You must be logged in to rate content!

6 minute(s) of a 160 minute read

8-12-2011

On a go slow again I'm afraid. I'm in the middle of moving workshops and it is a bloody nightmare!

...and Josh "if gravity lets go" we will all explode so where the oil will go will be the least of my worries....especially seeing as the engine is in the back... it's spelt waiting not waithing...and yes tarmac clogging the air filter was a big concern of mine so I bought a tarmac eating dwarf space chimp that is housed within the roll cage - hence the title! -Try to pay attention in future

9-7-2011

Workshop walls and floor painted,

Racking built,

Tons of sh1te moved using a pu205 gti - nightmare!

Tons of ******* set up and found homes for - nearly there!

As you can see from my other workshop pics on this page, I now have a little bit more space around the car!

On with the build.

11-15-2011

I drove it today! Albeit sitting on a plastic crate, but a big step anyway. Fixed my water temp gauge, all in needed was an earth to the actual sender base, because it's in the water hose. Doh! Also got the clutch slave arm adjusted properly - easier said than done. Then I thought ******* it, let's drive it!

Rear number plate is way too low to be practical it turns out, so I'll be moving that next and then get the bulkhead and some seats in.

Ps Hi dan, just seen your post. How far along are you with yours?

11-16-2011

A pic of how I earthed the temp sender. Simple but effective.

...and yes it was good to get it rolling at last!

I also had the usual problem of the electric reverse drawing too much juice and killing the engine, which so many bike engine cars have suffered from. I have had a 2 farad capacitor tucked away for ages now incase I needed it. I'm going to give it a try, Wiring it in between the battery and the reverse motor. Hopefully that will stop the voltage drop when you use the reverse.

11-17-2011

That's about it really. The electric reverse is a starter motor. When you turn it on with the engine running it draws a lot of electricity, it must be either making the spark too weak or not giving the ecu enough volts or possibly both and the engine looses revs and cuts out.

Wiring a power cap in is like having an extra battery, the only difference is it can deliver all its stored power very quickly and hopefully this will cure the problem. They use them in large in car audio setups, to stop the headlights dimming when the subwoofers deliver big base. Therefore power capacitors are common as muck, cheap (mine was £10 on ebay) and they are sealed too so can be mounted anywhere.

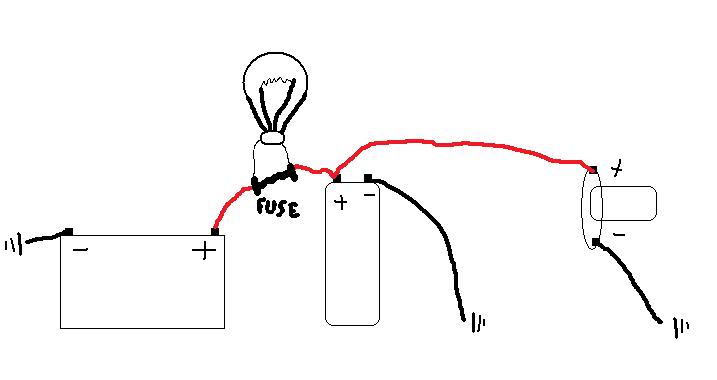

The only other thing worth noting is the initial Charging of the capacitor. You have to charge them through a resistor. But the best way to charge them is to use a light bulb. You can wire the cap in between the battery and the starter with a big fat fuse between the cap and the battery. Then remove the fuse. Place a resistor (or light bulb) in its place to bridge the gap where the fuse was. The bulb will light up bright and then fade to very dim when the capacitor is charged. You can then remove the bulb and replace the fuse and you are ready to go.

11-28-2011

I've wired the cap in temporarily but I haven't had a chance to test it properly yet. It didn't need charging as described above tho, I just wired it in and it quickly charged to 12v, when battery cut off was removed it gradually discharged to nothing over about 60 seconds.

Couldn't drive it yet I have been sorting out the number plate.

Doesn't look like much, but it's an inch higher, should make all the difference as before it had only 3 inch ground clearance. I've glassed it in now, but I haven't taken a pic yet,

12-1-2011

After glassing and a bit of tidying

Finished

All back together

12-3-2011

Buggered about for ages today and it is definately the ECU that doesn't like the voltage drop when the electric reverse is on, because when I wired it to a stand alone battery and hit reverse the engine kept going - trouble is it still kills everthing else electrical. I tried the power cap in between the electric reverse and the battery and it is not up to the job. Therefore I'm going to have to use a completely seperate battery for the reverse, but I ran out of time today. I will let you know how I get on.

Prior to this I took it for another test run and then tried to get the idle to match the manual 1100 rpm for a 2000 carb R1, but it kept cutting out, even when it's warm. So I then set the idle by ear and it idled perfectly - but the rev counter on the Acewell digi dash said 2200rpm exactly double what it should be. Because the rev counter is 12v, is it possible that the rpm output from the ECU is 6v (because bikes are aren't they?). And if my idiotic ramblings are correct, is there a resistor or something that could re-jig how my digi dash interprets the rpm signal?

I also checked to se if the carbs balanced and they were close. 1 was 2.5 and the other 3 were at 2, but I can't remeber what the scale was!

Anyway I've had a dig around and found that r1 carbs should be 22cm/Hg at 1100rpm.

Very cool build!

Posted by Diggymart on 2/5/20 @ 8:09:06 PM