By diyauto

I tried to give the shop all the instructions on how to do the walbro fuel pump properly for an 08+ STI. They didn't follow all the directions and so the car would start poorly. Not being a gear head or grease monkey, I used my laptop and several different threads to dive into fixing my fuel pump on my own rather than go back to the shop. I lost trust in this shop so if you want to do something right it is best to do it yourself, at least for this.

I did some plastic removal on the fuel pump housing and used the double o-ring trick on the fuel pump nipple. Once all put together I fired up the car and it was as if it was stock.

More tuning with Phatron once again. This would take about 3 weeks to do. We would do a few pulls a night. Before we would do them till 2 in the morning. He is on the west coast. This time around I just could not pull that off anymore. Plus I had to switch up my places to do these pulls in order to avoid being a target for the "you know whos". At the end we were at 350 TQ, 340 WHP using Airboy to calculate the road loads.

Could we push it more? Yes. Did we want to? No. 400 WHP as a limit is known but one dyno compared to another is never the same. Knowing that this was my only car and extremely important for me to have running, Phatron talked sense into me to not go further at this time. The car has been on this tune ever since.

I made a contact with a fellow South Florida Subie owner and he pointed me in the direction of a shop that has done work on many of the local subies. Gustavo at TAV Racing in Doral. Extremely nice guy. He used to race his own open wheel car and has a beefy 2007? STI. He had this car in his shop when I went to see him:

Stroked Cosworth Long Block in a full race car. The hole thing was gutted

My first upgrade with TAV was Group N Engine and Transmission Mounts

Cobb came out with the launch control addition and I added that to my tune.

So, June comes around and I continue to do research on this forum and cannot get over the fact that my stock pistons suck so much. I decided I had to change them. But doing a swap is not what I want to do. I want to drop a short block in. This would minimize the amount of time that the car would be at the shop to swap motors. I went back and forth on buying a fully built block and building my own. In the end I decided on building my own block.

The idea was to buy parts slowly over the next few months until I had everything by Christmas. I couldn't hold back. The purchases began in late June with:

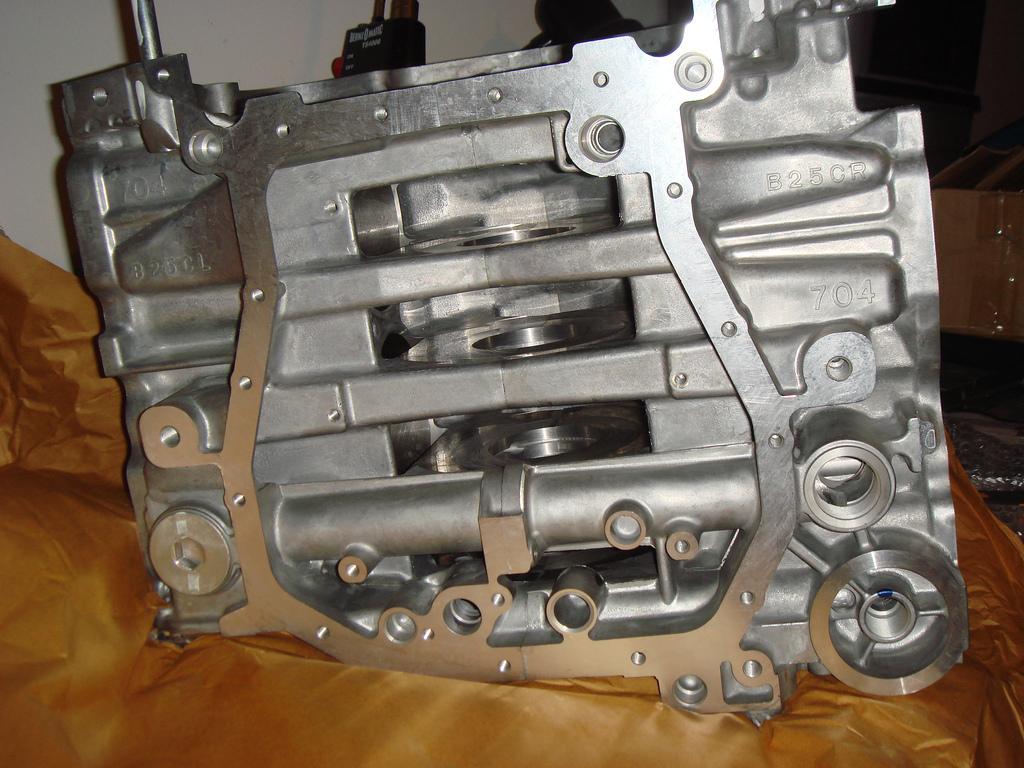

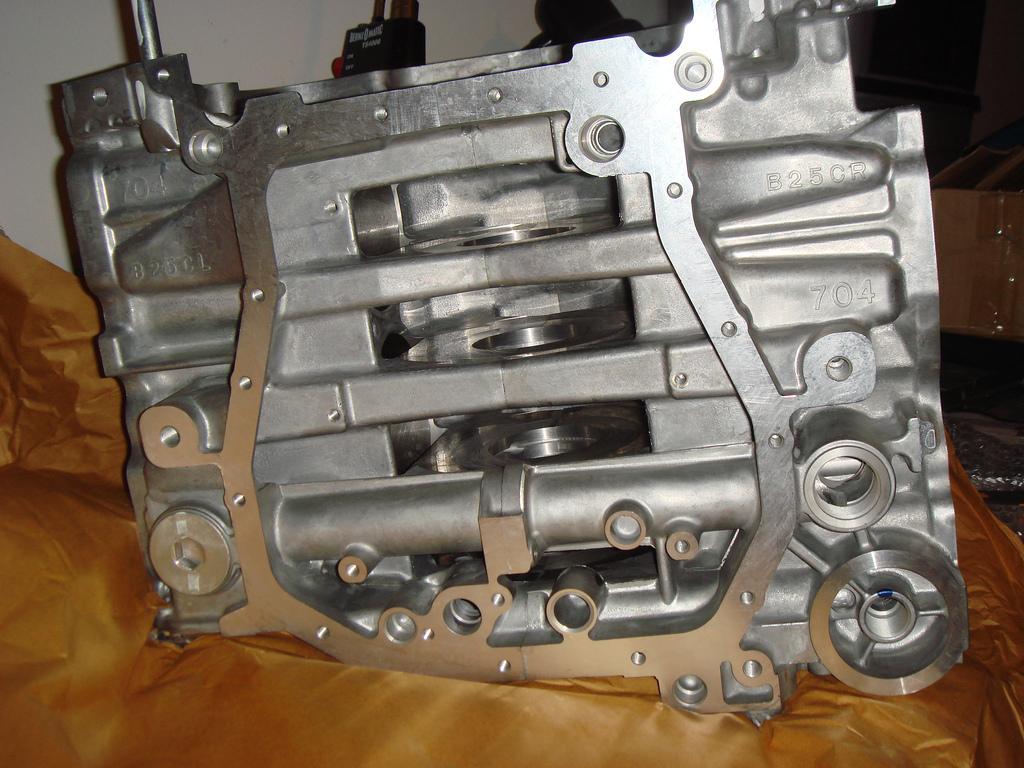

A new EJ257 block

You must be logged in to rate content!

5 minute(s) of a 118 minute read

8-14-2011

8-14-2011

Work is done

I tried to give the shop all the instructions on how to do the walbro fuel pump properly for an 08+ STI. They didn't follow all the directions and so the car would start poorly. Not being a gear head or grease monkey, I used my laptop and several different threads to dive into fixing my fuel pump on my own rather than go back to the shop. I lost trust in this shop so if you want to do something right it is best to do it yourself, at least for this.

I did some plastic removal on the fuel pump housing and used the double o-ring trick on the fuel pump nipple. Once all put together I fired up the car and it was as if it was stock.

More tuning with Phatron once again. This would take about 3 weeks to do. We would do a few pulls a night. Before we would do them till 2 in the morning. He is on the west coast. This time around I just could not pull that off anymore. Plus I had to switch up my places to do these pulls in order to avoid being a target for the "you know whos". At the end we were at 350 TQ, 340 WHP using Airboy to calculate the road loads.

Could we push it more? Yes. Did we want to? No. 400 WHP as a limit is known but one dyno compared to another is never the same. Knowing that this was my only car and extremely important for me to have running, Phatron talked sense into me to not go further at this time. The car has been on this tune ever since.

I made a contact with a fellow South Florida Subie owner and he pointed me in the direction of a shop that has done work on many of the local subies. Gustavo at TAV Racing in Doral. Extremely nice guy. He used to race his own open wheel car and has a beefy 2007? STI. He had this car in his shop when I went to see him:

Stroked Cosworth Long Block in a full race car. The hole thing was gutted

My first upgrade with TAV was Group N Engine and Transmission Mounts

Cobb came out with the launch control addition and I added that to my tune.

So, June comes around and I continue to do research on this forum and cannot get over the fact that my stock pistons suck so much. I decided I had to change them. But doing a swap is not what I want to do. I want to drop a short block in. This would minimize the amount of time that the car would be at the shop to swap motors. I went back and forth on buying a fully built block and building my own. In the end I decided on building my own block.

The idea was to buy parts slowly over the next few months until I had everything by Christmas. I couldn't hold back. The purchases began in late June with:

A new EJ257 block

A new OEM nitraded crank

Early July I decided to get some internals:

Cosworth Parts

Cosworth 99.5 Pistons

Cosworth Rods

Cosworth Piston Rings

Late July I went ahead and ordered some supporting parts for the build. (Pics to come)

ACT Xtreme Street Clutch

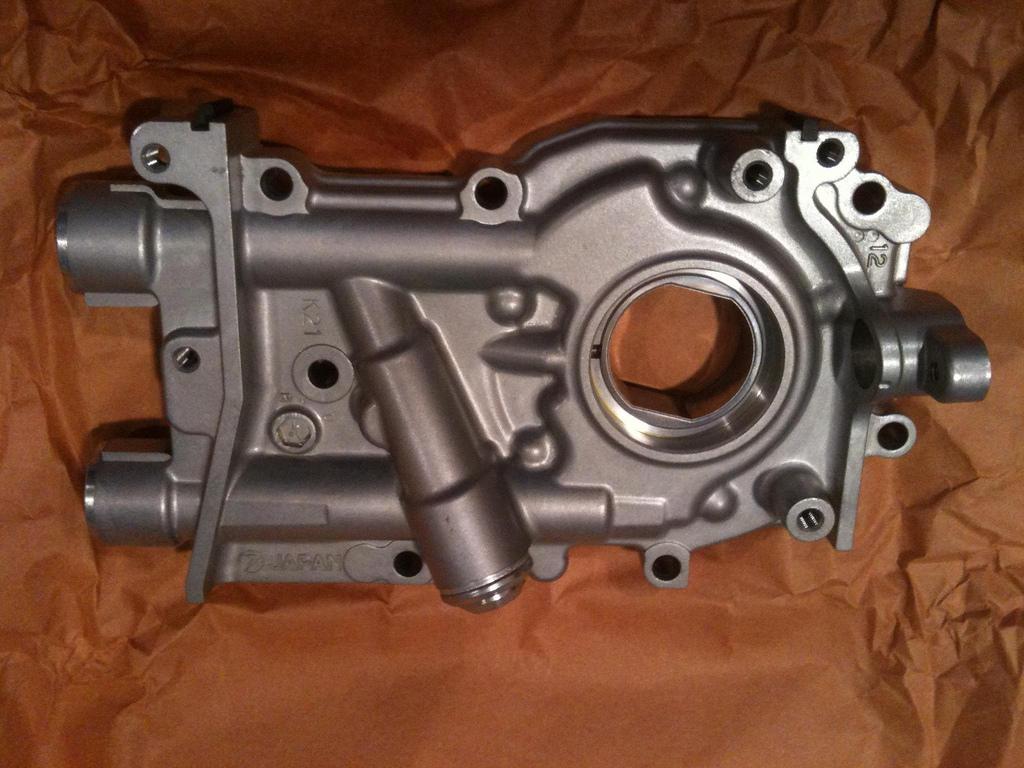

OEM 12MM Oil Pump

Ribeye?

Read the Full Article:

http://forums.nasioc.com/forums/showthread.php?t=2226222&highlight=build

Great build and details!

Posted by Diggymart on 2/20/19 @ 1:21:20 PM