You must be logged in to rate content!

10 minute read

DIY Rotors and Brakes (Front)

Compliments of cmarshack @ http://mbworld.org

10-23-2013

OK, so there is no DIY for a brake job on this forum so I figured I would snap a few shots of my recent rotor and pad replacement.

I know that there are people that feel OEM is the best way to go and I do not want this to turn into a debate as to what rotors and pads are the best. What I do know that is that I always do these jobs myself, I always do a lot of research and I have always had better results going aftermarket that OEM.

I decided to use the same setup that I had on my full size Range Rover Supercharged. I figure if it works on that beast, it should stop the GL.

I went with EBC Sport rotors which are dimpled and slotted along with EBC Greenstuff pads.

One thing to be sure of is the size of your rotors. The GL comes in two different size rotors for the front and I figured since my car came with the 20in wheels that I would have the larger rotors (373mm). When I pulled the wheels to do the job I found that mine were indeed the smaller (350mm) rotors. Good thing I ordered on Amazon...

So if you decide to do this yourself please note that this is FOR REFERENCE ONLY. I AM NOT A MECHANIC, ANY DAMAGE YOU DO TO YOUR CAR, YOURSELF, YOUR ANIMALS OR ANYTHING IS YOUR FAULT, NOT MINE. READ ON AT YOUR OWN RISK.

First remember to work on your car on a flat surface. Use wheel chocks and jack stands and never lay under the car while it's off the ground.

Below are the tools and parts you will want for this job:

- Rubber Mallet

- Breaker Bars

- Ratchets with 20mm and 17mm sockets

- 9mm allen wrench (actually hard to find so don't assume your set has one)

- Impact driver with T30 Torx bit

- Long flat head screw driver or small pry bar

- Torque wrench

- C clamp (I really like the Quick Grip like below)

- loctite

- New wear sensor - OEM

- New rotors | Part Number: GD7399 for 350mm | Part Number: GD7545 for 373mm rotors

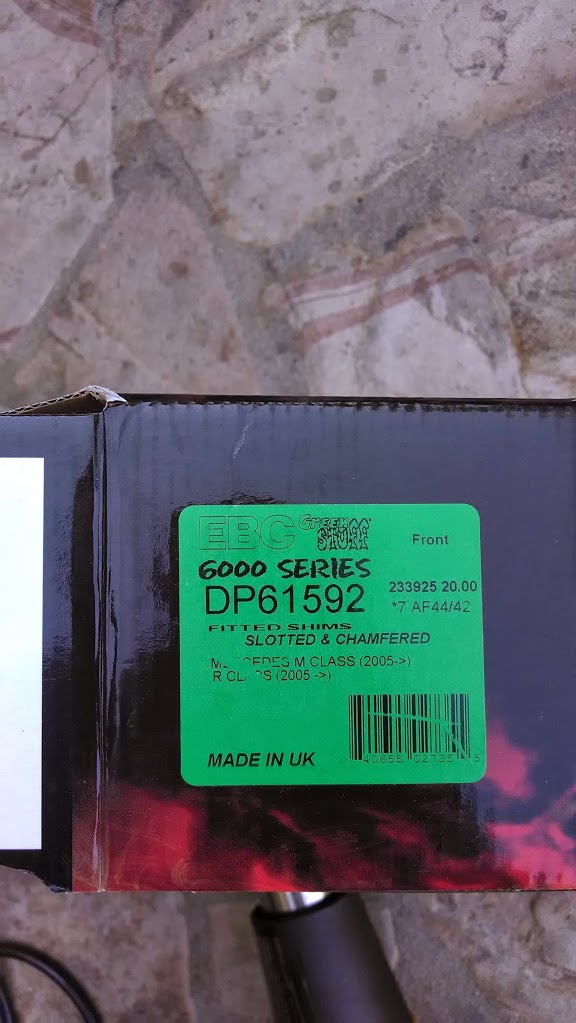

- New pads | Part Number: DP61592 for 350mm | Part Number: DP61860 for 373mm

1. Pull the front wheels and you will see the rotors and calipers:

Here are my worn bits:

The new stuff:

2. Next you will want to loosen the T30 torx screw securing the rotor to the hub. This is likely rusted on there so the best way is to use an impact driver. This works by striking the driver with a mallet. When you hit it, it turns the screw. This does two things: Makes sure the bit does not slip and breaks it free at the same time. You can get one at Harbor Freight for not much $. If you don't have one I would try heat and make sure you have new screws on hand for the re-install.

3. Remove the Plastic caps from behind the caliper which will expose the 9mm allen bolts that hold the caliper to the mounting bracket. You can see the bolt in the picture below (it's inside the rubber boot thing)

4. You will want to hang the caliper from the strut with some string or wire so that it is not hanging from the brake line.

5. Now you will need the 20mm socket and a large ratchet and very likely a breaker bar to remove the Mounting bracket that you just took the caliper off of. These are on there with loctite and can be a bear to get off. Once again, heat helps here but leverage is your friend...use a long breaker bar. There are two 20mm bolts that you must remove. You can easily see them on the bracket. (sorry no picture)

6. Now you are ready to remove the rotor. Give is a whack on the top edge with your mallet. It should break free. There is nothing holding it on now except rust and break dust, but you may have to give it a few whacks around the edges to break it free (remember it's going in the garbage so if you need to hit is with a metal hammer that's ok).

7. Press the caliper pistons back into the caliper. The best way to do this is to used the clamp like the on in the picture below: As you squeeze the grip it will slowly push the pistons back into the caliper. If you do not do this you will not be able to install the caliper over the new rotor with the new pads.

8. Now pry the inner pad out of the caliper with a flat head screwdriver taking caution not to puncture the boot over the piston. Also note that there will be a wear sensor on the passenger side clipped to the inner pad. If you did not get a warning light you may be able to reuse the sensor. If your light went off you WILL NEED a new one.

7. Time Install all the new stuff! Rotor 1st with the 30mm torx screw at 10Nm and some loctite securing it to the hub. Then the mounting bracket with the 20mm bolts tightened to 80Nm and more loctite. Then press the new inner brake pad into the pistons on the caliper. Set the outer pad in place and then place the caliper over the new rotor and into place on the mounting bracket. Now install the 2 9mm caliper bolts. I do not know the torque spec but make sure they are tight. Now replace the plastic caps over the rubber boots and everything should now look like this:

Replace your wheels and check out your new slammed GL!

Don't worry...when you start the car it will level out again!

This is what they will look like after the bed in coating is worn off:

Below is a good method for bedding in your new pads and rotors: (From the EBC website)

"Drive your vehicle steadily within the first 300-400 miles of road use only using the brakes violently in case of emergency. During this time use the brakes lightly and intermittently to achieve a matching between the pad and rotor which we call break in or bed in.

The speed with which perfect brake in will have occurred depends on how often the brakes are used. If you drive on a freeway or motorway and do not use your brakes for miles at a time, break in periods will be much longer. Using the brakes with caution during their early life will extend their wear life and greatly reduce the chances of rotor vibration or “shimmying” as it is known in the States. During the bed in time the pads will only contact the disc on a limited area until tiny irregularities in machining or misalignment of the pads against the rotor have been removed. You can easily see how far you have progressed with bedding in your new brakes by looking through the wheel spokes and evaluating pad contact. The rotor should look shiny and smooth across its surfaces from outside to inside in all areas of the rotor. If you have purchased EBC gold zinc or black zinc coated sport slotted rotors, all of these coatings should have been visibly removed across the entire braking area of the rotor. Break in times on European vehicles is usually considerably longer than on Asian or US built vehicles because of the design of the brake system. European vehicles use a “taller” brake pad and may tend to contact on the outer edges of the rotor first and gradually contact more towards the centre of the axle over the first few hundred miles. After you are confident that the pads and discs are perfectly mated, use the brakes on a quiet and safe road 5-6 times at medium pressure bringing the car from 60mph to 10mph. Drive the vehicle for a few miles to allow the brakes to cool and repeat this procedure. During this final break in a brake odour will almost certainly appear and this is perfectly normal. This is known as green fade where the surface resins within the pad finally cure and burn off.

This bed in procedure is for STREET driving only. For race use bed in please see notes inside the package."

I hope this is helpful to anyone considering a brake DIY!