You must be logged in to rate content!

4 minute read

My front CV AXLE DIY

Compliments of aioros @ bimmerfest.com

8-1-2010

This is just to put on writing and in pictures of my experienced on changing the left front cv axle on my 01 330 xi. I'm not gonna explain it step by step, you can look at a better DIY video on youtube, which I used as a reference. But I will point out some of the things that the video does not show.

Picture #1: I lifted the car and set it on jackstands

Picture #2: A look to the back side. You can see the boot all tore up and the grease all over the place. I found out that the tie-rod, the sway bar and control arm outer ball joint are bad and need to change.

Picture #3: I used a ball joint remover to remove the tie-rod end. i bought a tie-rod remover but it did not fit. I needed one that it is not wider then 2 3/4" on the top. you can see it in the last picture.

Picture #4: Something the video doesn't show is to remove the bolt holding what I believe is the speed sensor.

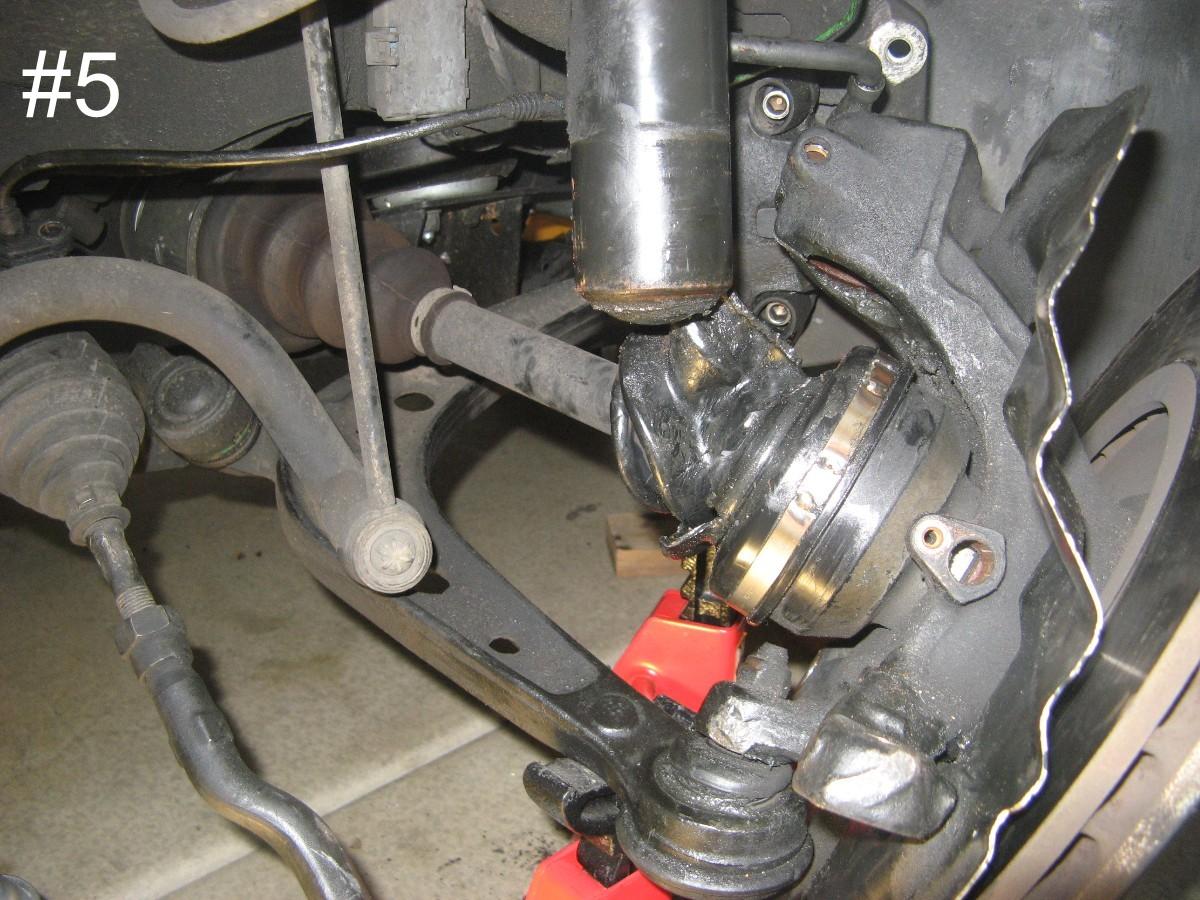

Picture #5: Tie-rod is off, sway bar is off (16mm wrench and torx wrench) and brakes and caliper are off. the video shows unscrewing the 2 guiding screws in the caliper but fails to say that you need to remove the 2 bolts that connect the caliper to the steering nuckle and to unscrew the cap for the brake fluid so you can remove the caliper from the rotors.

Picture #6: it was very hard to unscrew the axle nut (I don't have an impact gun) plus none of my two 36mm sockets fit in right. I bought one in sears thin enough to do the job. With everything out of the way, I used this phillips screw driver and a dead blow hammer to separate the axle from the hub. It need it a few hits.

Picture #7: self explanatory.

Picture #8: the old axle and the re-manufactured one from NAPA ($70 + $55 core)

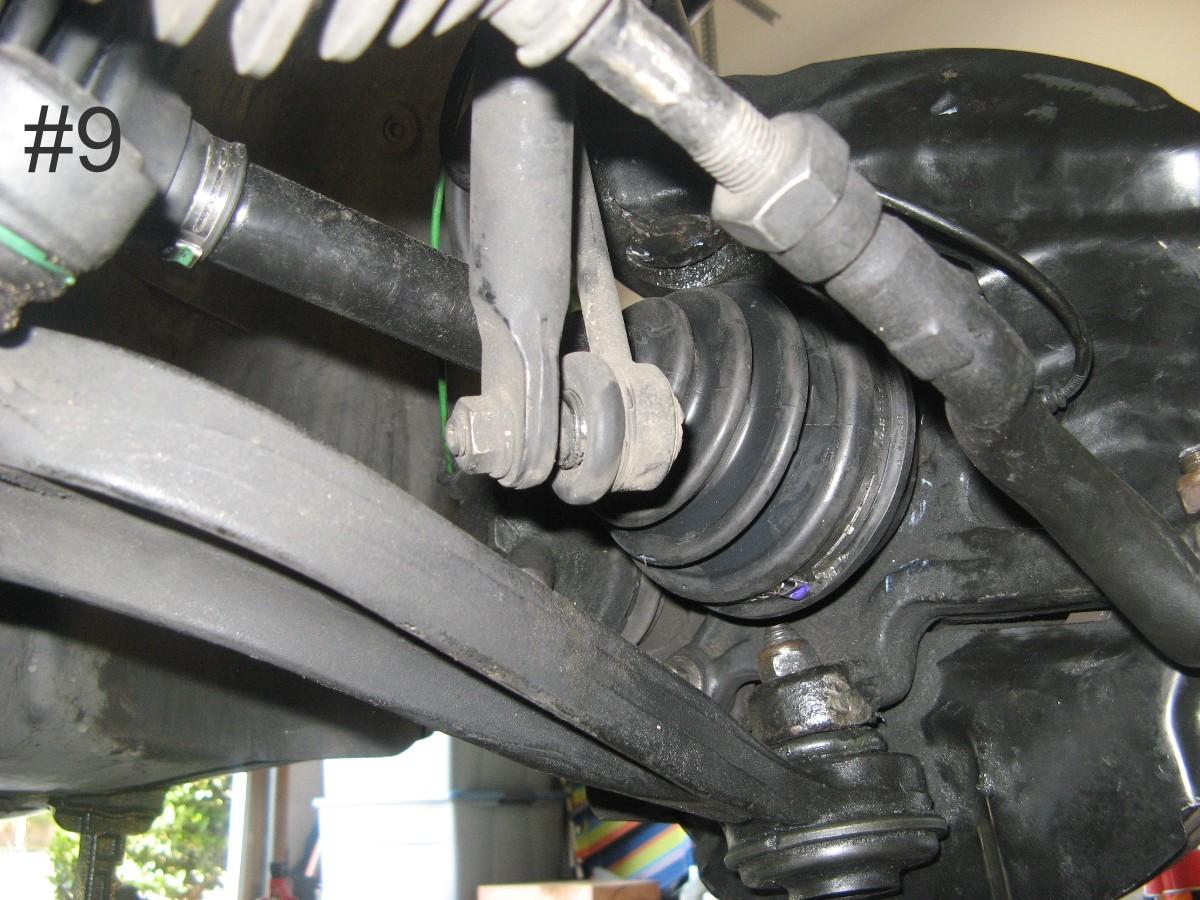

picture #9: it shows everything put back together but it was a BIG-HUGE PITA to make the hub go in through/over the axle. i used a 2x4 and the dead blow hammer and pounded it very hard a lot, a lot of times until there was enough thread to screw the nut.

Picture #10: Tools that I used. 16mm-to-19mm sockets, 36mm socket, ball joint remover from harbor freight, 1" dia pipe as a cheater bar, torx wrench, hex socket wrenches, 16mm wrench, ratchets, lots of paper towels, carb cleaner, common sense, etc.

the two sockets on the top are the 36mm that didn't fit right in the axle nut.

Since I couldn't find the torque specs, this is what I used:

-axle nut 100ftlbs

-lug nuts 70ftlbs

-tie rod 50ftlbs

All other bolts very tight