You must be logged in to rate content!

3 minute(s) of a 417 minute read

7-3-2018

Thought I had uploaded some of these pics but I guess not. Hell of a month taking care of my dog after a torn ligament/dislocated knee which has zapped a lot of funds. Along with a new job with weird hour shifts haven't really had time to work on the 30 very much.

Picked up a z3m cover since I regretted selling mine a few years ago. I began to try and degrease it & figured it was a waste of time, my buddy gave it a nice hot tank bath & dog approves. Also got hooked up with a little emblem for my hood piece to complete it. Meanwhile I took my whole hood off & scraped off the foam & gave it a good scrubbing to get everything off, unsure if I should refoam it or leave it be.

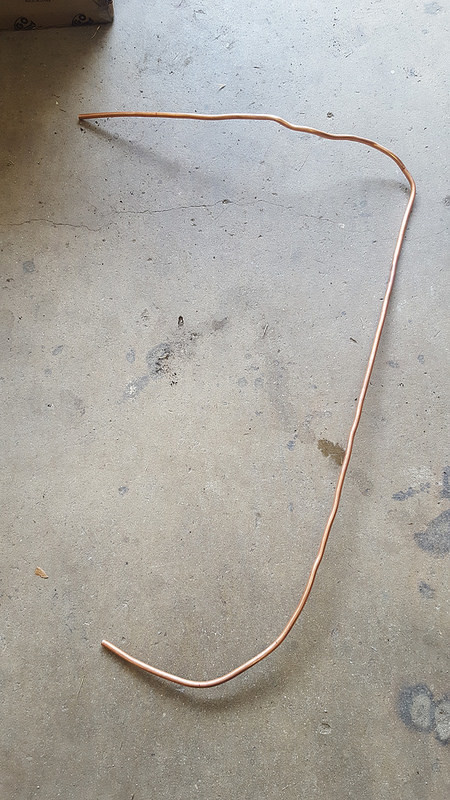

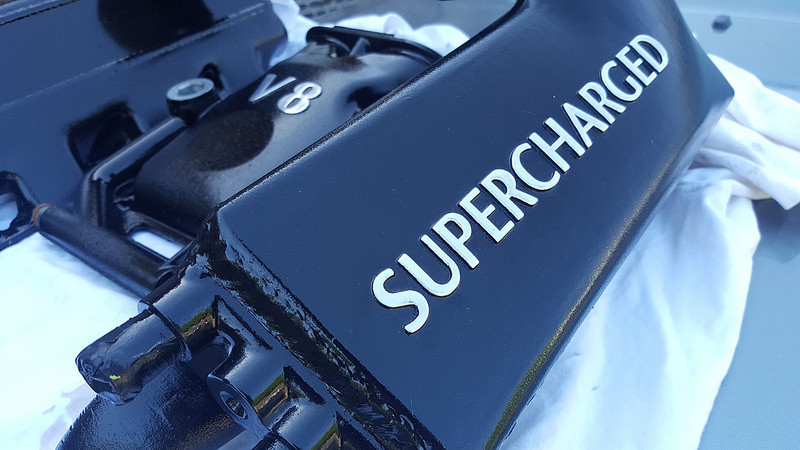

I went ahead and got rid of the ratty e34 overflow plastic line I got from the junkyard & made it out of copper instead. I realize I didn't take pics of the flares but theyre there. May just go ahead and use the left over copper for some fuel/breather lines to get rid of excess plastic. Still planning to relocate the charcoal can to a stock e34 location under the fender, gave the SC a more indepth cleaning, waiting on new needle bearings to come in. Figured I'd use up a scrap can of etch primer/high temp enamel I've had laying around to brighten it up. I had someone ask if its orange peeled but its just the texture, which will probably be a PIA to clean eventually. I know its not much of a secret but using chapstick or the likes on raised lettering will make your life easier. Wipes right off once everything is cured.

This is cool!

Posted by Diggymart on 10/24/21 @ 3:22:32 AM