You must be logged in to rate content!

2 minute(s) of a 87 minute read

6-5-2011

And the crankshaft..

Crower Forging

2.200 rod journal

3" Main journal

4.365 stroke

76 lbs

6-5-2011

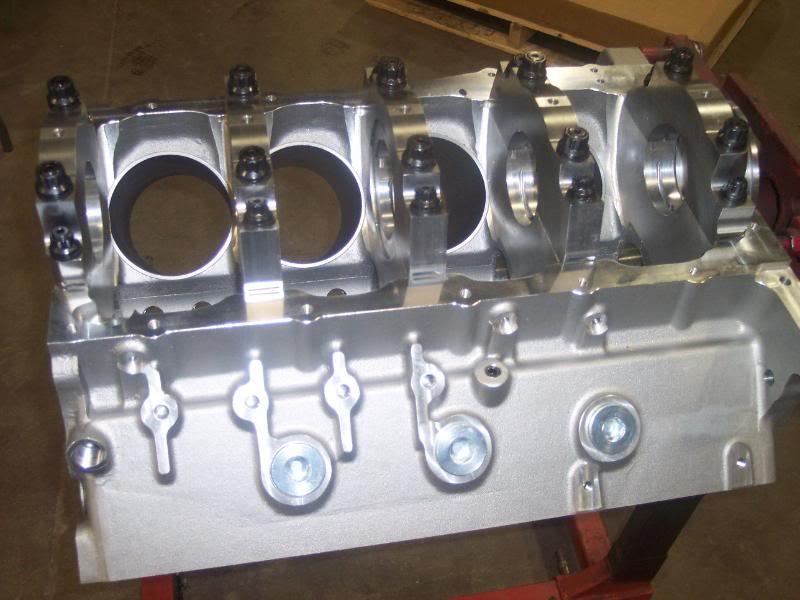

And it goes in this..

I can attest that with the caps removed, I have no problem lifting this block off the table, setting it on the stand ect... I couldn't even think about doing that with a grout filled bare iron race block..

JW

Comments

Congrats BOTW!

Posted by Diggymart on 2/6/19 @ 3:16:51 PM

Great build with details and photos

Posted by Diggymart on 1/23/19 @ 11:29:08 AM

Awesome build, amazing you can get so many passes at 750 horsepower. Nice job!

Posted by stevegolf on 3/13/21 @ 3:45:39 PM