You must be logged in to rate content!

6 minute(s) of a 128 minute read

10-13-2009

I'm not a transmission guy at all, so I don't know much of the details. What I do know is that it has the good clutches, heavy duty intermediate drum and sprag assembly, and JW Reverse manual valve body with transbrake. The only problem that I have had is that the transbrake wont hold past 4,000 RPM. Doesn't matter how loose or tight the converter is. It has something to do with insufficient reverse line pressure, I think. I have made it work for me though and with the transbrake, I can go to the floor on the throttle at the line without having to worry about pushing through.

I didnt get a chance to work on her today until about 6PM. I did find the stuff that I needed though.

The first thing that I tackled was the fuel system. Because the car is a 98, I have a metal tank. The metal tank has plastic baffling/liner inside. I didn't sump my tank, so we drilled through the back center of the tank and welded a male AN fitting for the external Magnafuel setup. Plastic shavings were everywhere and the heat from the welder made a mess of the plastic in there. I don't recommend doing it this way. Anyway, long story short, I suspected that there could be some plastic shavings in the pre filter. I was correct. Cleaned it all out and it should be good.

Steve talked me into taking the intake off again and giving it another good washing. He stuck his bore scope in there and found a few little shavings that I missed. This wouldn't be neccesary normally with a FAST90 but mine is RTV'd together in the hopes of keeping it together under boost.

Got her all buttoned up and turned here over. Fired right up with good oilpressure. Sweet! Now all I needed to do was switch the brake caliper. Swapped it out, bled the brakes and bolted on the front tires. Tried to turn the wheel and it wouldnt budge. Took it off and the freaking caliper was rubbing on the 15X3 Weld Prostar with a small spacer. These calipers have already been ground down and he didn't even use a spacer with his 15X3 Weld Drag Lites. Anyway, after about 20 min of grinding, the grinding disk was spent and I had no way to get another one. I'll go to the hardware store and pick up a couple of grinding disks tomorrow afternoon unless I get called with some sort of emergency for work. Should be able to start tuning tomorrow.

About time you got the bug back.

I got the grinding done and started working on the tune. I had to crack the throttle a bit to get her to hold steady at 900 rpm. Lots less vacuum. Also had to pull a bunch of fuel. It's got a good sound with a very mild lope. Took her out and did some part throttle tuning and noticed the temps climbing. It was about 90* outside and was leveling off at 217* in the log. Been trying to burp the system but it's building up too much pressure. I dont think that the cap is working correctly. I am burned out right now. I'll tackle it tomorrow.

10-14-2009

The part throttle portion of my timing table should work good for you if you want to start there.

Pretty much everything above .56 Cyl Air.

As you can see, I had no timing in the stock motor at anything that resembled WOT. I will be adding lots more timing as soon as I can get the temperature

ECT. I've done everything to bleed the system that I can think of and I am fairly certain that I have gotten all the air out of the system. On a 30 min (at 2900-3000 RPM) drive in 90* I am hitting 232* on the datalog. I may have to move the intercooler up somehow and get the air bridge back on under the car. I was thinking of buying the Griffin but that would just be up higher and the thickness would also bring it even closer to the turbo.

I put the air bridge/pickup/dam on this morning and did a bunch of driving. That helped some and I think that I can make it work better if I trim the aluminum L bracket on the bottom of the IC. That should expose another inch or so of the air dam. The only other thing that I can do to help is space the IC forward a little more.

Then I can put the blanket on the turbo and wrap the down pipe. That should get me to 205-210 or so in the heat of a summer day.

I was working on the tune aswell so I had to get on it a bunch of times. God I missed that feeling. ****'s like crack. She felt pretty good. I did a little hit on the way home against Boner and then I was cruising easy and all of the sudden the fuel pump shut off. Switch was on. Pump was off. Everything else in the car was still on. Got out. Checked the lines. Checked the wires to the pump, went back in the car, switched it on again, and it came right on. I had a full tank of gas also so the pump wasn't cavitating or anything. Weird. Gotta keep my eye on that.

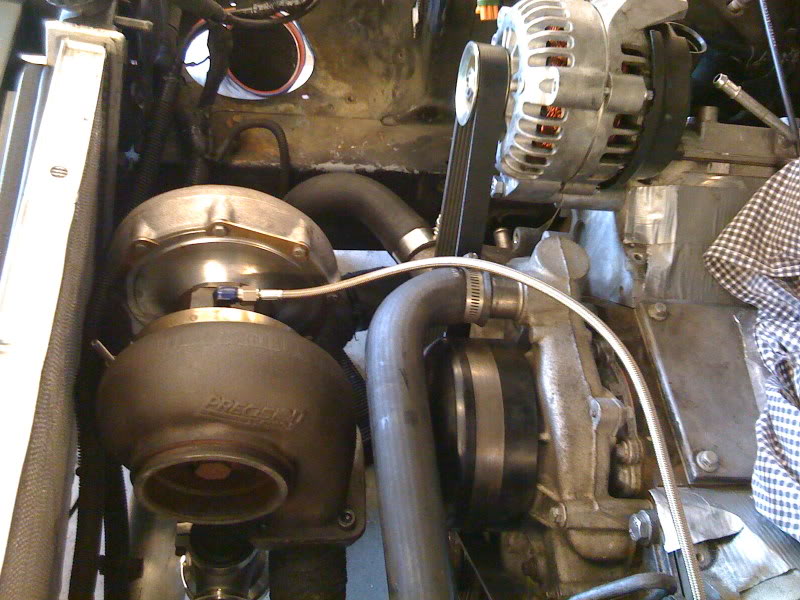

Took the car out tonite for a little tunning. It is 62* outside and the turbo LOVES IT! This is the first time that I have experienced the turbo setup outside of the usual balmy Florida summer weather of low 80* to a high of 100*.

Hopefully get my AMS 500 controller hooked up tomorrow and make some low boost passes at the track on Wednesday. It will warm up a little by wednesday but it should still be the best air that we've seen since early March.