You must be logged in to rate content!

11 minute(s) of a 219 minute read

12-15-2010

jeremy, the ulitmate goals will be 800. why? whynot? but to start off with, going to run a head spacer and keep the boost down... need to figure what does what with the build and will give me time to save a few pennies to build the mechanicals to handle big boost... but expect around 450 to start off with...

speaking of which, the turbo madness has begun...

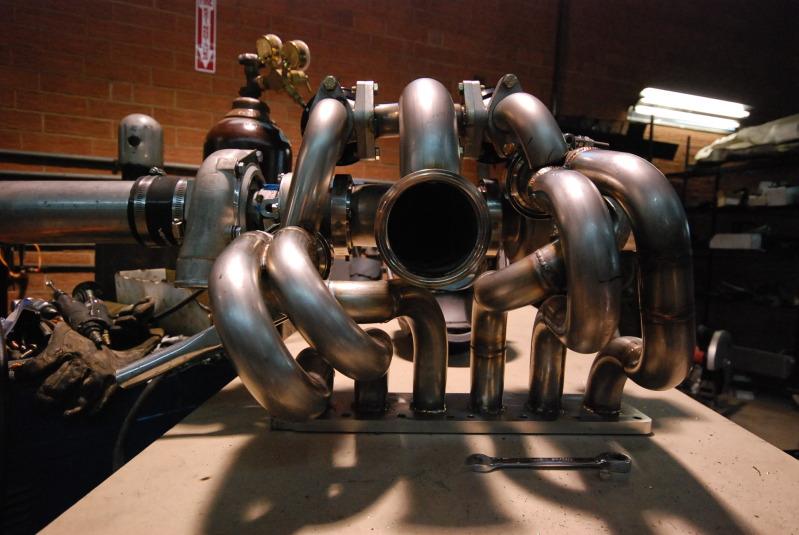

Yesterday, doug began fabricating the exhaust manifold and dp.

He used 3" 90 degree stainless bends, and split them down the middle to merge both downpipes together for both turbos.

And a turbo mock up pic... imagine it all sitting behind the head.... giggity...

12/20/2010

not really sure if this needs much explanation...

12/21/2010

so enough bullpoo and on to business. sorry the update was weak last nite but had a long day since its a short week for me. so this is what the knuckle heads up at eurowise came up with so far....

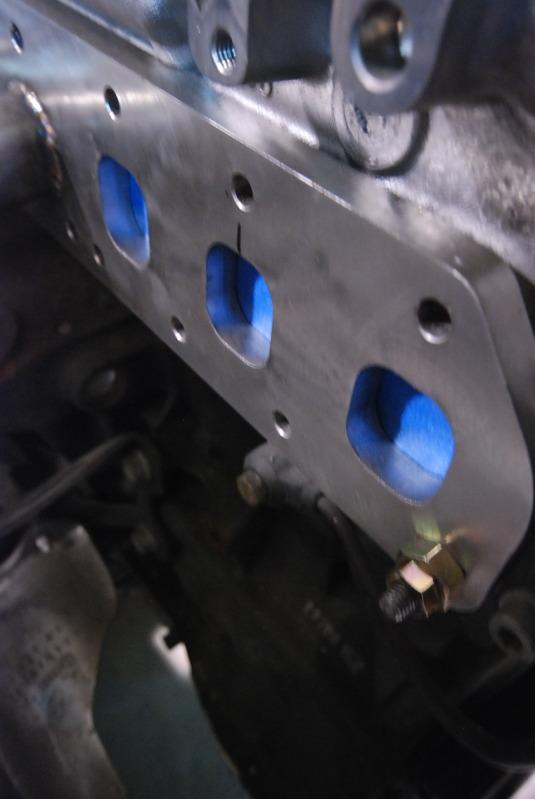

Due to the R32 cylinder head's rectangular exhaust ports, they formed 1.5in exhaust piping into rectangles and tig welded them to the flange. Due to the length of piping going to be used and the weight of a turbo and wastegate per 3 cylinders, they will brace the manifold and turbo once built...

Bank 1 mocked up

And the durty begins... a few different views to help with the perspective.

And a pic showing how far the cold side is from the brake resevoir....

12/23/2010

sorry..... just got back from a little party.... only 3 more christmas parties left....

either way, they got a good bit down today... hopefully enough pics to turn your

upside down....

upside down....

They began working on the last 3 sets of exhaust runners.

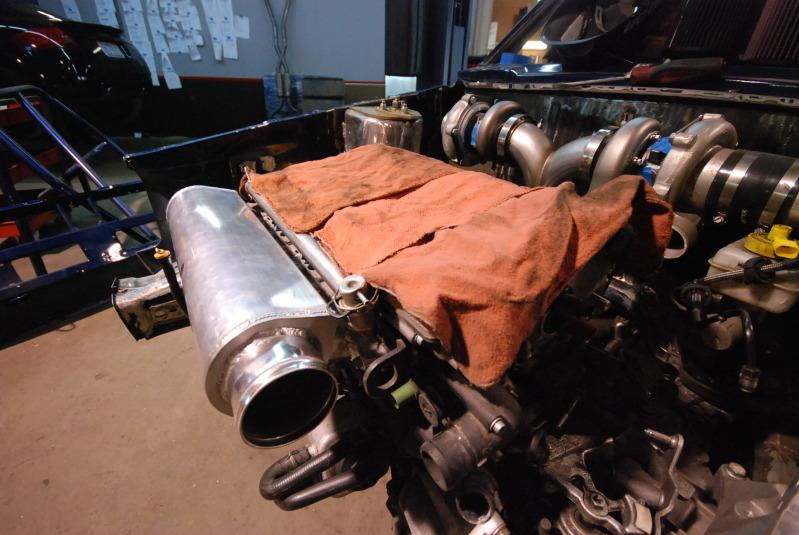

The special order k&n air filters came in. This will be the location (not sitting above the hood  ) of them once the inlet pipe is fabricated.

) of them once the inlet pipe is fabricated.

They started the build of the intake manifold today also.

Doug tacking the plenum in place. Notice the earphones.... He's a big REO Speedwagon fan

The end caps welded up and manifold mocked up.

Next up they worked on the valve cover. With the engine raised for oil pan clearance, and with the stock oil cap on, the cap comes very close to the hood. So Mike had a trick idea and used a custom fill cap to solve the issue.... Way to use that noggin MIke

The current oil cap height.

The pop up oil cap we're going to use on it.

The oil cap screwed on.

The cap in its completely seated position.

And the trick comes all together.... They machined the original fill cap off the valve cover and welded a piece of aluminum tubing in place, then welded the pop up cap on.

1/3/2011

So what got accomplished today at eurowise..... exhaust manifold updates.

A perspective from the top.

The exhaust taken off to show it off, mainly to compensate for my small gerbal like package...

1/4/2011

so towards the tail end of the day yesterday, eurowise got the a3 application wilwoods in from momentum, thanks guys

they also welded the oil return line bungs on the oil pan...

i know, pretty boring compared to the previous days work, but still very necessary and much appreciated....

1/5/2011

you might recall the original ruined dash that was used for mock up... it"s gone and the new dash was re-cut and fit into place. I'll probably re-upholster it with hair off esher's and tobi's chests... if it isn't enough, i'm looking for donors.....

the last pic was a trick.... if you noticed the dash before the turbo's you're officially a knuckle head...

and finally everything, up to this point, back in the bay.... ANYONE notice anything a little different..... give you a clue, its yellow...

1/6/2011

So they started working on the waste gate piping today. My only request was no open waste gate..... So this is how it goes...

They decided to go with the similar form and design from their downpipes. They will be 1.5 stainless 304 inlets and outlet tubes, and the dump tubes will merge together and transition from a 1.5in to 2.25 and dump into the downpipe. The inlets will come right out of the collectors.

a close up of doug's welding skills....

And pics of the single wiper hole shaved....

progress they've made today on the mani setup...

Good one!

Posted by Diggymart on 7/6/20 @ 3:16:11 PM