You must be logged in to rate content!

7 minute(s) of a 97 minute read

7-17-2012

Rob,

That Torque arm setup is pretty nice. I have also looked at Jakes Rod Shop's torque arm...

http://www.jakesrodshop.com/public_h...CTURES.html#18

I am really leaning towards Hotchkis' 3 link however. They are still in testing phase at this point though.

I will PM you my phone number. I may be away for meetings that week though.

7/18/2013

A little history lesson on this style wheel and also why I chose it. For starters, Panasports are copies of Minilites. Minilites have been around since the early 60's at least. They were used on various racing cars from SCCA to Formula One. The wheel of choice for early SCCA Trans Am was the American Racing Torq Thrust. As seen here on the 68 Penske Hilton/Sunoco Camaro.

Rumour has it that because of some wheel failures, the torq thrust was replaced with the Minilite. Here is the 69 Sunoco Camaro wearing them:

I don't like to speak in absolutes unless I am certain, but every vintage SCCA Trans Am 2nd gen I have seen is wearing Minilites. Here is the Warren Agor Camaro on them:

And here is my car on the 17" Minilites.

My choices for both the wheels and the finish on the underside and engine bay are to emulate the vintage Trans Am racers. Here is the engine bay of another vintage racer:

8/14/2013

Slightly boring update.

I have been away for work doing some training classes for our field guys and am now on a job assignment.

Air and Water, I am at a powerplant near KSC, but not on Space Center property.

For the updates:

- Headers have been shipped to Jet Hot. Jet hot tells me I should have them by the end of this coming week.

- I have purchased all the tools I need to fab my AN lines (Brake and fuel).

- I have ordered a bunch of the fittings I need to complete the plumbing.

- Several random pics below

- As soon as the headers return, I will begin assembling the front end.

9/23/2013

Yes yes, I suck at providing updates.

I have some engine assembly updates, just cant seem to find the pics. Headers, intake, harmonic balancer, water pump, starter, all installed.

Probably the biggest news I have is that I ordered deeper front inner fenders after taking measurements for the front tires. They are 1/3 carbon and 2/3 fiberglass. The exposed surface in the engine bay will be satin finish carbon fiber. Exactly as the pic below, just satin finish. They will hopefully ship at the beginning of October.

The headers are 304 stainless and were $799. So now I have $1200 into a set of headers...  I wanted the coating for heat control under the hood.

I wanted the coating for heat control under the hood.

Yeah, it is frustrating to say the least. Oh well, we are really busy at work with the end of the fiscal year being September, so not exactly getting much garage time.

I have managed to get the majority of the ebrake and cabling fabbed. All of the Lokar brackets needed to be modified (one of them cut, bent and welded). Those are out getting powdercoated right now before I mount them on the car. The rear axle brake lines are done. Single flares were sooooo much easier than double. I also used that Nickel Copper tubing this time and it was so easy to work with compared to stainless. It could be bent without a bender. I still used my benders though to get really nice tight radii.

In regards to the bending and flaring... It isn't hard with the right tools. One drawer of my toolbox is dedicated to bending/flaring tools. Good benders make bends a piece of cake, even with stainless. Flaring can be tricky. Significantly more specialized tooling is needed. I have a Blue Point/Mastercool Hydraulic flare tool and a Ridgid 37 degree flare tool now. The Blue Point/Mastercool is a really nice piece and dies are available for every type of flare possible. Since I eliminated the stock distribution block and master cylinder, all of my front lines needed to be custom along with the axle since it wasn't stock. I just plunged right in and bought everything needed to fab them.

As far as the heat control with the Jet hot coating, it should be pretty significant. Literature out there states it should reduce the surface temp of the header by 50%.

Yeah, a month will be tough, but I have other small things to work on along the way. I just need to be better about posting updates.

9/24/2013

Some crappy cell phone pics

Cut, bent and welded up bracket for the ebrake cable adjuster

11/14/2013

I figure I will tease everyone into thinking there is an update. There are several little things, but nothing major, nor pic worthy. I still sit waiting for my inner fenders to do the front end assembly

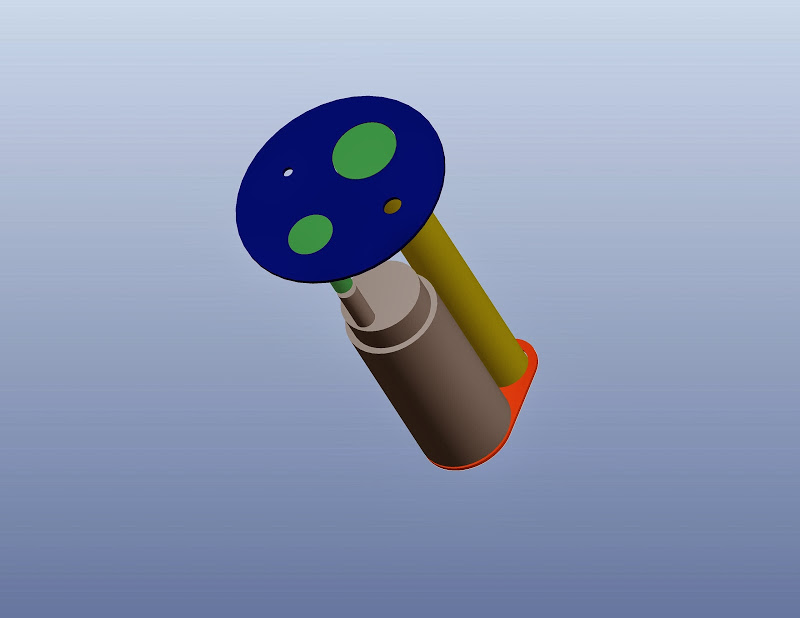

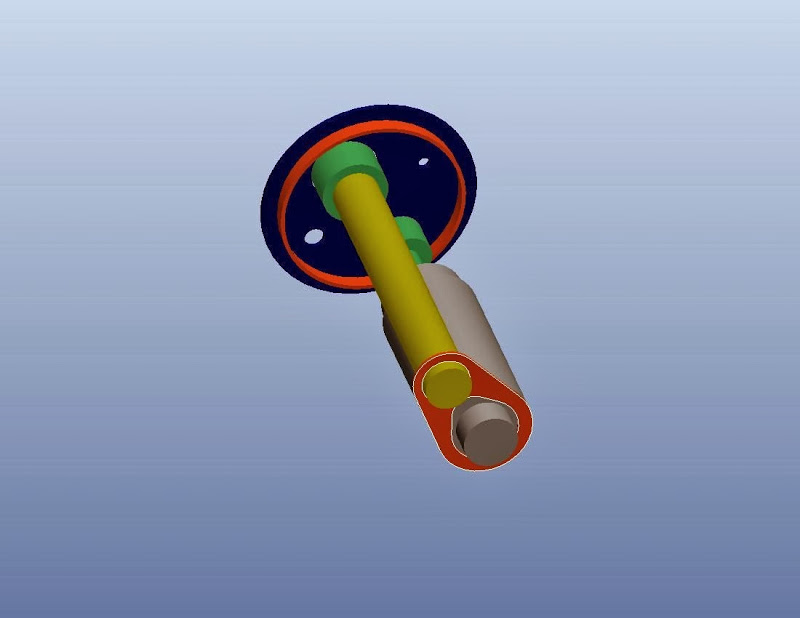

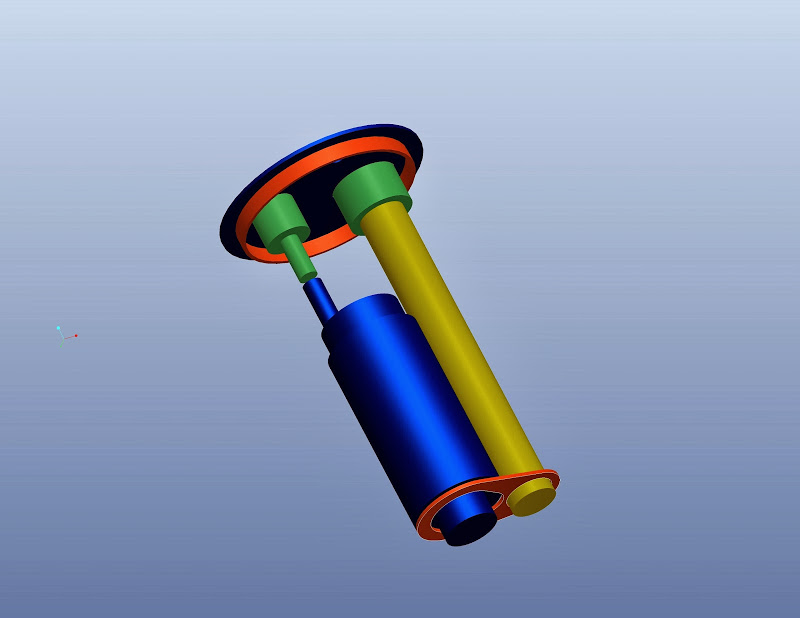

In the meantime, I am building a new fuel pump pickup to use my in tank pump with a carb. I will post the Pro-E model later tonight of the new fuel pump pickup.

11/15/2013

BLAH BLAH BLAH. Boring stuff. I hate my job. Been on the road for basically the last 6 weeks. UGH. Anyhow, at least I could work on this stuff remotely.

Long story short. Bought an EFI tank because I got a good deal on it. However, carbs don't use same pressure nor flow as EFI so I have to regulate it down. This also necessitates enlarging the return to handle the amount of fuel the regulator will be dumping back into the tank. Explored several avenues, easiest was redesigning the in tank pickup to work properly with the carb. Models below. Parts getting laser cut this weekend, welded next week. THEN I plumb my fuel system.

Love the 70’s Cameros!

Posted by Diggymart on 1/29/19 @ 2:44:21 PM