You must be logged in to rate content!

4 minute read

Adjusting the timing on a 68 Continental

Compliments of Barry2952

Tools Needed:

Flathead Screwdriver

Vacuum Gage

I followed Pony Carb's instructions for fine tuning my newly rebuilt carb. It is a work of art. Too bad there's no clear air cleaners.

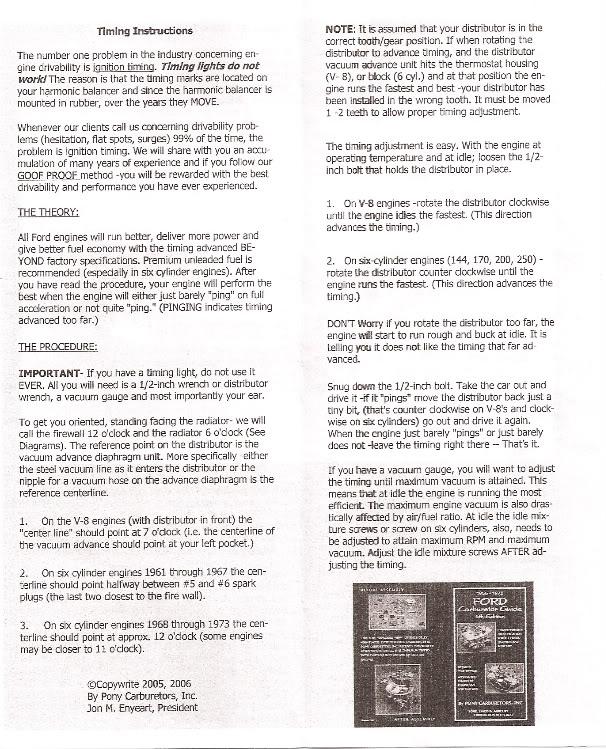

John, at Pony, was emphatic that I NOT use a timing light. He insisted that timing lights give false information due to the fact that the vibration damper, with the timing marks, can turn on the hub that's attached to crankshaft. The rubber insulator allow the outer section to turn, making the numbers meaningless.

It was explained to me that the best way to tune a carb is vacuum/rpm which is an indicator of peak efficiency.

Pony's instructions are listed below. After actually following the instructions (usually a last-ditch effort) the Mark II ran perfectly. I decided to test their instructions on the limo. First, the limo hasn't run in 3 years. Second, it ran horribly when it was parked.

I put the gas tank back in the car after letting the fuel line soak in acetone ovenight. Hooked up the gas line and tried to start the car. It chugged a few times before I noticed that the choke wasn't closed. Manual closure of the choke brought the car to life, but it ran badly and wouldn't idle at less than 1,000 rpm.

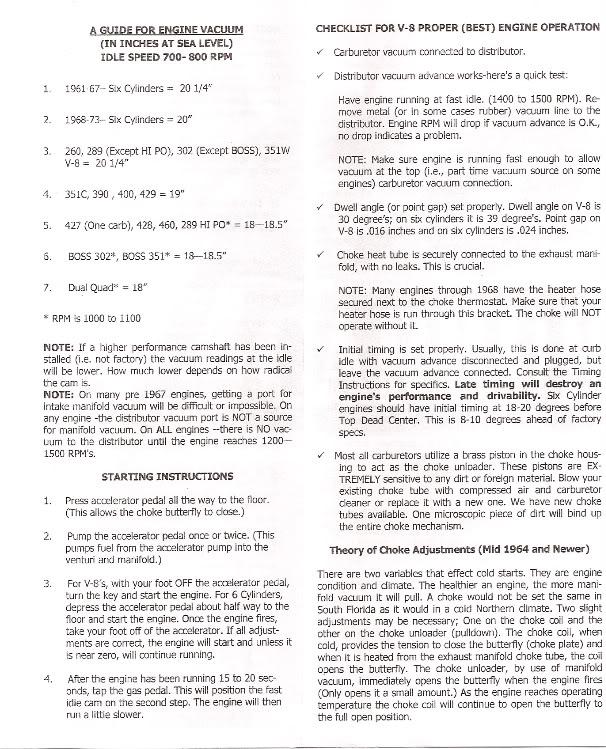

I used insuated spark plug pliers and pulled the boots off the spark plugs one at a time. There was no change when I pulled 3, 4, 5 and 6. That sounds more line a fuel problem so I stopped the engine and turned the idle adjustment screws to 1 1/2 turns as a starting point. At this point I hooked up the vacuum gauge to a manifold vacuum port.

I observed that there was a direct relationship to rpm and vacuum. I turned the screws in until the vacuum dropped and the ngine stumbled and then backed the screws out until maximum vacuum was attained. I found it much easier to discern visually what the vacuum level was over discerning by ear what the rpm are.

I then adjusted the timing, again to attain the highest rpm and vacuum. The engine vacuum crept up with each adjustment back and forth between the idle scres and the distributor. When I could no longer discern upward or downward vacuum or rpm I locked down the distributor and what was a bucking bronco became a docile thoroughbread just waiting to run.

With two vehicles that went through transformations I am convinced that they are correct. However, I just wanted to be sure so I hooked up a dwell tach. The dwell was right on and the idle was about 550 rpm, near stall, but not quite. I had started with 20 inches of vacuum and ended with 26. That's a sign of a healthy engine. The truth came with hooking up the timing light.

It's very difficult to capture a strobe picture, but I managed. You can see the white slash in both pictures. It shows the car running at 550 rpm at 30° BTC, which is not possible, and proves that the vibration damper on my car, in fact, both cars, had shifted.