You must be logged in to rate content!

9 minute read

RedlineGoods Steering Wheel Cover installation

Redline Automotive Accessories Corp. will not be held liable for any labor, incidental or consequential damages of any kind. Proceed at your own risk.

Removing the steering wheel from the car

The first thing that you need to do is remove the steering wheel from the vehicle. To do that, you must first disconnect the battery. A charge is held in the system to power the airbag, so after disconnecting the battery, wait for 1 hour before working on the system. This is longer than needed, but better safe than sorry.

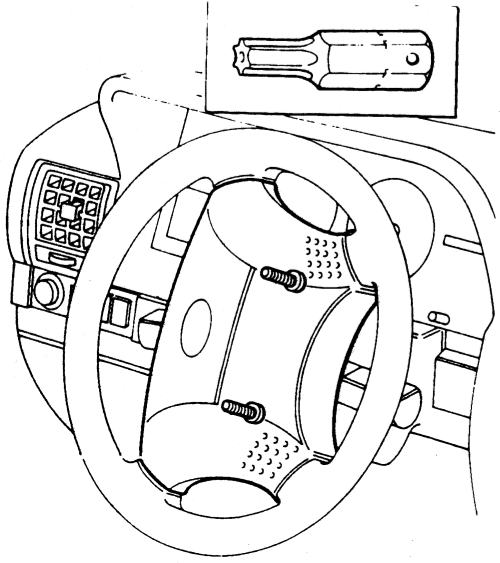

Once the battery is disconnected, you will need a long 3/8 inch drive Torx 30 bit. There are two holes, on the back at 3 o’clock and 9 o’clock when the wheel is centered. It is easier to remove these two bolts with the steering wheel turned 90 degrees from level as seen in this picture:

Once the two screws are loose, it is best to manually steer the wheel back to level again as it makes it easier to re-assemble.

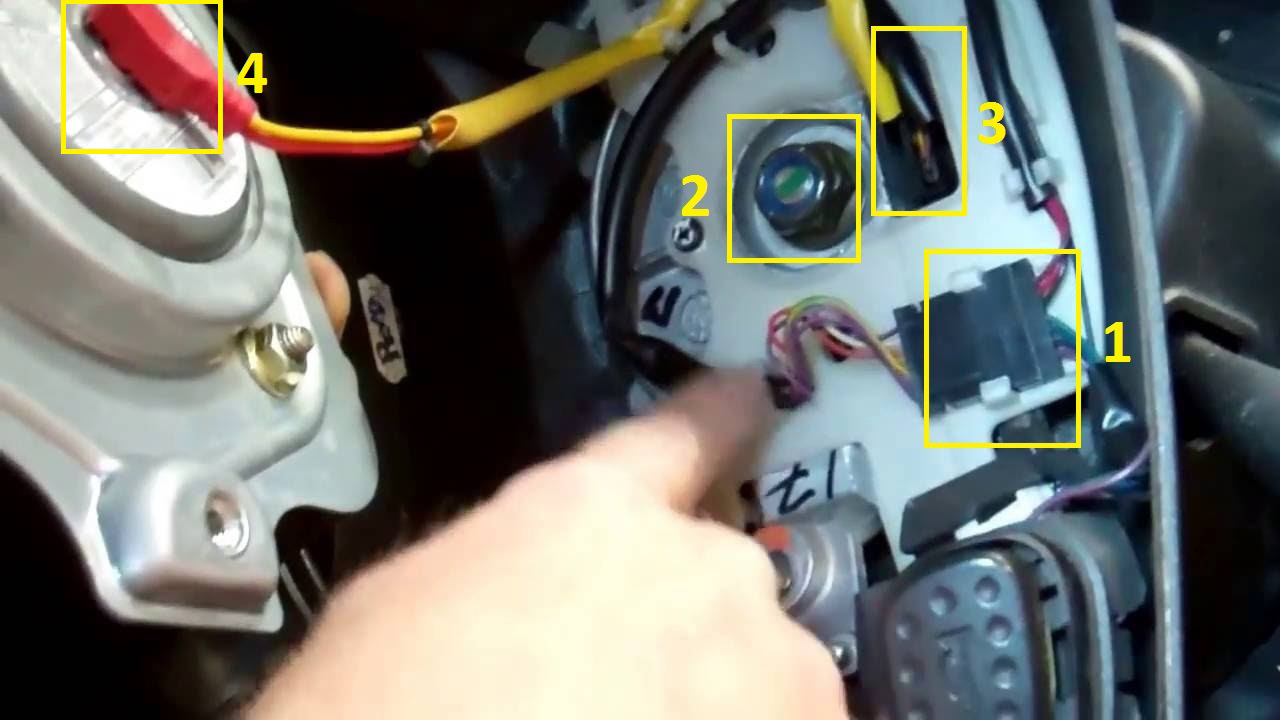

Once these two bolts are out, the airbag will be free to come out. Carefully disconnect the airbag plug (it is kind of tight) and make sure to not how the plug is oriented before removing. As seen in box 4 in the picture below. Set the airbag somewhere safe off to the side. The large nut in the center of the wheel holds the steering wheel to the column as seen in box 2 below. Loosen that nut, but do not remove it yet, you are going to be pulling hard on the wheel and leaving it on will keep it from hitting you in the face when the wheel finally loosens. Do a few blows with your fist to the back side of the wheel to help loosen it from the column.

There is a plug that has to be disconnected to remove the wheel completely, it is large a flat and in the upper right area behind the airbag seen in Box 1. Once that is unplugged unclip it from the plastic wheel base and push that plug and the airbag plug through the hole in the back of the wheel (Box 3) as you remove the wheel.

Wheel wrap replacement

Customers comment:

First off, I like to do things myself, and after hand stitching the entire wheel, it turned out nice, but took me almost 12 hours to do the stitching by hand. Looking back, I probably would have just paid the extra and had the wheel reskinned by the RedlineGoods installer.

The wheel skin needs to be removed, to do this you will need a hook type knife. Use the knife to cut the stitch which allows to peel back the old leather. This can be seen in the next two pictures.

The leather is glued in place around the spokes on the wheel. It is a rubber cement type glue and it does not really take much more effort to remove the skin where it is glued down. The thing to note is that you will need to get some leather glue to use in these areas when you install the new skin.

Once the skin is off, you will now need to remove the dark colored plastic backing that is on the back of the wheel, it is held on by four Philips screws

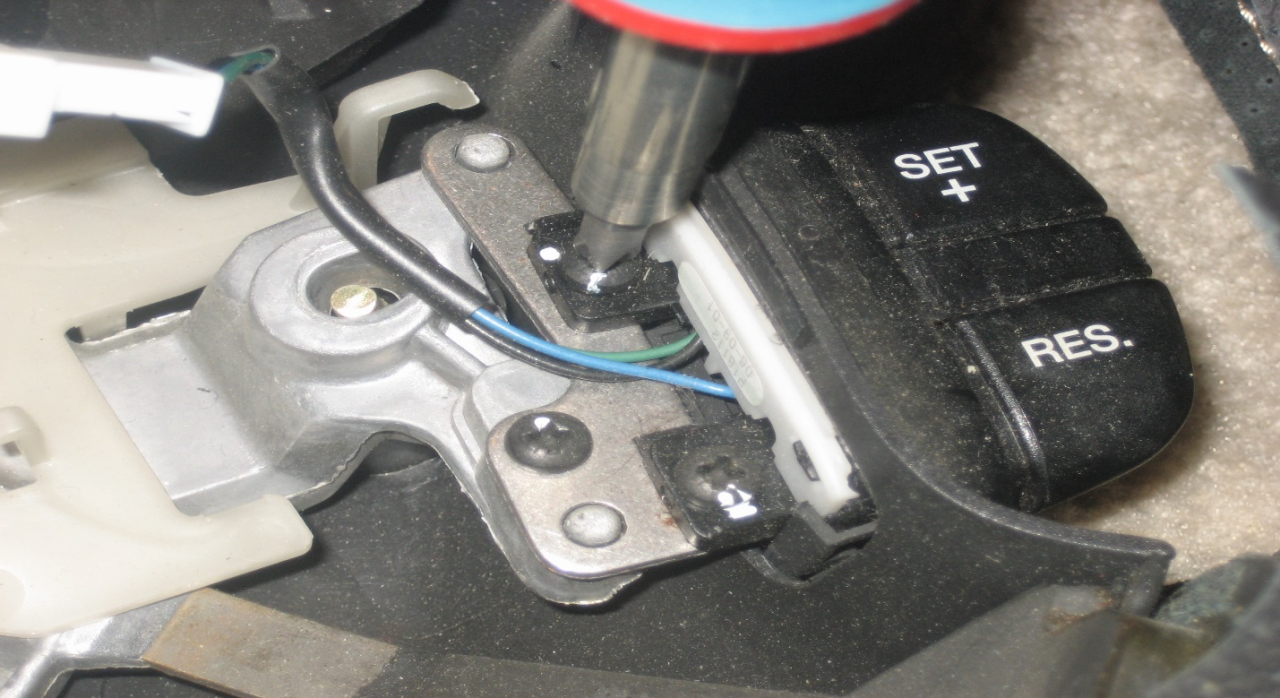

After removing the four screws, you need to remove the cruise control and radio controls from the wheel if yours is so equipped. Doing this requires the same size Phillips screws to be removed.

Once the switches are unscrewed, unplug them in the wheel, remove them and set them aside. The rear trip piece can now be removed, it takes a little flexing of it to get it over where the cruise and radio buttons were, but it does flex well. Once it is off this is what you have piled up after loose fitting the new wheel skin.

Now on to the stitching, RedlineGoods includs more than enough string to stitch the pattern chosen for this installation, probably could have done 1⁄2 more, so don’t worry if you have to waste a little string. Also the string is plenty strong, as you pull it tight after a stitch was made, there is never a thought that the string would break.

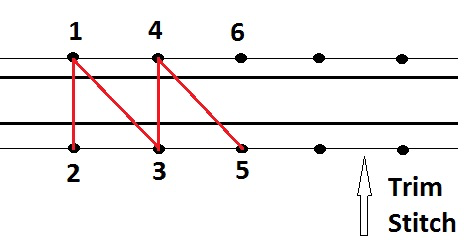

To start each section tie a large (quadruple) knot on the end of the string farthest away from the needle and then tied another double knot to hold the string on the needle, once you have done that it is just a matter of stitching. Re-use the holes that the edge sewing used, I have tried to show my pattern in the picture below:

The red lines represent stitches that are on top, here is the pattern instructions:

Start from the underside pushing the needle and thread from under hole 1

Now with the string through, thread from 1 to 2

Now with the thread and needle through 2 and back under the leather, go to hole three

under the leather and poke the needle and thread through 3 from the underside

Back on the top of the leather go from 3 back to 1 and push the thread and needle

through the leather

We are now back on the underside of the leather after pushing the needle and thread

through, on the underside go from 1 to 4

With the needle and thread coming up from the back at position 4, you are now at the

repeat position (from a stitching standpoint, location 1 and 4 are the same)

Other patterns could be used (see YouTube for samples). The spokes of the wheel need to be glued down (where there was factory glue). Example product to be used is called Suede and Leather Glue made by Aleene’s Original, but there are tons of upholstery glues and any epoxy- based glue will work. The glue chosen for this installation is a water wash-up and non-toxic. Any glue that comes through the perforation holes can be wiped up with a damp rag. Gluing and stitching pattern are shown in the next two pictures:

You now just work your way around the wheel, this probably takes close to 8-12 hours to do by hand (depending on stitching pattern chosen for your installation it can be achieved in 4-6 hours with an easier pattern). Each time you stitch from one side to the other, pull on the string hard to make the leather tight. Also as you work your way around the wheel, make sure that your pattern is straight.

Once the stitching is done, you are ready to put the back plate back on. Again, it is held on by 4 Philips screws. It helps to pinch the sides of each spoke cover on the backing piece as there are channels that it goes into below the leather.

It is a tight fit, but you want the leather to be under the cover as it will give it a more finished look. Finally once you screw the backing piece on, then you are ready to put back on the cruise and radio controls if equipped. You now have a nice looking wheel.

Repeat the process in reverse for installing the wheel. Abbreviated, you will push the red airbag plug and the flat black plug back through the rectangle hole in the steering wheel. Then the wheel goes onto the column, making sure it is in the same position as when you removed it. Clip down the black wire back into its holders where it was before, and then attach the wheel holder nut, and torque that nut to 43nm or 32 ft lb. Plug the red plug back into the airbag orienting it as it was at the start (if you did not note that, it is shown in the picture earlier in this write-up). Rotate the wheel 90 degrees as you did to remove the airbag screws, and taking your torx 30, and tighten the two bolts back down making sure not to cross-thread them. Go connect the battery, and personally I always sit in the passenger’s seat with ear protection on when I turn the key the first time, just in case!

Enjoy! J