You must be logged in to rate content!

11 minute read

Let's see how much m20 heads suck

Compliments of ForcedFirebird @ http://www.r3vlimited.com

9-5-2012

Lol!

Rest of what post? We are flow testing m20 heads, not much more to it.

Soon!

I can tell you this garage "ported" head that came from elsewhere flows worse than stock (158CFM vs 171CFM @ 28" .400" lift).

Flowing all the intakes to have a solid comparison. We only flowed one port on the "ported" head so far and a few on the stock head.

![]()

Kronus would not be anything in this thread without the inspiration for his artistic ability!

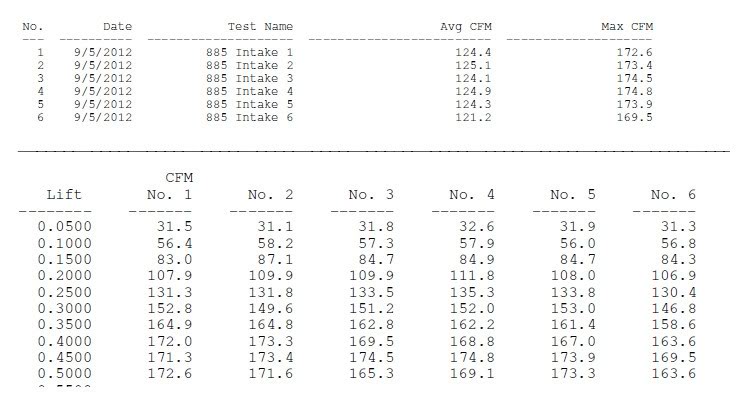

Our findings on a bone stock head randomly selected:

9-6-2012

Soon. We have to make a testing tube to be accurate. A flange and a few inches of piping welded up will do the trick.

Today we will test the "ported" head fully to see how consistent the previous owner was.

9-7-2012

This is common procedure for flowing bare heads. When doing port research, the manifold will be attached as well as a throttle body minus the plate. The clay may vary 1cfm or so pending the shape, but when you lightly peel it off, it stays near it's original form.

It's how many cubic feet per minute the ports flow.

Close up pics of what porting? The original owner of the "ported" head we flowed used pics on the internet to ruin his head. Pics won't do anything for you.

We have almost decade of porting and flowing experience, you actually have to feel the ports with your finger tips to know what was done.

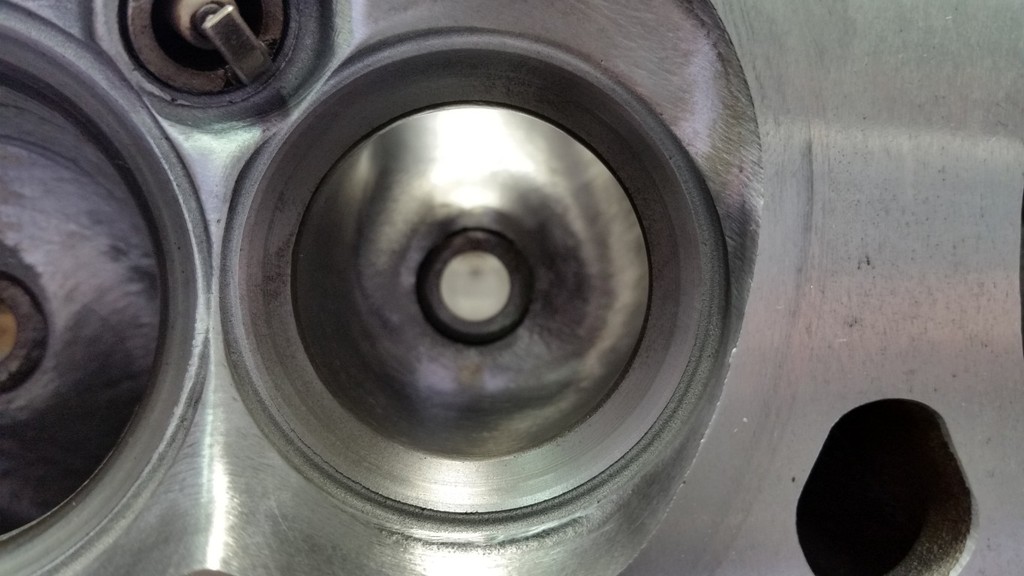

Here's a close up of some iron heads I ported. You can look at the pics all you want, but without a flow bench and flow testing tools, it's nearly impossible to copy from pics. It took several hours on and off the bench testing for dead spots and grinding out just a tiny bit here and there. Not only that, but the typical back yard mechanic doesn't have a way to measure volume, and how can you look at a pic and tell how much and where the material was removed in the chamber?

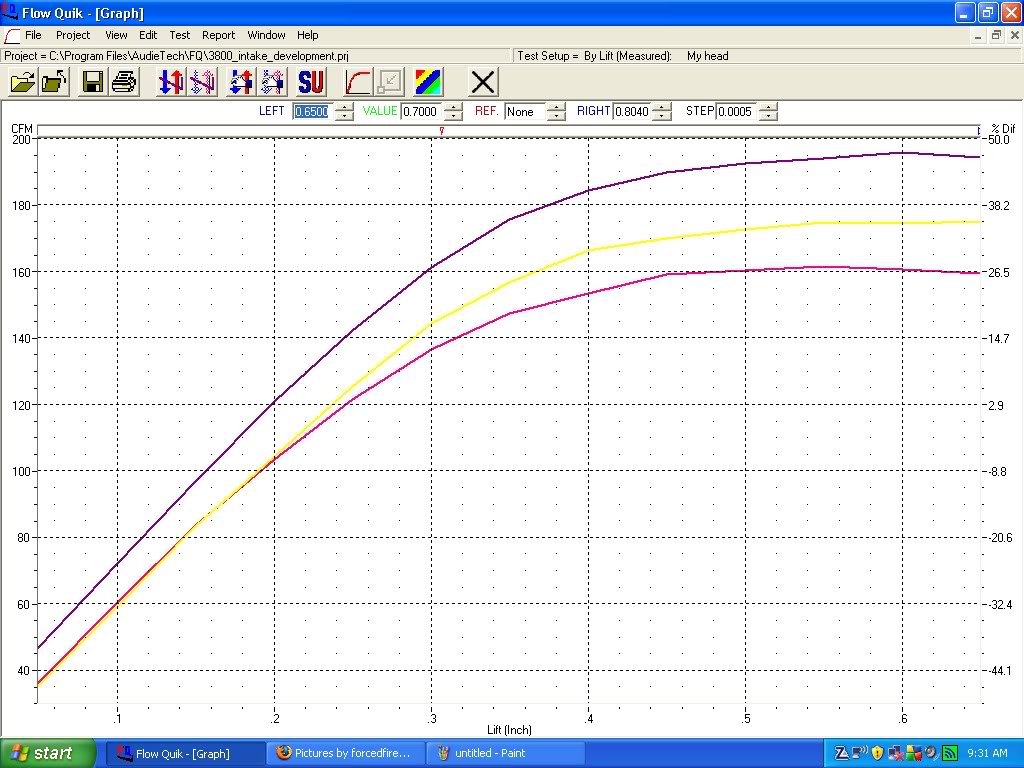

And here's a few plots of that head. Bottom line is stock, next line is after many tests and hours, the top is the flow when the heads left my shop.

Don't expect that from the m20. Old school iron heads with rectangular ports have a lot of potential where the m20 already flows well for it's size.

It's not complicated. Just took building the plenum and purchasing about $3000 in equipment, vacuum sources, piping, wood, aluminum etc.

This is why the best heads are flowed as a unit with the intended manifolds on it.

Potential is linear, the actual head flow is not.

We can get in to exhaust, but would like to keep this thread about flow.

http://www.e30tech.com/forum/showthread.php?t=106851

We have flowed them in various configurations, can even flow with the actual exhaust on it, the bench was designed around this kind of testing. Sure, it's easy to say "this head flows xxxCFM: and when the intended manifold is bolted on, it drops, might even bring it back down to stock bare heads.

In the past I have gotten a unit (heads/manis(s)) to flow more than a bare head.

9-8-2012

We started messing with clay, adding material in places, changing the shape etc. The clay can be shaped in a way to gain ~6CFM.

We are baking the carbon and blasting a manifold now to put on the head to keep the results stable. Hopefully we will have some results today.

9-13-2012

Well. The eta, seta and 885 manifolds have been flow tested. The results are very surprising.

eta manifold is better than you think. Let's start there.

9-15-2012

This is with the manifold attached, injectors installed, all vacuum lines blocked and throttle locked open. The non-test ports were also taped shut to prevent cross flow.

http://wot-tech.com/pdf/BMW%20M20%20Comparisons.pdf

We are several tests in![]()

The variance between ports are negligible, extremely close to equal between castings and individual ports

Also, Digger, those numbers are full "I", full sETA and full ETA. Didn't post our findings on mismatched parts.

9-19-2012

So after almost 100 flow tests and many hours in porting and research the eta manifold ported to match an 885 TB loses 4cfm averaged over all lift values vs the 885 manifold.

If you ported your 885 manifold, you killed the flow. It's already too big.

Now not only did you hurt flow, you decreased velocity.

11-12-2012

Let's get the results more consistent when testing without a manifold.

It follows the angle of the port entrance, then bell-mouths from there...

11-13-2012

Leave the heads and manifolds alone, all the "ported" stuff we tested either was same as stock or worse. Even if your "ported" head flows the same as stock, you are ruining velocity.

The seta manifold is junk in all aspects. We will prove it eventually, but, from what we have researched so far, the best bet is to use the eta manifold bored to match the "i" throttle body and 885 head. It's just theory based on flow numbers at the moment until we can get on a dyno and prove it, or see if the eta manifold hinders top end performance at all, but think it will be better overall - especially in the lower RPM's.

11-15-2012

I posted numbers![]()

The seta manifold flowed worse than the eta, proved it on my flow bench. The eta manifold barely flowed worse than an "i" manifold, almost dead even with an "i" throttle body (both on 885 heads).

Digger, I meant that the "i" cam would be a limiting factor on getting the b25 to see b27 torque.

11-19-2012

You can't port a head and expect solid results unless you have access to a flow bench.

Will be posting numbers here shortly, but we have gained as much as 20CFM in a few high lift areas. It's getting interesting now. 17 flow tests with removing material in between and flowing for results.

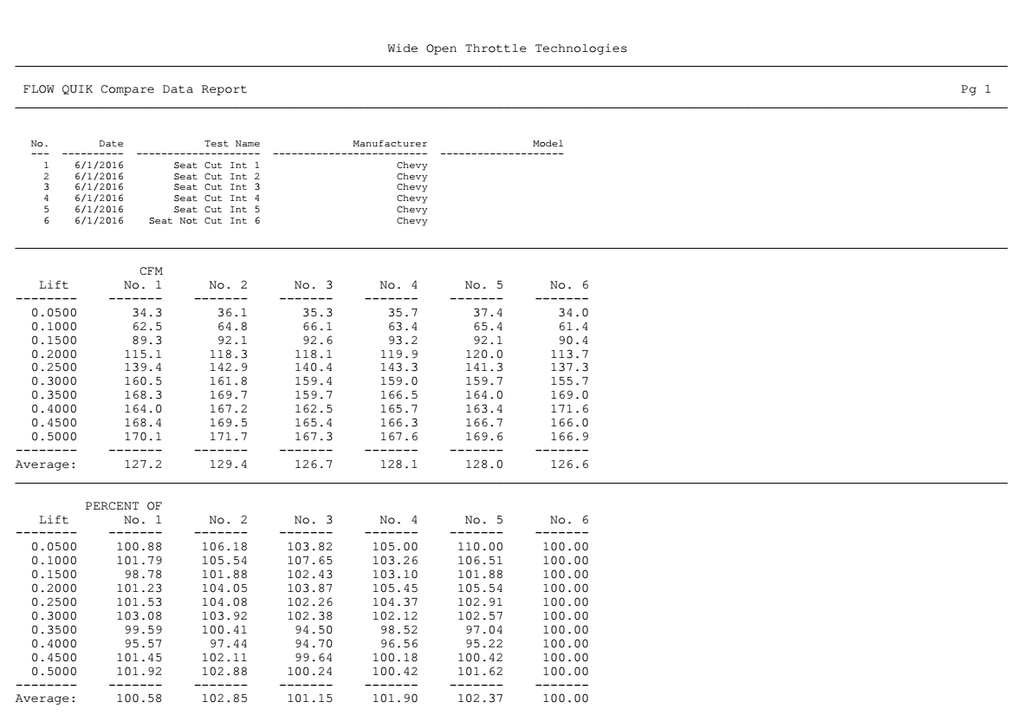

Here you see real numbers and percent of gain over stock.

http://wot-tech.com/pdf/885%20Port%20Testing%201.pdf

I have said it before. For now, the manifold already flows more than needed and any change to the manifold did not help flow at the valve. The valve/bowl is the restriction in a stock m20 setup. A few more CFM and the valve coefficient will be reached.

12-14-2012

Yeah. It's easy to gain flow in high lifts on m20 heads, like well beyond usable cam lifts.

No, we aren't done with research. The 885 head will probably need to have material added and reshaped to gain in the low lifts, but time will tell. We have hundreds of flow tests in and are using up all our cracked/damaged heads. Since we are putting time/effort/money into the research with no immediate returns, the process will be slow since it's being done after shop hours/weekends etc.

I can see 240hp no problem if you are talking at the crank, many guys including Digger are over 200 at the wheels which would be near 240 at the crank.

We back our findings up with dyno runs. Last one was 10whp gain by swapping on our porting only, not even a map adjustment in the PCM.

7-6-2016

Back from the dead. Thousands of flow tests later and we have learned quite a bit.

First off, the heads have a huge range from the factory and the valve job make or break them. We see a range from 165cmf to 181cfm from the wort to best flowed to date (max peak). Weather or not they have ever been rebuilt or had valve jobs is difficult to tell on these old machines.

We have tested the Ireland, Super Tech and stock valve comparisons, as well as purchased several Serdi multi-angle single insert seat cutters, cut the seats fresh with differing angles (qty and degrees), then flow tested, then removed material to suit, re-flowed etc etc. There is so much data, probably just easier to mention highlights, most of the tests have been very small differences.

Big bore throttle body (measured 64.5mm) showed zero increase in flow, in fact the numbers matched verbatim to the stock 60mm (~59mm). But, when putting a 48mm eta TB in place, the flow topped out at 90% if an "i" TB, so we know the stock TB really isn't a choke point on stock components. Only thing one would gain is a very slight increase with tip in throttle response, and maybe low RPM HP gain, but would have to be measured on a dyno. We are not going to waste research/time on a dyno for the m20 bbtb, as we tried it on a GM car and it only showed a 2hp difference, but that can happen in back to back runs, not consistently measurable.

The factory manifold drops a bare head flow about 5% average over the lift range, but as much as 8% in areas, obviously, in the higher lifts.

Most areas in the chamber seem to hurt flow when material is removed, so bottom line is, you really need to flow these heads if you plan on modifying them. Best thing to do otherwise is a good stock 3 angle valve job and rebuild.

8-10-2016

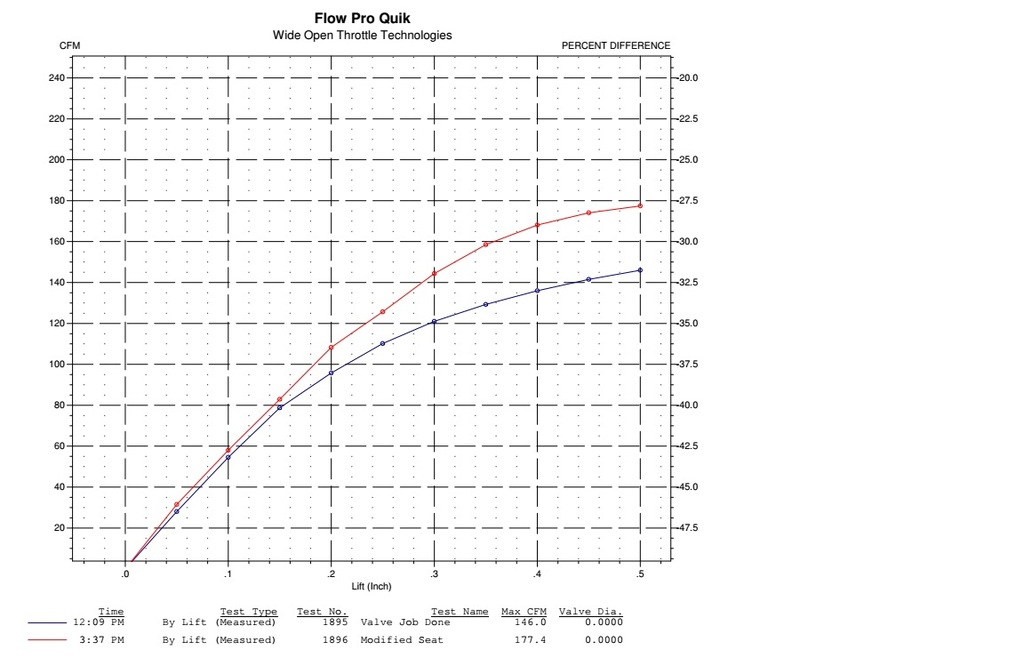

Slow on presenting data, but here's a comparison valve job only on a stock port with a stock valve. This is using the 5 different cutters, we tested both intake and exhaust with these cutters to determine what ones work best with what heads/valves. We now have to change all our advertised numbers as they were increased. Forget that it says Chevy, this is an m20 head, just always forget to change it in the software.

This is an example on a v6 head, but we get similar results from an m20.

Valve job alone with selected cutters based on flow numbers.

and modified with a second cutter, then by hand.

and the results.