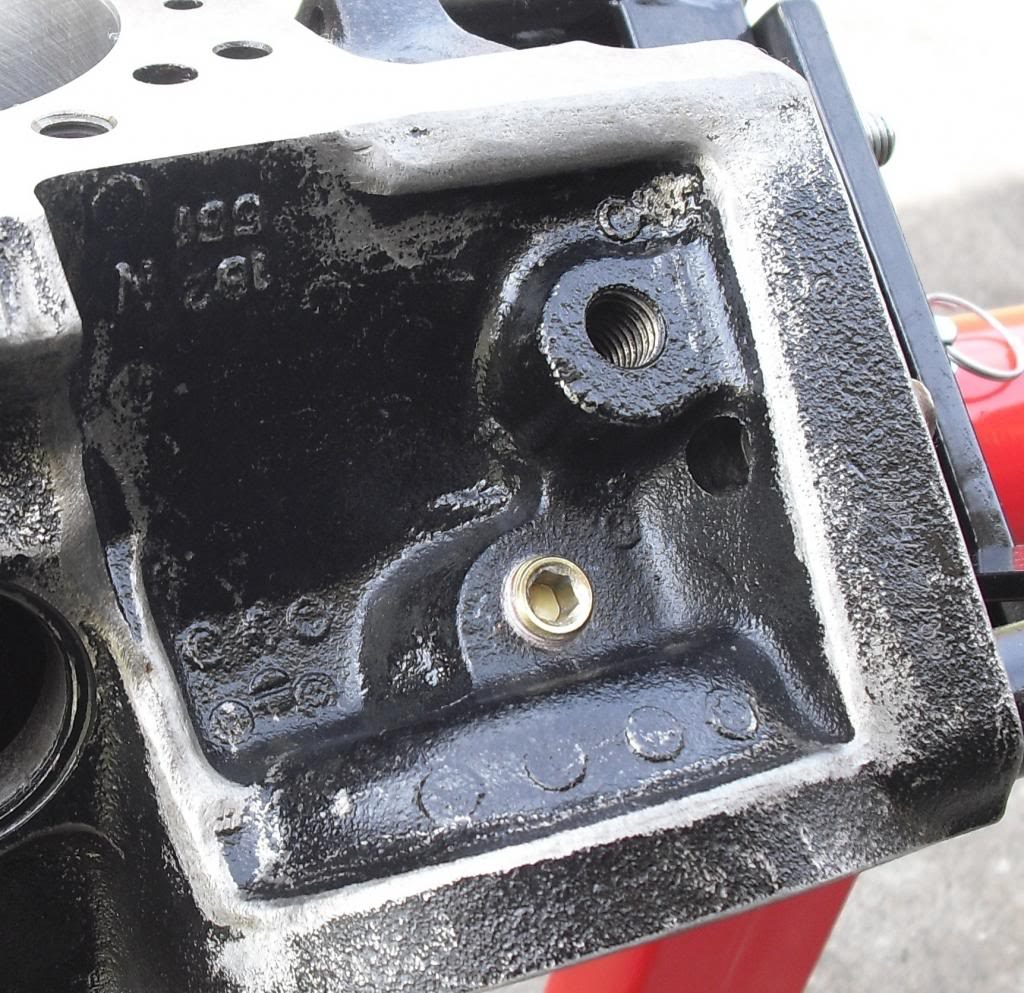

i allso went through the valley and cleaned the rear oil return hole by making them bigger , also at the front of the block i open up the front holes and made them level to the valley floor. you can see that i also have tapped the oil return holes on the valley floor.

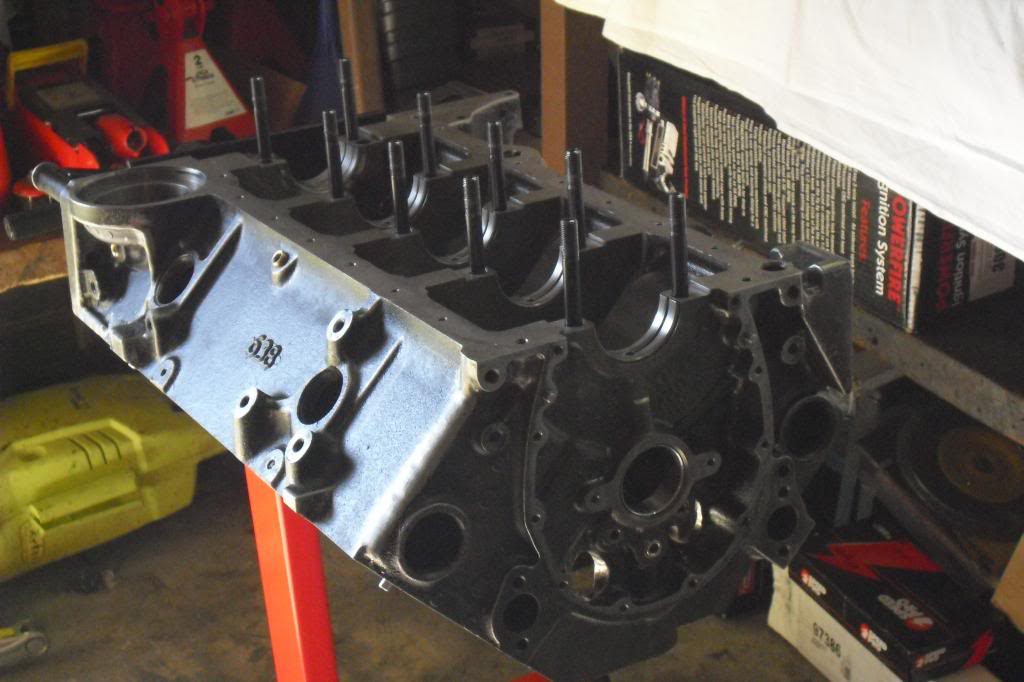

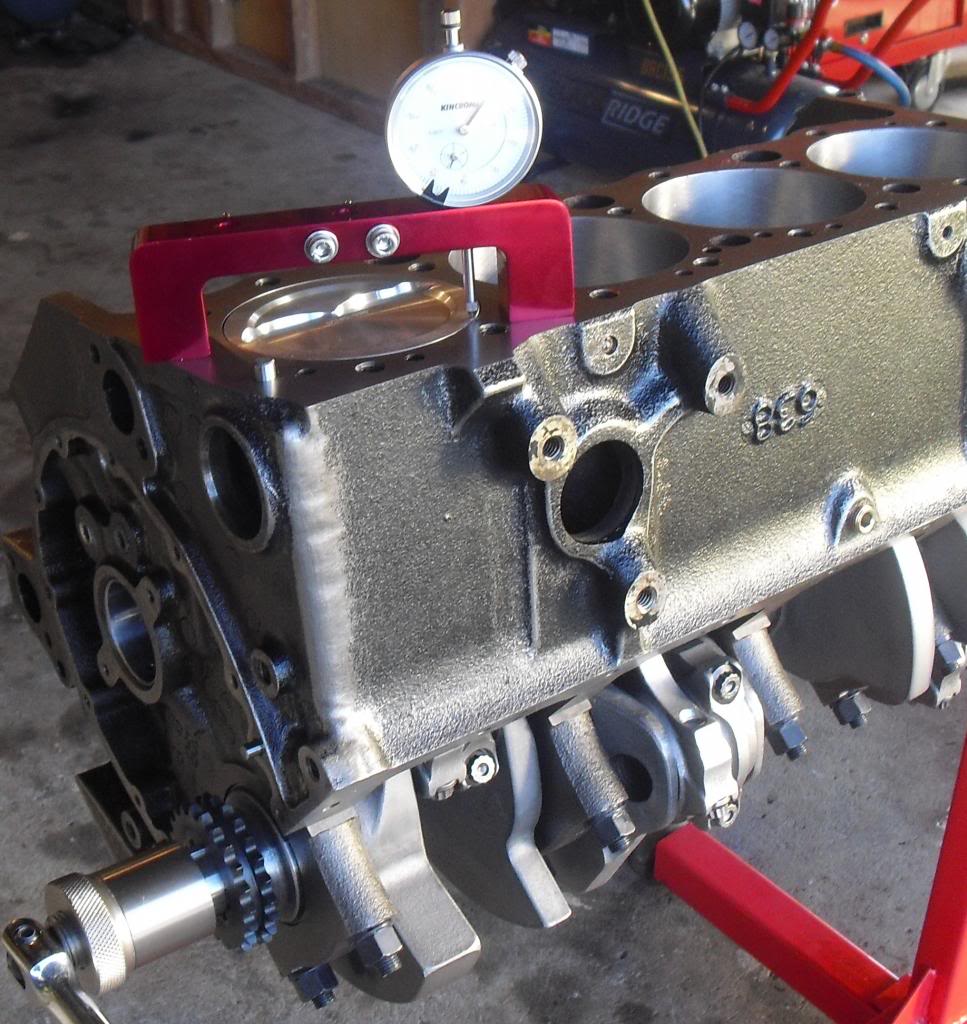

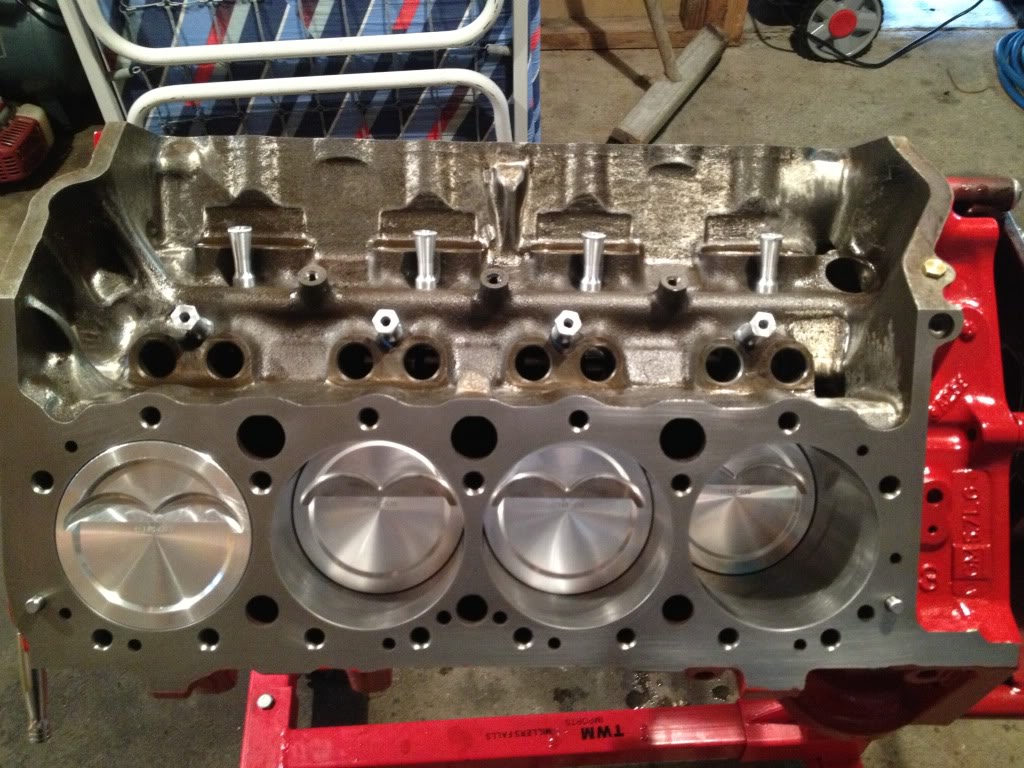

here's a photo of the block cleaned up and readly for dummy assemble. have allso fitted arp studs.

now it time to fit the crank and check for clearance.

clearance come out a bit tight so will have to get some .001 under size bearing. won't have the new bearings for a week or so.

this is a photo of the rods that going in. what i like about this rod is it's a 6 " with 7/16 bolt and stroker cleared. only had to clean up bottom of the bore a little and pan rail was sweet. if you look at the piston you can see it use's a skinner oil ring and the pistons pin don't go all the way in the oil ring landing like ofters do.

3-2-2013

next was to fit the rods and piston into the block , i did this with out the rings on the pistons. same as the crank i also checked the rods clearance.

after fitting rods and piston i checked for rod side cearance and crank end play.

had too do this the old school way with feeler gauge and piston. when doing it this way you have to use the lower bottom of the piston as this is the widest point.

as for piston to valve clearance , yes plenty.

this scat was a balance kit that i got, but i had changed the pistons as the dish in the piston were to big at 19.60cc. when i had it re-balance , only had to remove 36 grams of weight from the crank so not to bad.

next thing i did was fit the stand off tubes in the valley. i had the block decked to zero so i also checked piston to deck hight.

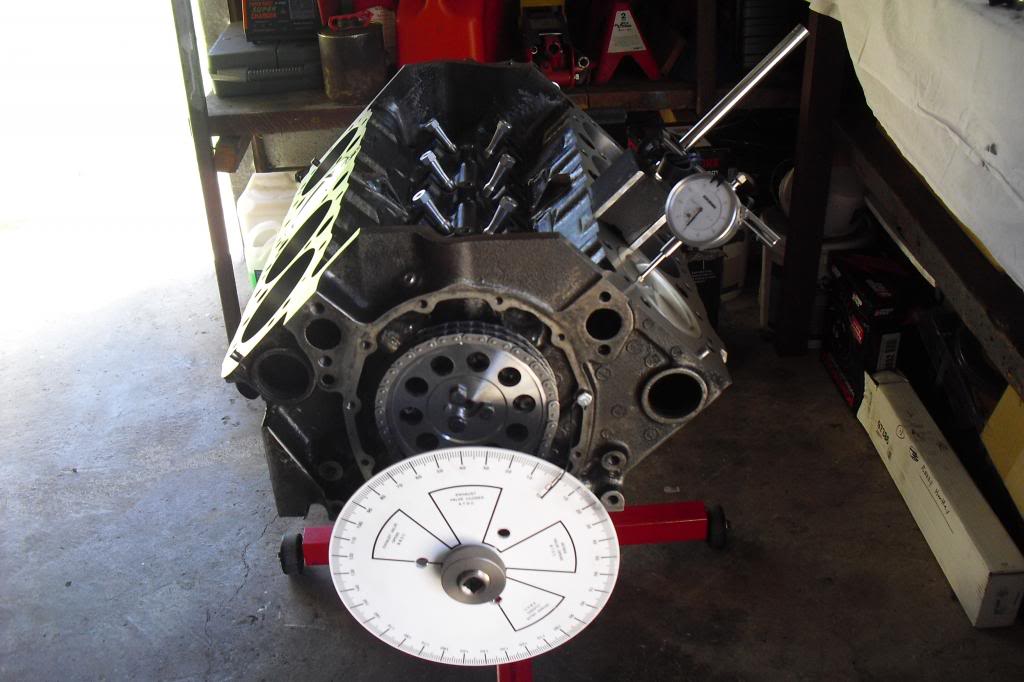

now the cam , timing chain was fitted. in this frist photo i found top dead center and then dail the cam in. on the cam the intake center line was at 106 so this is where i dailed the cam too.

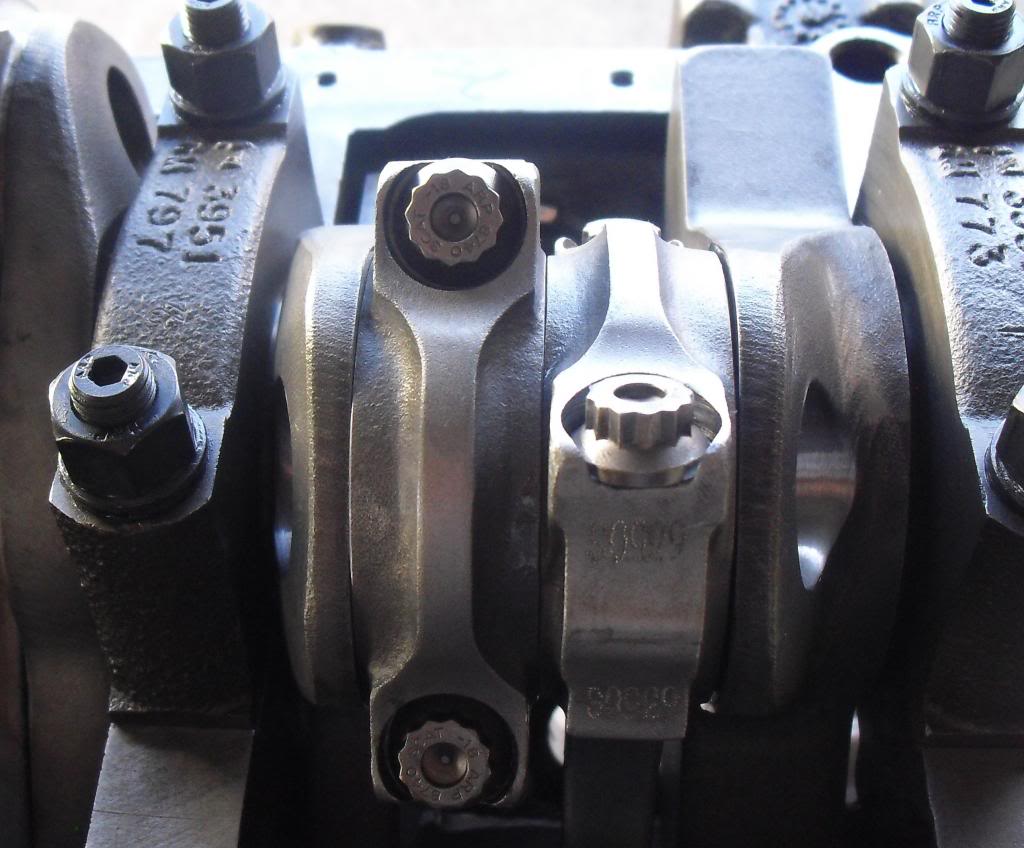

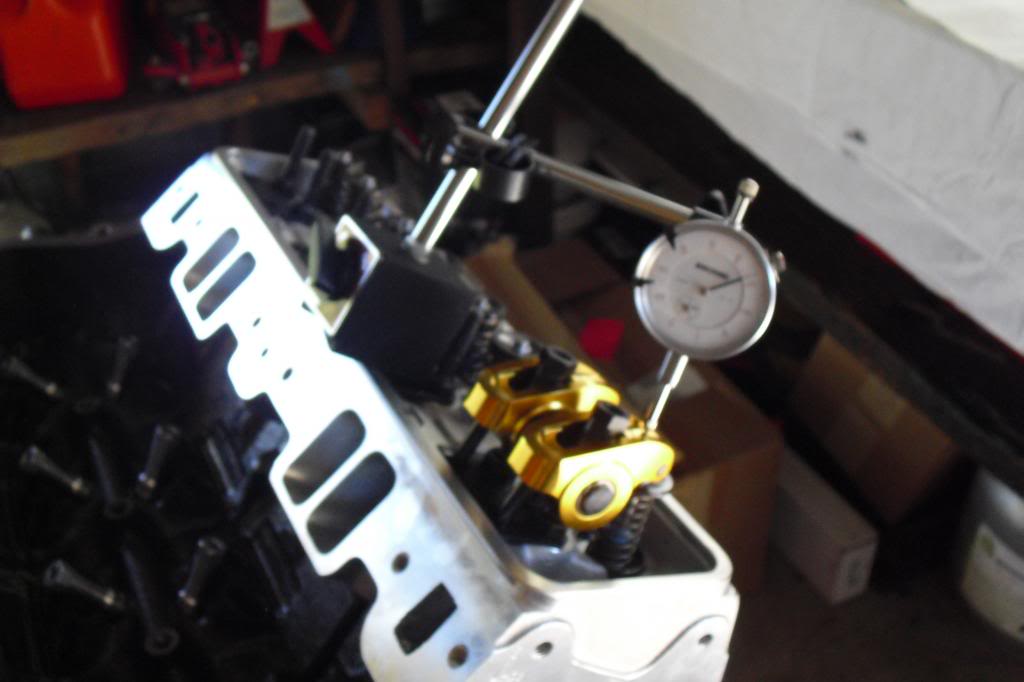

i fitted the heads with the head gasket but did not torque down. in this photo i was checking piston to valve cearance , roller rocker sweep and push rod length.

now this is where i got to , the last thing i did was to check the intake manafold for a line-ment. next on my list is too strip back down , paint the block , wait for the under size bearings and start final assembly.

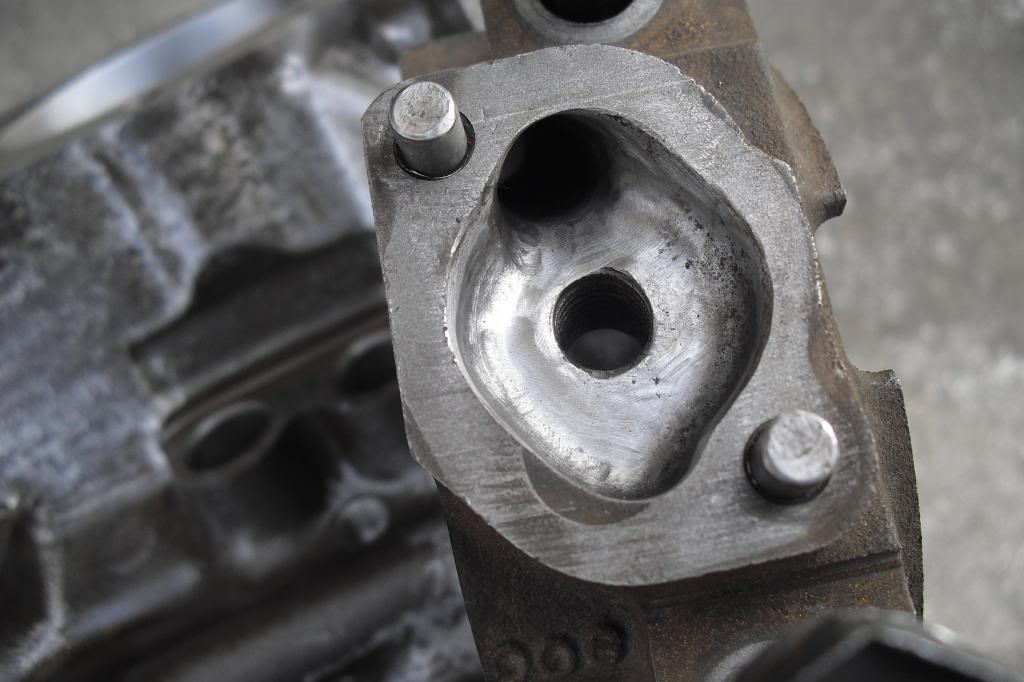

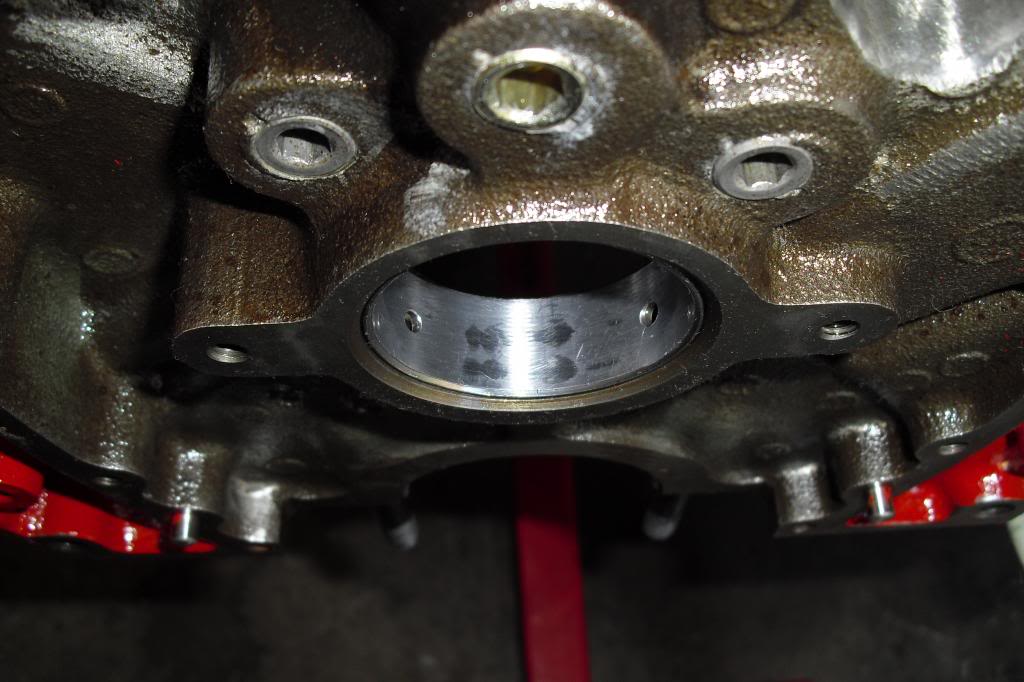

next was to clean up around the pump securing bolt on the rear main and blend it into the discharge hole leading into the block.

in the last photo i clean up entrance and exit holes in the oil filter location. the idea is to flow the oil passages so that the amount of oilpressure lost, as the oil progresses from the pump to the bearing is reduced.

3-3-2013

as for cam it's a xr282hr. gross valve lift is .510 / .520 duration @50 230/236 intake center line 106.0 lobe separation 110.0 and with 1.6 roller rockers which make it 544/555 gross valve lift. which should make around 480-500hp at the flywheel and still be street friendly.

3-5-2013

thanks for the good info , had done the hot wash , spray with brake clean to clean the suface, then masked up and now all painted. here are some photos of how it come out.

4-7-2013

was looking at bearings to replace the ones i have. the part number on the one i have is ms909h which is a std bearing. now my clearces on the crank was to tight so which set do i get is it ms909h1 undersides or ms909hx smaller .

4-8-2013

ok now thinking about the end play on the crank , have read in a couple off books with different answers for crank end play. some say between .004-.007 and others with .002-.006 , so which is it. when I checked my crank for end play I got .0025 . so is this with in the margin or to tight.

thanks thats a good tip for using water pump gasket , as for the main bores would of hope so as the mains and studs were fitted for deck plate honing and would off hoped that this would of been checked first before work was done. when i fitted the crank for clearances it did turn over very easy with no issues at all.

this is my frist ever engine build and the plan was for a very strong street engine , saying that i mean 80% street and 20% strip time.

i'm not a pro so i don't have all the tools , a dail bore gauge would of been what i would of used to check oil cearance if i had one. i'm building this in my garage and working with what i have.

as for the oil pan here a link to the one i have and will be using

http://www.summitracing.com/parts/su.../model/caprice

and this is the oil pump that i have.

http://www.summitracing.com/parts/mo...make/chevrolet

4-9-2013

was talking to my machine shop today and he seems to think that my main bearing clearances will be fine as it not a race motor ,and will spend most of the time on the road. what do others think. should I go with what I have or wait and get the hx bearings.

4-12-2013

going back to when i fitted the cam in the block with out the chain it turned over freely and easy. after fitting the chain it was a bit harder to turn over so at the time i did'nt think to much of it.

sorry wrong photo.

when i did the dummy up i founded that the billet timing set from comp cams part number 7136 was really tight fitting , had to use a bolt to pull on to cam shaft noise , then when i striped the block back down this is what i found. the cam bearing still looks to be ok and smooth to touch. now will the chain free up like with its frist run or should i just replace it with a new one.

4-14-2013

thanks grary , it's not to bad. better to know these thing now before it togiver and it frist start up.

have decided to get new main bearing ms909hx which will give me more cleancers for peace of mind and will be getting a new timing gear set as the one i have is just to tight which puts to much load on the frist cam bearing. go's to show how important a dummy up is before final assamble.

7-24-2013

ok i think that covers timing chains , gears abd belts.

Has been a while since my last post. Have change the main bearing to hx .001 undersize which gave me 2.5 clearances at the mains. This also free up my tight timing chian as well. so after a couple other checks I have started reassemble. here are some photo's

now every thing is free and turning over very nicely. i have should have known better, as i record when i stripped the block it had .001 undersize bearing from factory.

after this , I fitted the timing cover , pointer , block off plate for fuel pump and the oil pump.

before fitting the sump I had to remove the engine from the engine stand to fit the one piece seal and rear frost plugs

after fitting oil pump and pick up and checking and was happy with every thing , the sump went on.

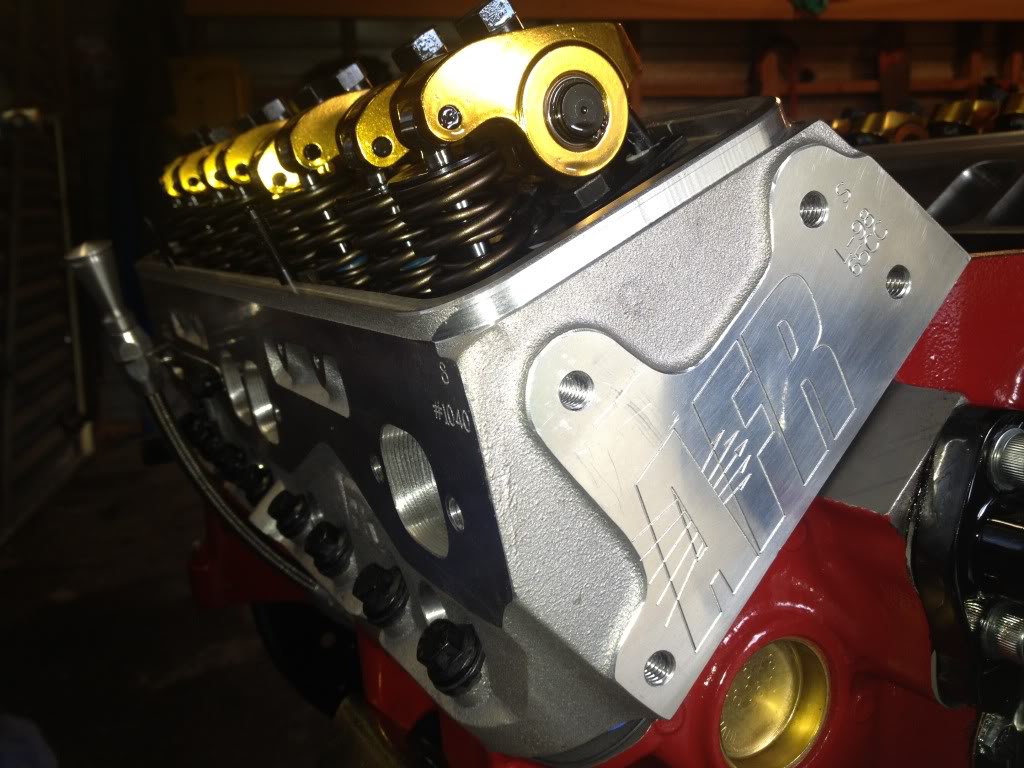

The head I have chosen for my engine are 195 AFR heads, I don't know much about heads but these a are very nice set. after checking heads , I bolted them on and was very pleased how thing are coming togiver.

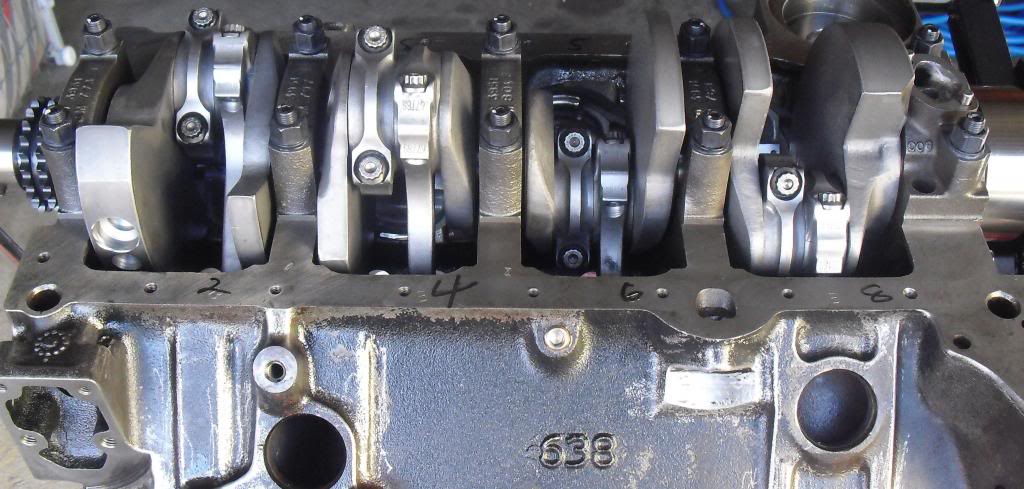

next thing was to put in the Hydraulic Roller Lifters and Hardware.

next on the list was to install the pushrods , and the 1.6 roller rockers

now the flex plate , balancer , water pump , starter motor , dip stick , engine mounts and oil filter.

next on the list was to make temp plates to port match my intake manifold.

found some cool valve covers and the intake manifold is now port matched to the heads and bolted on.

now time time to prime the oil pump and to see if there is any oil pressure.

now just the finishing touches , carb , fuel log , dizzy , leads e.c.t

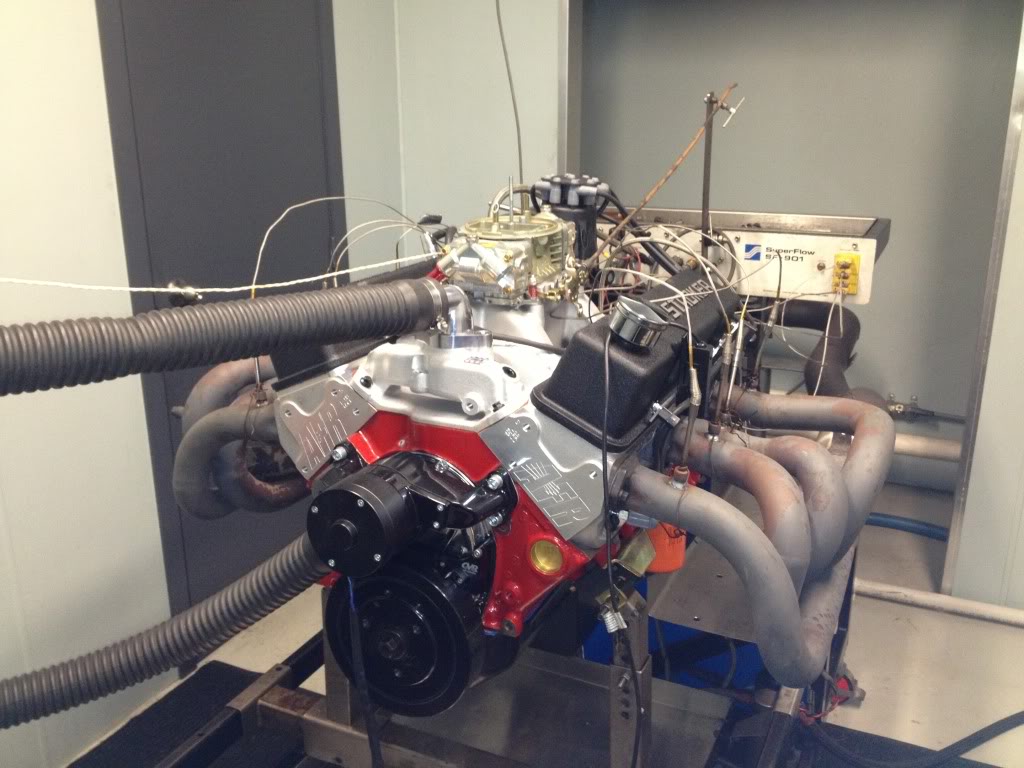

if all go's well will have hp / tq numbers next week. now what numbers do you think it will make , I say 480hp and -502tq.

7-25-2013

As for cam it's a comp cam xr282hr , gross valve lift is .510 / .520 duration @50 230 in /236 ex intake centre line is 106.0 and lobe separation angle 110.0 , with the 1.6 roller rockers lift will 544 in / 555 ex.

As for cam it's a comp cam xr282hr , gross valve lift is .510 / .520 duration @50 230 in /236 ex intake centre line is 106.0 and lobe separation angle 110.0 , with the 1.6 roller rockers lift will 544 in / 555 ex.

static compression is 10.017 and the dynamic effective compression ratio is 8.004.

8-6-2013

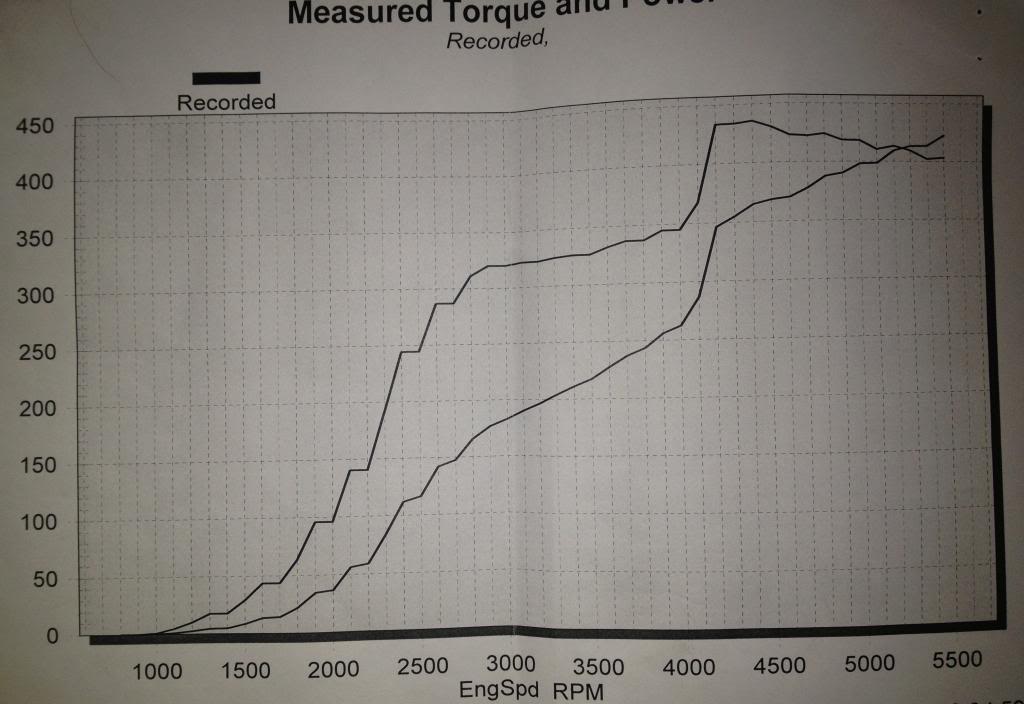

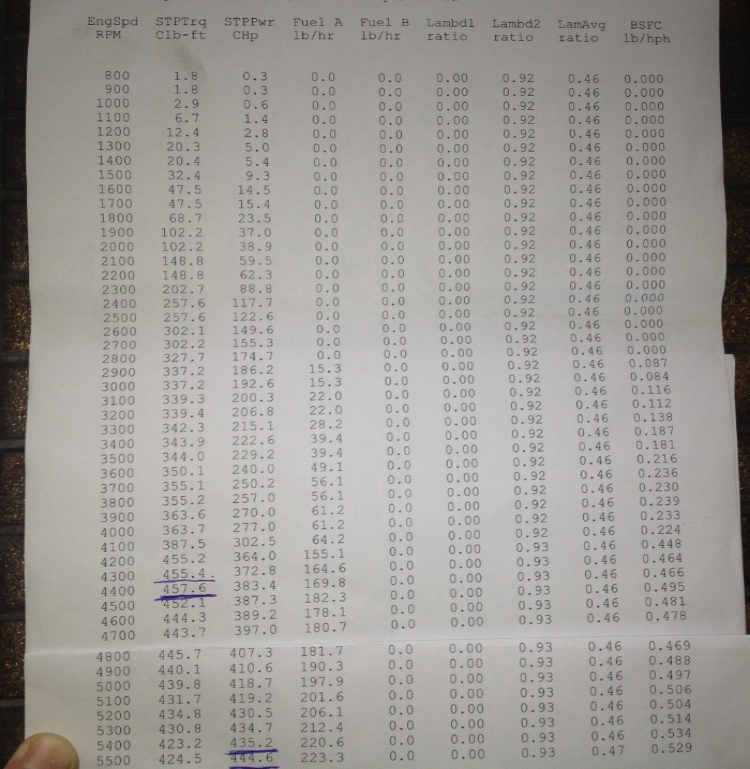

hi every one , got the numbers. I must say I was disappointed , next time will look at a different cam as it was to small for the combo. anyway it made 450hp @ 5500 rpm and 457.6 tq @4400 rpm.

8-7-2013

they only did a couple of pulls , carb was to lean as had to up the jets to 76 in the front and they left 83 in the rear. could not run the vacuum on the dizzy as it was going to avd in timing , so they lock it out. on the paper they put 32 for total timing so not really sure. did put a 1 inch spacer on but it lose 10 hp. not to sure what s.f.c is. air/fuel ratio was 13:1 @ idle and 11.8:1 @wot . there was so much more they could have done , just poor work man ship. I still think it not dailed in right.

8-13-2013

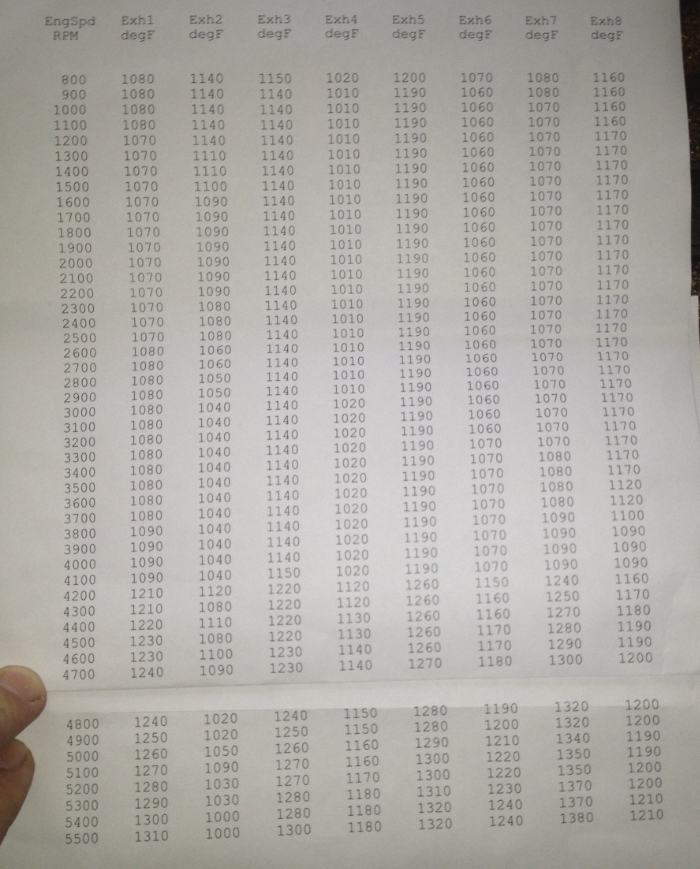

ok this what they give me , have alook over it and see what you think.

8-14-2013

no other pages ,they wrote on the first page 13 idle and 11.80-12.00 which must be air flow ratio. they also put 76/83 jets and timing @ 32. I removed rocker covers and found I had to re-adjust the roller rocker as 3 of them was loose. I also strip down the carb to clean an it had 73 / 83 jets not 76 in the front bowl as stated.

have asked around and from what i can tell , not many people had any thing nice to say about them. one even say that they try to break the engine on the dyno so they can fix it. i did ask when was the last time they calibrate it and the answer i got was never. i should have known better but was to egger to put on the dyno.

1-7-2014

hi every one , have changed plans and now fitting to a ea falcon , now look at what size wheels to run with. This is what I was thinking , 265/60/14 rear and 225/60/14 front and 3.45:1 diff ratio with 2500rpm still convertor in a 350 turbo trans. what do u guys think.

??

Posted by Diggymart on 1/3/20 @ 8:05:22 PM