You must be logged in to rate content!

10 minute(s) of a 107 minute read

3-21-2009

So today I ran the oil return and it worked out perfect. I got the wrong fitting for the motor side of the oil feed. I must need a 1/8 npt x -4. I got a -3.

I got the rest of the t-bolt clamps and shortened up the tube on the upper radiator hose for better clearance of the power steering pump pulley.

I took the rest of the cold side tubing to my friend's house to finish up the TIG welding. I decided to keep it as 2 peices, leaving one coupler in between for quick removal. He also welded the BOV tube and a threaded bung for a screw-in type IAT sensor.

3/24/2009

We are bringing the car over to a friends shop to clean up the rats nest of wiring and put the inside of the car back together on Thursday morning. Not sure how long that will take but I will be present as much as possible cracking the whip. No more than another week.

3/30/2009

LS2Formula got the wiring almost done. I finally got some good work for Friday and today so I haven't seen her in a few days. I don't have any work scheduled for tomorrow so we will get the dash back in, run some vaccum/boost lines and maybe put in some fluids. I'll get some pictures up tomorrow afternoon. Hope to fire her up before the end of the week.

That may or may not be this week. She has to be able to get to the exhaust shop under her own steam.

This is how she will go to the exhaust shop.

Today was productive. I got the starter on. Made a very ghetto bracket to hold the radiator in place for now until my decorative aluminun cover gets made. Made a plate to cover up the A/C hole. Put some sound deadning **** behind it (thanks Heavychevy and Up2Nuthingud). And most importantly, the dashboard went back in which was a huge psychological barrier for me (thanks LS2Formula).

He will finish up getting the stereo in and buttoning everything up after we crank it up which should be in the next couple days.

I did run into a little trouble while bolting down the intake. I got 2 bolts that are giving me a hard time. Hopefully just need to run a tap down in there and clean up the threads

4/2/2009

Got it fired up today but no oil pressure.

This was a truck motor with a deep truck pan and long pickup. There was some sludge in the pan so I replaced the oil pump just to be safe as well as the pan, and the pickup. I may not have seated the o-ring on the pump correctly. I'm not happy at all about having to drop the pan. It's kind of a pain in the ***.

4/5/2009

I got the pan off last night. There are a couple things that it could be but nothing that really jumped out at us. The o-ring was a little sloppy on the pickup tube. I'm gonna take the stuff to our engine builder to see what he thinks on Monday.

4/7/2009

I got a new oring for the pickup tube yesterday and installed it correctly. After about 15 seconds of cranking, I got oil pressure. Fired her up and she sounded really good. No knocking or any weird noises. So that was a major relief and step forward. Won't idle but the tune is WAY off as this setup is so much milder than the old one but with twice as much injector, and a 2 bar map sensor.

Still to do:

1) I have to buy an overflow tank for the coolant and install it. Stock one had to go in the garbage due to it's location.

2) I may have to pull the intake again as Steve believes that water was coming out of one of the back tabs on the crossover tube in the head. I hate pulling this ******* intake off

3) Bleed the brakes.

4) Find somewhere to mount my trans cooler under the car.

5) Have a bung welded in the down pipe for a wideband so that I can start tuning.

6) Get the rest of the interior back together.

7) Get an ailgnment due to the new K-member.

8) Have exhaust made.

9) Get the boost gage installed.

10) Plumb all the vaccum lines to all the vacuum nipples that I have all over the place.

Could I get some help with the vacuum lines? Here is what I have.

1 availabe vacuum port on the intake manifold.

1 port on the compressor housing of the turbo.

1 port on the side of the wastegate.

1 port on the top of the wastegate.

1 port on the back of the boost gage.

What goes where and why?

Suffered a major setback tonite. Turns out that the water leaking out wasn't from the crossover tube. Water is pouring out the back header bolt hole. I have to drop the motor and will likely need another 317 head.

4/8/2009

Been talking to a bunch of people today and the general concensus is to drill, helicoil and rtv. I guess that it is common on small block chevy's to hit the water jacket when helicoiling a header bolt hole. I'm going to give it a shot as these heads are just temporary and I will be using my AFR's once I get some rods and pistons in this thing. I don't want to get into any more expense of buying another head and head gaskets. That will be a few hundred dollars in the toilet.

4/9/2009

Initially just off the spring in order to get it all dialed in. I do intend to run a boost controller in the not to distant future. I was thinking of going with the eBoost2.

I was going to drill and helicoil the header bolt hole. I bought a stud and ran it in there first just to see if I could catch any threads. Way down in there it felt like there were 3-4 good threads. I decided to pack the hole with JB Weld and run the stud in behind it. I smoothed it all in around the stud and bolted it all back together. I used the slow set JB Weld so I couldn't test it last night. I think that it will work. Other than that, I was able to knock a few more things off the list.

1) Bleed the brakes.

2) Wire up WB02 sensor and start tuning.

3) Get the rest of the interior back together.

4) Get an ailgnment due to the new K-member.

5) Have exhaust made.

6) Get the boost gage installed.

Well I drove her home tonite!

Water leak is fixed.

Still have some things to do but she is road worthy. Only got her to 4K RPM but she starts whistling at 3K and gets pretty noticeable by 3.5K. Then you get that woosh of air when you let off the gas. It made me smile. Car makes ridiculous vacuum at idle. I need to close up a hole in my throttle blade as I cant get the idle below 1K once she warms up.

I'll get the front clip on tomorrow morning and start doing some tuning. I just did enough this evening to get her running. I hope to drive to the track tomorrow night but not down it.

4/11/2009

I took her out for her first real maiden voyage. Here are some initial observations.

1) Running a little hotter than I had hoped 210-220*. Will the air dam help on a radiator that is standing up with shrouded pusher fans on the front? I am going to put my tin foil cover on the turbo today to see if that helps. Also running straight water right now so going to put in some water wetter.

2) I have a small leak from the extension on the upper radiator hose. Put in a GM seal tab. Gonna see if that fixed it. If not, some RTV should do the trick.

3) Oil return seems to be working good. No smoking from the turbo.

4) Transcooler was relocated to under the car beneath the passenger seat. Seams to work well there.

5) I started doing some tuning with HPTuners. I got most of the idle and part throttle done. I dont have the boost gage hooked up yet but HPTuners has a custom PID that converts MAP Kpa to Boost PSI and it was showing 12 psi as soon as I tried going WOT. I thought it was a 5 lb spring in the wastegate. Is a 44mm Wastegate not enough for this turbo?

6) Somewhere between 4500-5K RPM, the car falls on its face and breaks up. I think I am floating the valves as I think that the springs are the stockers. I doubt that I am blowing out the spark with a #8 plug and a 035 gap. Thoughts?

4/11/2009

Reggaped the plugs to 022. Pulled to 6K no problem part throttle. I was definetly blowing it out.

Decided to do some WOT tuning. It was very rich once it got into the 7 lb range and would break up. Took about 5% of the fuel out beyond that point. Got on it in 2nd, got a little hesitation at about the 2psi mark and then HOLY SHIT! It pulled so ******* hard that I knew something was wrong and let off. It pegged the MAP sensor at 14.8.

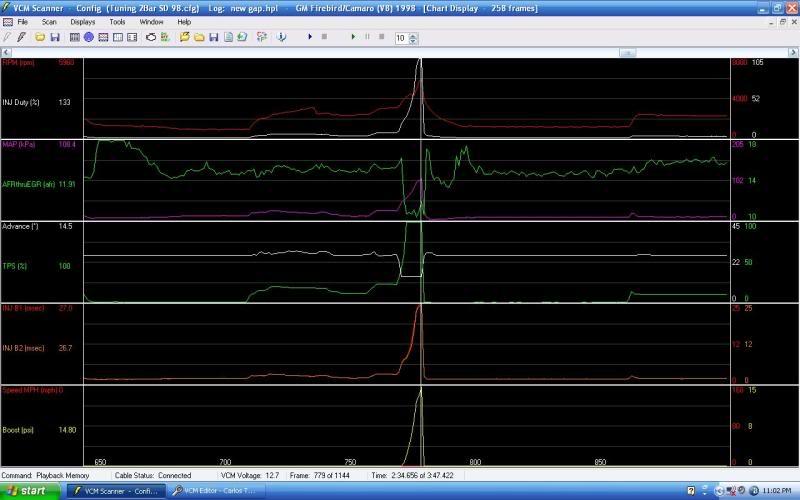

I'm pretty sure that the wastegate is not right. I am going to take it apart tomorrow morning and see what's going on in there. Look at the 133% injector duty cycle LOL.

4/14/2009

I got my hands on a 60mm wastegate. Thanks Rich (XdamxincX). I'm going to try to get it on in the next day or 2. I have to cut a bigger hole in the hotpipe and weld in the new 2" tube that goes to it. No point in screwing with this 44mm wastegate anymore. Even if I could get it down to 9-10 psi, don't know that that will be low enough for the screet.

4/15/2009

I got my 4" exhaust built today. Sounds much better now.

Looking from the back of the k-member forward.

First bend off the downpipe.

Looking from the front to the back going thru the k-member.