You must be logged in to rate content!

16 minute read

1984-1988 Corvette T5 swap

Compliments of [email protected] @ http://members.cisdi.com

1-4-2008

updated: 2/22/2015 Frequently asked questions... Why the swap?: Many corvette owners either have a failing 4+3 transmission, or an automatic and want a cost effective swap. This can be the solution. How Much does it cost?: A 4+3 car will cost between $500 - $600. An automatic car will cost between $1000 - $1200. What about gear ratios?: If swaping from an automatic, your rear end gear ratio is probably 2.59:1. All 4+3 cars had 3.07:1 gear ratios. Lets play some math to figure out what you should swap and why. A T5 has the following gear ratios: 2.95 1.94 1.34 1.00 .63 Your 700R4 has: 3.06 1.63 1.00 .70 Your 4+3 has: 2.88 1.91 1.30 1.00 .60 (OD ENGAGED 4th) A ZF-6 has: 2.68 1.80 1.29 1.00 .75 .50 Now, why I broke it up this way is rather important. 700R4 owners with stock rearends will find the 700R4 will be about 15MPH at 1536 RPM on take off and in OD will go 65mph at 1522RPM. Swapping to a T5 in these cars will have a pretty consistant takeoff around 1481 RPM, and a highway cruise at 65mph at 1370RPM. These are pretty close gearing combinations which make a T5 swap a good replacement for a 700R4 if you are going to leave the stock rear end. Similarly, a 4+3 car with a 3.07 rear swapping to a T5 Will be in the 1750RPM range at 15mph, and 1625RPM on the highway in 5th vs 1550RPM in 4thOD with the 4+3. Swapping to a ZF6 however from an automatic car is a bit more drastic. Your 15mph takeoff is going to be around 1368 RPM which will cause quite a bog leaving a light, and your 65mph RPM cruise in 5th will be 1631RPM, and in 6th will be 1087RPM which won't be possible rendering 6th gear pretty much useless. So, I went through this little math rant to explain why a T5 swap is a very good replacement for a 700R4, and still a good replacement for a 4+3. However, if your going to swap to a ZF-6 you really need a minimum of a 3.33:1 rear end ratio, where a 3.54 is much more optimal. Are T5's strong enough?: For warranty purposes, the T5 is rated at about 300foot lbs of torque. Some people break T5's with stock engines. Other people have years of successful trouble free operation with highly modified motors. Most issues with T5's are third gear. If you use the clutch, and have the shifter stops set properly you should have good luck. Why not a T56?: A T56 generally speaking will cost more. If you are swapping from an automatic, it might be more reasonable to swap to a T56 since you need to obtain the bellhousing/clutch/hydraulics anyway. For 4+3 owners, this can't be justified since the T5 uses most of your original components. Also keep in mind, you can only use T56's from 93-97 Fbodys which are still getting top dollar at the junkyards. Expect to pay about $1500 + pedals. For that money, go ZF6 if your gearing can support it. What about a ZF6?: A ZF6 is a good transmission, but are becoming even harder to get than the T56. Expect to pay about $1600-2000 for everything from a donor car. If your gearing can support it, go for it. What about a TKO kit?: Some retailers sell nice direct bolt in TKO kit's for corvette. As of 10/8/07 average pricing for this kit is $3460. As of 10/19/07 retail price for a TKO-500 is $1895. The 2" left shifter offset is a $349 option. So after that your paying about $1200 for a cbeam adapter, new yoke, VSS decoder, zip ties, floor patch, shifter boot, & wiring pigtail. But the kit DOES work out of the box and requires little to NO fabrication. What FLUID does a T5 take: 83-87 uses gear oil or 10w30 motor oil, 88-92 WC-T5's REQUIRE ATF.

About the swap...

The T5 is a popular transmission made by borg warner in the 1980s. It was used on the 83-92 Firebird/Camaro.

For the swap to work with your existing clutch, you need to get a transmission out of a V8 fbody with the 26 spline input shaft.

The T5 transmission is similar length as your current 4+3 transmission, and the yoke is the same spline count (27) so you

will use your existing: Yoke, bellhousing, clutch, hydraulics.

The T5 transmission is designed to be mounted in a Fbody at a 18* angle counter clockwise, and is mounted using a horizontal

cross-member, and torque arm. Due to these case differences in the tailshaft section, an adapter is required to bolt the

T5 to the Corvette CBEAM. This adapter has been engineered by PRO STREET (now Tommy's Speed Shop) and is available for $175 shipped.

Issues that may turn you off to the swap:

When installing the transmission in a Corvette, the shifter mounting flange will be 'straight up' and horizontal with the vehicle.

The shifter location is dead center of the transmission and forward thus requiring some modifications to the shifter assembly to retain

correct shifter position.

This modification required welding an adapter to the shifter, effectively changing the location. The side effect

of this is the shifter will slightly fall in 2nd gear, and slightly rise in 5th gear. Additionally, the shifter

base will contact the shifter plate under the forward cup-holder, therefor the cup holder will need to be cut

on the bottom, rendering it useless.

On my swap (700R4 to T5), the 700R4 was 30 inches, where the T5 w/ bellhousing was 31 inches.

I have a Dana36, so I can use an 85-96 MANUAL DANA44 driveshaft (1" shorter) to make it work.

Folks with a Dana44 rear end (85-88 4+3 Corvettes) will need to have theirs cut down by 1". This can be very costly ($250+)

You can get the driveshaft to work if you bolt it up PRIOR to tightening the cbeam

If you are not scared, and your ready to go we need to buy some parts to do the swap. Here is your shopping list, and suggested prices: 4+3 to T5 Swap (With Dana44 rear end) Minimum parts list: 1) T5 transmission from 1983-1992 V8 Fbody (Camaro/Firebird) ($100-250 used) 2) Cbeam adapter from Tommy's speed shop ($175 NEW) 3) T5 hurst shifter OR mustang shifter ($50 used) 4) Electronic VSS out of an 86-90 Firebird #10456087 ($20 used) 5) Driven speedo gears for your rear end ratio ($20 NEW) 6) Misc Materials - Fiberglass, screws, electrical tape ($30-40) Swap can be done for $400 - $600 If you want to shorten the driveshaft, or have a custom driveshaft made budget another $250. 700R4 to T5 swap (With Dana36 rear end): 1) T5 transmission from 1983-1992 V8 Fbody (Camaro/Firebird) ($100-250, used) 2) Cbeam adapter from Tommy's Speed Shop ($175, NEW) 3) T5 hurst shifter OR mustang shifter ($50 used) 4) Electronic VSS out of an 86-90 Firebird #10456087 ($20 used) 5) Driven speedo gears for your rear end ratio ($20) 6) 1984-1988 Corvette manual pedal assembly ($50-100 used) 7) 1984-1988 Corvette clutch hydraulics ($50-100 used) 8) 1984-1988 Corvette bell housing ($40-50 used) 9) 10.5" 26spline clutch assembly ($150 @ Fort Worth Clutch, NEW) 10) 12.5" (10.5" clutch), 153tooth flywheel ($175 @ ebay, NEW 11) Misc materials - Fiberglass, screws, electrical tape ($30-40) 12) Dana44 driveshaft (32" yoke to yoke) ($50-75 used) Swap can be done for $1000 - $1200 I used a new TIMKEN polymer/metal throwout bearing when I did my swap. I also used a Timken pilot BEARING rather than the supplied bushing that came with the clutch kit. This added about $75 to the cost.

SPEEDOMETER CALIBRATION PARTS:

Your T5 needs to have the appropriate Drive/Driven gears as well as

VSS sender for your Dash/ECM to read. Most 3.23+ V8 T5's have a 7-tooth drive

gear #14071731 (PURPLE). You will need to obtain the correct DRIVEN gear, and VSS.

VSS sender part number is 10456087 and looks similar to this:

DRIVEN GEARS: (Calculated with 26" tires!)

These are all discontinued from the dealer, so you'll have to

get them from PATC. 18, 19, 22 are most common. 21 is hard to find!

18 tooth (p/n ) Orange: 3.23 Rear end ratio

19 tooth (GM #14090592) White: 3.42 - 3.54 Rear end ratio

21 tooth (p/n ) Red: 3.73 - 3.95 Rear end ratio

22 tooth (p/n ) Gray: 4.00 - 4.11 Rear end ratio

**If you have a 3.08 or lower, you will need to obtain a 9 tooth DRIVE

gear #14053347 (RED), and correct DRIVEN gear to calculate your propper ratio.

For example: 9 tooth drive, and 22 tooth driven = 3.08 (Stock D44, early manual)

For example: 9 tooth drive, and 18 tooth driven = 2.59 (Stock D36 ratio)

Drive and driven gears look like this. Notice the plastic white DRIVEN gear

is on a metal shaft. Discard this shaft. When you purchase a DRIVEN gear, make

sure it is not a 1pc plastic gear with plastic shaft. If you look at the VSS

above, you will see the shaft is not removeable so the gear MUST slide over

the shaft in the VSS. The 1pc plastic gears with shaft are for CABLE DRIVEN

SPEEDOS!

Again, if the gear cannot come off the shaft, and look like the pic below it is the WRONG DRIVEN GEAR

SHIFTER MODIFICATION:

(F-body HURST) 1) Take apart the shifter 2) Cut the base rod off 1/4" beyond the end lf the splines 3) Cut off about 1/4" off the base stub below the angle so its straight 4) Weld a peice of metal stock, 3" to the left, and 2" rear 5) Weld the rod you cut off, so its exactly 3" to the left, 2" to the rear 6) Trim the bottom of the forward cup holder so the shifter doesn't hit it when shifting into 5th.

This should put the stick straight up in the normal Corvette location.

(Mustang T5 Shifter / or Mustang HURST shifter )

1) Measure the distance between the front and rear holes on the transmission

2) Drill out the new front 2 holes

3) Follow the instructions above to change the offset.

If you are swapping from a 4+3 follow this section... TRANSMISSION REMOVAL: 1) Raise the vehicle to a safe height and secure it. 2) Disconnect the battery 3) Unplug the TV cable from the throttle body if applicable 4) Remove the exhaust system 5) Unbolt the exhaust hanger from the transmission 6) Unbolt the transmission pan on the OD unit, and drain the fluid, then replace the pan 7) Remove the transmission cooling lines from the OD unit 8) Disconnect the 2 wire VSS connector, and the 3 shift solenoid plugs if applicable 9) Unbolt the driveshaft, and remove 11) Disconnect the shifter linkage from the transmission 12) Remove the rear exhaust hanger from the CBEAM 13) Place a jack of appropriate size, under the transmission 14) Remove the distributor 15) Unbolt all 4 bolts holding the cbeam in place, pry it forward away from the differential 16) Unbolt the 4 transmission bolts. 17) Keeping clear from the transmission in case of a fall,Lower the transmssion down 18) Slide the CBEAM out of the way 19) pry the transmission away from the engine 20) Lower the transmission to the ground, drag it away from the vehicle 21) Place a small jack and a block of wood under the oil pan, and jack up 2" 22) At this point, I recommend replacing the clutch/flywheel/throwout bearing with new parts Now skip ahead to the INSTALLATION secion...

If you are swapping from a 700R4 Follow this secion TRANSMISSION REMOVAL: 1) Raise the vehicle to a safe height and secure it. 2) Disconnect the battery 3) Unplug the TV cable from the throttle body 4) Remove the exhaust system 5) Unbolt the exhaust hanger from the transmission 6) Unbolt the transmission pan, and drain the fluid, then replace the pan 7) Remove the transmission cooling lines 8) Disconnect the 2 wire VSS connector, and the TCC/gear switch plug 9) Unbolt the driveshaft, and remove 10) Disconnect the shifter linkage cable 11) Unbolt the torque converter inspection plate 12) Unbolt the flexplate to torque converter bolts 13) Remove the rear exhaust hanger from the CBEAM 14) Place a jack of appropriate size, under the transmission 15) Remove the distributor 16) Unbolt all 4 bolts holding the cbeam in place, and pry it to the outside of the 700R4 and forward 17) Lower the transmission slightly, to gain access to the top bolts, and remoev the CBEAM 18) Using a 14MM swivel socket, 36" extension, unbolt the top 4 transmission bolts. 19) Remove the bottom right transmission bolt 20) Remove the bottom left transmission bolt 21) Keeping clear from the transmission in case of a fall, pry the transmission away from the engine 22) Lower the transmission to the ground, drag it away from the vehicle 23) Remove the flexplate and discard 24) Place a small jack and a block of wood under the oil pan, and jack up 2" 25) You are going to need to install the pedals and hydraulics. I did this last.

INSTALLATION:

I used a brand new flywheel for my swap.

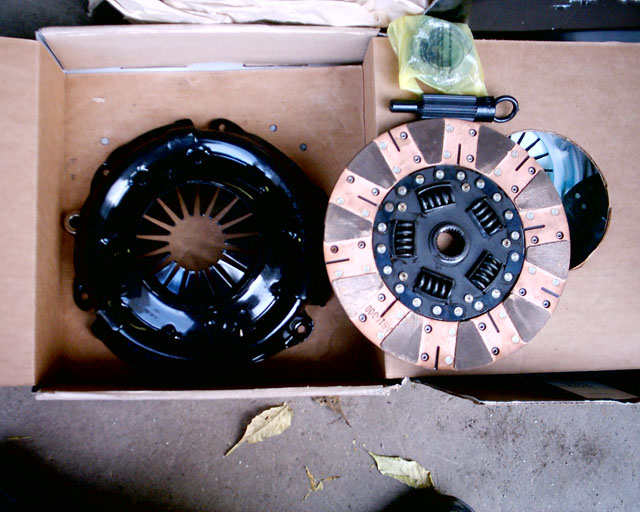

And a new Dual Friction clutch kit...

Let's start with some new parts. Or if your clutch is good, skip to "CBEAM Adapter Installation".

Clutch/Flywheel/Throwout bearing/Pilot BEARING

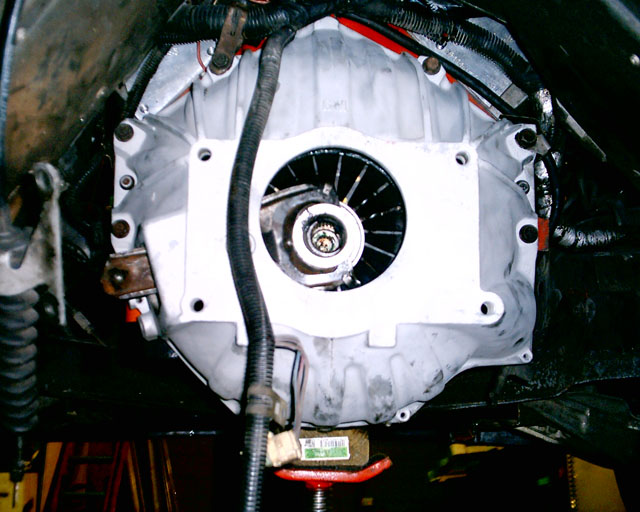

Install the new flywheel, torque to 74lbs

Install a new TIMKEN pilot bearing instead of a brass bushing

Install the clutch and pressure plate, torque to 34lbs

Install the bell housing and torque to 34lbs

Everything should look like this now.

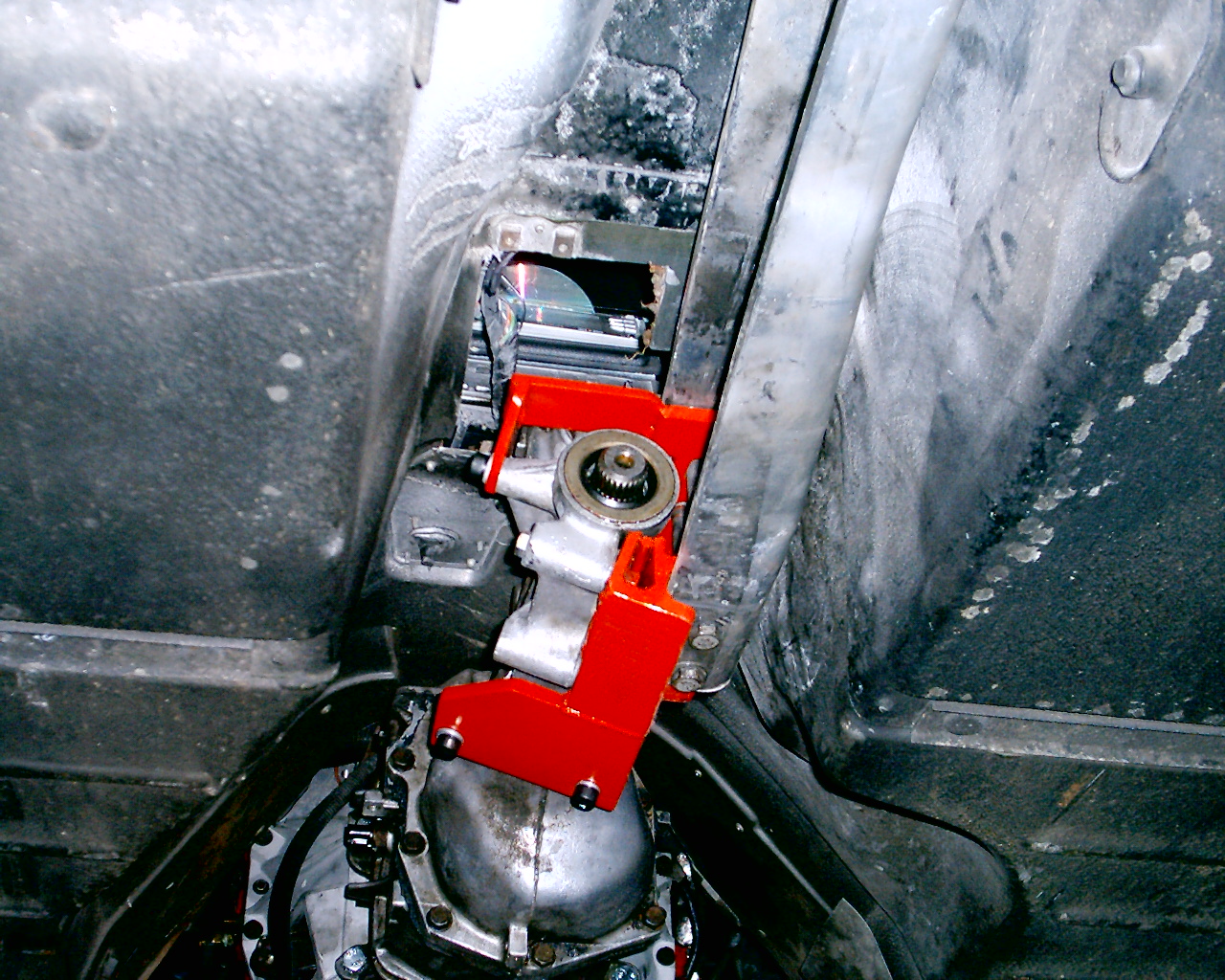

CBEAM Adapter Installation

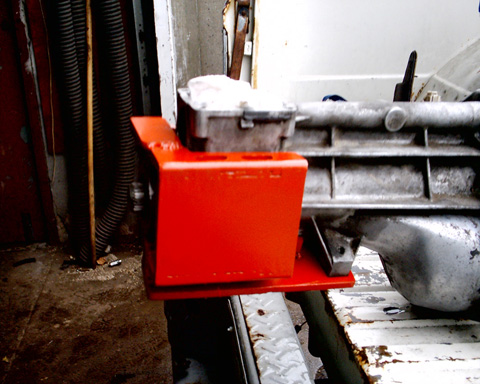

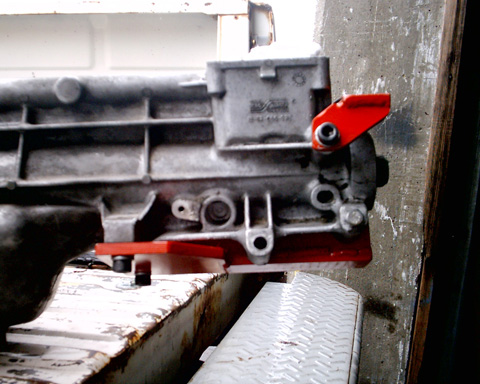

Next, Install the CBEAM adapter bracket to the T5 tailshaft with the supplied hardware:

Your cbeam adapter should be installed like this using supplied hardware.

CBEAM Modification

You will need to grind a little bit off your cbeam. Measure from the front of the cbeam back 3.5" and draw a line horizontally. Then beasure from the bolt holes and go .5" outward, and draw a line from the front to the rear line. Grind off that area.

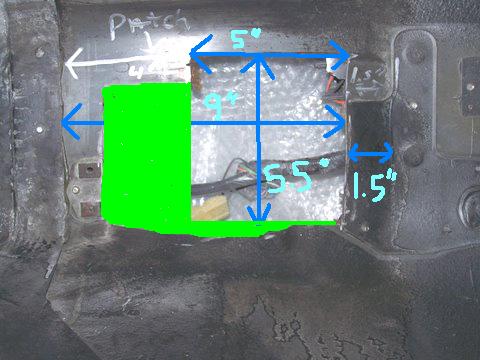

Cut a hole in your floor, PATCH THE REST!

Using these pictures as a guide, ensure a hole is cut into the floor section over the tunnel. Make sure any shifter or related components are removed:

The following picture illustrates the measurements of where the hole should be. The measurements are from the seat-mounting strap forward. My vehicle was an automatic, and had a hump for the shifter which I removed. I cut the hump out which game me a rectangle hole in the floor. I then had to fill in the green area, leaving a 5.5" wide by 5" long square hole.

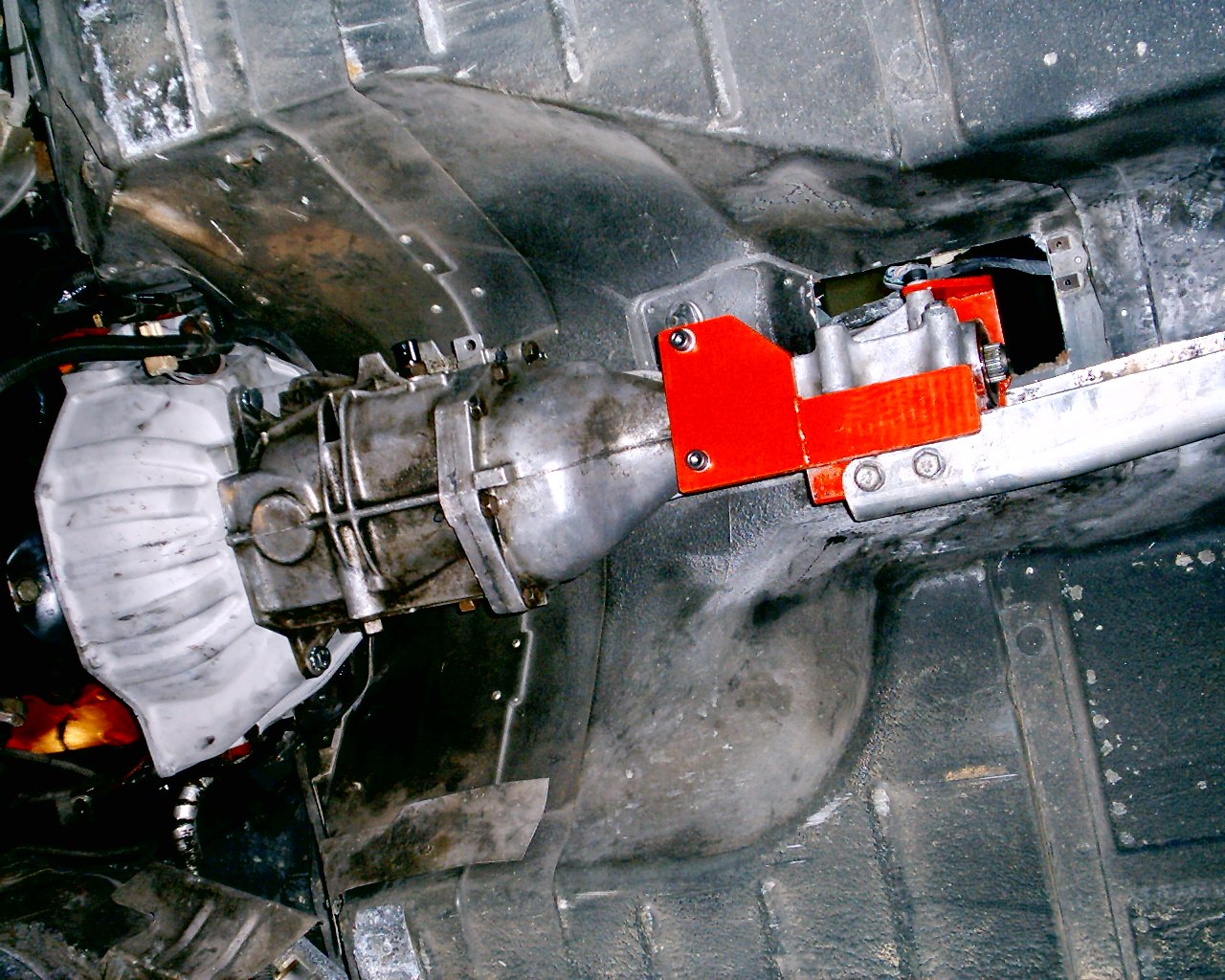

Transmission Installation

Now, Lift the T5 up into place and slide forward into the clutch, until the transmission stops

Have a friend step on the clutch pedal while your pushing the transmission forward, until it seats in the bearing.

If you do not have the hydraulics setup, you can pry the fork to the REAR simulating clutch action, to seat the input

shaft into the pilot bearing.

Align the transmission, and install all four bolts

I've found this next step is much easier if you disconnect the parking brake cable that goes from left to right in the rear.

Next, slide the cbeam over the adapter, and forward (to clear the differential)

Now you're going to want to jack the transmission all the way up, then slide the cbeam back to bolt it in.

Install all four cbeam bolts, and the driveshaft.

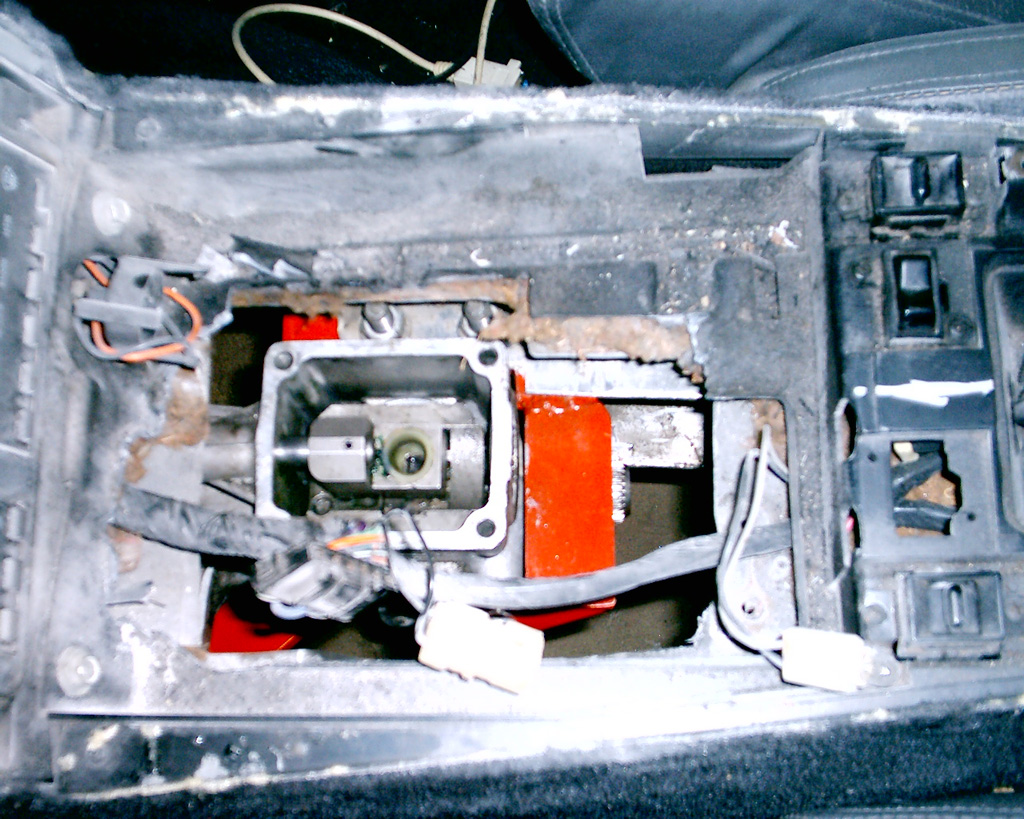

Shifter Installation

Remove center console, stock shifter, and Install modified shifter from the top.

Install hurst shifter boot, using self-tapping 6mm screws

If swapping from an automatic, you will need to send the green/red wires down to the reverse light switch

on the transmission. You will need to tie the purple/yellow wires to the clutch switch.

Final check

Reinstall exhaust and double check all torque values

R E F E R E N C E S PARTS SOURCES: CBEAM ADAPTER: Tommy's Speed Shop 216-316-9812 http://www.tommysspeedshop.com/ ATTN: Tom SPEEDOMETER PARTS: PATC Transmission Center 1-888-877-1008 http://www.transmissioncenter.net/ Note: You want a VSS Gear for an ELECTRONIC Sender! CLUTCHES (Dual friction): Fort Wayne Clutch 1-800-258-8243 http://www.fortwayneclutch.com ask for: HD 10 1/2 x 26 DF $160 + ship FLYWHEEL (Lightweight): Kajunjon-whitneytx Enterprises 254-694-6600 ask for: #V2023 for 86+ 1pc, or #V2025 for 84-85 2pc ($150 NEW)

USEFULL LINKS:

SPEEDOMETER CALCULATOR: http://www.bgsoflex.com/speedo1.html

T5 SPEEDO GEAR SWAP HOWTO: http://www.thirdgen.org/techboard/faq-board/351475-wc-t5-speedometer-gear.html

T5 SPEEDO GEAR SWAPS: http://sethirdgen.org/t5speedo.htm

T5 INFO & ID: http://www.5speeds.com/t5/