You must be logged in to rate content!

87 minute(s) of a 464 minute read

9-26-2012

AFGMOTO1978 Build Thread

Compliments of afgmoto1978 @ www.rx7club.com

9-26-2012

Okay so if figured where I documented my build way back when wasn't where it should be. So here's a rehash of the build with a lot of the fat removed.

This build all started after having a very disappointing engine blow-up (motor three) at the track while running out of gas. lol

So what was going to be a basic build up became a five year and counting constant modification.

So enjoy!

4/3/06

"

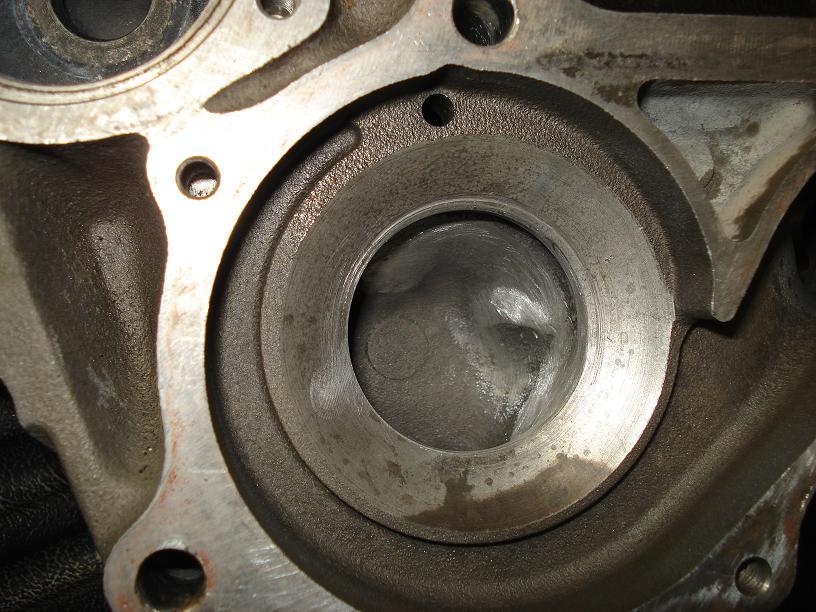

Well, the motors out of the car and at Pineapple for a rebuild. Damaged the rotor bearings by starving them for oil and then detonating on top of it when I ran out of gas at PIR. Hopefully that's the only major damage done to the engine. Apex seals a Ianetti's and they look fine.

Starting to strip the car for a proper paint job instead of the Matco Special I have on mine.

Just got my SSR Comp-H wheels (15lbs each) and V710 tires in last week too. (Miss these wheels and those were great tires)

Things to do/get still:

Raceshop four point cage

Delrin Bushing kit (in the mail)

AutoExe under chassis brace and front tower brace (didn't happen, Winter 2012 CF Underbody / Chassis reinforcement in the works, finances willing)

99 Spec plateless front end turn signals, Feed side skirts (In the Mail).

Datalogit for Power FC (In the Mail)

Apexi BOV (Send Check) (Not enough air flow, went with Synapse unit!)

Rebuild Efini's (lol)

Another BOV for Secondary Turbo that I can plum back into the intake track.

Fabricate Custom Y-Pipe

Either fabricate DIY air box or buy HKS Racing suction kit and replace the foams for

K&Ns (By the way foam does jack all for filtering - Apex "Hint Hint")

Custom DIY V-mount - I really don't like what's out there (no ones putting vibration/durability in mind and the end tanks are a joke) and I have access to a full machine shop so why not.

Decide if I want to modify the wiring harness so the battery and all relay/fuses are in the Passenger storage bin, or heat wrap what I have and call it good for now. Majorly time consuming. (Holy Crap I had no idea what a bitch this was going to be)

Modify stock seats, DIY upper to improve lateral support and still fit within cage.

Jesus, this going to be expense and time consuming. "

^So true, lol

4/13/06

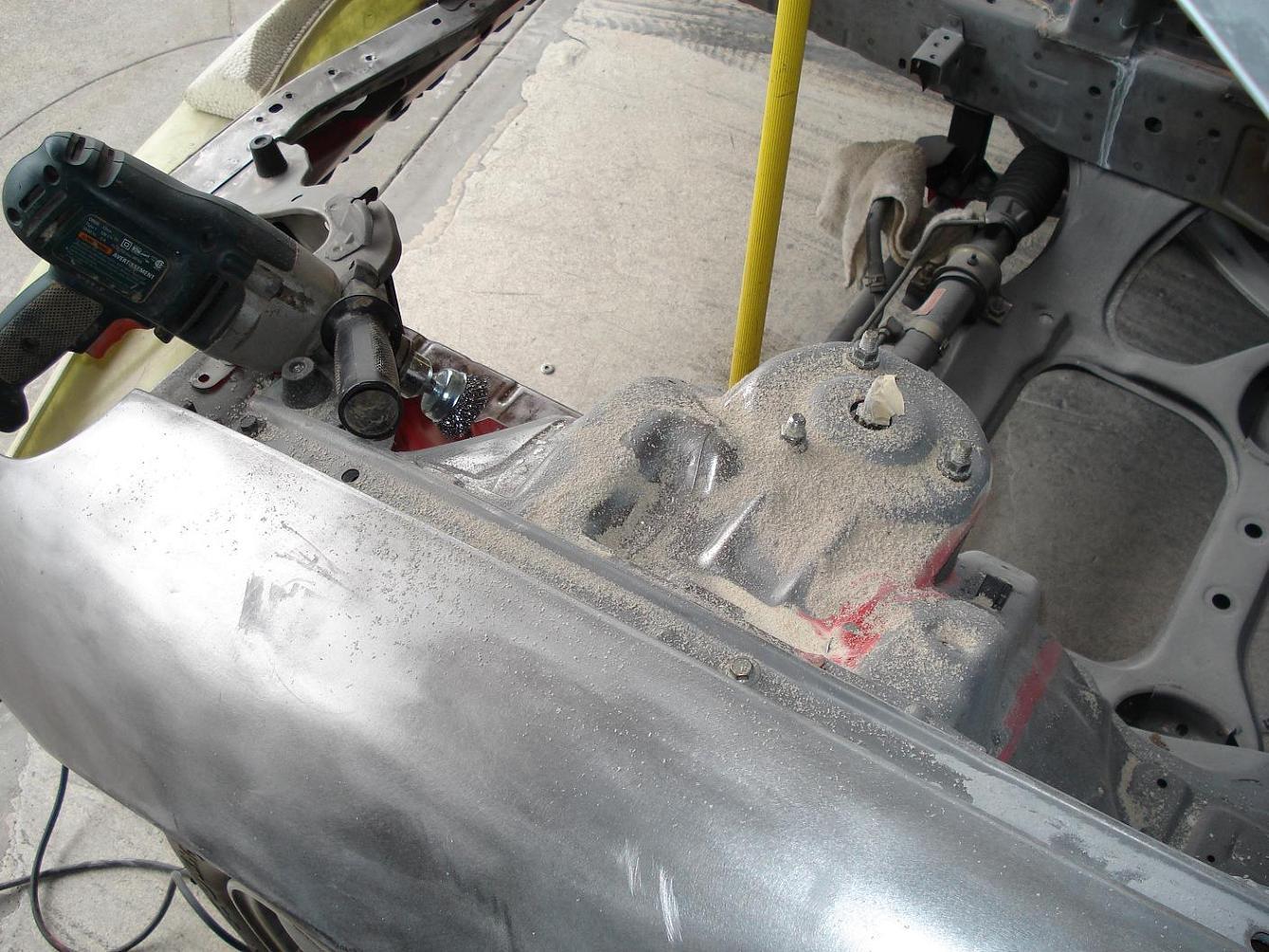

Oh ya this gonna cost me $$$$. Spun a bearing and broke a one piece ceramic apex seal.

Enjoy in my pain. Pan'n for gold are ya.

Yaaaa, I wanna go to Hawaii!! Yaaaa

This is still depressing to look at even after 6 years have past.

I'm smiling, but I'm crying inside.

Dude, can I use your shop....

Apex...sure (Damnit, another dead beat in my shop)

Without this guy cartapex aka John Farris letting me use his shop and being patient for 4 years while building my car it would have never happened.

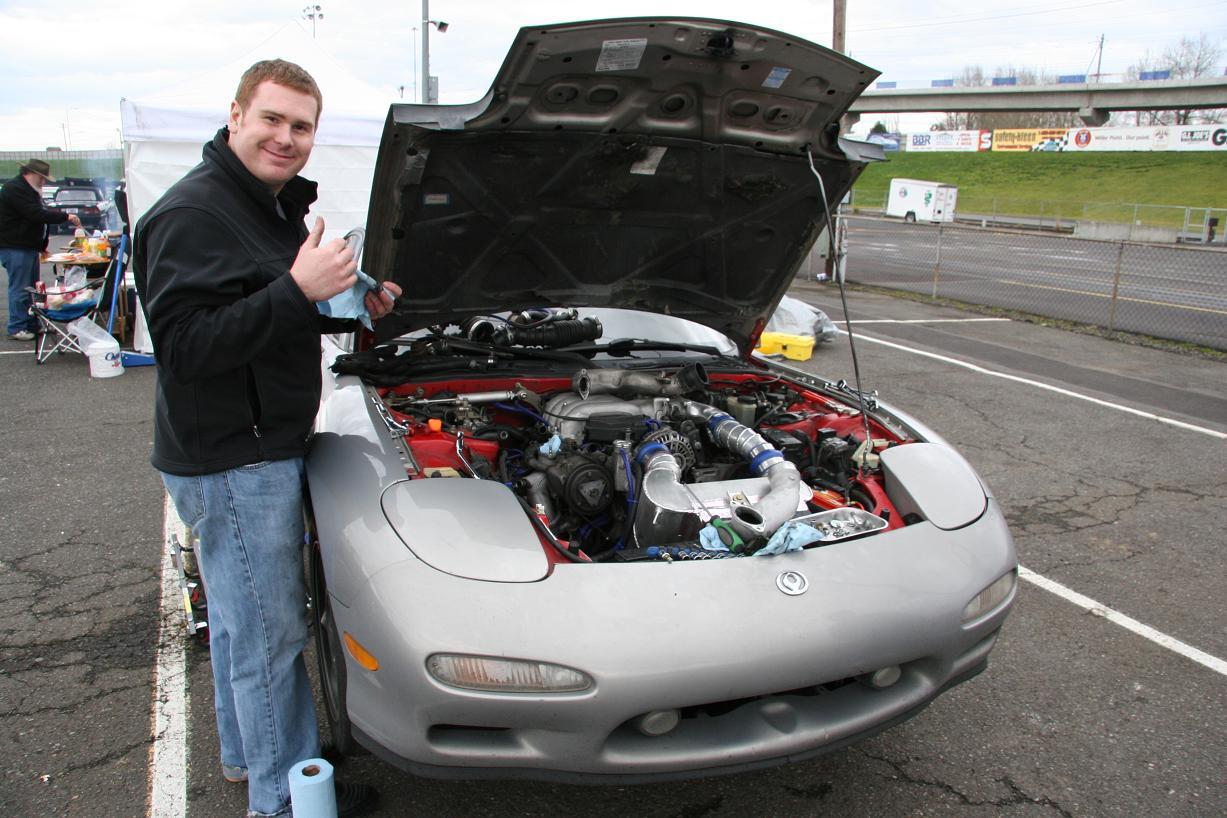

Photos of my car the day I blew the motor.

Well found some front end damage repair work on the right front. Whoever did it wasn't very good. Going to have to buy a replacement piece from Mazda and weld it on.

Soda blasting the chassis next week!! Soda Blaster guy is going to pick up the car Monday.

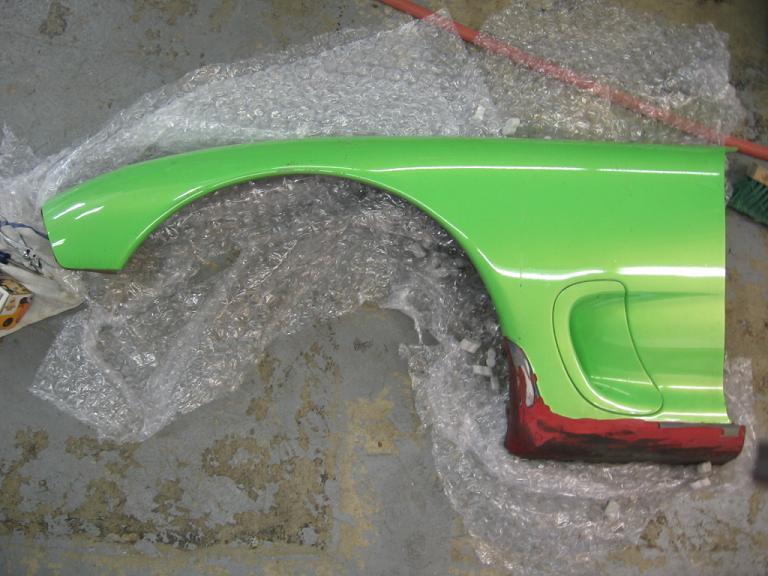

Got the fender that I won off of ebay; opened the package and I was like...WTF?! That's a green fender.

This picture of the interior shows how cheap my old paint job was.

Fender damage, going to have the body shop check if the chassis is even straight.

4/22/06

Well got more of the car apart, found 7 dolla in change, mostly pennies. Half of them embedded in the sound deadening or cough drop syrup. Found a few grapes and the carpet was wet with what must be 9 year old water. ewww

Dad is formally forbidden to have cough drops or grapes in the car as of now. Will get new carpet from the GB going on, will get black. Order a factory replacement that took 10 months to get.

Okay pics:

Even without the motor the 7's got POWA!

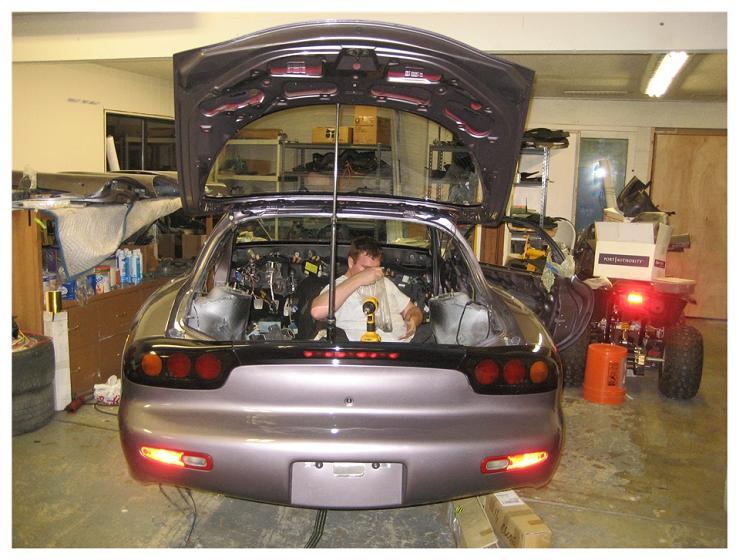

What the back of the dash looks like and the HVAC unit, which is pretty simple.

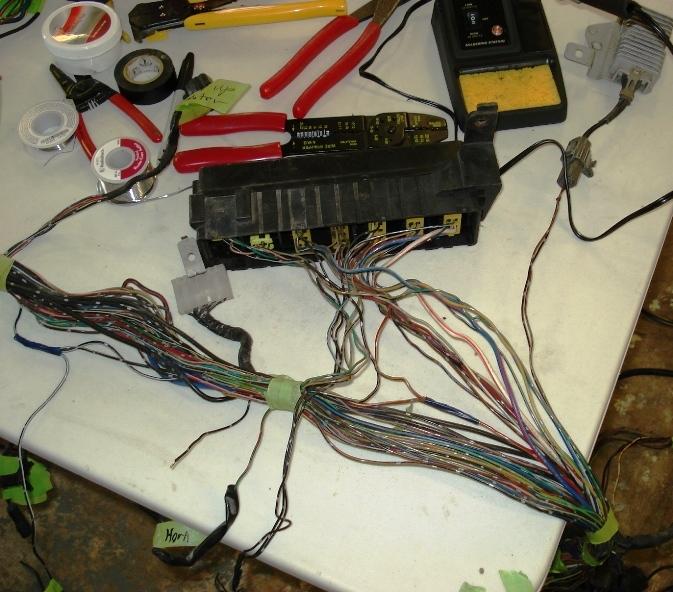

Long *** engine harness that weighs 30 lbs.

And last, the yummy stuff found under the carpet.

4/29/06

Update, got the car back from the soda blaster. He did a pretty good job, missed a few things but all in all a good job. Wish I had acid dipped this car actually

Prep and bondo now

Speaking of bondo, I have some unexpected bondo on the driver side rear corner panel. I knew about the bondo on the passenger door. Remove and clean up for new stuff. Hoping the DR rear panel isn't fawked up too bad. Will find out tomorrow

Bodywork turned out to be a majorly long drawn out ordeal - knowing what I know now I would have paid some one to do it.

5/7/06

Found more bondo on the driver & passenger side under paneling. Did some more paint removal, two more days of this and a frame straightening and it will be ready for new bondo and primer/sealer.

I found out my car has a cocaine problem!

Good news, all my one piece ceramic apex seals are good except for the broken one. So, I only have to buy one replacement and a shyte load of other stuff tonight. Yaaa, I need a second Job, Yaaaa.

N3y2-10-s80 - Housing, Rotor - Rear $529.25 $529.25

1881-11-404 - Seal,oil $1.45 $1.45

N326-11-d03 - Bearing, Pilot $6.00 $6.00

Nf01-11-d54 - Bearing,needle $17.70 $17.70

Nf01-11-d53 - Washer,thrust $5.60 $5.60

N3a1-11-d00 - Shaft $341.40 $341.40

4352-11-363 - Spring, Rear Outer Oil Seal $3.35 $6.70

4352-11-353 - Spring, Oil Seal - Front Outer $3.35 $6.70

1202-11-343 - O-ring, Outer Oil Control $13.00 $52.00

0820-11-341 - O-ring, Inner Oil Seal $6.70 $26.80

Nf01-11-c17 - Spring, Side Seal $4.30 $51.60

4801-10-502 - Bearing, Competition Main $76.40 $76.40

4801-11-111 - Bearing, Competition Rotor $86.05 $172.10

Nf01-11-c24 - Spring,corner Seal $1.85 $22.20

8871-23-180 - Seal Set $54.30 $217.20

N3a1-10-507 - Seal, Front Main Oil $6.35 $6.35

1668-10-556a - Seal,oil $6.60 $6.60

Fd01-56-191a - Protector,pipe $10.35 $10.35

Fd01-43-860e - Insulator,master Vac $52.50 $52.50

B455-32-279 - $5.05 $10.10

P043-27-238 - $4.65 $9.30

P011-25-123 - $2.30 $9.20

1368-25-124 - $1.85 $7.40

E016-50-796 - $1.35 $2.70

G225-51-274b - Lens, License Lamp $4.00 $4.00

G225-51-273 - Gasket $2.05 $2.05

Ea04-51-146a - - $0.95 $0.95

Fd01-50-6g0b - Rr Window Mould $67.45 $67.45

Fd01-50-6ax - Mldg Up, Frt Wndw $44.25 $44.25

Fd01-34-313 - Ball Joint Boot $8.70 $17.40

Fd01-34-213 - Boot, Ball $9.00 $18.00

Fd01-59-821 - W/strip Lt $33.95 $33.95

Fd01-58-821 - W/strip Rt $33.95 $33.95

B455-56-149 - $0.80 $12.80

Fd01-68-601b - Insulator, Hood $109.75 $109.75

Fd01-50-794a - Protector $8.00 $8.00

Ga7b-50-795 - Cap $1.35 $8.10

0118-56-242b - $0.65 $2.60

Fd01-50-640b - Mould Rt, Beltline $78.90 $78.90

Fd01-50-615 - Joint, B/wndw Mould $4.50 $4.50

Ea04-51-146a - - $0.95 $0.95

Fd01-51-674 - Clip $2.45 $2.45

Fd01-50-650d - Mould Lt, Beltline $78.90 $78.90

Fd01-50-619a - Clip $2.00 $2.00

Fd01-69-320c-02 - Sun Visor Lt $59.70 $59.70

Fd01-69-270c-02 - Sun Visor Rt $66.25 $66.25

Hg31-69-220b - $56.10 $56.10

R504-17-470a - Case, Control $51.00 $51.00

Je11-40-355 - $3.40 $13.60

N326-14-151 - Chain $22.80 $22.80

$2,448.00, More to come later.

Pricing for new carpet is $1700 at the dealer, $910 from Mazdacomp. It's so worth it have a membership with them.

More body photos

5/25/06

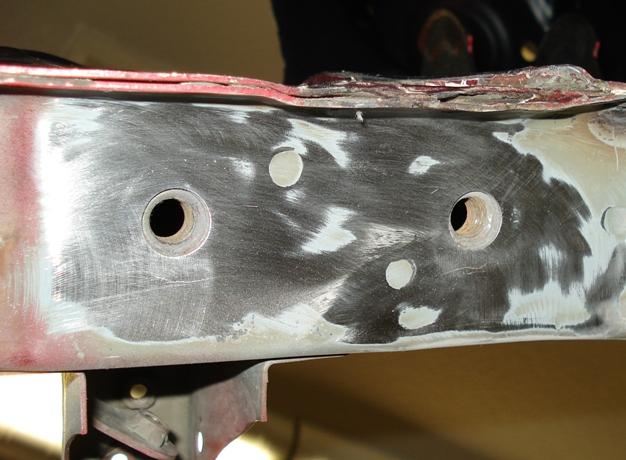

Alright! The car is finally at the frame straightener and he said the major parts of the chassis is on the money already. Just have to pull down the pressed in section under the driver side door and maybe a few small adjustments here and there.

Lookie lookie what I got in the mail today from Japan....99 Spec taillights!

Also got the paint, went with PPG Tungsten Gray Metallic, same paint color as the Mazda 6. Pretty similar to my bike and a lot easier to color match down the road in the event of an unfortunate fender bender with a tree. Came out to $827.15 for all material needed, got a 40% discount, thanks Industrial Paint Supply!

6/3/06

Okay, Got the car back from the frame straightening and they did a good job. Still need bondo under the driver side door, but not nearly as much. I added a pic of the damaged area for a frame of reference, sorry for the different view angles.

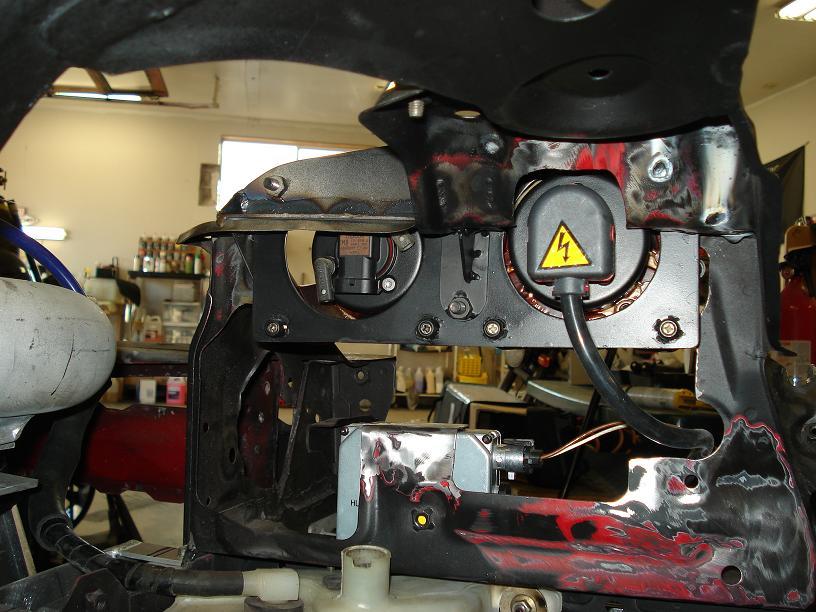

Got my Rotary Extreme sleek headlight kit in Thursday and they look sweet. Mounting for this kit was a total joke, decided to make my own framework.

I also got a free Mazda 323 last Wednesday. Man what a piece, but once I fix the things wrong with it, it will be an good commute/backup car. Thanks Apex for letting me use your Golf, you are truly a friend (notice the background advertising).

Started doing bondo today and will be doing tomorrow. (And the next twelve months) Having a DA saves a lot of time. Notice the amount of mud on the door, not sanded yet, but damn!

6/12/06

Started work on retrofitting the aluminum stiffening brackets from the stock front bumper the urethane 99 bumper. Some interesting details are in the pics. It will be interesting how well it fits up.

Got my motor back from Pineapple!! So pretty, so pretty. Another motor I miss

Got more bondo work done Yesterday. Started applying the skim coat before I left John's shop last night.

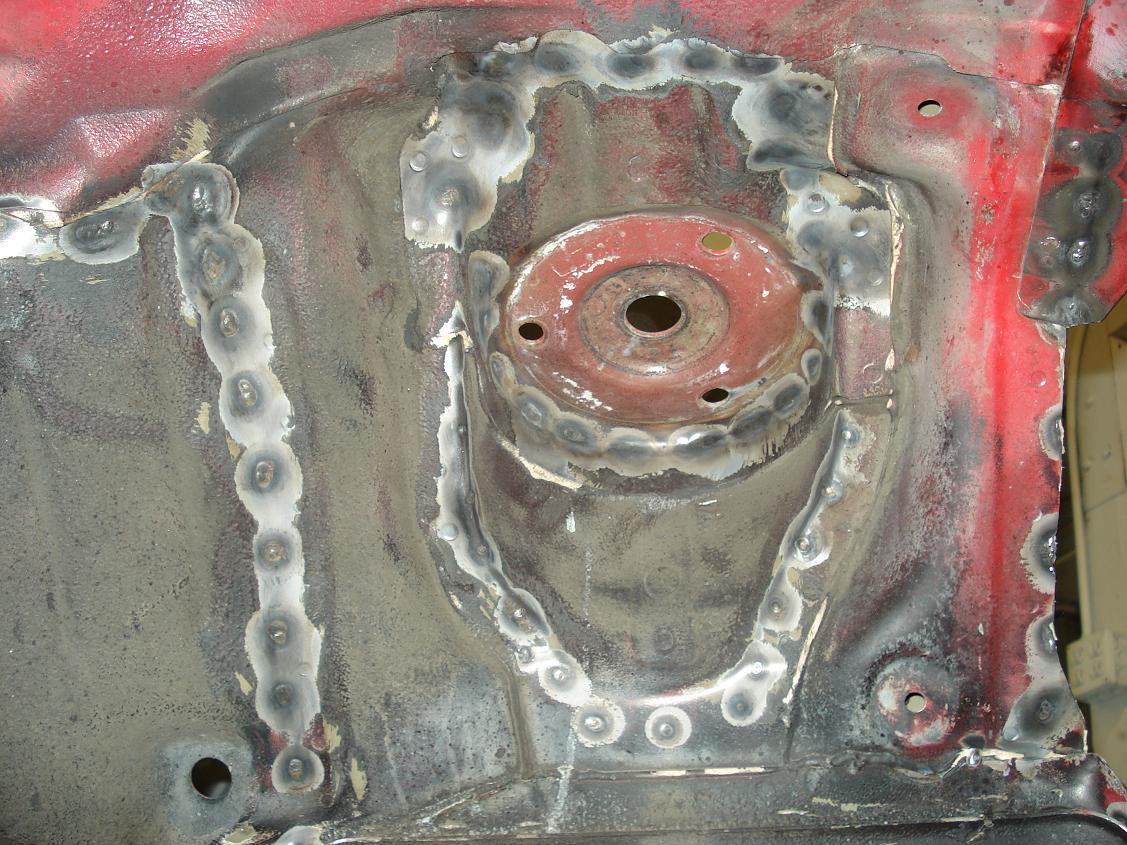

Started stripping the sealer in order to stitch weld some key areas. Not going to go all out and do the whole chassis. I know some of you may say "Why not?", but this car is a street car first, race car second. Who am I kidding, I'm an interior removal and eight point cage away from making it into a racecar. When I find a good R1/R2 chassis later down the road I will go all out and make it a race car. Had one, but traded it for another FD (Trying to sell it now)

6/20/06

Started stripping the sealer off the interior cabin yesterday and did some more today. Got 10lbs of dry ice after going to three different Baskin Robins. Put the ice on the sound deadening and chip it off once it got cold enough. What takes weeks to remove conventionally took about an hour and half to do with this method.

6/24/06

I spot welded instead of seam, for the simple fact that the welder John has doesn't give me enough control and power to make a really good weld. So spot welding it is, I will see noticable gains in rigidity, but not nearly as much as if I did 1" stitches. Which may be a good thing since this is a street car primarily.

Stopped welding because I was sweating ***** with the welding gear on in the 90 degree heat today and started fitting up the front bumper. I need to massage some areas which was expected since this is a nok-off. It will look good when it's finished though.

Fitted up the bumper, cleco made the job a lot easier. I still have a low point at the center between the bumper - hood transition, but it's an easy adjustment.

Will be finishing "spot" welding the chassis and bondo throughout the week so I can paint it next weekend.

The glass guy is finally coming down to look at it Monday.

7/1/06

Finally got the bumper fitted and I got it pretty lined up considering it isn't an OE bumper. Got it sanded down for paint too. Removed the front windshield and found some rust.

7/4/06

Well, finished spot welding the chassis and put new 3M seam sealer on the interior cabin. I also finished the bondo. Rolled it over to the paint area to start the process of paint. Was able to get the interior painted, but Tyler the painter found out that the definition of Etching primer was lost in translation between PPG and the rest of the paint manufacturers out there. PPG's etching primer is an adhesive promoter and etching primer to other manufacturers is just that etching primer, something you can sand to find the unseen/unfelt low spots in the body. So here's my baby all prep and ready to get her first layer on and the tailor has the wrong fabric. ****!!

This turned out to be totally untrue, but it didn't matter. I used the wrong bondo in the end and had to redo everything. God I hate bodywork.

7/16/06

To remove baking soda off a metal body you have to spray vinegar on the car...Instant surface rust especially were the bondo was!

8/15/12

Well, I'm back where I was when I was about to paint. Did everything right this time around, metal prep, type of bondo, etc.. It look a 1/5 of the time this time around. Hopefully by the end of this month I should have some paint on her. I did some organizing of parts while I was at it. man do I have a lot stuff for this car!

Alright, after looking at it, applying bondo the the rocker panel would be a bad idea considering how many times this car will be jacked up to change tires in the future, so I re-sealed and will be sanding the extra once dry to get a smooth transition. Final sanding of bondo now, paint is getting close.

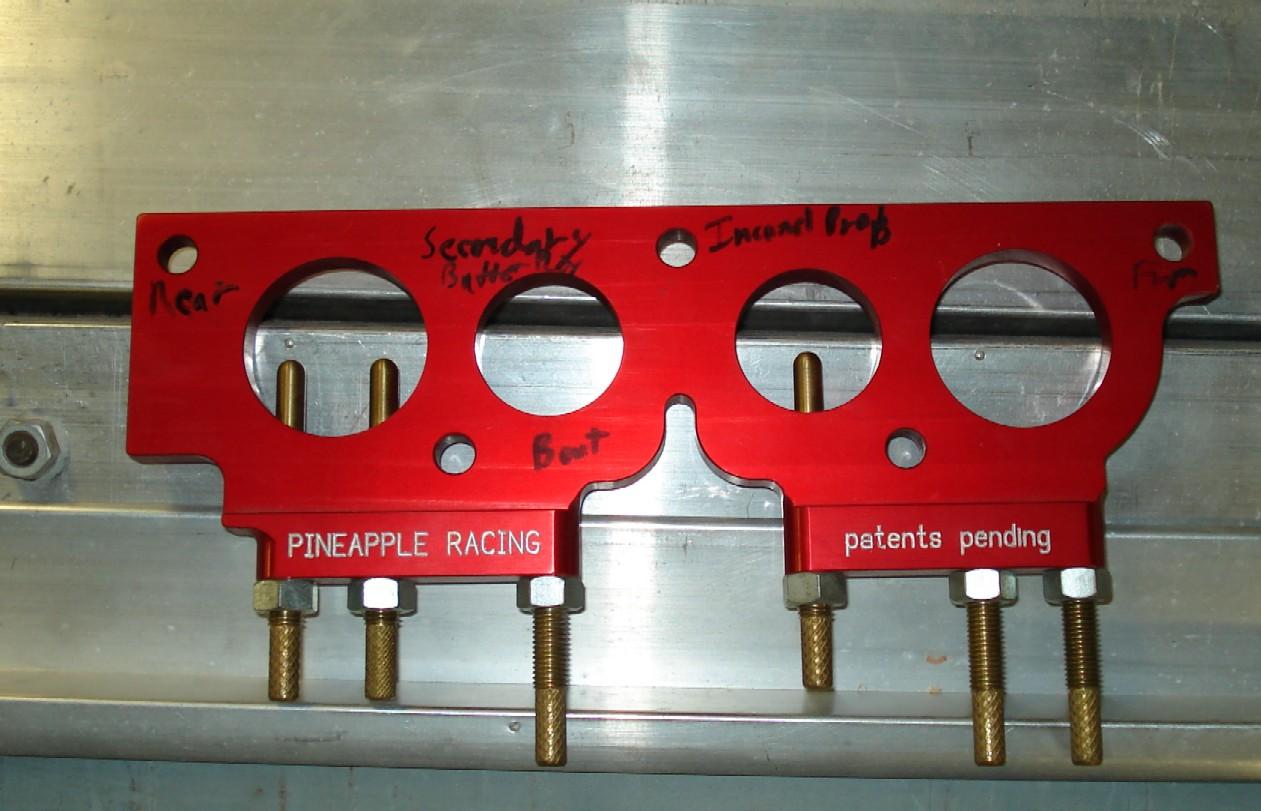

I attached some pics of parts I got recently from Pineapple. Air pump elimination idler wheel and twin exhaust temp kit. Idler wheel is the ****, egt kit not so much.

8-23-2006

Whole lotta sanding

Here's another goody from Pineapple....Intake Air Flow Balancer. From this unit Rob say's you can balance the front/rear intake track air flow, which it isn't in stock config. One piece to the equation why the rear runs leaner than the front. You tune it by using the exhaust temp at the marker. Hence I recently purchased their exhaust temp setup. Interesting concept, never used it.

8/29/06

So last weekend was interesting, had three FDs in the garage getting work done on them.

I finished sanding the first main layer and applied glazing on my car, then worked on Vince H. 94 31K FD.

9-1-2006

I dropped the fuel tank today and will be fab'n up an internal swirl tank, that way it's in a protected environment and isn't in the way or visible. "Why no officer that's not a swirl tank in my cabin without any fire safety barrier, it's a water injection tank...ya, water injection tank.....what's that in the corner, my water injection tank, Doh! Never got around to doing this for myself, but did do it to two other tanks for other people, one day I will get around to doing it.

I got my Nardi steering wheel today too, I trying to decide if I want to Mod it and make it a D wheel or just leave as it is.

9/3/06

Spyder dropped off his new TIG welder so I could properly finished welding my front end. I finished spot welding today and started resealing. Need to do the under body now since I burn through the undercoat where ever I welded. The welds weren't all that pretty since I was welding over all the welding done previously with the 110 MIG. I did it to get better penetration into the sheet metal. Sanding, sealing and paint prep tomorrow and the first layer will be put on later this week! Yeeesss, sweeet.

Disclaimer - My welding has improved considerably since then.

9-22-2006

Got all the Delrin suspension bushings pressed in except for the trailing link bushings. Trying to decide whether to retain the RE trailing arms I have or put the stock units in. (Put the stock unit in) I had to machine a custom press tool for remove and install some pieces. Good stuff.

I opted to not put zerks on because it would have provided negligible gains in maintenance. I was total wrong, ended up putting them on and glad I did it. I will have to remove all the suspension at least once a year to check wear anyways. Yeah right! Haha Another reason is only two or maybe three piece I could actually do it on; all others would have had clearance issues. Wrong again

It will be interesting to see the pros and cons of this setup both at the track and public roads. Track...Awesome, Public Roads..No so much, my car is vibrating itself apart. Holding a conversion with someone is hard too.

9-23-2006

Alright got the Trailing arm bushing pressed in, but still trying to decide on which set to use. I also got some new goodies from Adrenaline Racing Adrenaline Racing | Your online performance parts portal, Tein EDFC version 2.0 and Tein hood dampeners.

While getting the underbody cleanup I noticed that the drive side sway bar mount had a few cracks, unfortunately it can't be fixed with a weld and grind. Total wrong, fixed it later down the road. This was caused by the stock sway bar mount being hit by a large rock a long time ago...man that was a long time ago...anyways I have an upgraded mount that tied into the engine cradle with a cross bar so this crack although not ideal isn't a show stopper.

The more you look at a car the more you find wrong with it.

9-24-2006

Finished sealing and painting the under body, cleaned up the suspension frames and installed the front engine cradle in order to attach all frontend plastics to finish the body work, looking good.

10/6/06

Finished stripping Brake caliper and applied the first coat of paint. Waste of time went to a BBK. Also got my Tein Flex's back from being rebuilt and all put back together.

10-9-2006

Started the process of putting the motor and tranny together for mockup time. The way things are turning out I going to do mockup before any paint gets layed on the body.

11-25-2006

I finally got my carpet that's been on back order for 9 months now. Directly from Japan. Glad I waited, fitment is OEM.

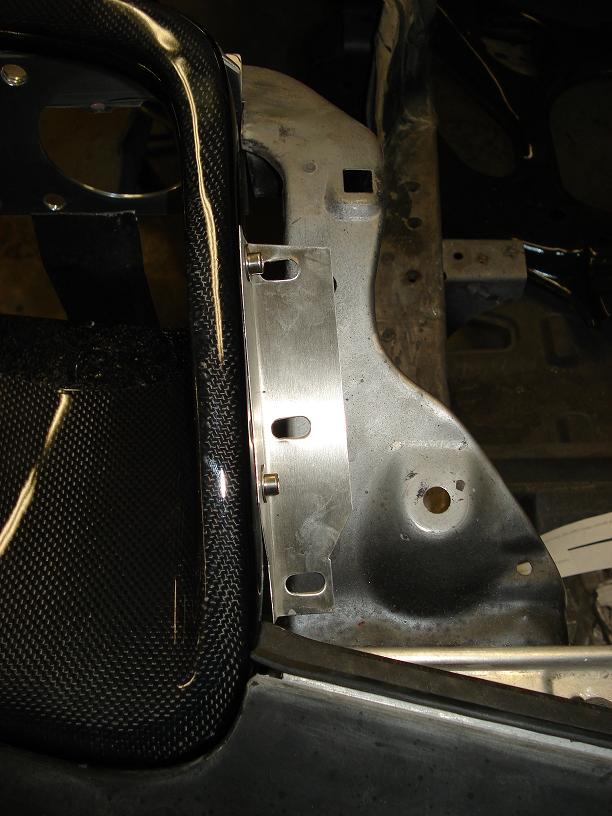

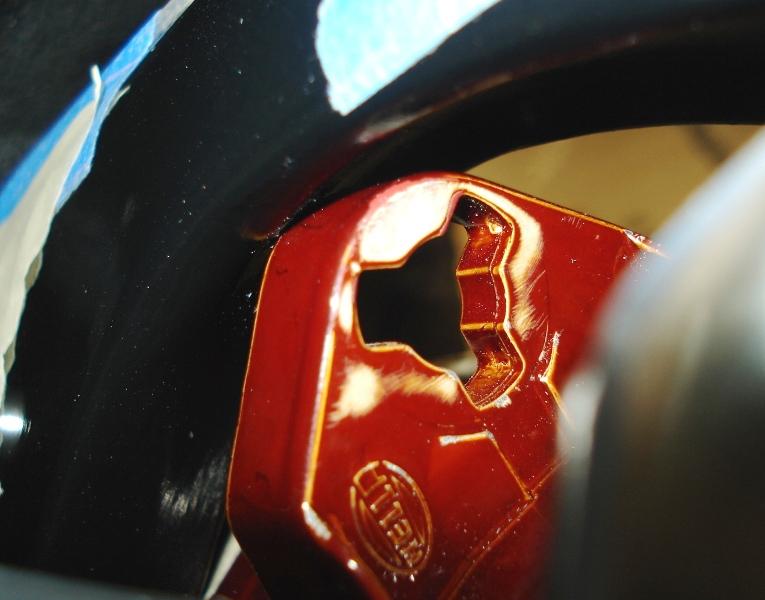

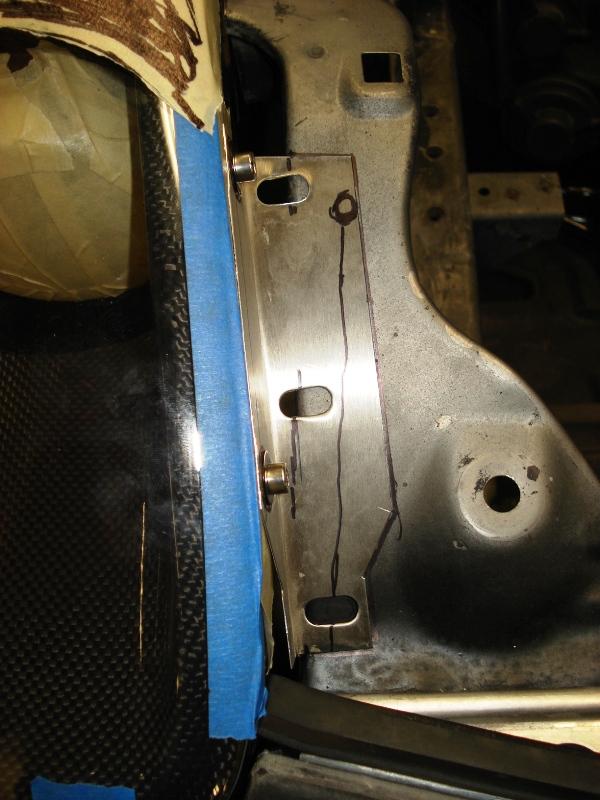

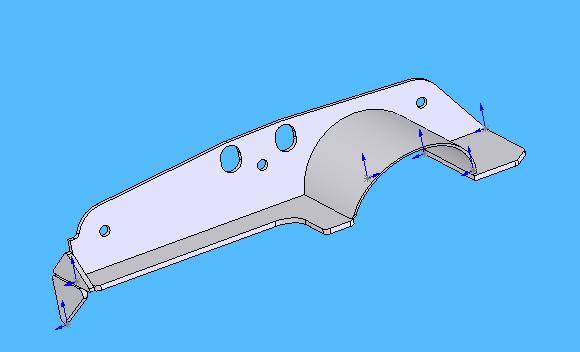

Started fitting up the RE flushmount headlight kit. Some missalignment issues with mounting plates, missing lexan lens and headlight adjuster springs shut me down. Some areas in this design could be improved (and will be), but overall an okay kit. Instead of going with the RE spring bolt adjuster combo, I ordered the specific adjusters for these head lights at: http://www.rallylights.com/hella/90mm_modules.asp. $60+ bucks, but adjustment will be a lot easier and the headlights won't eventually move on you like the bolt spring combo will. After looking at the plates and how they tie into the chassis, I'm going to create my own out of stainless and tie into at least two more points on the chassis to give it more rigidity and durability. I know overkill, but that's me.

Since I'm sooooooo far behind, I plan on spending at least a few hours every day to get things rolling again. LOL

12-11-2006

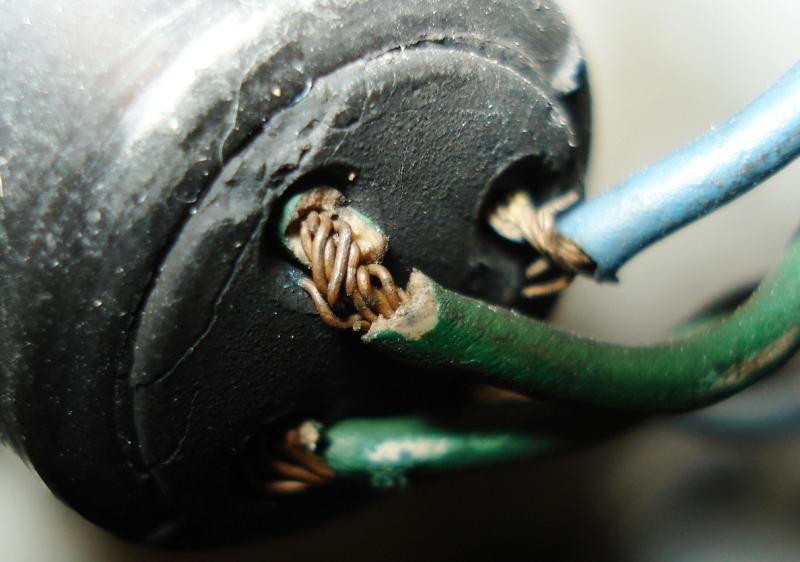

Well this last week was productive at work (60 hours), but thoroughly frustrating working on the car. Broke the wires on a switch on the tranny, broke a stud on the exhaust manifold, broke an easy out in the process of trying to get it out, not having the drill bits need to install my EGT probes, the list goes on.

Anyways, the lesson for today boys and girls is if you ever do something like this, make damn sure you separate and bag all your hardware if you don't you will waste countless hours trying to find that special 10mm nut you need.

Whatever you do don't do what I did with the following egt probe sensor location. EGTs in this location are well beyond 1000C and will burnout your probe in no time.

12/12/06

Alright, got the busted stud out; had to mill out the remnants, I wouldn't recommend breaking one of them.

Also got the EGT probes in place.

Whatever you do don't do what I did with the following egt probe sensor location. EGTs in this location are well beyond 1000C and will burnout your probe in no time.

12-15-2006

Got the hub out of the upright finally, had to buy a separator. However, I have yet to get the stubborn half shaft out of the other upright/hub assembly.

12/22/06

**** it! Okay the stubborn half shaft is finally out only after death wheeling the CV hub off (band saw was a futile attempt) and then putting 45 tons of press force with a solid footing. Only then, was able to get it off.

So new bearings and retaining clips are in place, getting new 10mm longer than stock wheel studs today and at least the rear hubs and uprights will be all together and ready to be used today.

12-24-2006

Ported the turbo wastegate ports and such. I left 2mm of overlap on the wastegate per Pineapple Rob's recommendations. Checked the turbos and they look okay.

12-29-2006

Alright, got the motor, tranny and my Mazdaspeed power plant frame in and ready for all my custom fab work. I got a Koyo Rad and a Greddy RS Recirc BOV for the secondary turbo for bypass duties Thursday. I got this stuff at Speed Concepts off of TV Highway; they can get just about anything you want aftermarket-wise.

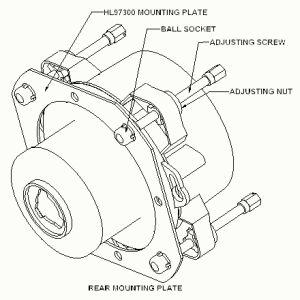

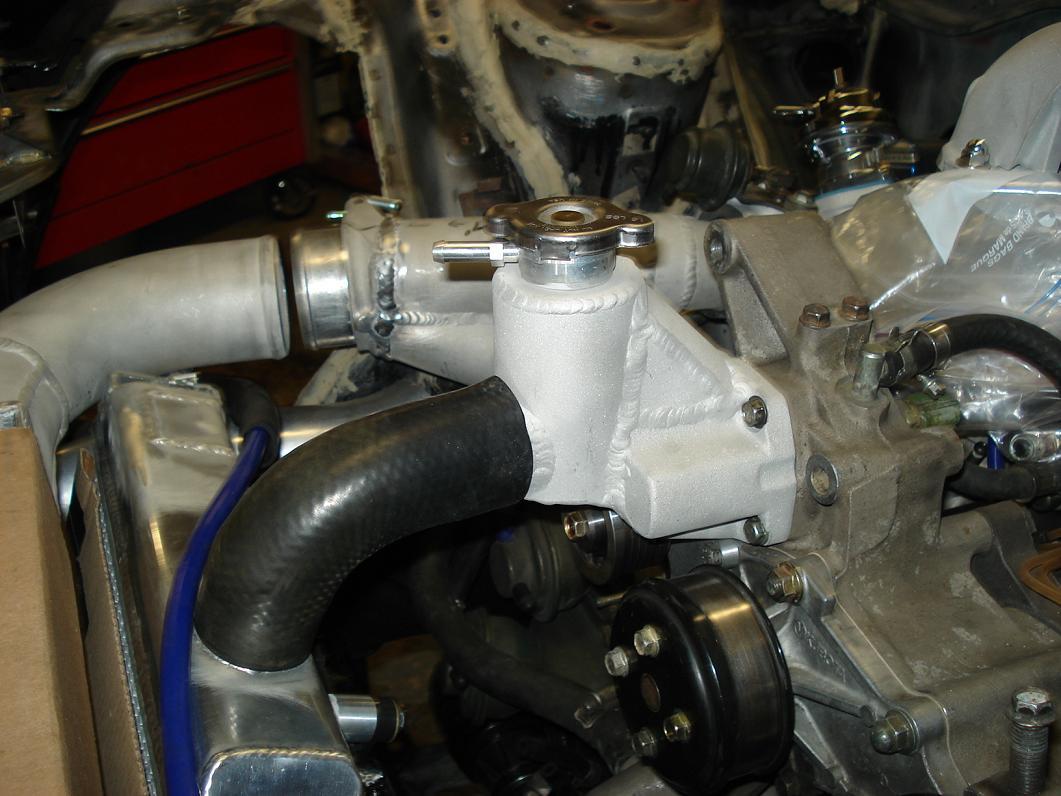

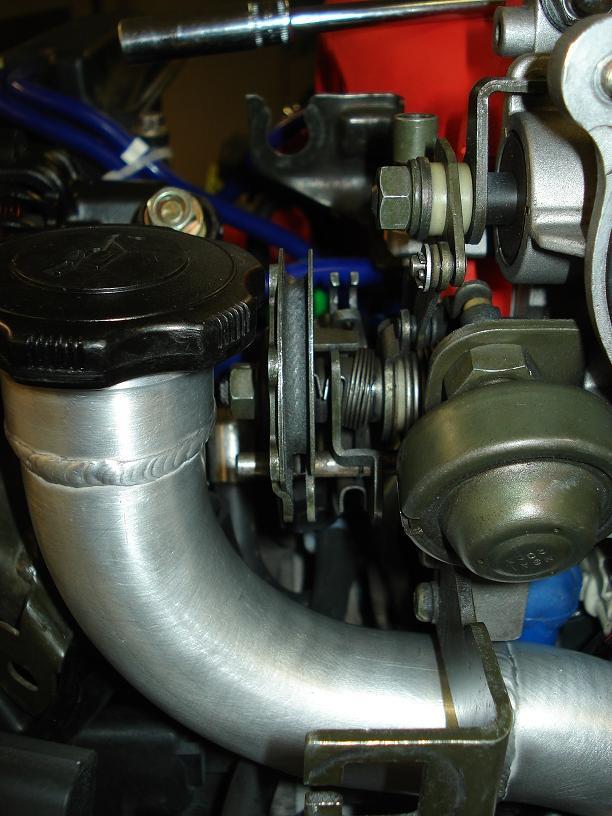

I have the Pineapple Idler Wheel kit installed for the air pump relocation, this idler wheel prevents the water pump wheel from skipping when the air pump is removed.

I will be reusing my Spearco bar & plate IC I already have for the twins and will upgrade to a larger unit when I go single next year.

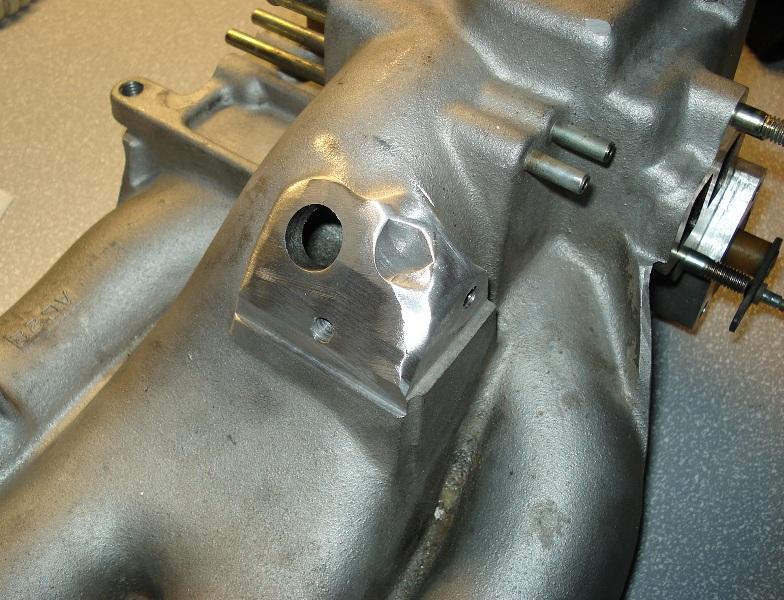

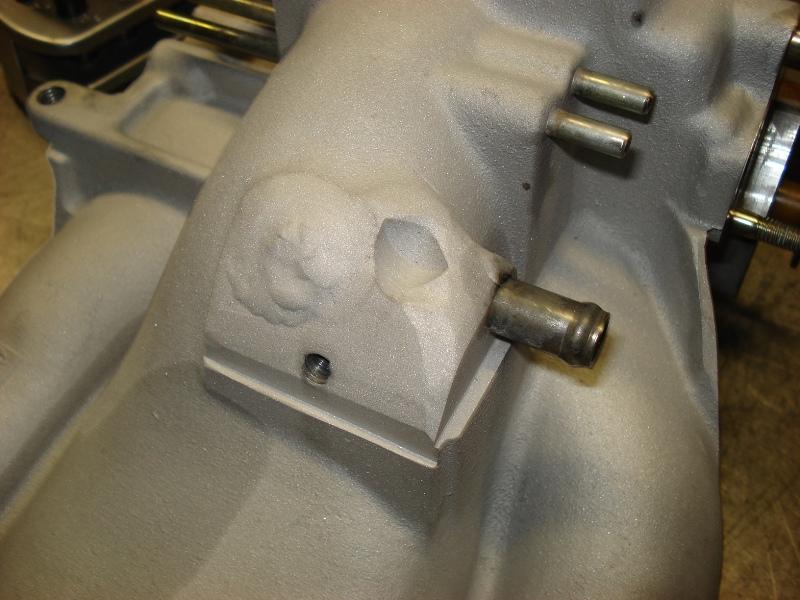

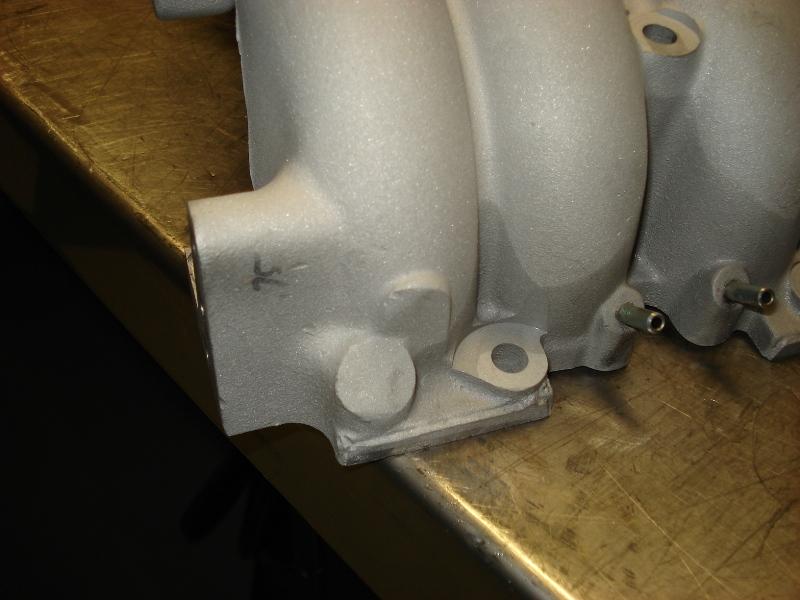

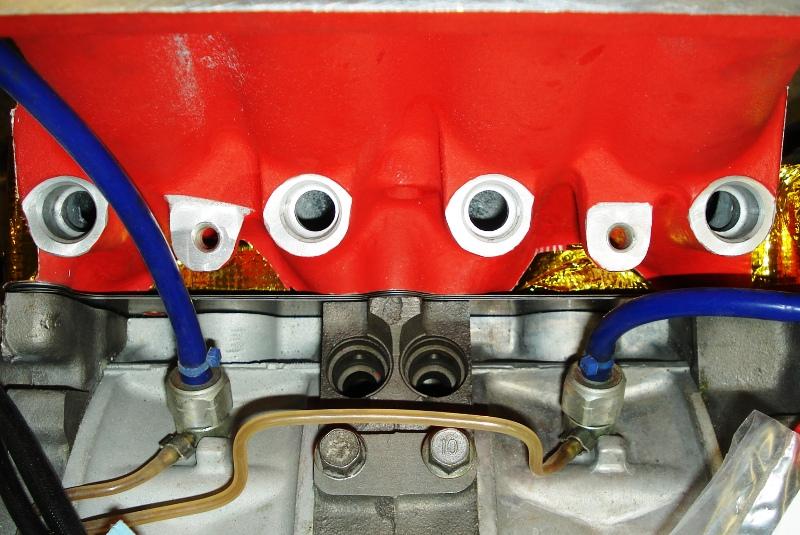

I'm also in the process of mod'n the UIM by relocating the brake booster vacuum plug from the rear secondary port location to the -20deg idle control valve mounting location. Granted both front and rear rotors will be affected now, but it will be equally affected, which in theory should aid in getting a closer AFR ratio between the front & rear.

If some of you were wondering the reasoning; Mazda put it there because of it's proximity to a RHD brake booster. That's all great for RHD, but its a stupid location for a LHD setup with that long *** air line across the firewall. This setup should clean that up nicely, which will make room for my new strut tower bar I will be making too.

1-2-2007

Alright, relocated the brake booster bung. Had to fab up a special tool for an air hammer to get it out and in the new location. Plugged up holes and sand blasted it; it will be ceramic coated later.

1-4-2007

Got the stainless head light plates done and the Hella light mounting holes are just off (1/16), doh! Anyways I was at least able to start proper mockup. Overall fit up is pretty good, but I need to remake the headlight plates, cut off the unused ear on the high beam lamps to clear the housing, make some custom support plates to properly support the front of the covers for high speeds, remake the existing cover support brackets. Basically everything except the housing and lens! Put some tape on the lens to get an idea of how much I would want painted black.

1-19-2007

after getting the sleek headlight kit all properly fitted up with the new headlight bracket I made, the bulbs are finally in full view (the marker lines show how much of the lens was blocked with original setup). However, I didn't like how little material was left on the remained headlight structure so I've been redesigning and fabricating a welded structure that I should be finished fabricating today and have it welded on the chassis tomorrow.

1-22-2007

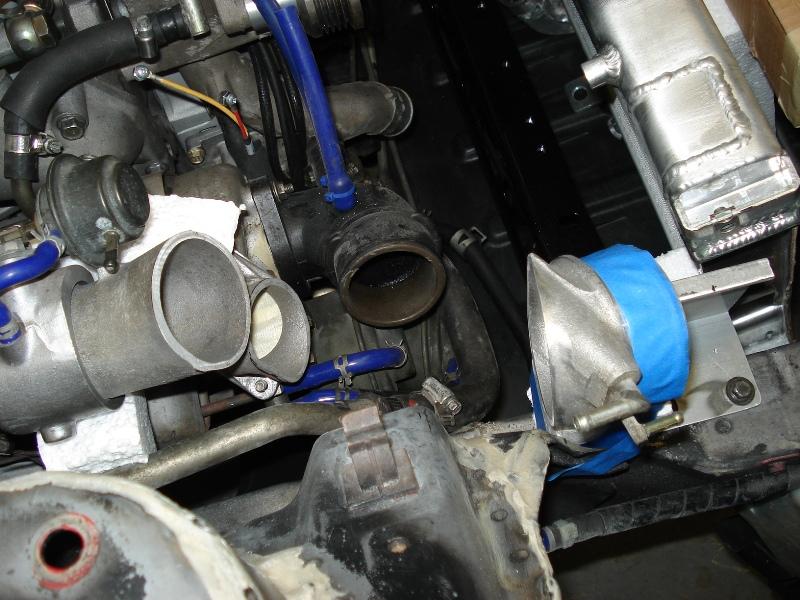

Got the new headlight frame all welded in and it turned out pretty good, nice and solid. I still need to add a gusset to support the bottom of the headlight panel, but other than that, Im there. Also started playing around with the turbo ducting and how Im going to join the two turbos, the picture will give you an idea of the direction Im going. Also I plan on having the bypass valve (Greddy BOV) on the secondary plum back in to the intake serpentine tube.

Alright stopping point more updates tomorrow.

1-27-2007

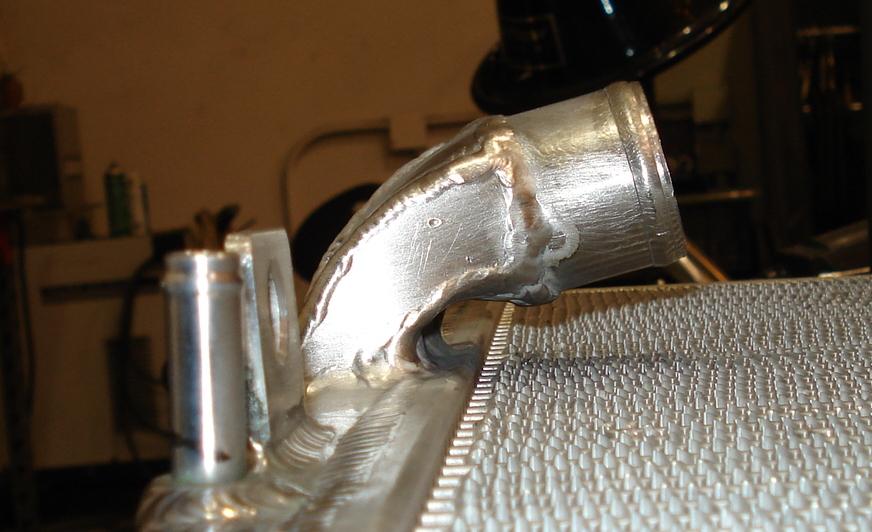

Alright, got the headlight shroud mounting plates done, looks nicer than what came with the kit. Also, I finally got my IC core and proceeded making the end tank for the turbo side and welded it on once I welded and smoothed out the internal seams.

Tomorrow I will modify my Greddy elbow to the configuration I want it to be (wish I could get the HKS elbow (Still do) that comes with their v-mount kit, but oh well). I also started fab'n up the twin turbo connection tubes. Hope to get that done tomorrow too.

1-29-2007

Got most of the routing for the twin turbos done, just need to cut a section for the secondary tubing. Currently have it all tack'd up to confirm everything lines up. I also have the intake side IC endtank started, but need to wait for some 3" tubing to finish the routing before I finish it. I started on modifying the greddy elbow too, but didn't like the direction I was going....need to put more thought into that. Man, I tired.

Oh, I also got some Mackin industries 20mm longer than stock wheel studs.

2-4-2007

Alright, got the IC and ducting done. The Secondary turbo BOV is in, just need to finish welding in the recirc tubing. The throttle body end tank is a bit frankensteinish, but it will work great. Trying to decide if I want to weld on the Tial BOV on the throttle body end tank or at the cold side end tank of the IC.

I need to get the rad fan I want and I should have all the mounting done by end of week. I still need to do the oil cooler mounting, waiting for some fittings before I go further on that. Making progress.

I'm also trying to decide if I want to mod the hood so it's vented. A lot of work, but it would be functional and bad ass at the same time.......

2-12-2007

Okay, so I fabd up a mount for the Radiator and I didnt like how it turned out so Im redoing it. However, I was able to put rivnuts on the driver side frame rail for the rad mount. FYI, if you ever use these things be sure to do a mockup on another piece with the same thickness to get the crimping settings right. These things are prone to spinning if not installed properly. On that note I added epoxy to the mix to further reduce that risk. If you look at the mockup panel I did you can see three different degrees of crimping, the center on is what you want to look for.

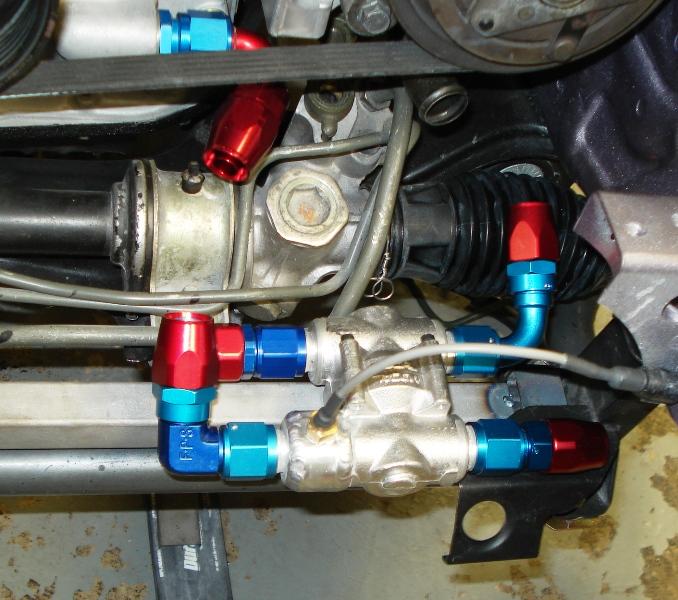

I also started playing around with the mounting location of the Mocal oil thermostat. I was hoping to utilize the stock inlet/outlet lines, but its not looking like that will work. I have to go buy more fitting for the twin oil cooler setup.

Tackd the headlight support tabs too, welding upside down isnt easy.

2/13/07

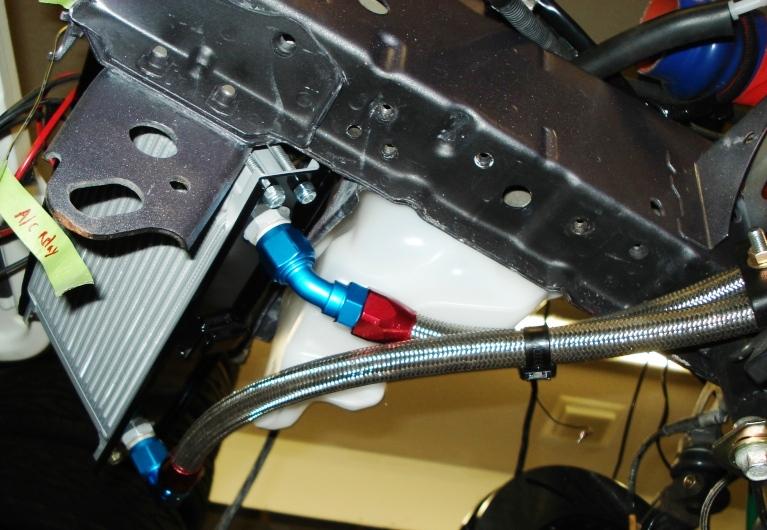

Got most of my oil line fittings so I went ahead and started playing around with the setup. Wish I had gone with Setrab oil coolers back then, would have save me a lot of trouble

2-25-2007

Today I got the water outlet tank done. I also have most of the oil cooler mounting pieces made, just need to weld everything together.

3/5/07

Finished the oil cooler mounting, need to get the oil thermostat tied in and then the hood vented. Should have gone with Setrab oil cooler from the beginning, would have saved me a lot of hassle.

3-19-2007

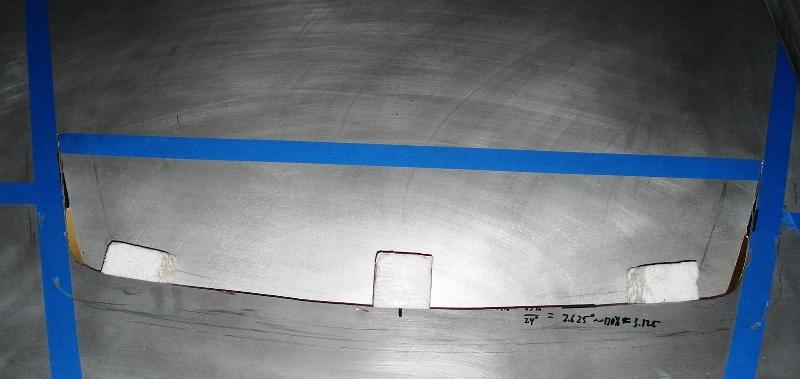

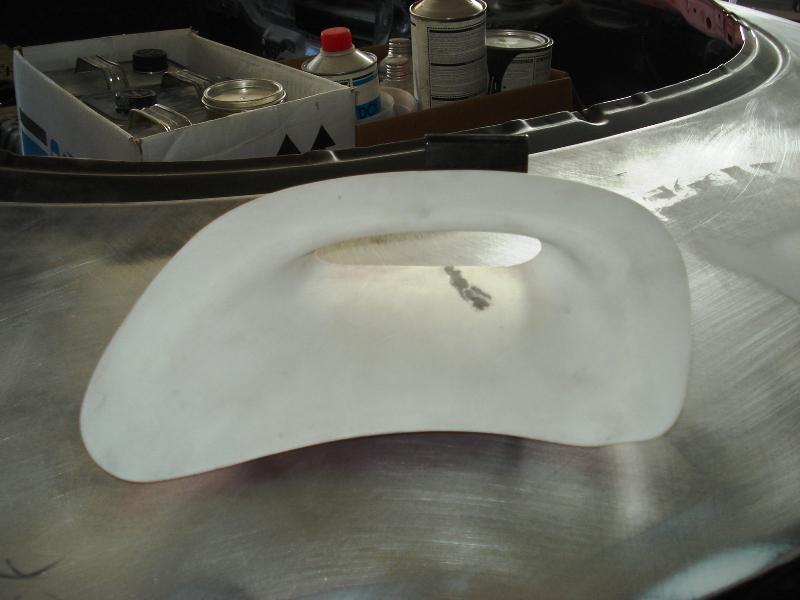

I was able to start on the modification of my hood. Need to cut out the support structure, form the lip and then weld on a new support structure. I also got a hood pin assembly and will be putting that in too.

3/26/07

Support structure off and planning on how I will make the new support structure.

3/27/07

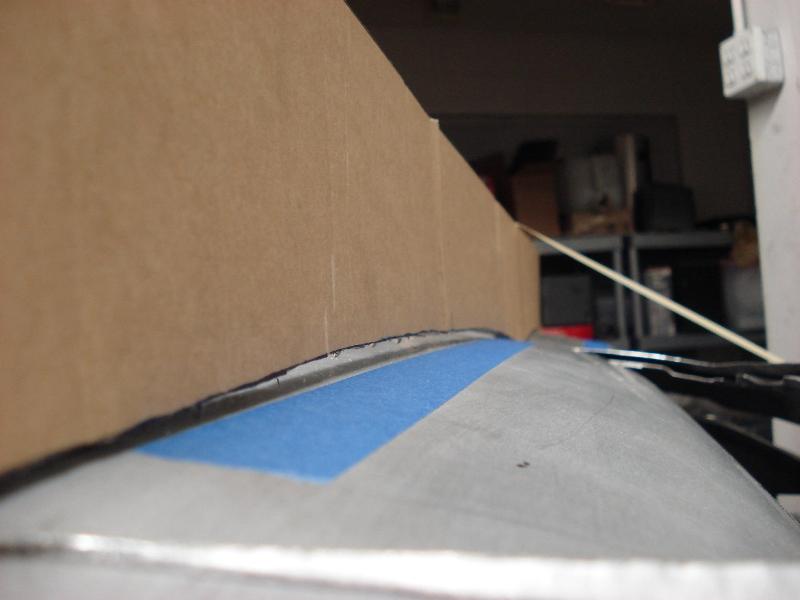

Started the process of forming the front lip and made a template of the curvature I need to follow for the support structure. Will be making a support frame before I finish the top surface. Need to remove the exposed support frame under the new lip now.

3-30-2007

Framework being laid out on the hood.

4/1/07

Got the HID ballast mount & headlight mounting done and some of the framework for the hood done. Also Plugged up the radio antenna hole, bondo next.

4-2-2007

Alright the frame for the hood is mostly done, just need to make closeout panels and a few other things to finish it. Turning out pretty good, not perfect, but that's to be expected without a jig. This hood will need a lot of filler to cover over the shrinkage/forming experienced from the welding. If you plan on doing something like this....DON"T....buy yourself a hood and save yourself the work and frustration. But damn it turned out awesome!

Bobbo Koski also helped me for a short time putting in the side skirts this weekend.

4/3/07

First layer of etching primer, this will be sanded off to find the remaining low/high spots.

Hood needs one more piece welded on, the aesthetic welds grinded and bondo laid up on the A surface and it's done.

4-4-2007

Fab work done on hood, need to apply lots of bondo now.

4-12-2007

Alright in process of finishing body work and fitting up things. I had to trim the bumper in order to have the body lines lineup. Fitting up the sleek light housings such that the lens are flush with the bodywork and the gaping somewhat even is proving a royal pain. The lens I have aren't exactly correctly shaped and will be needed some shaving to look symetrical.

The hood has it's second coat of 3MPFBF glazing on and should be done sanding by this weekend. With some help I should be done with bodywork by either the end of this weekend or mid next week. And then Paint! LOL

4-16-2007

Got the headlight housings and lens to lineup with the rest of the bodywork. I had to cut into the driver side headlight housing to even get it to drop flush with the bodywork. Somewhat my fault for not compensating for a non symmetrical chassis/bodywork layout, but still it shouldn't be this hard. I have one more tab to weld on the chassis for the headlights and then it's bodywork from then on until paint.

"I've never heard anyone complain about the RE sleek headlight fitment... Was it really that bad?? Or was it your custom brackets and projectors that caused the problems? " - Ungradedd

Well the saying goes "Ignorance is bliss" and this is a good example. Knowing what I know from my test engineering background the mounting structure wouldn't last that long or provide a stable footing for the lights. However, I did make it harder on myself by making my own setup, so my difficulty was both my doing and the poor design of the RE units mounting.

Note, what you don't see in this setup is the additional support I added to the outer most corner of the bezel. When at speed the cover would flex downward.I did this mod later in the build.

Well I think I'm done with bodywork. With the assistance of Bobby, I was able to get it done this weekend. The painter will be giving it a once over to see if I need to fix a few areas. If all is well, it's going to be painted this week.

4/19/07

The paint/body shop I was going to use said it still needs a lot of work. When I get back in town, I going to see what their talking about. Basically, my bodywork is still too wavy. I'm getting a second professional opinion to verify and if it's true it means I still have a lot of work to do. Complete skim coat and sand with a long block. Basically another 100 hours worth of work. Plus the painter seems gun shy, he basically does panel repair not full cars and doesn't have the time to do a project like that.

4-30-2007

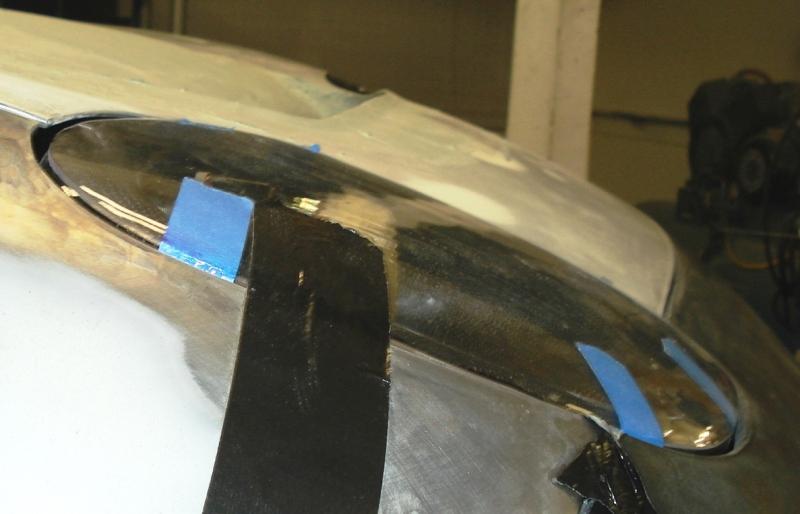

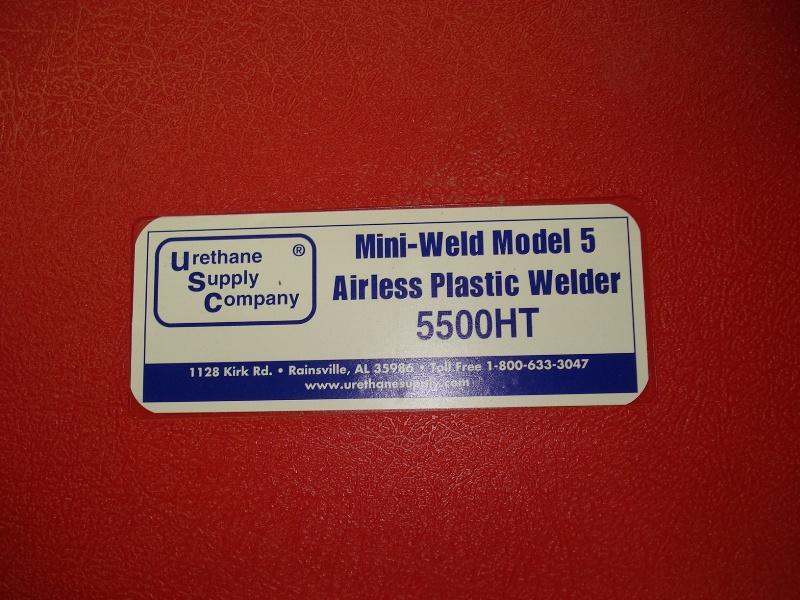

Alright, did some touch up on some of the ~wavey~ sections and got the car all taped up for the spray on "Mud". Also fixed one of my fender vents with the nifty plastic welder I got. Well worth the money buying that kit. Also, for those who have hood struts, you might want to grind off the excess material on the hood mounted pivot tab. It won't sit properly otherwise.

Harbor Freight has them: Plastic Welder & Welding Kit

5/1/07

Alright, Leo helped me put on the spray-on body filler, 3mm thick! After looking at the options I'm going to try and see if I can rent are booth and have Leo paint it. (Looking back on it I wish I had painted my own car)

5-7-2007

Well finished sanding at 2am today. Very, very sore now. Primer and jams painted shortly.

I also got somemore goodies this weekend

5/10/07

Got my seats in Yesterday, it's going to be a tight fit, but it will work. Will have to modify the floor and make custom side mounts for them.

See picture for Snap-On plastic welder part number and the a view of the emblem hole I filled on the rear bumper. View of surface before I sanded.

I though the material I used would be compatible, but unfortunately I was wrong. Should have used a plastic based body filler instead.

5-10-2007

Car ready for primer, hopefully Leo will have the primer on by the time I get to the shop today to wet sand it.

5/11/07

Primer wet sanded, didn't get done till 3am today. Bobby and Spyder help. If wasn't for them I would have never gotten it done that night.

5-14-2007

Car is painted - Knowing what I know now I should have done the paint job myself and been patience with the process. The PPG paint materials I used required a 48 hour cure between coats. But instead did it all in one night. I should have done more research on the materials I used and asked more questions on what was required. As of now paint is bubbling in a lot of areas.

PPG Deltron 2000 - OEM: 32P Mazda DBC912270 SC "Tungsten Gray Metalic"

VOC: 6.0/% Lead: 0.00/MSDS: BDC1

Tinting guide:

DMD1690 - 1828.4

DX685 - 116.7

DMD1683 - 554.0

DMD1676 - 68.1

DMD1605 - 171.0

DMD1607 - 19.2

PRL98 - 155.7

DBX1689 - 583.5

DMD650 - 136.2

5-17-2007

Ceramic coated my piping. LIM, UIM and added gold heat shielding to the LIM - At the time this stuff was expensive - $50 a sqft.

5-20-2007

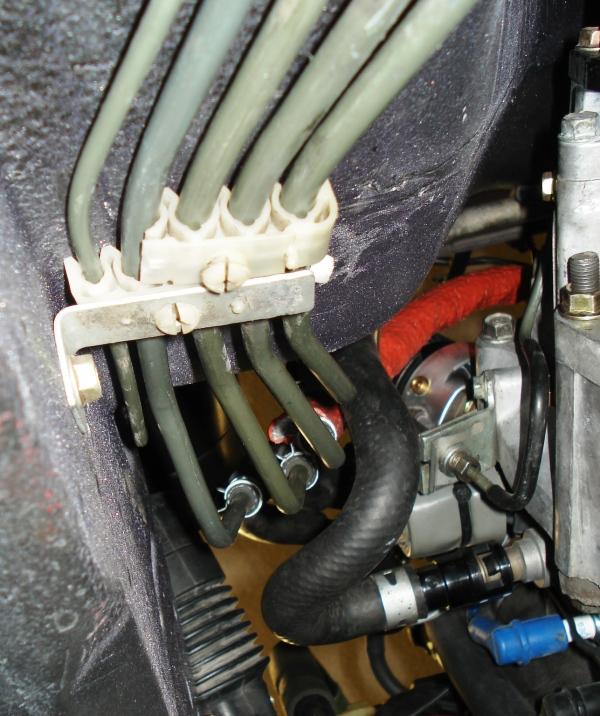

In process of engine build mock up and mod'n. As expected I have clearance issues with the new LIM, but nothing too extreme. Did some porting of the water pump housing to improve flow. I also simplified the rats nest, used my blue silicone hose for the lengths and routing needed before I cut up my expensive Viton hose I got. Waiting for the fuel injection kit I ordered to come in and Spider to bring me a few replacement items he borrowed awhile back....

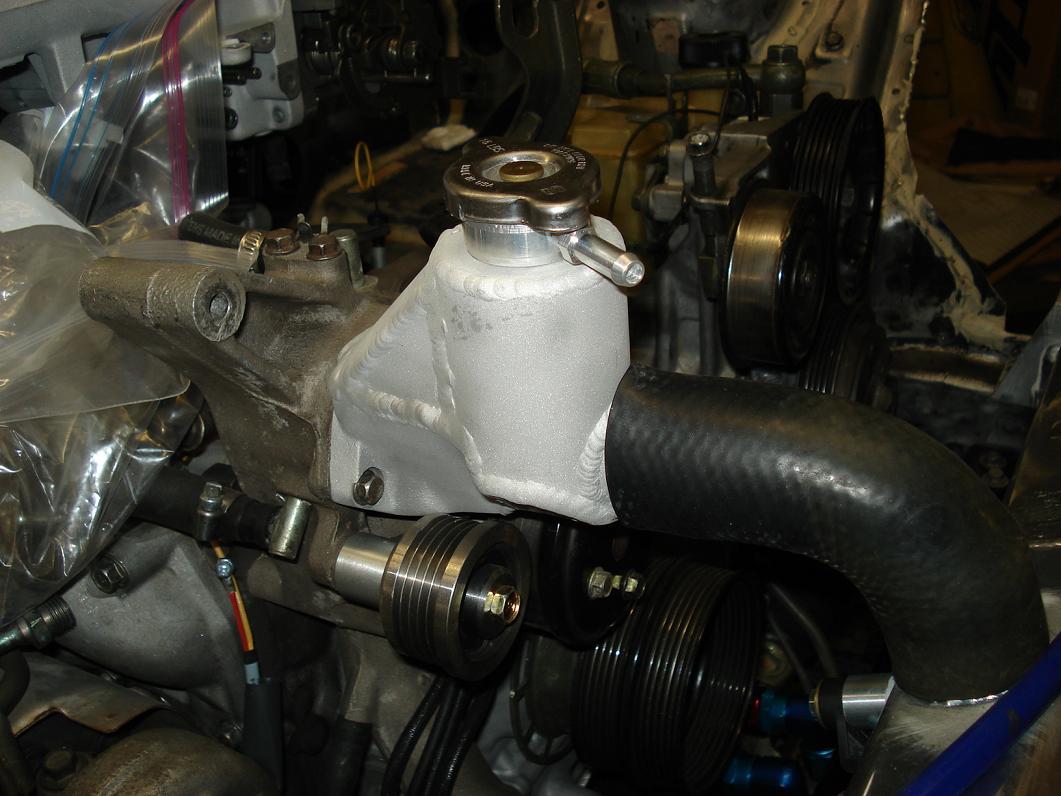

5-24-2007

Still waiting for the fuel injection kit to come (RX7Store), but Spider did bring me an alternator, be it a bit oxidized (thanks Mark). I took more pics of the clearance issues observed caused by the GZ LIM and the difference in location of where the throttle body is now. I did a little metal forming with a BFP so that the throttle body mounting tab lined up with the throttle body. The stock oil filler neck does not fit now, so I ordered an ReSpeed aluminum filler neck, decided to buy instead of fabricate. I also ordered one of there machined oil pedestals.

5/25/07

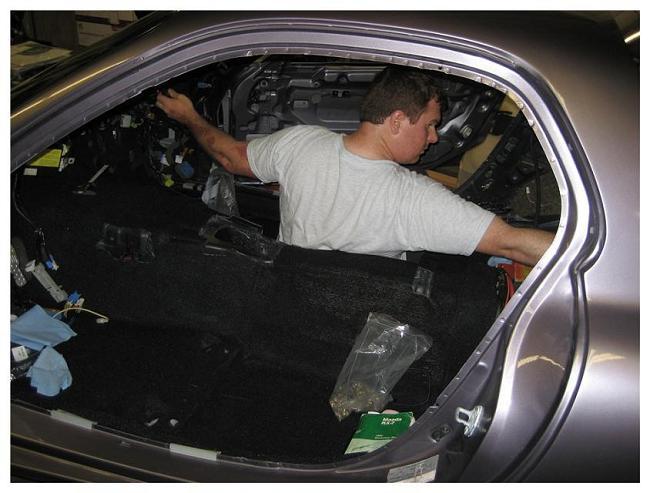

More progress today, engine build nearly complete, waiting for the fuel system I ordered to come in to verify everything fits before I put it into the engine bay. Got the ReSpeed oil filler neck and oil pedestal in today; nice pieces. I also cleaned the interior compartment and started laying up sound deadening.

5-29-2007

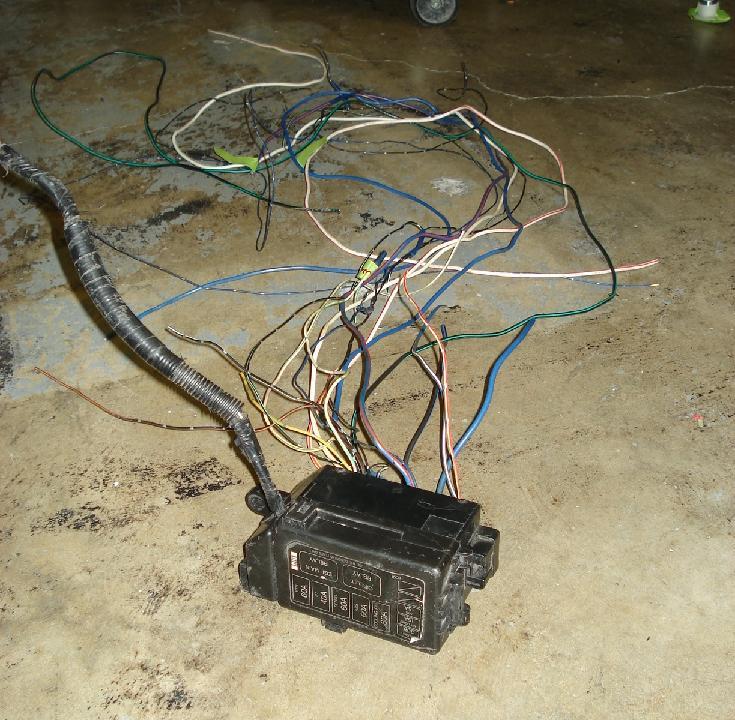

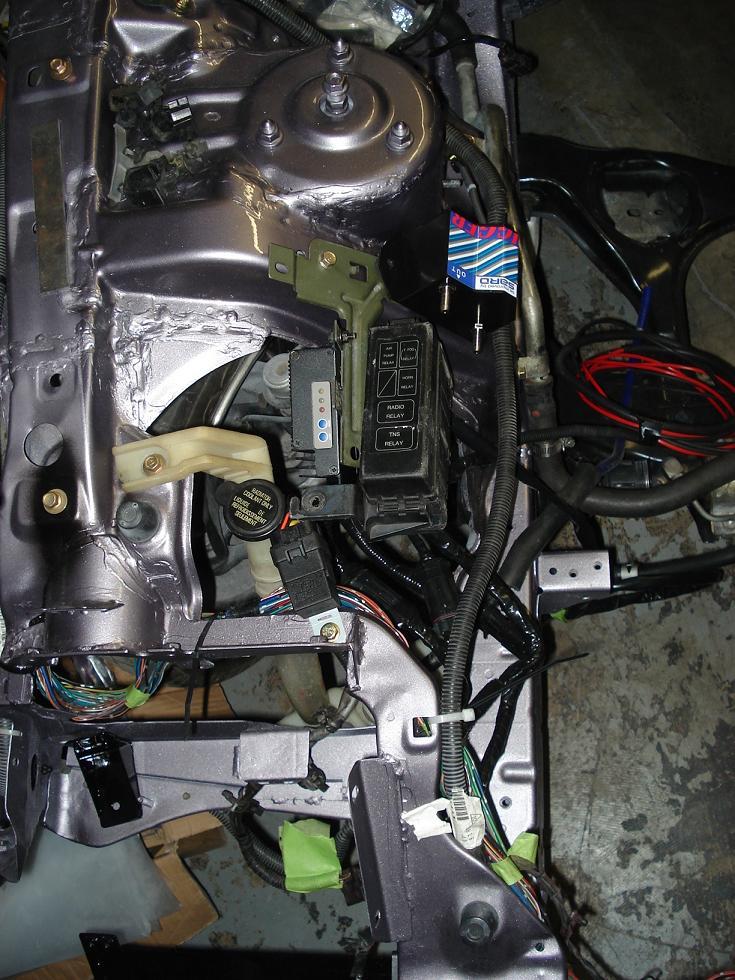

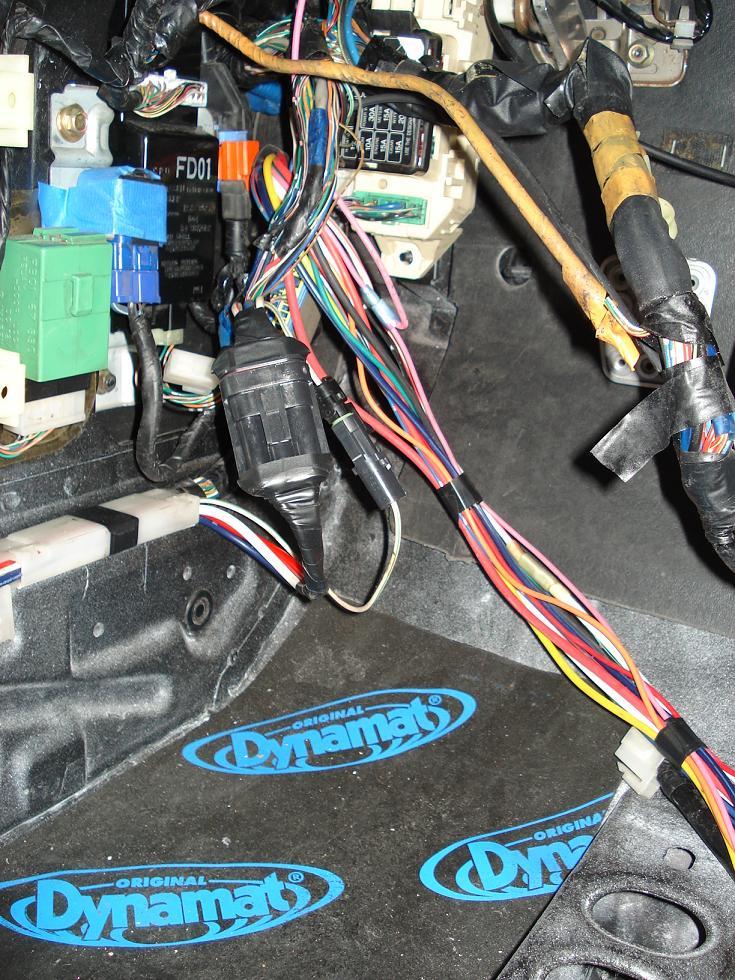

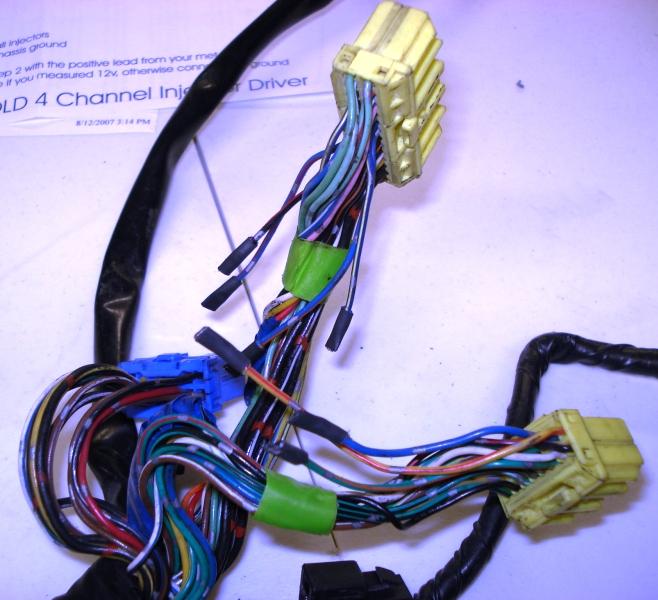

Started the arduous task of putting the wire harnesses back in, thanks to Wadejg letting me use his FD as a template to work off of, I was able to make some progress without scratching my head too much. I now have to modify the main chassis harness and engine harness now, yeah. Relocating the battery cables, relay boxes and fuse boxes on the main body harness. I then need too removing redundant items on the engine harness.

5/31/07

I removed the unusable diagnostic plug & wiring and most of the fan relay/control setup. I retained some of the wiring that may potentially be used by the Spal fan controller I will be using instead of the stock setup.

Man do I have a lot of wiring to do!!

6/3/07

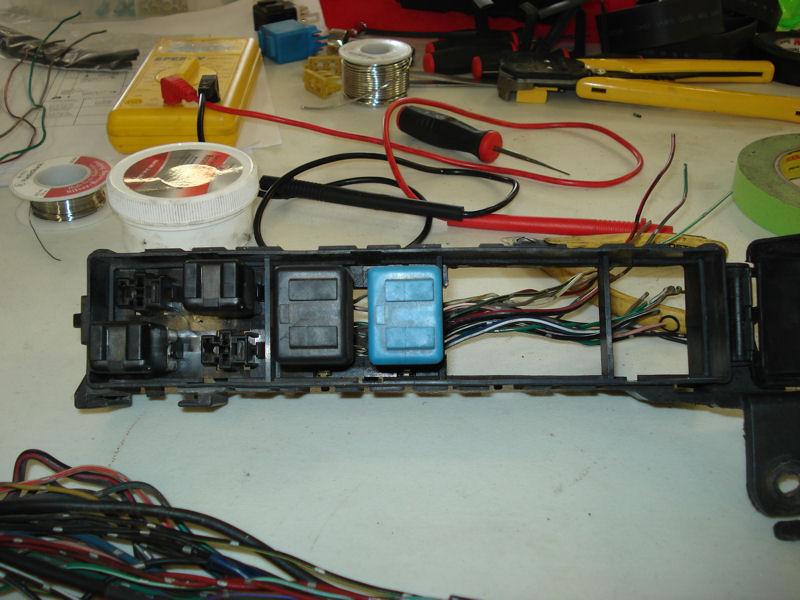

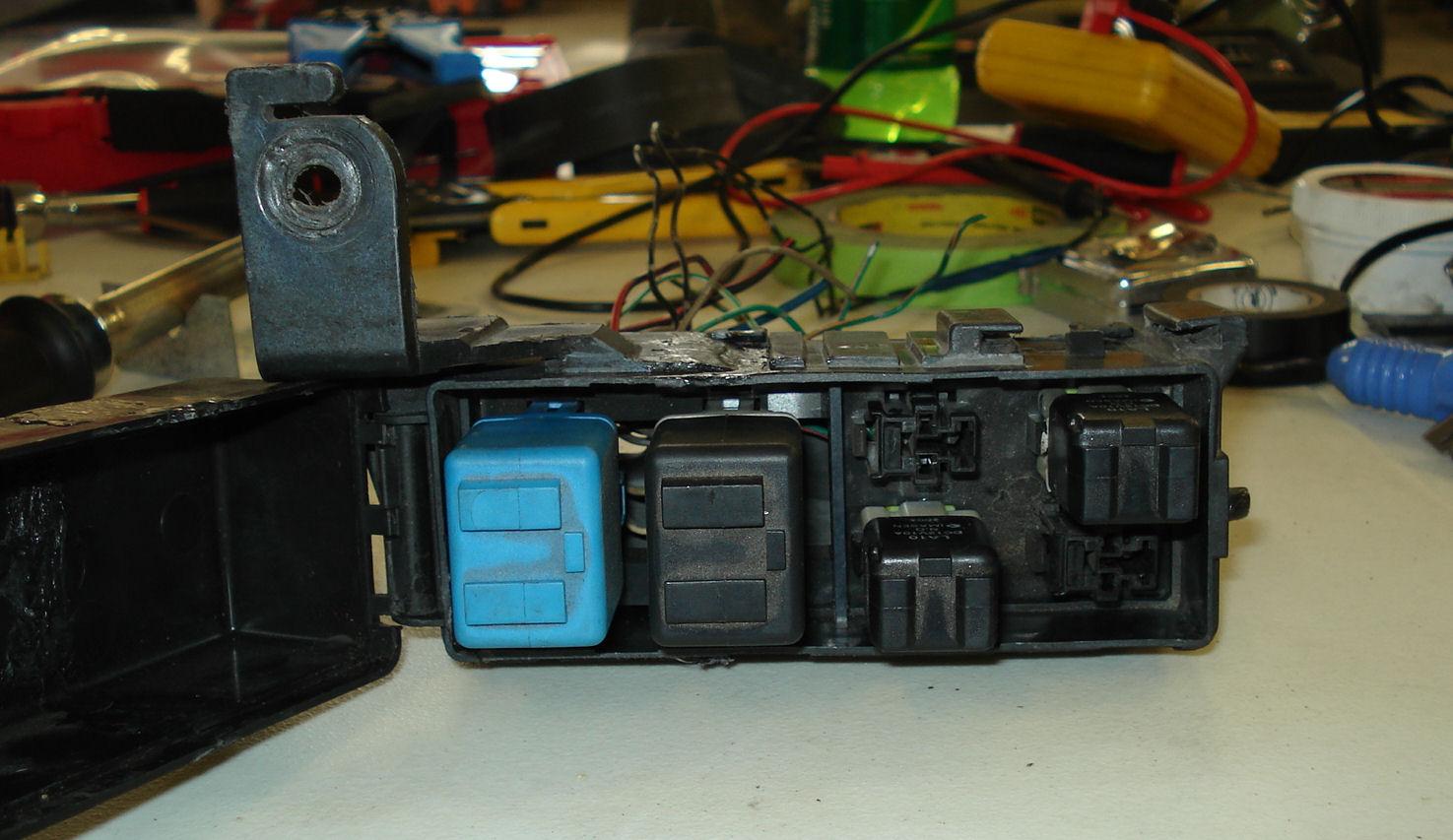

Slowly modifying the body harness (don't want to F up something), thank god Mazda provided detailed wiring diagrams on the net or I would be F'd. Anyways, removed and moved relays, modified the front relay box to house less relays, (Another plastic welder product). Just need to make a new mounting frame for the relay box where the fan relays used to be.

The Spal fan controller box will be mounted on the same frame. Picking it up Monday. Looks like the wiring I saved from the original setup will be used for this controller.

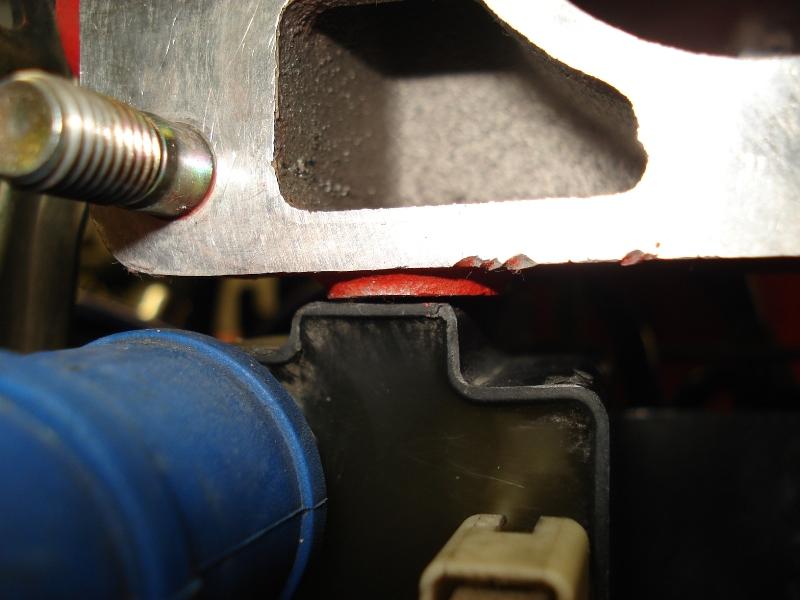

The quick disconnect plug will be using for the battery relay box I will be moving with the Battery. The plug will be placed where there is an unused orifice on the driver side firewall. Need to cut grooves for the prongs and it will slip right in.

6-5-2007

Completed wiring the new front relay box and started integrating the new Spal fan controller. I'm also integrating a removable secondary relay for a potential second fan if it looks like I need it.

Today finish that up and start working on the battery relay box relocation and what not.

6-24-2007

Got a little stuff done today, started setting up the external kill switch.

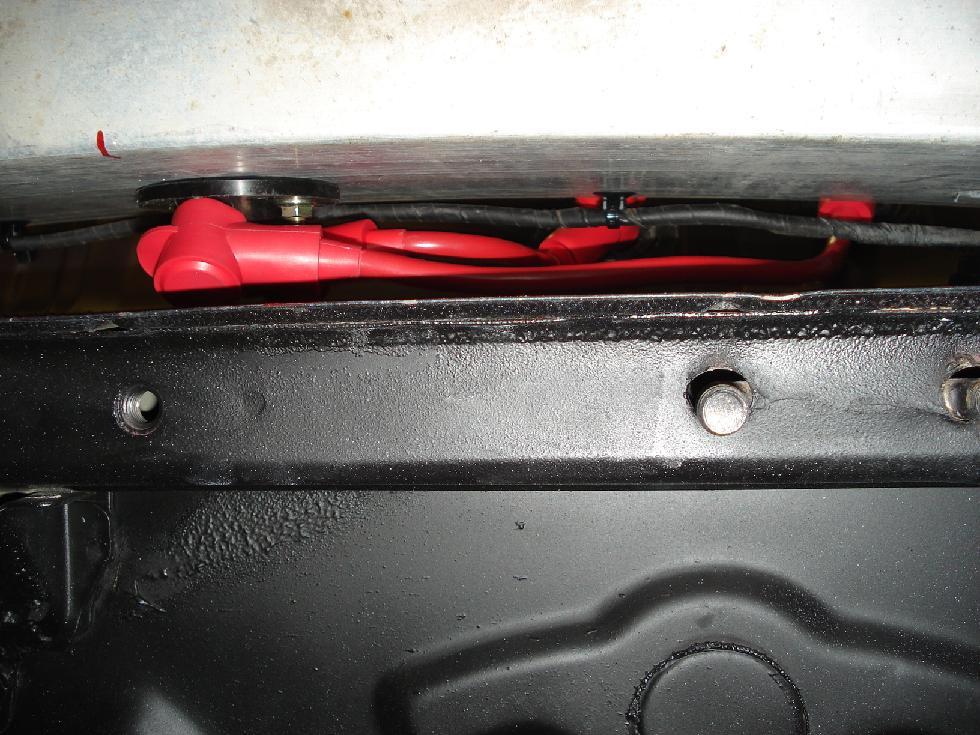

Wish I had just put the kill switch next to the battery. Would have saved a lot of weight.

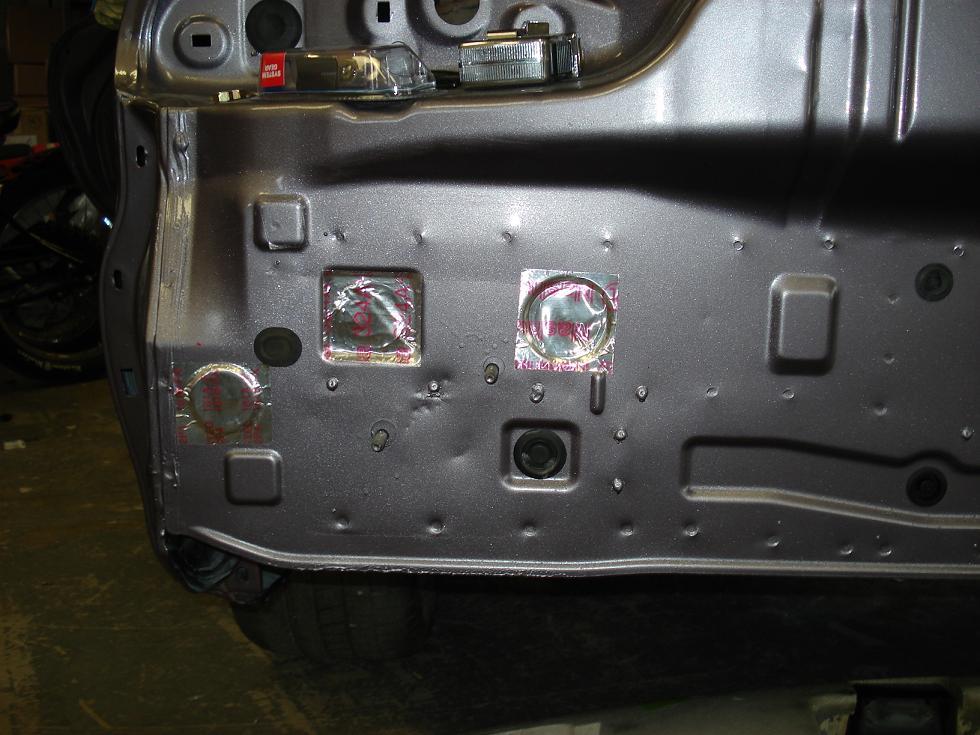

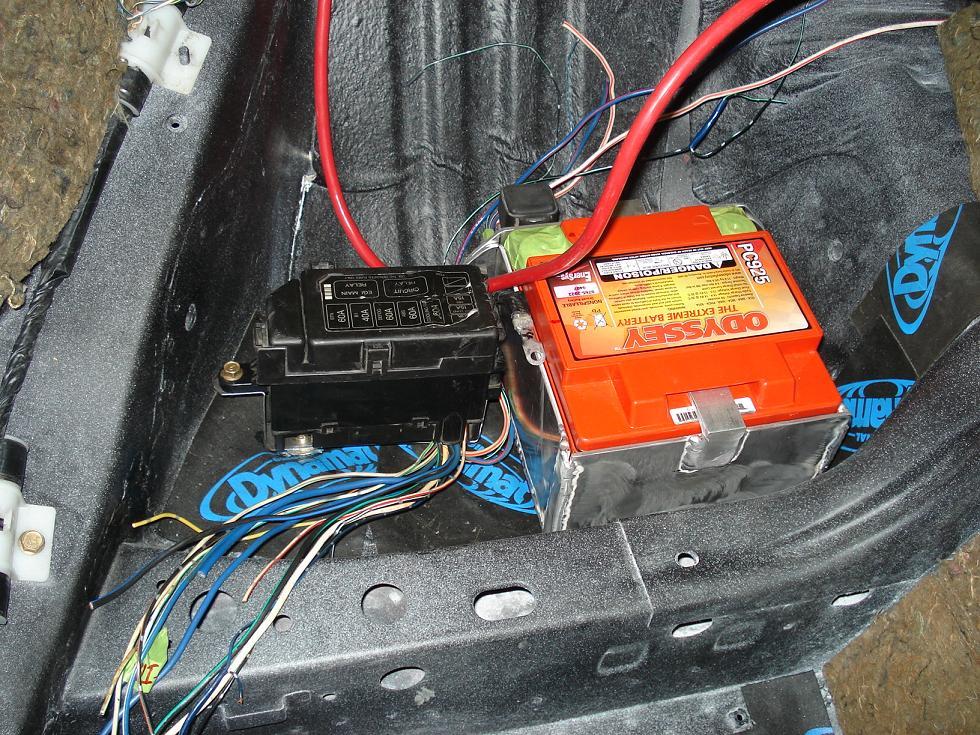

Started putting body plug on and couldn't for life of me find or remember if the holes I covered with aluminum tape had plugs or not. Oh well. Started to also put the battery and fuse block in, need to get some special hardware to finish the battery install.

6/27/07

With the assistance of Bobbo and Spider things have started rolling at a faster pace.

Setup of the firewall plug is nearly complete, had to double up on a few wires, but no big D.

Spider started greasing the Delrin bushings, replace my worn-out steering end-links and putting new dust seals on the upper A-arm. Though I need to either buy or borrow the tool necessary to instal the new bust boot clips.

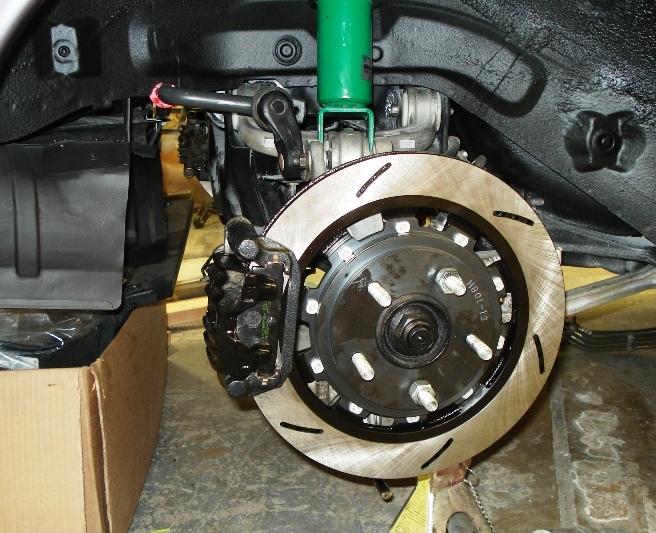

Bobbo, cut out my rear brake shields for preparation of my new BBK I'm getting. FD New Brake Options Re-reinstall my diff and put half shafts on.

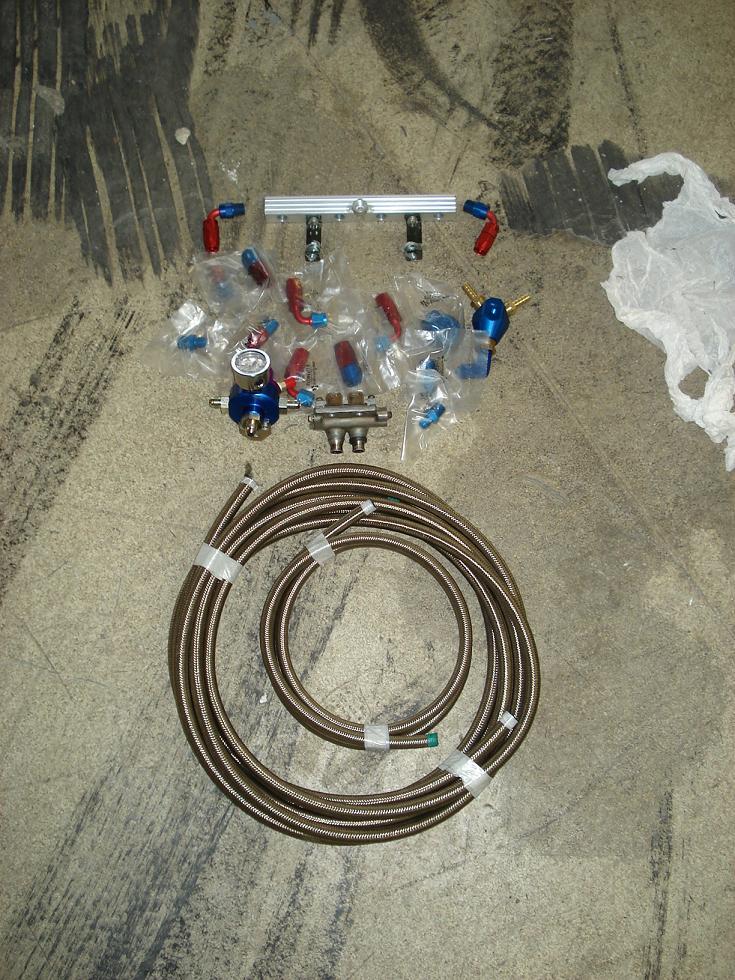

Oh and I got the GZ Secondary Fuel rail (1 of 4 available for sale at GZ). After talking with Frank at GZ and a few other experienced tuners, I may run four 1600cc or four 1000cc injectors for secondaries running two injectors in series. That way I would utilize all the GZ injector ports and I wouldn't need to integrate a resistor. 550cc side feeds would be used on the primary rail for good low idle smoothness. Overkill on fuel, but it would actually turn out to be easier in the long run with my future single turbo setup. Stay tuned.

6-30-2007

LOL, well the umbilical cored is done and I need to route to the passenger compartment now.

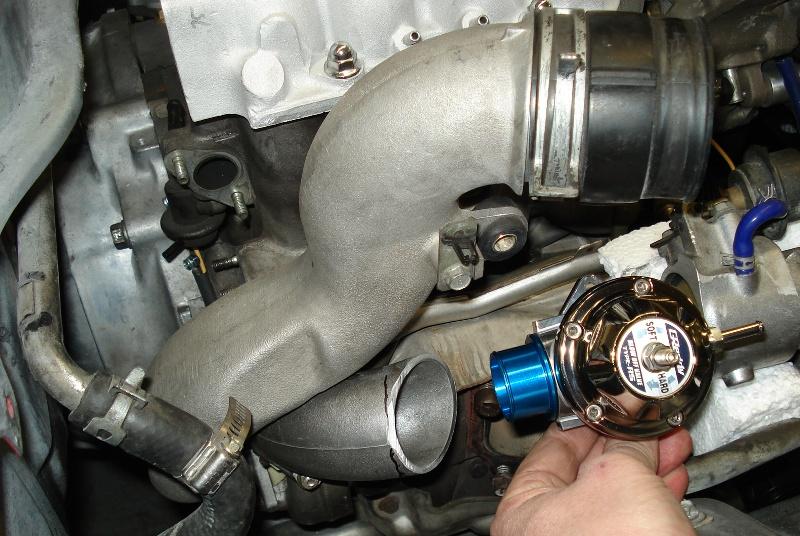

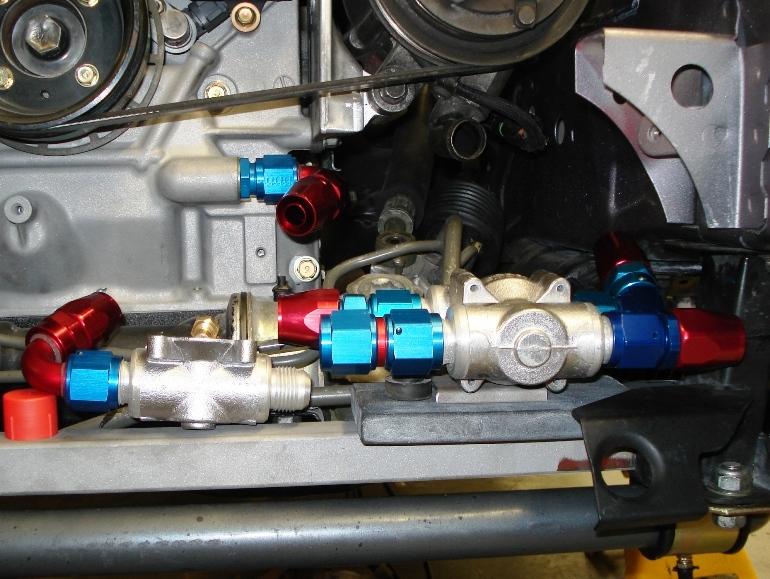

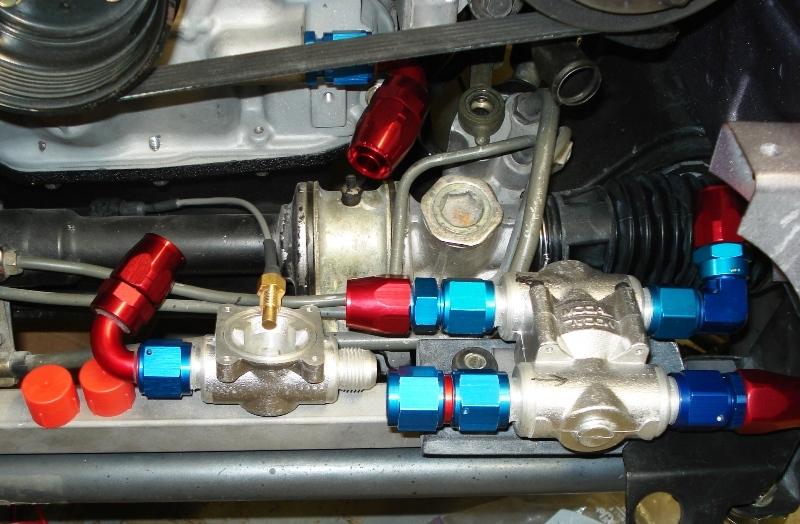

Got some parts recently, two Synapse Engineering BOVs, these just became available in limited quantities. Awesome units by the way. Mostly complete fuel system setup, got the secondary rail and fuel reg from GZ and the rest at Oil Filter Services (they have everything!). Just need to get injectors.

7-1-2007

Mostly done with the wiring in the passenger compartments. Still need to tie in the battery cables and finish the main distribution box mounting.

7/3/07

Interior wiring complete. Attached is a pic of a before/after refurbish body panels.

7-9-2007

Finally got all four corners of the suspension put together (had an issue with recieving a wrong half shaft assembly from MC) and put on the heat shield material for the exhaust. A bit overkill, but the passenger shouldn't have an issue of being slowly roasted.

7/15/07

Well I was hoping to have the motor in the engine bay by today, but in order of ease of setup and installation I need to wait for my injectors to come in and I need some fittings for the FPR. Then fabricate a mount for the FPR and the pressure vessel for the wastegate control. Easier to remove and install stuff with the motor out.

So mostly done with mod'n the engine harness, just need the injectors and injector clips. I went with 4 1000cc secondaries, two in series per side. And two new 550cc side feed units (main reason on holding off on installing the motor, major PITA to install those).

7/24/07

Finally got my 1000cc secondary injectors, need to make new mounting tabs for the rail to seat the injectors better into the LIM.

Expect my primaries to be clean and ready to go today and I will be getting my BBK!

7-26-2007

Big Brake Kit in now, had to modify a few things, but that was to be expected. Finally got all my injectors, should have the motor in the engine bay later this week. After looking into it, I will be add an FJO low impedence fuel injector controller to the mix for proper fuel control.

7/27/07

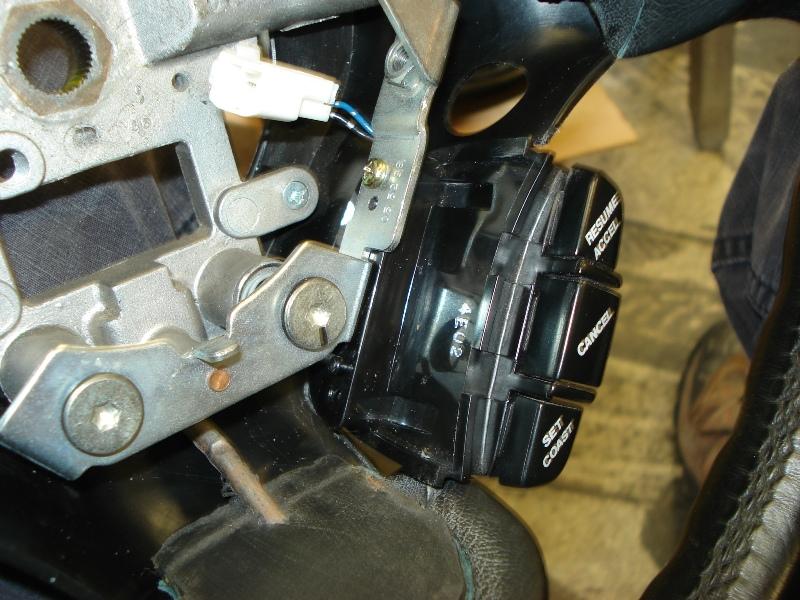

Modified my Nardi steering wheel to accept the cruise control switch module and installed the wheel on the steering column.

7-30-2007

Motor and tranny are in; secondary fuel rail fits, but is a bit tight with the Marren fuel dampener in place and the synapse bov may not work at the secondary boost control setup because of clearances. Will have to see when everything is in place. Rear brakes are also done, had to sand off material on the pads in order to fit. I had this same issue with my stock brakes and HP+ pads.....

And the dash is being repaired, the back lip of the center speaker pod was peeling up.

8-8-2007

I modified the oil thermostat to include a section for an oil temp sensor; I did this to eliminate the giant cluster F$%K the Mocal temp sensor adapter would have caused. Just need to fab up a rubber isolated mount to the sway bar mount stiffening bar and oil lines can then be routed.

I also removed all the old pealing top coat on my 93 center console and re-textured it to look and kinda feel like a 94 unit.

8/11/07

Almost done with the oil cooler mount/sway bar stiffening bar. Had to make another fuel Y splitter, the original was to big of a diameter tubing, doh. Got my RE street diffuser, nice piece, but it got damaged during shipping, will fix cracks and coat with rhino liner, or something with similar properties.

8-15-2007

Finished wiring in the FJO Peak and Hold Injector controller and cleaned up the engine harness while i was at it. I had some major routing issues with lines and wires, so while I was finishing wiring up the injector controller plugs and wires, I did rerouting of a coolant line and some vac lines. I'm so looking forward to get my single and getting rid of these control valves and lines.

The only thing I really don't like about this whole setup is the fuel lines to the FPR, I need to looks deeper into my options as far as fittings go...maybe AN fitting bangos, if there's such a thing.

Figured out the routing of the fuel lines to the FPR, had to think more 3D. Engine harness in, now need to finish main harness in the engine bay and most of my wiring except for lights should be done. Finally

8-19-2007

Fuel System Done

8/20/07

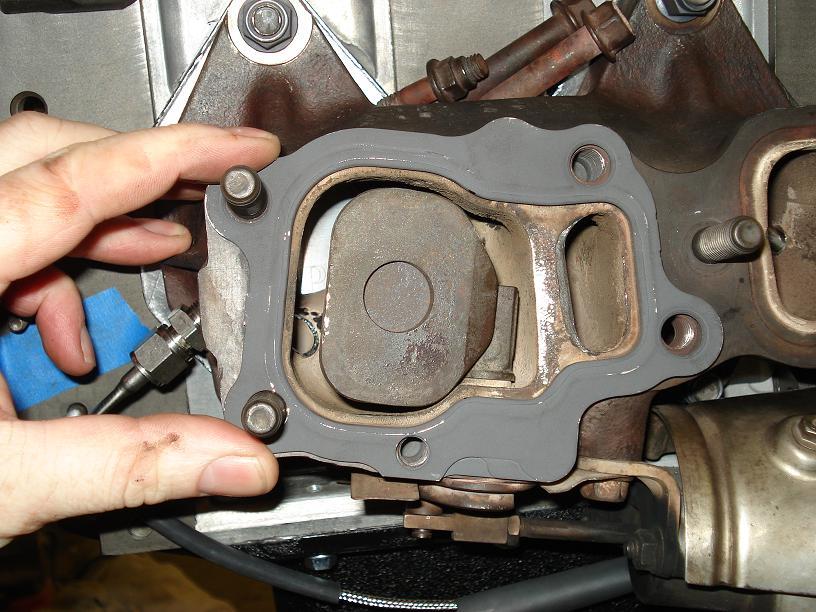

Exhaust mostly in, need to mod the mid cat pipe to fit new Greddy Evo2 catback, weld in the wideband bung and weld in a check valve for the air pump tube. A while back I had Pineapple make some custom ultra high temp exhaust gaskets. In the past I kept blowing through the originally supplied units. As a test I modified one of the their header gaskets. No blow-by and it reduced dBs under the cabin as a side effect. Good stuff.

Also finished wiring in the battery, starter, alternator cables. And the body-engine harness.

8-23-2007

FPR mount done, and close to being done with the mid cat. Finalize boost controller mounting and the remaining accessory wiring needs to be completed. Possibly may be able to start the motor this weekend.

Mid cat pipe done, just barely had enough leftover tubing after cutting to re-weld. My big cluster F of a relay box, fan controller, Boost solenoid and fan relay is next on the list.

8-25-2008

As I feared the Secondary BOV interfers with the ABS unit, so I need to rotate that tubing assembly. Heat sink for the WB in, needed two crush washers to get the orientation. Mostly finished with engine bay wiring except for the headlights and EDFC(routing). Started install of EDFC stepper motors, thank god for work instructions. And I found out the FC dip stick is a nice upgrade to the short FD dip stick unit, gets to the finger ring should be a lot easier now.

I needed to modify the secondary turbo tubing I went ahead and put in one of my synapse BOVs. Also finished the engine bay wiring, utilized the AC firewall plug. Next will be finishing the Secondary intake tube recirc tubing, air pump air line routing, welding in water temp and water level bungs into the Rad, welding in the second BOV after the IC (for better throttle response when motor is under vacuum) and all the wiring to the dash.

8-29-2007

Had a little unpleasant surprise the other day; the primary turbo accessory fitting came loose. So I made a plug for it since I will be tapping into the tubing at the juncture where I will get a more accurate pressure differentiation between the primary and secondary turbo transition. The secondary BOV and tubing is in, man talk about a tight fit. I almost needed five year old hands just to tighten the small set screws for the Synapse BOV.

Water temp and level sensors are on the Rad now and I need to decide where I will locate the primary BOV and special air filter for it. Where ever it is placed I need to tap into the air filter for the air pump. Minimizing tubing length may be the determining factor.

Nice build!

Posted by Diggymart on 12/10/19 @ 12:54:14 PM