You must be logged in to rate content!

6 minute(s) of a 209 minute read

2-28-2013

2-28-2013

well then you're in luck because tonite i got back out in the garage and got busy finishing what i couldn't last nite.

i started off where i left off on the sound deadening on the trans tunnel. it didn't take too long to get to this point

and from there to

and a few minutes later the floorboard was done

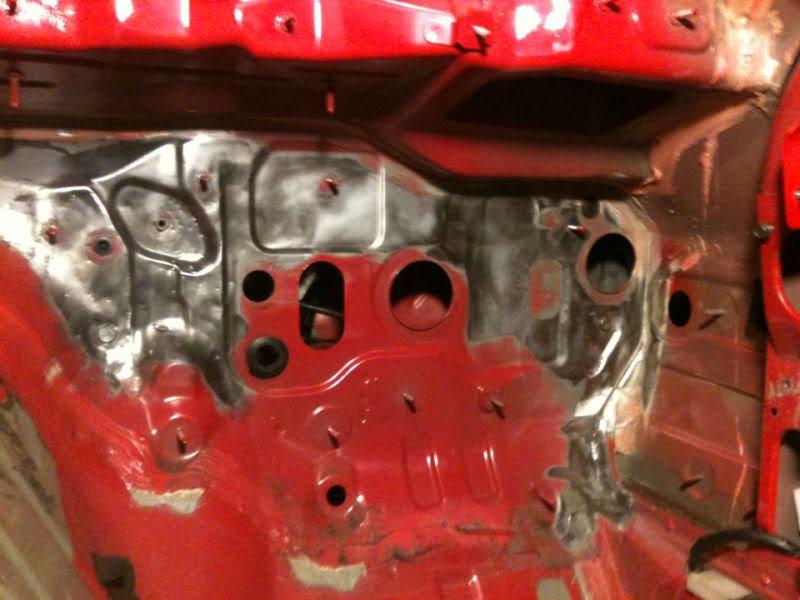

next up was the firewall

the first piece actually came off pretty easily as one piece. next up was the mid section which was alittle tougher

i kept going at it until...

FINALLY, all the sound deadening material was gone...almost anyway. i wasn't satisfied until all the little remnants were gone. i also had to start removing the seam sealer so i broke out the drill and some wire wheel attachments

i quickly realized this was gonna take alittle more time than i had hoped. i started focusing more on the little sound deadening pieces that were left over since they were harder to remove than the seam sealer. i began getting the hang of it

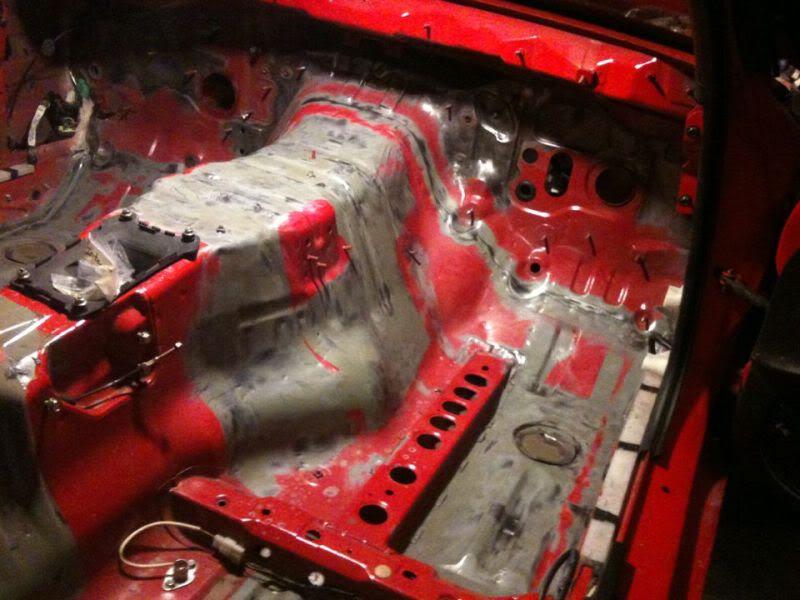

and from there i just took off. i would do alittle bit of the sd and then alittle of the seam sealer. dust started to pile up so every so often i would stop and vacuum. it actually helped me to see the progress alittle better as well. after a few hours i had the front half of the floorboard and the firewall DONE. i decided this was a good stopping point

since i had the wire wheel out i went ahead and went over the entire floorboard and all just to give my aftermarket sound deadening alittle something more to hold on to. i was also thinking of spraying some adhasive promoter before putting it down. it should stick fine without it but, i just wanna make sure.

i've still got a good bit to go before i can start preparing to weld the seams. i may be able to get out there with the wire wheel tomorrow and get the rest of the floorboard and seams cleaned up. i may switch it up alittle and try some welding tomorrow just for a change of pace. i'm alittle sore from all the different bending, squating, pushing, pulling, etc but i'm kind of on a roll these last 2 days and i'd like to keep it up.

anyway, i guess we'll see if you guys get another update tomorrow. until then, comments welcome.

my plans are to spot weld the seams, coat the bare metal with paint or primer, then lay down the sound deadening material and start putting everything back together. i'm gonna dye my carpet black and reuse it. if this was strictly a track car i think i'd go carpetless.

anyway, today i had to get another wire wheel but afterwards i got back to the car and finished up with the sound deadening/seam sealer removal. i don't know if i mentioned it but, the other day i went to harbor freight and picked up a cheap mig welder so i can learn to weld. i didn't have any scrap to practice on until today. i got a thin sheet of steel from lowe's and when i got home i gave it a shot just to get the feel of it all. the sheet of metal i got was really thin so i did burn through it. i messed around with wire speed and all and before putting everything up for the nite i decided to try spot welding a few spots that were already stripped down on the car.

it was basically just point and shoot. i didn't wanna burn through the car. there are some spots where i did go through the floorpan when removing the sound deadener with a chisel and i wanna be able to weld those spots back up. i don't wanna burn through tho. any tips on welding for a beginner? i've done alittle reading and all but, i didn't realize the metal was so thin on the car. the welds that i did do were quick but i could still see the undercoating smoke. after it cooled i felt underneath and i could feel the coating peel. it didn't burn through tho so i guess it worked fine. any advice before i tackle the rest of the interior?

here's the outcome of the past 3 days

it may not look like much but, man what a tedious task it was and it's still not over. well, that's it for now. i've got a full week of work starting tomorrow but, i'm gonna try and get more done when i get off at nites. hopefully the next pic i post is of a bunch or spot welds evenly spaced between the seams.