You must be logged in to rate content!

6 minute(s) of a 278 minute read

10-26-2006

very slow progress. Too many other projects and such, but should have the rest of the bottom end buttoned up tonight.

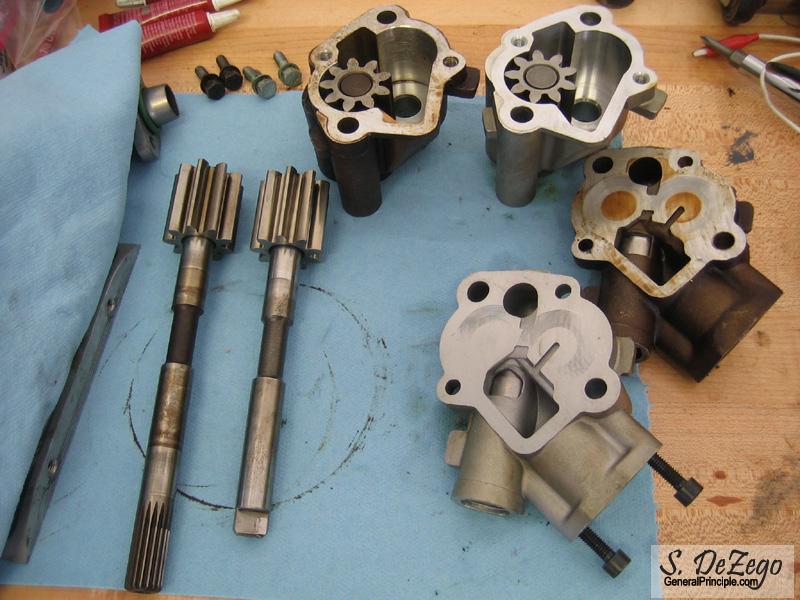

in the mean time here are some pic of the Oil Pump.

In case anyone is planning on changing directions Mid stream as I did (Dist vs COP or WS) or in case you just enjoy saving a few $s, here is a tip.

If you plan on running the 16v Oil pump drive Gear and dist block off setup you can swap the Shafts from an old 9a oil Pump into the much less expensive ABA oil pump. I don't think the 16v PL has the recess notch on the Oil pump shaft becuase it does not have clearance issues as the 2Liters do, but irregardless.

Pics tell the story. oh, yea, you MUST have a press!

November 04, 2006

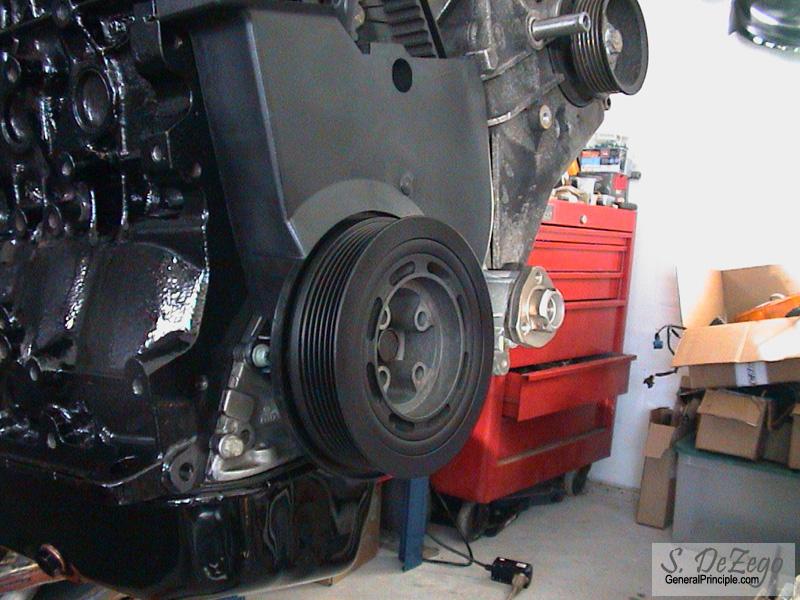

Another week out of town on business, but made some progress in the machine shop today. Here is my way of modifying the ABA serp pulley for the wider 16v/20v belt.

- Total cut was ~5.8mm

- .001" press fit

- perfectly eccentric and uses stock crank centering

- perfectly balanced

December 10, 2006

Yea, that was the only one I had at the time from a spare motor. Since that pic I did get up an OBD1 ABA TB

I really haven't finalized the routing design just yet, but I have a plan and a fall back plan.

My Main Goal is to keep a nice compressed flow out of the charger down into the FMIC (Drivers side) and then from the FMIC P/S up into the TB.

Having the air filter on the PS might be a bit tricky to route and probably impossible with the stock air box, but running the Eurosport Coolflow and a K&N looks doable.

I really want to go back to the stock air box, so I may run the air box on the Driver's side where the battery is and trunkmount the batt.

I also plan on making the charger bypass mechanical from the stock G60 butterfly/Bypass welded onto a pipe just before the TB.

Shawn

January 02, 2007

In the process of doing the head now, just too many things going on at once. I finally had a chance to finish the install of Megaaquirt on my current setup and am in the process of tuning. Fired right up and had it idling perfectly rock steady with 42# injectors @ 3 Bar in about 5 minutes ...needless to say it did not idle like this with Digi.

Anyway, here is what I am working on with the head and should have some more pics in the next few days.

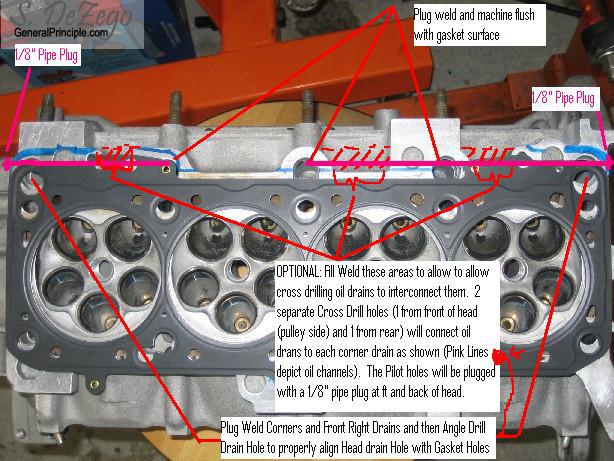

I ordered up some T6 AL Rod(s) and I am going to cut some short discs and knock into the head drain holes and then plug weld flush with the head's gasket surface. The corner holes, as well as the right front drain, will be angle drilled from the drain holes in the gasket to the drain holes in the head. This will align the crush surfaces on the gasket properly with the head.

This next step is really what I consider an optional one, but since I am already welding on the head, it is not much more work. I am going to interconnect the 4 rear oil drains via oil galleys. This is to prevent any oil pooling near the exhaust valve guide seals from plugging the 3 center oil drains. 1 will be connected to the rear corner and 2 will be connected to the front corner. This requires filling the areas shown below hatched in red and then cross drilling 2 galley holes (one from the front of the head and one from the rear) to interconnect the oil drains. These do not need to be big. A 1/8" pipe plug at the front and back of the head will then plug these pilot holes (just like the factory did for the lifter Oil Galleys)

January 08, 2007

Update: I didn't get to finish the welding on the head yet, but did make progress of sorts. Tonight, I logged 25 miles on the MsnS setup that I built up for this motor. Had a snafu on the first run the other day but got it sorted. I still need to fine tune, but it runs absolutely amazing thus far

S

January 10, 2007

As just mentioned, I finally got the Megasquirt setup installed that I had build over 6mo ago. It is all hooked up on my current G60 8v setup, so I get any bugs worked out and get a base tune for the new motor etc. I am really beside myself as to how well MS works and it's capability After only about 30min of driving by myself, I have the car about 90% tuned. The software for MS is truly amazing...

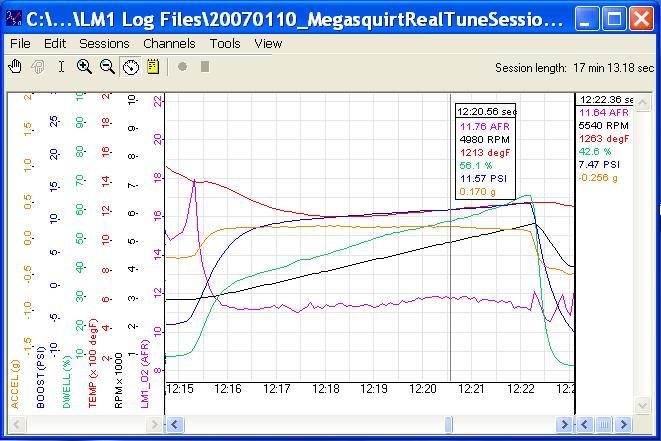

Here is a quick data log from my LM1-LMA3 wideband. The spike just before boost is because I have Acceleration enrichment turned off for tuning purposes. It is still a bit on the Rich through boost because I had the Authority set low in Autotune, so that it was only able to make small changes at a time. Still learning the software and just need a bit more driving time before I can close this chapter. But not before a little Digi vs MS Dyno showdown. I still have Digi currently in there that I can swap back and forth with a harness plug change