You must be logged in to rate content!

5 minute(s) of a 70 minute read

6-7-2008

The compression on my motor, if memory serves me correctly will be 10.8:1, and Will had a few reason's for not trying to go into the 11 and up realm. I run almost 12:1 on my Harley on Super all day long without problems, but this motor is not going to be running too high of a compression ratio. Goodluck on your motor, I read your post and saw the pics of your LT4 when you lost the motor on the track. I have the same car that you have, same color inside and out. Might even have the same options!................Noland

The reason that I did not go with a 396 and went with the 383 was because of alot of reading on here and seroius talks about the Pro's and Con's of all options out there within reason, with price being a secondary factor at the time. I have a 4-bold main 400 block, crank and heads sitting in my storage unit that I could have made a 4XXci out of, but chose to stick with the more reliable 383 for the type of driving that I do. One of the cons of the 396 pointed out to me with were centered around the 396 pistons and their location of the wrist pin to oil ring groove proximity. I didn't want to have something that I would have to go back into anytime soon, so that's why I'm here.

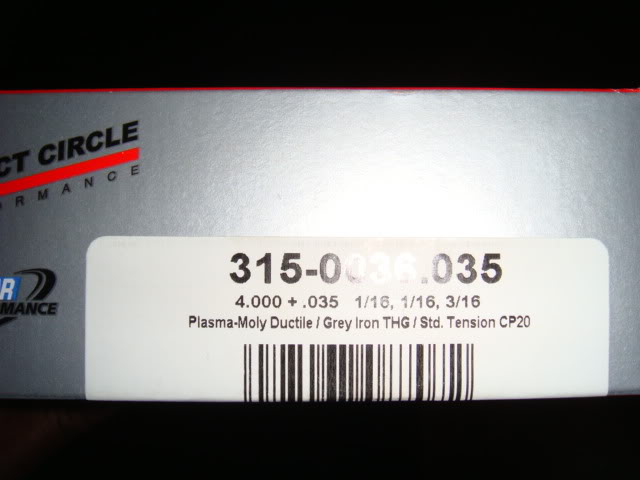

The rings that I'm using are Hastings Powerflex High Performance Plasma Moly Rings. 1/16, 1/16, 3/16.

As you can see, these are the standard tension rings, not the low tension.

I'm also using King Bearings for my Mains and Rods, and Dura-Bond for the Cam.

As far as opening up anything, I'm not touching a THING!......Will is going to do all of that. I left the head gasket, crank, rods, bearings and rings all sealed up. When he came over to look at the stuff and told me that the bearings were packaged in a specific order, I knew right then and there that I was outside of my realm. I look at these as I would for SubSafe components, I'm not qualified to install it, so therefore I won't touch it!.......LOL Thanks for the heads up!

6-8-2008

Here's a little insert from Eagle's 2008 Catalog which touches on the advantage of the Internally balanced crankshaft. Not to be confused with an internally balanced motor:

What is the purpose/ benefit of an internally balanced

crankshaft?

Generally Eagle cast crankshaft are to OE specifications. If the original

crankshaft was externally balanced; Eagle’s replacement crank will also

be externally balanced. With an external balanced crank, part of the effective

counterbalancing is actually on the harmonic balancer and flex-plate/

flywheel hanging off of the ends of the crankshaft. Externally balanced

engines perform very well on towing, street, & lower rpm engines. All Eagle

4340 forged steels crankshaft are internally balanced even when the factory

engine from the factory was externally balanced. Internally balancing is the

only way to go on high performance engines. On internal balanced crankshafts,

the counterbalance is achieved entirely with the counterweight of the

crankshaft. The closer the weight is to the components that it is counterbalancing

(pistons, rods, rings, and bearings), the less crankshaft flex that will

occur. This will extending bearing life and longevity of the crank. Crank

snout stress is also reduced because there is no offset weight spinning at

engine rpm on the snout of the crank. It is critical that when using an Eagle

internally balanced crank; that an internally balanced harmonic balancer &

flex plate / flywheel also be used.

Thanks for all the input and feedback..........It's easier foe me to avoid the problems and common mistake when someone who's been there tells me what to lookout for. I really appreciate it all!

Very nice Mike!.......Times seem to be rock solid even in the heat! Here's a few questions for you, why did you choose 30lb injectors for your motor? Was that what was recommended with the build or what? When Will told me what he expected my HP level at the crank to be on this motor, I called Jon (FCInjectors) and talked to him about what size I should get. He explained to me that the size injector was based off of the expected motor's HP output, and informed me that I needed 42's for my build. I then marched my happy butt off and bought a set of Jolly Green Giants. When I spoke to Will about his he informed me that he uses a smaller injector for his monster motor (600+chp) and his injectors see less than 80% duty cycle. Now i'm in a daze and wondering if I over achevied or if I made the right choice. The science behind these 383's and injector sizes seems to be "Smoke and Mirrors" to me at this point. Thanks for the update and hopefully you'll drive that beast down to Carlisle this year, we can get together, run down the streets and scare the Natives!......LOL