You must be logged in to rate content!

2 minute(s) of a 265 minute read

3-21-2014

4-21-2014

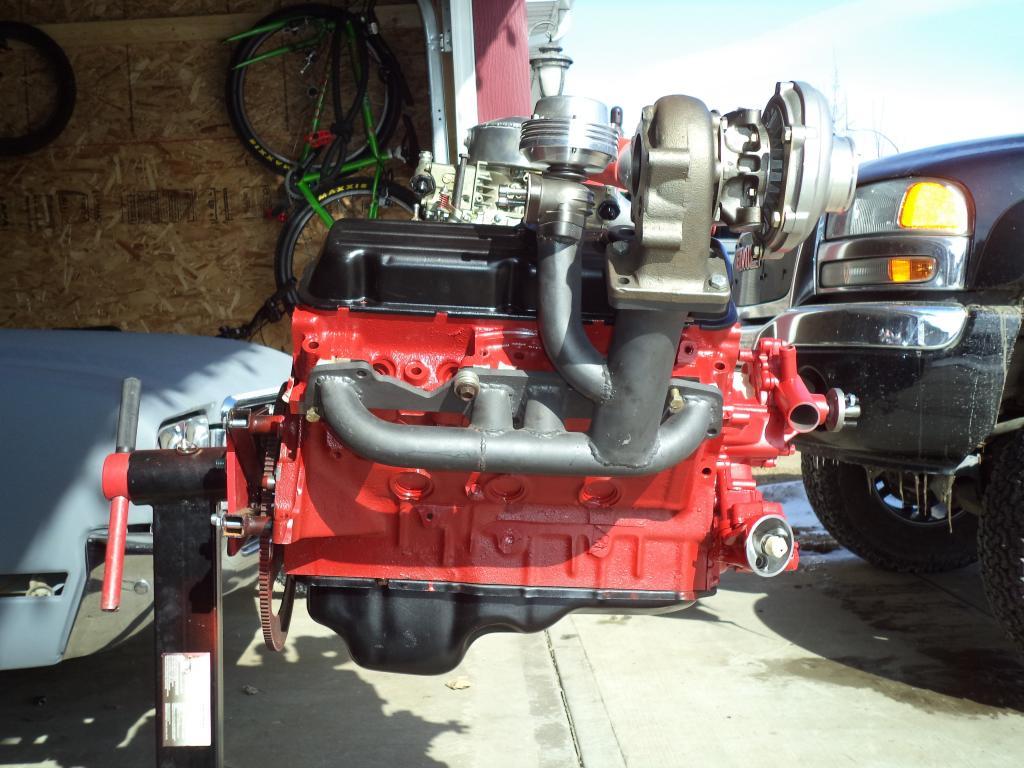

I put it inside for tonight and in the morning I will take it back out and work on de-greasing the engine bay, pressure wash under the hood and the underside or the car and then one more de-greasing, pressure wash, marine clean spray, blow down and then the POR 15 on the surface rust and Tremclad outdoor gloss black paint overtop.

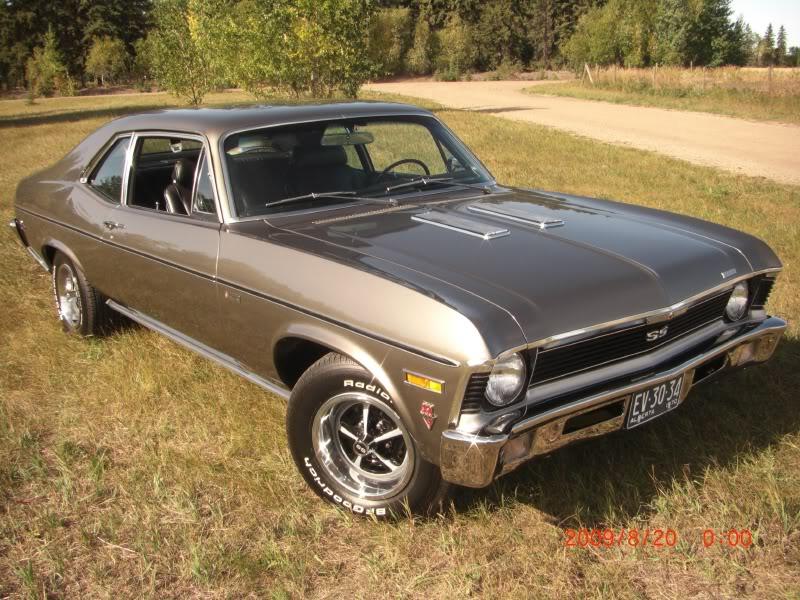

The body is rust free, mark replaced the quarters, front clip from a 71, removed the glass, and built it properly.

Yes there is surface rust on the underside of the car and frame. Por 15 will work perfectly.

The paint is going to be 1970 GM Shadow Grey:

I think it will look very good once it is painted! Do you like flat hood hiding the twin turbos???