You must be logged in to rate content!

14 minute(s) of a 99 minute read

6-10-2010

I have been told that my bending stud problem is:

- rotor holes too large & rotor is moving and bending stud(s)

- passenger side axle is 2nd to engage & that shock is causing it

- stud retention

after all we are only human, so of course everything is perfect. We also check all our products that come out of manufacturing.

stop making excuses. The stud holes in the axle hub are drilled out of SAE & GM bolt pattern standard for this car. It is completely out of tolerance on definitely 3 studs, possibly 4 out of 5. Can't tell whether the last 2 are out, but can definitely tell that 3 are out.

6-12-2010

well after having moser send a new axle and tearing all of this out; 4 out of 5 of the stud holes in the hub were out.

I will upload pictures when I get back home, but the new axle is in and works great. However, when we pulled the previous axle out at the shop, we happend to take a picture inside of the rear end axle tube and it looks as if one of the bearing holders inside the axle is cracked. Will be submitting picture to moser to see what they think. In the end of all this, we may be taking this ENTIRE rear apart AGAIN to check to make sure EVERYTHING is ok. After submitting pictures to moser of the mis-drilled holes, they still didn't believe me and even the shop who I bought it from didn't believe me.

Having my dads friends at work with a CNC machine & Moser giving all the details of the GM bolt pattern to us, WE machined a template to go by that is within SAE standards & tolerances. This was done in about 45 minutes and stopped production at my dads work for this time. I have also taken time to take the car apart several times and investigate the holes & studs.

I'm now waiting on moser to re-imburse me for this mistake and upon further investigation & talk to moser, we may also be replacing that bearing in the axle tube.

6-13-2010

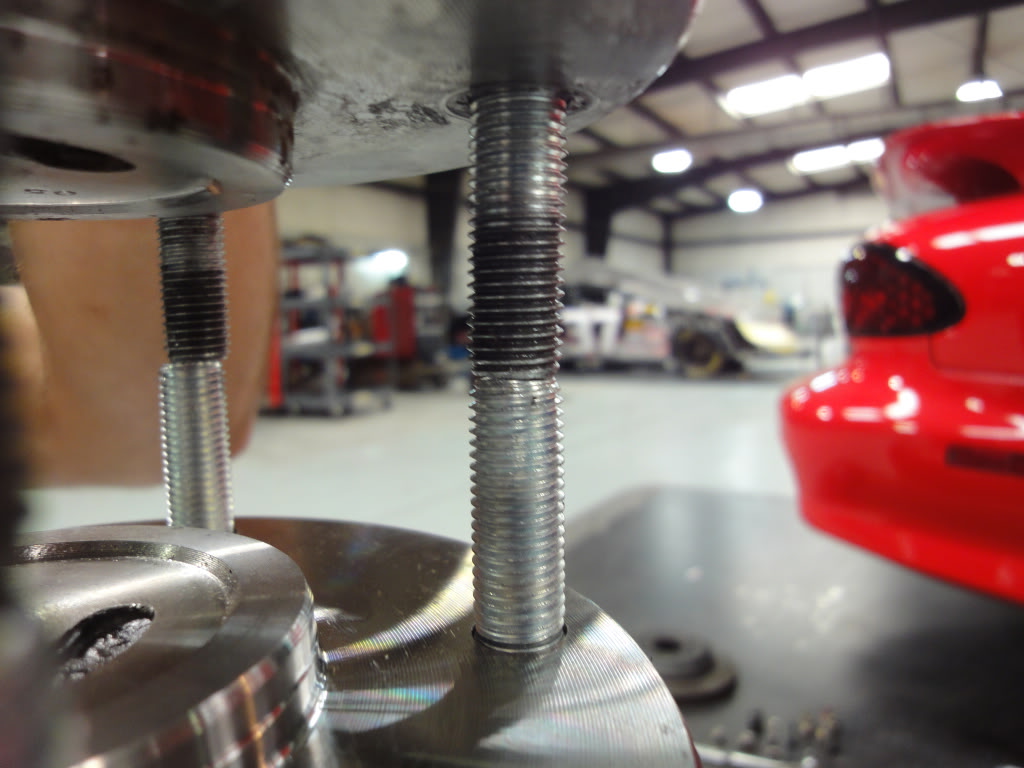

Note that the 1 stud does line up to the new stud.

OLD AXLE on TOP

NEW AXLE on BOTTOM

REALLY? Couldn't this have been avoided?

11-7-2010

all the standard STS piping is 2.25 inch.

My turbo outlet is 2.5 inch.... I actually wish everything was 2.5 inch... but so be it.

BTW... Updates.... Lifted up turbo ~2 inches. Purchasing turbo blanket in the next month, so when I get back from traveling I can install it along with a lot of other stuff around the house and on the Daily driver.

Long story short... a replacement OEM cd player from GM, their retail price for my malibu is $660 bucks... I looked the guy right in the eye and said you are stupid. Getting a new head unit online for the dd.

Pictures:

11-17-2010

thank you for that. Greatly appreciated. I'm in the works of doing the bung & screw in IAT sensor. Also going to get that hard aluminum pipe exterior powder coated.

other news....

Now I have to get to my daily driver car and swap the head unit (receiver). It is a 2006 malibu maxx, and the cd won't eject. Tried getting in there with a tool to get the cd out... no luck. Went to GM, a recertified unit is $250, and then the guy told me a brand new one is $660. I looked him in the face and said "who the **** do you think you are?" he had no response. I then told him I can get a fully functional mp3 player, ipod player...etc for $400 with all parts.

He then gives me this look of oh, you stupid young guy (25 years old here) don't know how to install that thing. and I then tell him I've got 8 years under my belt of this **** and I'm an electrical engineer. Again, didn't have crap to say back.

1-20-2011

Sorry for the delay Josh, been real busy with work and things over the holidays.

But back to the car. thanks a lot for the words, it has been a long haul and well worth it now. To answer your question about a separate oil system & etc questions. I have thought about it...and I have also tried my best to raise the turbo up. If I were to do it again I may have gone separate, which you would have to use some kind of pump to move the oil at around 40psi to the turbo and you would still need a way of scavenging the oil away from the turbo, which with that you try and keep the kinks, turns, height rise to a minimum. Now if you had a scavenge pump right off the outlet of the turbo this wouldn't be a big deal. So basically if I cut my rear section out for the T-tops, mounted the turbo up there setup a system in that area and then sealed it off and used some sound deadening material all is good. this is probably similar to what Paul Major did.

Your statement about the turbo getting hot enough, etc. You absolutely MUST WRAP your exhaust & turbo blanket. I installed manifolds back on my car and it was a night and day difference. It was really nice, as I bought brand new ones and coated them myself & put heat shields on them.

Sub Frame connector Question:

I will definitely have to look into the new STS cold pipe piece. Very interested in this, as I know my chassis is not liking me right now. I have dimples above my rear tires on my body panels and from experience & others it isn't due to me banging on it...chassis flexing.

Preferred turbo... well in my experience, and from talking to Turbonetics & Jose @ Forced Inductions & looking at the LS1 airflow & power a 60mm turbo of any sort is a freaking joke for our cars. they might be perfect for a smaller motor, but for the mighty LS1 they are a joke.

MINIMUM size I would start out with on a slightly bolt-on LS1 would be a ball bearing (high quality) 67mm turbo and if stock pistons, rings, rods, etc. I would NOT run more than 7psi of boost.

MAXIMUM size I would say for most daily drivers & NOT HEAVILY MODDED CARS I would end up with, lets say a car that has new heads (AFR 225 or similar) , new cam, forged components, maybe even a slightly bigger motor, would be a 76mm ball bearing turbo and the boost level would depend on the setup. I'm running ~10~10.8psi right now.

The selection of the turbo will GREATLY (duh) affect your car & its power. You make a shitty selection of a turbo and you will get mostly shitty results. Sorry, it is what it is.

Another thing is, STS piping is 2.25 inches; it would be nice if it was all 2.5 inch, as this would directly match up to the TC76 factory unit output.

Another thing is if you have a nicely done engine & car, I would recommend the upgrade race package on that 76mm turbo. Speak to Jose @ forced inductions if you are curious...that 76mm will pickup a good bit by doing this upgrade, however, the output goes from a 2.5 inch to a 3 inch. Wow momma.... LOL.

If you want low 500-ish horsepower, get a 67mm

If you want a mid to upper 500-ish horsepower get a 72mm ~ 76mm turbo (even 600hp)

If you want 700+hp ... well talk to Jose @ forced Inductions... LOL. I haven't experienced this, but he would be your best advisor. I would have to guess you would be in the 80mm+ territory.

If you can get a ball bearing turbo, get it. and as far as an oil restrictor, you won't need it unless the turbo manufacturer says they want one, or you are running greater than 75~80psi oil pressure.

4-12-2011

mine is pretty loud...didn't i load a youtube video ... here it is:

I will get a better video up soon, farther away from the car so you can hear it, when the damn weather quits pouring down. Nice, that is pretty loud.

There have been quite a few changes since my video. I still need to head back to my fabricator, have him install the threaded metal IAT sensor... and I'm debating methanol injection.

Currently tracking down a transmission leak, I think it is the rubber boot at the rear of the transmission where the driveshaft goes into the transmission. I do NOT think it is the actual rear seal.

THEN I'm going to hit up the dyno. So it may be another month or so before everyone gets my numbers.

It pays the bills nicely to travel with work, but it leaves no time to get things done at the house, I would have already had all of this fixed, but with my recent travels to Oman from November 11th to Dec 17th 2010; and then my trip to India from March 12th to April 9th I haven't had much time. Been trying to get the house all cleaned up and get my storage building in the backyard up.

Things should start coming together though

Joshua, as you are trying to make 500, to keep good spool time & etc, I would go with something smaller than a 76mm. Talk to Jose@Forced Inductions and tell him what you want to make & keep spool time to a minimum. I would think a 72mm would be fine to make 500hp, as my TC76 from Turbonetics I believe is capable of 800rwhp (could be wrong).

4-19-2011

I have not gotten numbers yet. trying to fix a small transmission leak now, and replacing both front wheel bearings/hub assemblies.

Doing basic maintenance.

It also doesn't help with work I have been out of the US for 2 months in the past 7 months.

Josh, call Jose @ Forced Inductions if you haven't. He is awesome. When I spoke with him, he said the smallest for my goals he would recommend would be the TC72. However, I told him 600HP...so for your 500HP or so you should be fine with a 70mm or 72mm. Talk with Jose about the ratio & sizing.

Also, for your questions about boost control... if you are wanting different levels you would be best to go with a Boost controller, where you can set it in the car to your liking. Are you running the factory pistons, rings, bottom end?

If yes please oh please run TR6 or TR7 plugs. The only real difference in the grade of plugs (standard...iridium..etc, is the service life) I'm sure you already know this though.

With regards to boost and all those factory parts, I wouldn't run more than 7psi; and I'm dead serious when I say that.

If you have aftermarket parts, then 10psi would be fine and just leave it. The way the wastegate spring works is it is the only resistance to control pressure, that is it. you do not get any other options, if its a 10 LB spring, then you will get ~9.8Lbs of boost roughly, its not going to be exact due to losses, more or less depending on piping design, intercooler.

with a electronic boost controller, you can change the boost on the fly, say you are in 5th gear doing 80mph and it is set on 10psi. you floor it, you will get 10psi. you can then change it to 14psi or 18psi if you wanted. I built the engine based on a maximum supportable boost of ~15psi, my limiting factor is my 2 bar MAP, as I have a HPTuners Custom OS 2bar installed. My rings & pistons along with my compression are good for at most 18psi (generalized statement).

if you have more questions feel free to PM me.

5-13-2011

damnit. Transmission is still leaking. I think that I have a damaged mainshaft bearing race inside the transmission housing extension. I put in a new rear seal and went for a drive and checked it out afterwards and it still leaks.

Going to take some pictures and investigate some more. Already bought ANOTHER new rear seal, and went ahead and purchased the new transmission extension housing that comes with the race bearing.

Hope to have the housing by Tuesday...start on it Tuesday night maybe Wednesday...hopefully be finished by Thursday night and if not will have to work on it starting that following Monday...traveling on the weekend.

5-15-2011

Well, found out that my transmission leak isn't at all a transmission leak. It is a drive shaft leak. Yeah how about that.

The damn thing is leaking between the seal surface at the point of the front shaft that goes into the transmission and its associated U-joint I guess you would call it.

5-18-2011

my moser 12 bolt has a detroit true trac. Love it.

Here is the leak.... was trouble shooting and the black crap is RTV I was using to determine if it was the transmission or the rear yoke seal

6-16-2011

I've run into a problem after fixing my yoke. Just FYI, my fuel setup is:

Racetronix PnP 255 in tank w/wiring harness

External Bosch 044 w/ window switch at 3k

Fuel rails (black anodized) and all AN fittings, Y at front of car, loop at back of engine

Aeromotive FPR

Aeromotive external filter

I swear previously, when I turned the key to RUN and the fuel pump primed and my fuel gauge went up to ~50psi (set at via FPR) and it would hold. I could then crank the car and it would crank just fine.

Now, I turn the key to RUN, it takes what seems a few seconds longer to prime and it peaks at 50 then falls right on its *** down to zero and the car won't crank (obviously).

Then key off, then back to RUN, and then I cranked it right when I saw the fuel press gauge peak and it started right up. It maintains pressure during running, even during WOT and it increases with MAP (FPR feature).

Only thing I have noticed is that lately my voltage gauge in the car seems to be reading high. I got under the car and checked for leaks... couldn't see any. Grabbed my 12V battery and some wire clips and went for the pump (in tank) forced it to run for a bit, then checked under the car, then forced it again, then checked under the hood.

i looked all over the injectors, fuel rail, fuel lines.... couldn't see a single wet spot. Any advice?