You must be logged in to rate content!

17 minute(s) of a 720 minute read

9-12-2010

First open hood and make sure your 240 has the big hole on passenger side radiator support wall .

First off, you remove airbox, open it up, and remove all of the temp operated preheat pipe "flapper valve"l inside the airbox.Bracketry, flapper & ALL. It pops out of little holes in airbox housing it mounts in.

Now clean the hella out of the airbox.

Now seal ALL the holes left in airbox from removal of the flapper. ANd the the deep " funnel shaped" hole in airbox side facing the front of car. Use Black PermaTex RTV Sealant.

Now find donor car, and pull the the plastic hoses/piping off on ithe OEM Volvo airbox off a 86-93 240, AND BE SURE to get the BIG rubber grommet and big C clip

that goes around the hole where accordian comes thru DS radiator support wall, from the airbox.

Now...On the driver's side I used the OEM Volvo parts(IE the 90* elbow, and the upright "snorkle" that has a 90* bend at bottom. I cut theupright snorkle toward midway in the upright, a littleat the time, until it fit in the 2 inch diameter(it's bigger on the bellmouthed ends) ABS plastic 90* "home type"water pipe. Have to "cut & try" by removing a little at the time. Use big, long straight cut tin snips made for heavy gauge duct metal.

I then used a little ABS plastic pipe cleaner to clean the parts where they meet, and then used a little ABS plastic glue, slid the two parts together. Make sure you have it all turned the right way here.

Then, I used PermaTex RTV Gasket Maker, to fill in the "bell" part of the 90* ABS elbow to the upright snorkle. Being careful to fill in the void completely, but making it look neat & professional.

On the Passenger side, I used a new IPD aluminum foily "Preheat pipe". Make sure you use one that is clean on the inside BTW, if using a used OEM one.

BTW,The OEM Volvo preheat pipe is made a lot better, but it's $100.00. Both are make to thread on the nipple on the bottom of the airbox. On the other end of it,instead of running it to the ex mani heat shield's nipple, I ran it to/towards an existing hole in the radiator support wall, that it on the passenger side. I think it's the hole made there for Rt hand drive car's airbox.

To connect it and make it look neat, I just used the OEM Volvo 90* elbow, the same one that attaches to the short accordian "tubing" that comes to the inside/thru the radiator support wall from the OEM Volvo airbox. This is all in the behind the grille area. It all fits in the passneger side hole on a 86-923 IINM. Mine is a 1991. Percussionist's 82 240 has the hole also.FWIW. 77,78,79 use a different set up and is even more easily modded & can use just one 4" ABS 90* elbow, I did this to my 79 245, helped a lot!

Now to connect the preheat pipe, to the other/big end of the OEM Volvo 90* , inside the engine compartment area, I used a 1969(IIRCC) 140 dual carbed B20, accordian "pipe".

On the 140 it ran from the plastic fliter/airbox, to the radiator support wall . I just so happens that is is the correct size on one end,to connect to the preheat piping , and the correct size on the other end to fit the big OEM 90* that sticks in thru the hole, into the engine compartment. I used a SS worm drive clampo to hold it there. And used silicone to hold it to preheat pipe..

I used some small malleble aluminum strappping I bought a Lowes, and cut, and bent/formed them to meet the ABS 90* elbows tops and tye wrapped them in place ,to the brakets, where they don't move & hit the A/C condender coil .

The aluminum reheat hose run under the radiator, and is fastened on both ends, and just sorta holdds itself in place due to it's stiffness. Same as Volvo did it.

The beauty of this mod is is uses mostly all OEM Volvo parts. All are easily found in the JY.

Pics below.

The existing pass. side hole.

Braket holding ABS 90*.

69 140 airbox accordian intake pipe.

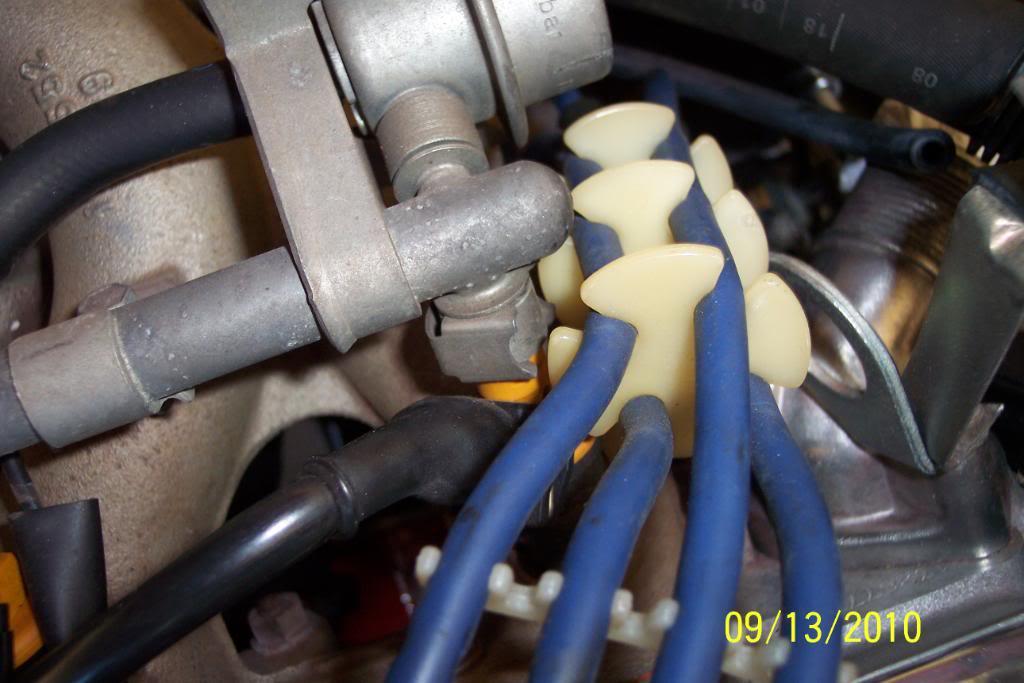

Where preheat hose fastens to bottom of airbox.

Sealed holes in airbox.

9/13/10

The S to S brace is just laying on there for idea of how it'll look when installed, as it header pipe.

One hose clamp short of being able to fill Rad with 50/50 AF/H2O. It's on the way though. Now it'll be on to suspension/brakes.

Tonite's pics below:

Pics of modded lower n/a heat shield:

I removed the OEM 52mm OT,OP, VM,Vacuum gauges I had , & replaced them with VDO Vision 52mm gauges. Bought blue light bulbs and installed them in all the gauges too

I now have VDO VIsion 52mm OT,WT,OP, VM, and vacuum gauges, fully numbered.

I'd like to find a place to mount the OEM 52mm clock And a aftermarket tach. Still working on that.

Also , remember the "dual air intake" mod, using the preheat hose as an additional intact for the airbox?

I modded the "snorkles" today. Gained some ID to them. And now they'll face to the front of the car.

Where I joined the 90* elbow to the snorkles.

Masked off the 90, painted snorkles with Vinyl Paint, to make look better.

And on the car, still gotta make small bracket for each.

Made some soft aluminum brackets today. Material available from Lowes & lends itself well.

I used the OEM Volvo pre-existing holes that were in the top radiator/fender cross brace/support , and used some Volvo bolts that I already had. They are the black ones in far sides of pic, in last pic.

Used black wire ties to fasten bracket to 90* elbows. Elbows are pretty ridgid & should stay in place . Gonna remove, paint them black, & reinstall them.

Well, got the FW, C & PP on tonite/early this morning. Got the Clutch release arm boot & T/O brg on CR arm which is now on the frt. of trans.

Which BTW, is holding 2.7 qts. of Royal Purple SychroMax Synthetic trans oil and has a new trans mount bolted on.

Percussionist is coming by in a few hours this morning(A BIG THANKS to percussionist too!!), to give a helping hand sliding the trans in place, so as not to break the fragile CPS bracket.

I bought two long bolts, cut the heads off, ground them to a point, to screw into block, to guide the trans up & in, to make it easier/less a hassle.

Trans is in, thank heaven. Percussionist was instrumental in helping with the install. Another pair of hands is very helpful when installing a trans.

Still need to install CCable(can't see the end of pedal under dash...yet. Pretty well hidden on a 91 244 it seems. I'll find it though. Starter wires too.

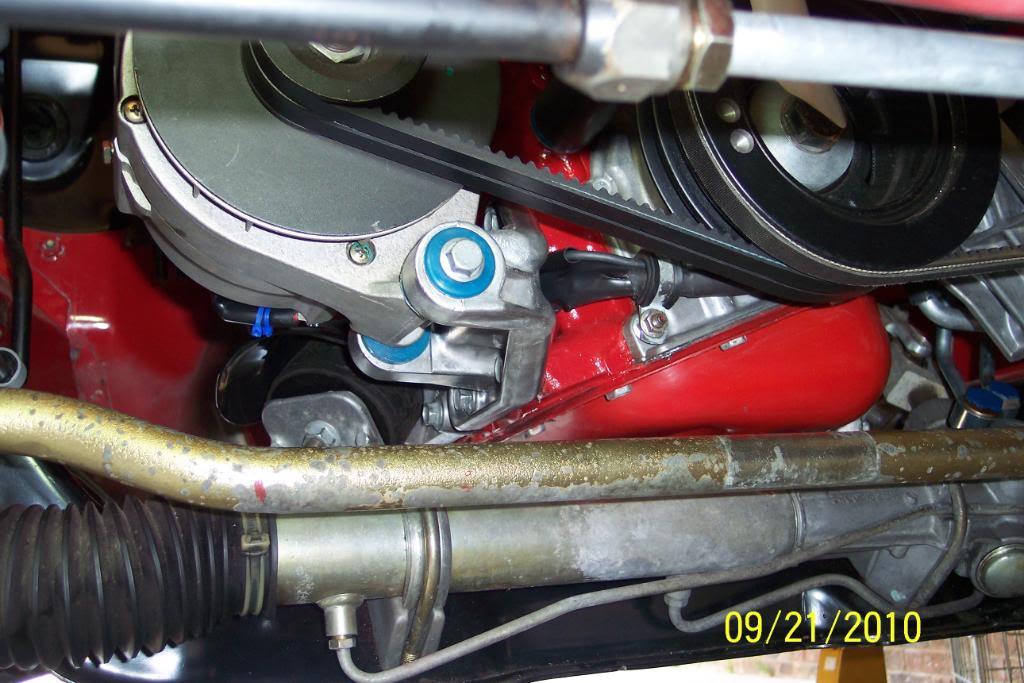

Got the P/S & A/C comp all done up last nite. And the new CPS is in place. On to MMs & more odds & ends.

OK, tonite I got the new clutch cable on, along with the little rubber block & the big heavy "counterweight"on the release arm & the new throttle cable installed.

Should be all set in this dept. for a long time.

And good thing too, it's tight fit under the dash, plus with my eyesight not good as it used to be, it was hard putting in those clevis pins & retaining clips.

And also installed new brake & clutch pedal rubber pads for good measure.

And BTW, the reverse light wire harness was irrepairable(to get it right)

So I ordered a new one. It is $105.00 dollars for 2 wires 2 feet long.. After the Parts guy brought me back to conscienceness, I paid for it.

Makes me think copper must be very hella rare in Sweden. So waiting on that before finishing up trans install & installing Drive Shaft and gear lever.

I decided to go for a little "bling". Now I have a shiny cam cover that is debadged. I'm playing around with different color OIL caps.

Got the cam cover on today. Modded the spark plug wire looms also,to keep wires & looms off the cam cover.I didn't want cam cover to get scratched by wires & looms.

Used all OEM Volvo parts here, just modded them a little. Came out right neat IMO.

And use the OEM Volvo spark plug wire holder, to hold the coil wire to inner fender, so it won't bounce around.

Well, got the new OEM Volvo Diesel MMs ,along with the turbo heat/oil shield for the pass. side MM. on tonite. Hopefully will make pass. side MM last longer on an N/A too. Also new oil filter with IPD magnet on it. Got 4 qtss of Castrol Edge oil too. And cleaned the cooling fan spotless last nite.

Hopefully the new early model fan/alt belts arrive next week. Having Alt /OP sender and top belt adjuster clearance issues. Going with the earlier 7mm longer belt. Hope it works.

And maybe the new OEM reverse light wiring harness will come in, and I can finish all under the hood & start suspension rebuild. We'll see.

Since I had bought those blue humped IPD radiator hose & heater hose clamps, I thought it would look better detailed if I painted the rest of the clamps on other things blue to match.

So.... I used a "model car" paint brush and some Rustoluem Spray paint & had at it.

For some strange reason,I had a problem with the Alternator clearing the OP sender, with the OEM Volvo 9.5mmx 818mm alt/WP belts. Not sure why,but maybe Scantech HB pulley's grooves being deeper or shallower, or the IPD Poly alt. brkt bushings, or Hepu WP or a combo of one or more, sure which.

All I know is before I took it all apart, the OP sender cleared the backside of Alt, OEM 9.5 X918mm long belt was long enough & top Alt bolt cleared WP Pulley.

I even tried the early B21 9.5mm x 925mm belts, still too short.

So, after much refitting,hair pulling, and cussing , I found both sets of the OEM belts too short to let alt clear OP sender, and also the top Alt holding bolt was hitting the backside of WP Pulley. WTF? If that don't beat all! Maybe visited by Swedish Trolls?

So I decided that a longer belt would keep me from having to relocate th OP sender. Although I had purchased some Harley SS braided oil lines, just in case I did not find said longer belt.

So....after 4 hours of "belt hunting" today, I think I have found some that will allow OP sender to clear back of alt, and top alt bolt not hit the backside of WP pulley.

And which will still leave a little adjustment left in the Alt/WP belt adjuster. Have trial fitted it, and I think it'll cure the problems.

BTW the belts I found ,that I think will work OK, are O'Reilly's "Master Pro" V Belt, p/n 7365(& under that number is: 15365), belt width/length is: 10mm X 942mm OC (3/8 X 37 1/8). OC = outside circumference??

Funny thing is A/Z's 11 x 940mm belt was a bit too long. Go figure.

I am still unsure of what actually caused the OEM belts to no longer be long enough. Has to be HB or IPD Poly, or both. IMO. What a "long strange trip it's been".

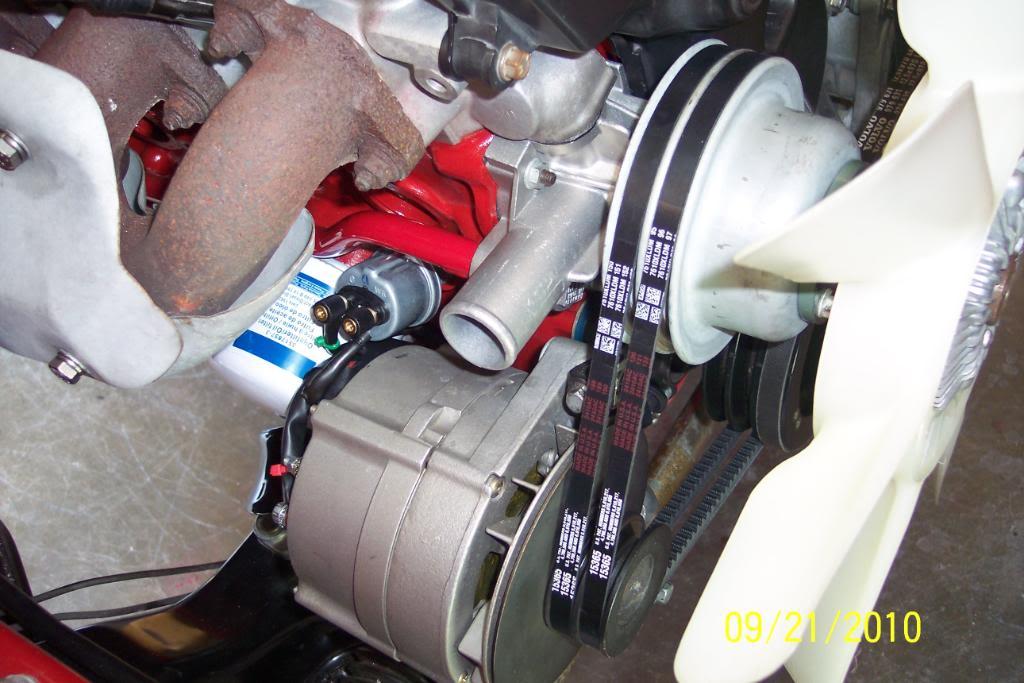

Pics of alt/wp belts that appear like they are gonna work OK. For other's reference if/when they have same problem. FWIW.

Well looks like the belts worked out just fine. And I still have about 1 inch left in Alt's adjuster slot. OP sender clears Alt, as does top alt bolt clears WP Pulley. Clearance problem must have been the Scantech HB + the IPD Poly bushings. Tolerances "stacking up".

Percussionist came by to help me get the stuff ready for the Parts sale, but we worked on the belts/alt/A/C Comp/P/S reinstall/belt set instead. THANKS percussionist!!

BTW, does anyone know if those little screw on "barrell nuts" on the VDO Oil Pressure sender( holding the wires on) will stand the heat from the exhaust manifold WITHOUT melting? I need to know soon. If so, I need to get regular metal nuts.

Pics below:

Belt part numbers for other's convience FWIW.

Nice build!

Posted by Diggymart on 3/30/20 @ 2:45:08 PM