You must be logged in to rate content!

8 minute(s) of a 202 minute read

11-11-2013

Around the time I started doing the wiring my roommate decided he wanted to buy a 240 hatch if the right one came along with minimal rust and no accidents. When people say they want to find something I take it as a challenge and within a week I found and he bought a nearly rust free roller with 0 accident history so the FD had a garage companion. We towed this thing 2 hours with bald and dry rotted tires, on a dolly, at night in, the snow.

It came with K-Sport coilovers worth more than he paid for the car.

Within a few days we had it stripped to nothing but a bare shell

Back to the FD now. My semester ended, I graduated and was hired full time where I had been working as an intern for two years and I wired all summer. I got the wiring back to stock while I was at my apartment and when I got it home I had a terrible idea. Wire Tuck. The main harness running around the front was always something that bothered me so it had to go.

I didn't actually just hack it in half. I cut wires one by one, calculating where I should cut it to be able to have the easiest time reconnecting it through the cabin.

All cut and marked for reconnection

One of the many mock ups for wire lengths

Lights working much better than they did before the wire tuck. There was no questioning whether the headlights would turn on with the switch and the running lights weren't constantly on.

11-12-2013

Here is the nearly completed wire tuck harness, my trusty sidekick enjoys walking all over things. Even though I don't have A/C or fog lights and some other things I wired it all up just so I knew there were no wires crossed up. I can always go back later and cut things out.

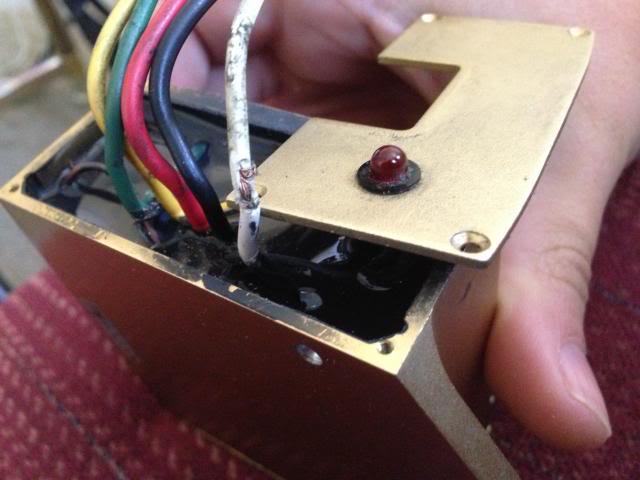

I also had to break open my twin power to fix a wire with a broken case. I made a thread on this. It wasn't complicated, just cut and spliced in a matching wire and shrink wrapped it. Then filled the case back up with silicon to seal it.

Then came formula D at Wall New Jersey. Naturally I was attracted to the Nexen Rx8 which was the lone rotary running that day. Unfortunately the engine let go in the first round.

With the wiring harness pretty much set It was time to try to start the car. The good news is that it started right up. The bad news is that it still had a surging idle. I eliminated two of the only other weak links I knew of by replacing the ISC gasket and getting a fast reacting IAT.

When I pulled the ISC off I cleaned it up the best I can and while I was doing this I noticed something strange in the ISC. Really have no idea what it is. Its's a very hard rubber piece.

Bolted everything back up and started it up with the same results. I have verified that the TPS is in spec Numerous times. Here are some videos. Don't mind all the wires hanging out, they are all for lights or properly hooked up but just not routed in an organized fashion. Also have massive exhaust leaks.

I thought the PFC was learning idle and I was going through the steps of the learn process but it really never did. the car would settle down and sound ok and then it would go back to whatever it wanted to do.

With the car still not running correctly I got pissed and you might say I got a little carried away but I decided to ditch the stock ignition and the PFC and go in the route of a complete standalone with direct fire. This will simplify the system and all wires for the engine will be new and fresh so the 20 year old wires will not be a factor. I started by pulling the motor again. This took all of like 3 hours.

Then I pulled the Heater core and carpet. Deep down I knew there was still something off about the frame of the car and when the carpet came up this was confirmed.

So I got in touch with my co-worker's friend who owns a collision shop and set up a drop off time to have it looked at and possibly pulled, correctly this time.