You must be logged in to rate content!

13 minute(s) of a 417 minute read

3-31-2016

Well little bits for the exhaust are starting to show up. Company sent me out the wrong X pipe but the right ones on its way... So if anyone needs a 2.25" stamped X pipe, let me know. Also have a cool little idea to piss off my neighbors in the works.

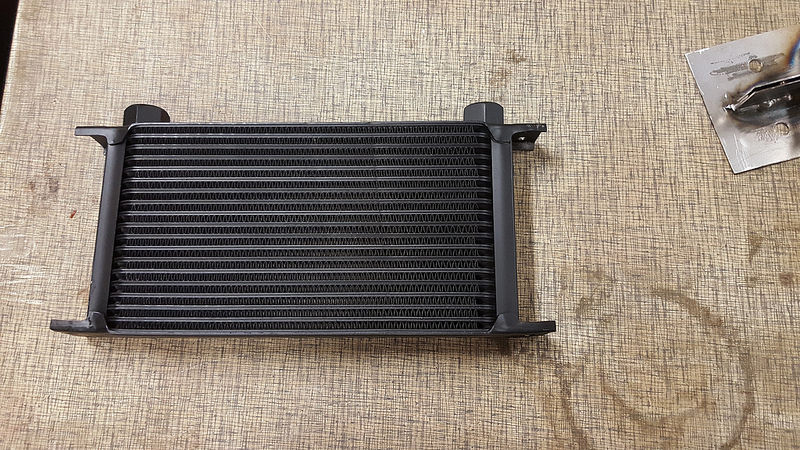

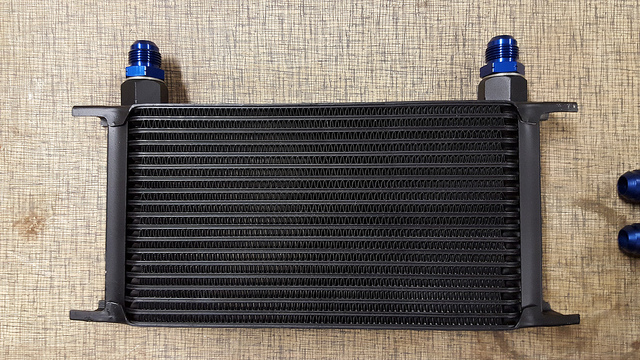

Resonators, flanges, oil cooler & oil thermostat should be here before the car comes back from JMP next week. Looking forward to getting this thing completed, getting very close.

Manual all the way; I don't really fancy the idea of the electric stuff cause I've read 50/50 reviews on most of them. Seems most of the solenoids either short out or just go bad. Besides heat & electronics don't really mix too well together so don't want to waste my money. Best ones are QTP it seems, but those are close to $500 for two. I can make a set of manual ones for under $60 that'll work just as good.

If I do cable driven, it'll have to be stainless & a thick spring since the condensation from the exhaust would rust the flange. I'm working on trying to get a TIG welder and have my friends brother teach me but that's a little ways away. For the time being I was just going to get a stainless flange and and pick up a sheet of 1/4" SS and do the 3 wing nuts till I have time to fab up something cooler. That way all I really need to do is work on the hinge & cable system later on.

In my opinion this is probably the cooler custom piece i've found but I'm curious how well the seal would be. Considering you can still see that the edges don't fit flush with the inner walls, so exhaust gases still pass through...

Link : http://absurdflow.com/exhaustflapper.html

4-1-2016

Ahahahahaha thanks man, by HOA im assuming home owners association?

I don't live in that great of an area of the city to have something like that. My areas the type of area you goto pick up hookers by the liquor store and etc if you really wanted to get a idea lmao.

I'm doing it for myself cause I always like the idea of just open headers, but LAPD & CHP would greatly frown upon that. Secondly it's to piss my next door neighbor off since she owns almost half of the houses on my street, and the guy across from me always gives me dirty looks when I'm working on my cars. He's only recently moved in about 8 months ago so after the fact of when I tore my motor out. Before when I used to drive it, you'd hear me from a block or two away cause I'd ring out my second and third from stop sign to stop sign for fun; just to put a smile on my face. It was more fun when I just had the exhaust manifold on my m20 dump out before I had the exhaust re-welded. Now that was LOUD.

Yeeeeeeeeaahhhhhhh I'm that guy.

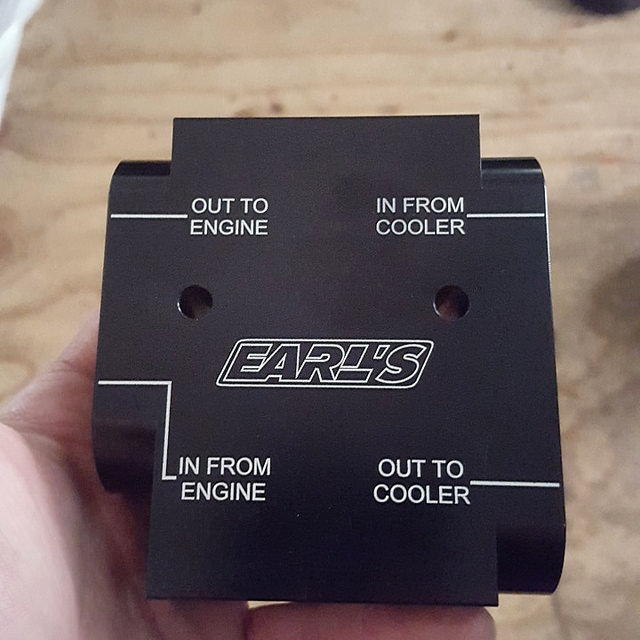

On a side note my thermostat showed up today... Anyone have suggestions for reasonably priced AN fittings?

4-6-2016

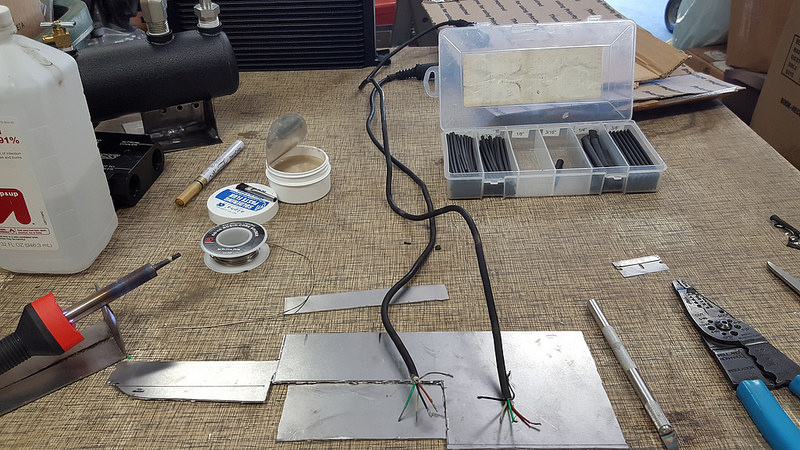

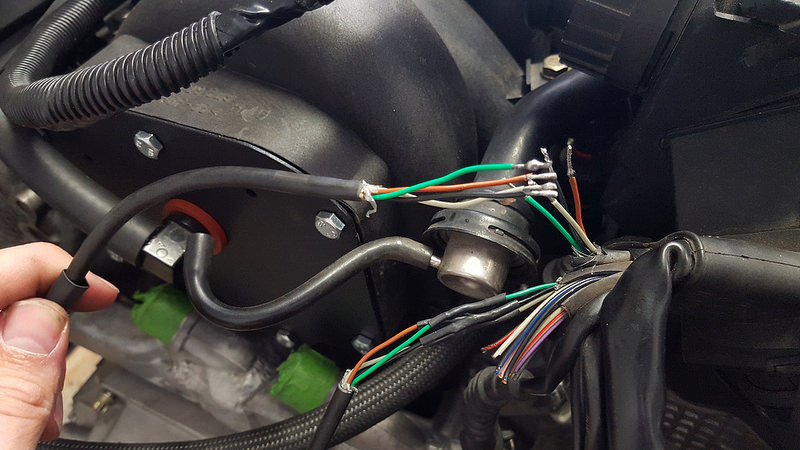

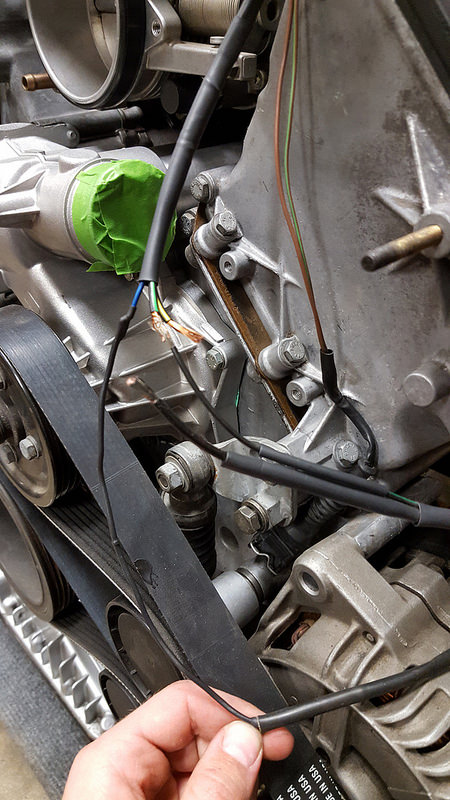

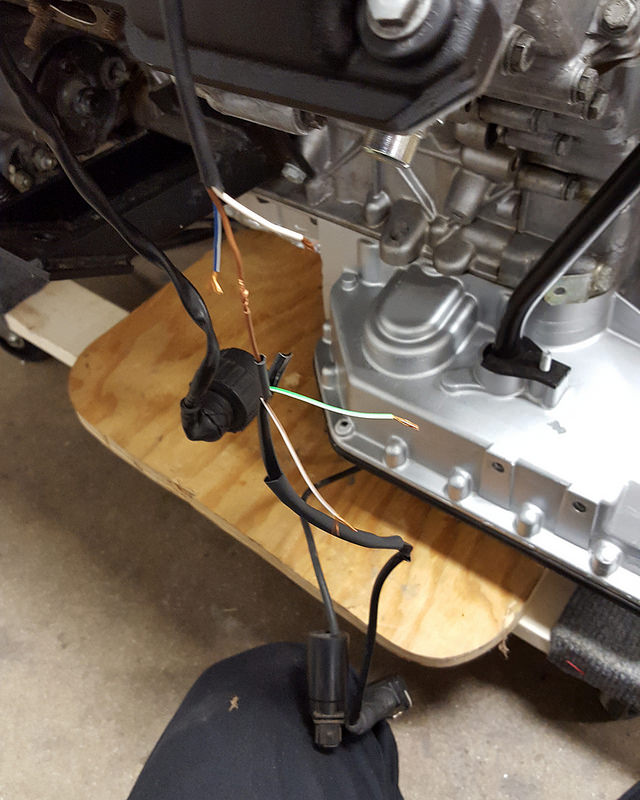

Went ahead and spliced the o2 wires back together; snagged them from the same car I got the o2 sensors from. Heat shrink ontop of heatshrink ontop of heatshrink. Cleaned, capped, and wrapped all the auto transmission wiring to avoid hassle. Can't recommend using Super 88 enough, best electrical tape I've ever worked with. Eventually I'll get some wire loom and make everything look a bit cleaner/factory ish. Hopefully I'll have the car back this Friday so I can get started on dropping it back in and turning it over. Just need to figure out two wires for the alternator & for the fuel purge valve. I have these few wires that I'm somewhat unsure of because they don't match my original harness from the 740 & the 540 that I pulled from the yard. Not sure if anyone can advise me on this, wiring isn't really my forte.

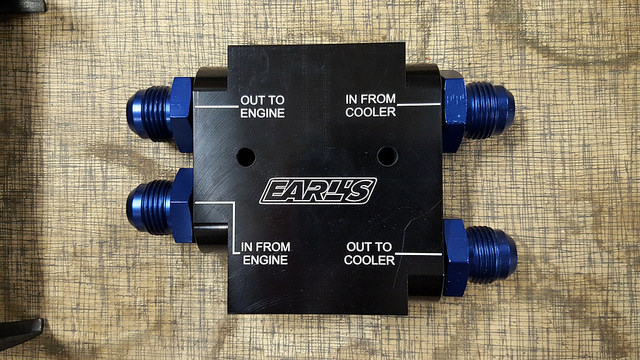

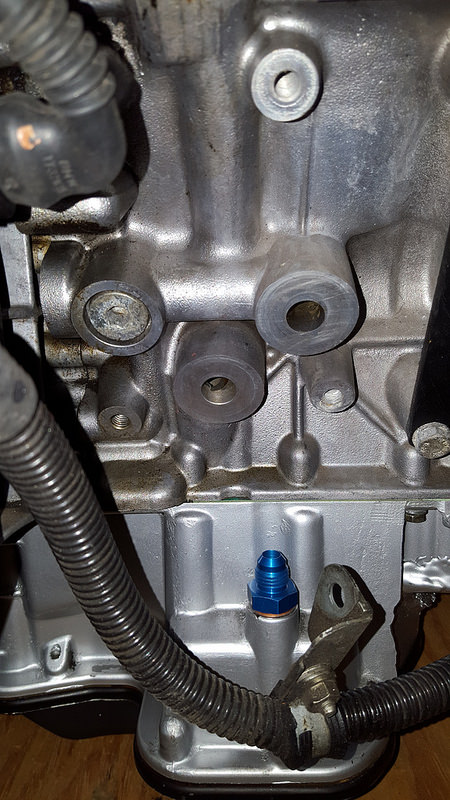

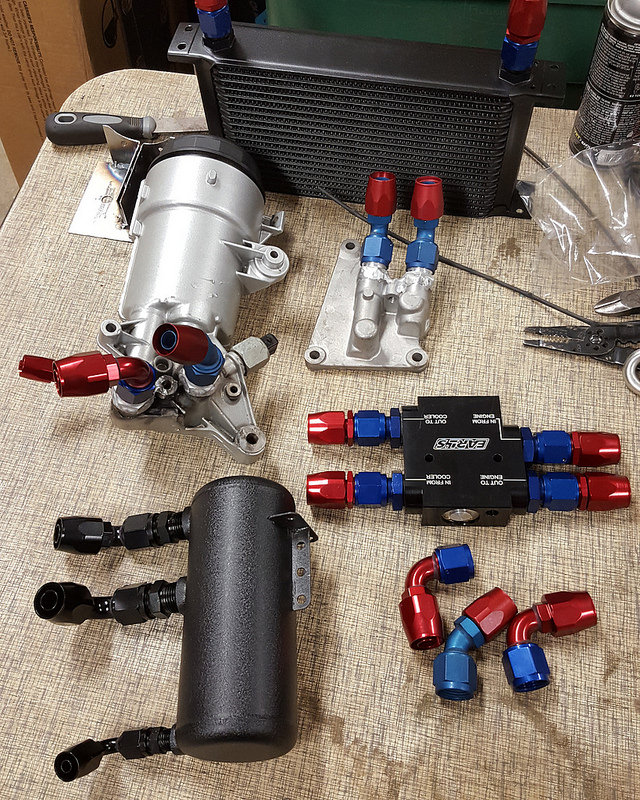

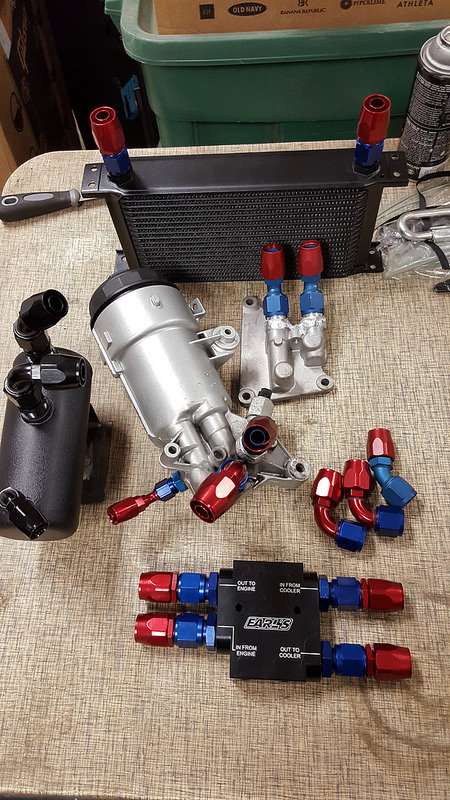

Oil cooler came the other day so once the car is infront of me I can start making a bracket and buy the AN fittings. Contacted Earl's plumbing since I wasn't sure what size fittings the thermostat required. Since they're based in the UK; they use UNF fittings there. I'm pretty familiar with NPT but it looks like I need to buy UNF to NPT adapters then NPT to AN to avoid leaks and cross threading. The UNF size is 7/8" 14 pitch for future reference. Going to check out Luky's down the street from me and see if they have any of these odd fittings.

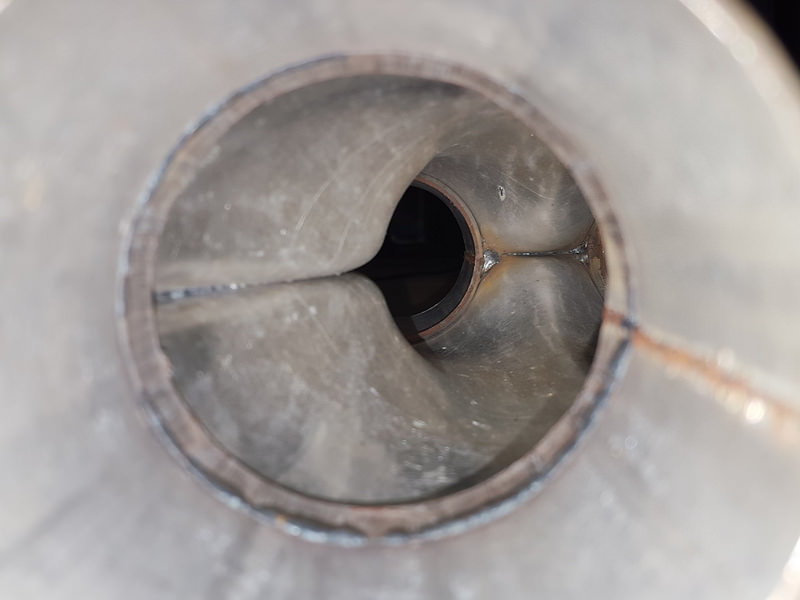

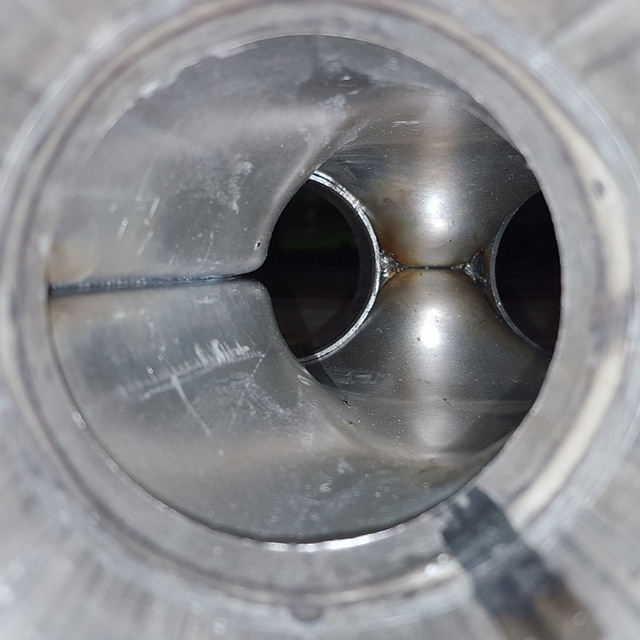

Received the 2.5" X pipe from the company and didn't really think there would be a great difference until I put them side by side. Really glad I went ahead and had them send the 2.5; looks like there's a pretty noticeable difference in the flow. Definitely looking forward to the exhaust work pretty soon.

Only things I really need to tend to at this point are the shift carrier & selector once the engine is back in. From there run a wire to the starter & alternator, and we should be in business finally. Oh yeah and I got this cool little mulholland sticket since I pretty much drive it everyday for work.

2.25"

2.50"

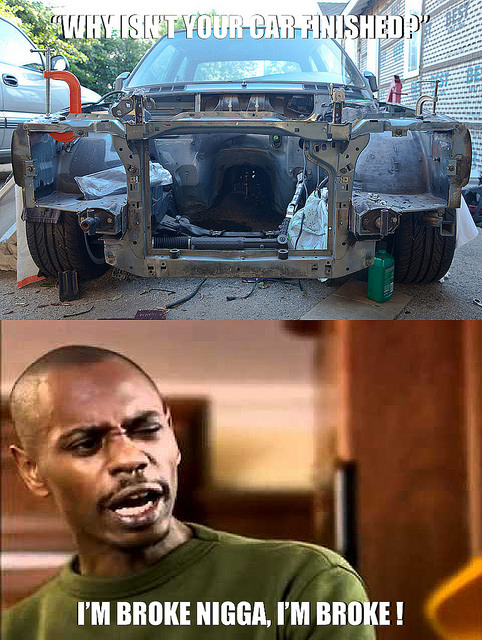

Oh and for a little humor; I keep seeing this one meme pop up on instagram since I had a few mins to burn I figured I'd make my own. Never made one before but fuqqitt.... This is the #1 most asked question from my friends and co-workers so I found this incredibly appropriate.

4-7-2016

Part 1 of my AN fittings; If anyone is local to the LA area. I can't suggest going to Luky's in Burbank enough. I would have wasted so much time and money playing what if's buying stuff through summit or online. Way easier to visit a place and be able to test fit everything before buying; beyond ecstatic. Also my mystery package now has a tracking number, so hopefully I'll be seeing it by the end of the month.

4-13-2016

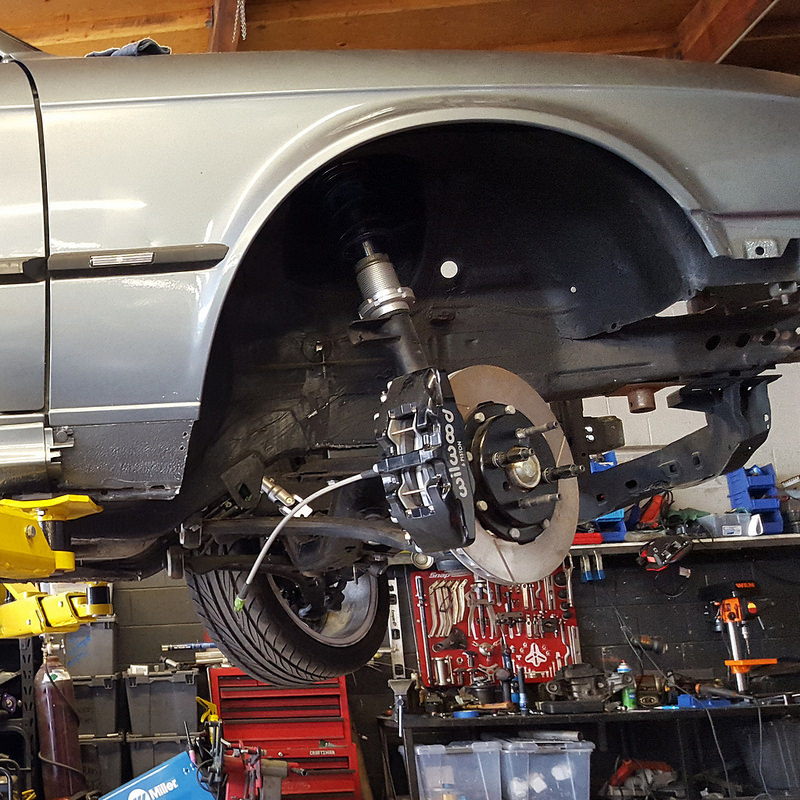

Well I got the car back from JMP Saturday afternoon. Jerrick did a badass job with the brake lines, after discussing the location of the brake reservoirs, we decided to move them again. Very happy with the outcome. Allan TIG'd the weld ons to the factory housings for me, did a pretty bang up job for cast aluminum parts. Got some nice professional looking wheel covers just to keep stray cats from pissing on my wheels and nice rotors.

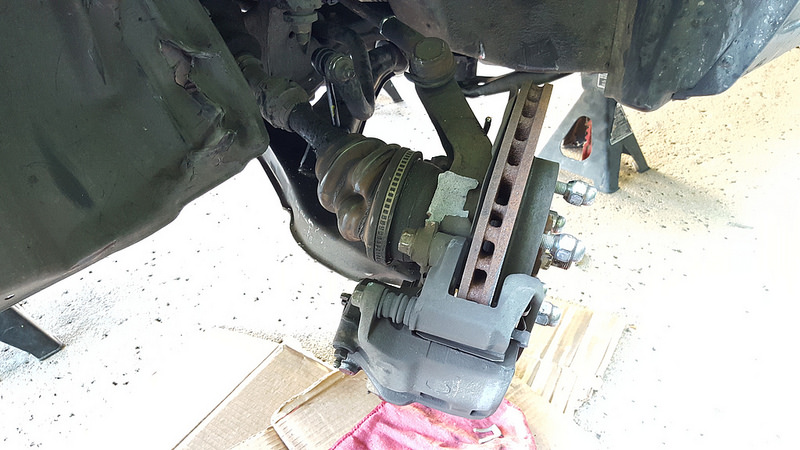

I got a call Sunday night that my friend crashed his car at around 11pm, so I had to come get it towed off to his house. Dudes so lucky not to had hit anyone or killed pedestrians. So after talking to his pops about how bad it was, this is my new project for the next week or two to get some more funds together for the e30. He snapped the knuckle, broke the shock off, bent the inner and outter tie rods, bent the axle pretty bad, smashed the control arm, and snapped the brake line off; just truly did a number...

Needless to say, curbs will always win against a car. So I've been running back and forth to Burbank a lot, hit BMA to get parts for the 00 Maxima, waiting on shocks and a used knuckle off ebay that I found for 75 shipped. Dealership wanted 380; aside from the knuckle and both front shocks, I got everything for around 380. So thats that.

I've splurged a little bit with some AN fittings... I think I have a problem guys.

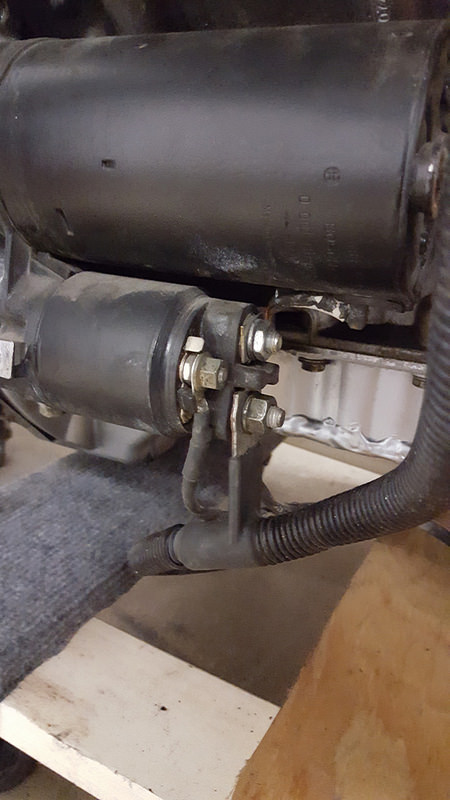

Came back last night and went ahead and did more research on my wires that I haven't looked too deeply into. Green/Black is 30h & Yellow/Black is 50 on the post. So i went ahead and spliced the wires I had from the original harness that were if I recall correctly 12 ga & 16? Grafted them onto the existing harness so fingers crossed. Spliced the alternator wire together, but I'm unsure where the green wire (igintion switch to the DME) from the 740 auto harness plug goes onto the 540 one; going to have to trace it back to pin 21 i believe and see where it is on the harness boxes. I'd think it would be with the blue, starter wires, and the oil pressure switch but nopes. Also went ahead and cut, spliced and soldered the oil pan sender to the oil plug connector since the 540 one didn't fit the connector I originally have. Found a e34 starter cable so I didn't have to go the home depot route. So ultimately as far as wirings concerned with the exception of the green ignition dme switch, everything should hopefully work.

Picked up another shift at work temporarily so that leaves me with 2 days a week to really work on this so I'm gonna try to get it dropped in hopefully one of these nights. Once I get the motor back in, I can get the SS lines made for the oil coolers and start routing them and only thing left on the list is cutting and re-welding the shift carrier/selector, exhaust work, praying the driveshaft is the proper length, running a line to the slave cylinder, and turning the motor on, then coolant stuff after all that.

This is cool!

Posted by Diggymart on 10/24/21 @ 3:22:32 AM