You must be logged in to rate content!

5 minute(s) of a 461 minute read

4-11-2017

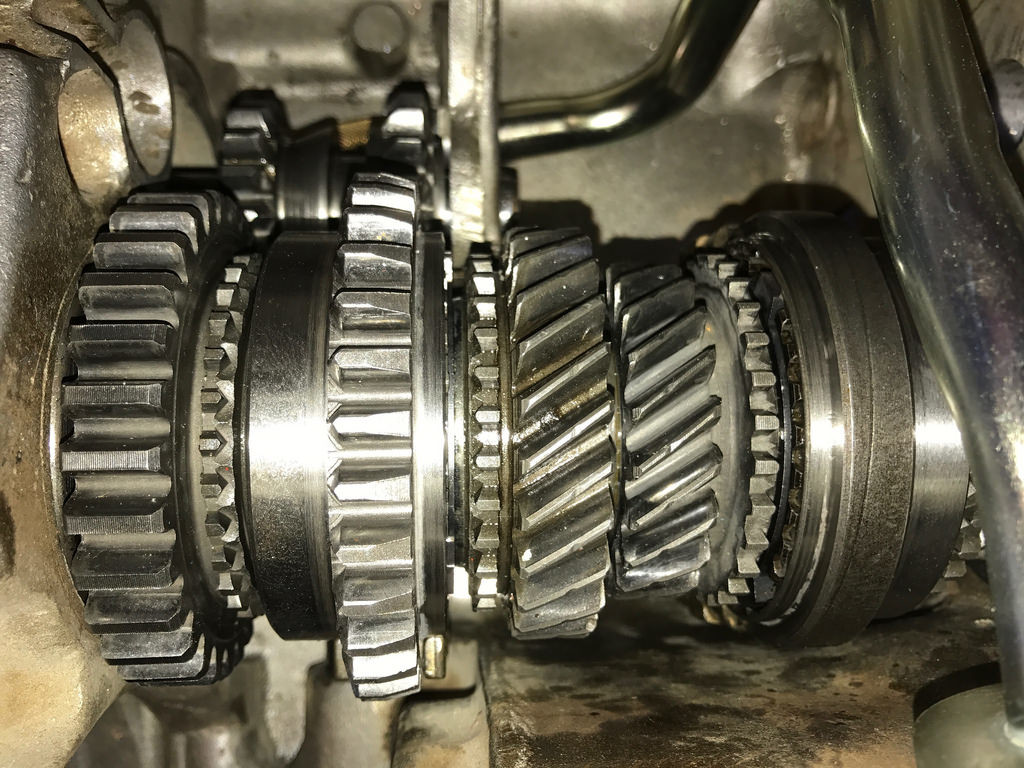

Today saw the start of the gearbox rebuild. If I did a step by step on this we would be here all week but it's 60% of the way there. Spent most of the day cleaning up the piece parts that have sat in oil since I disassembled the box. Brake cleaner in the parts washer worked a treat. New main, needle and roller bearings throughout as you would expect. Never want to take this box apart again![/size]

So here's a couple photos as I left it in the garage tonight. Used some spare gearbox oil left over from my Integra days as a build lubricant. Thinner than 20W50 that will eventually be in this so will get washed out of the parts in time anyway

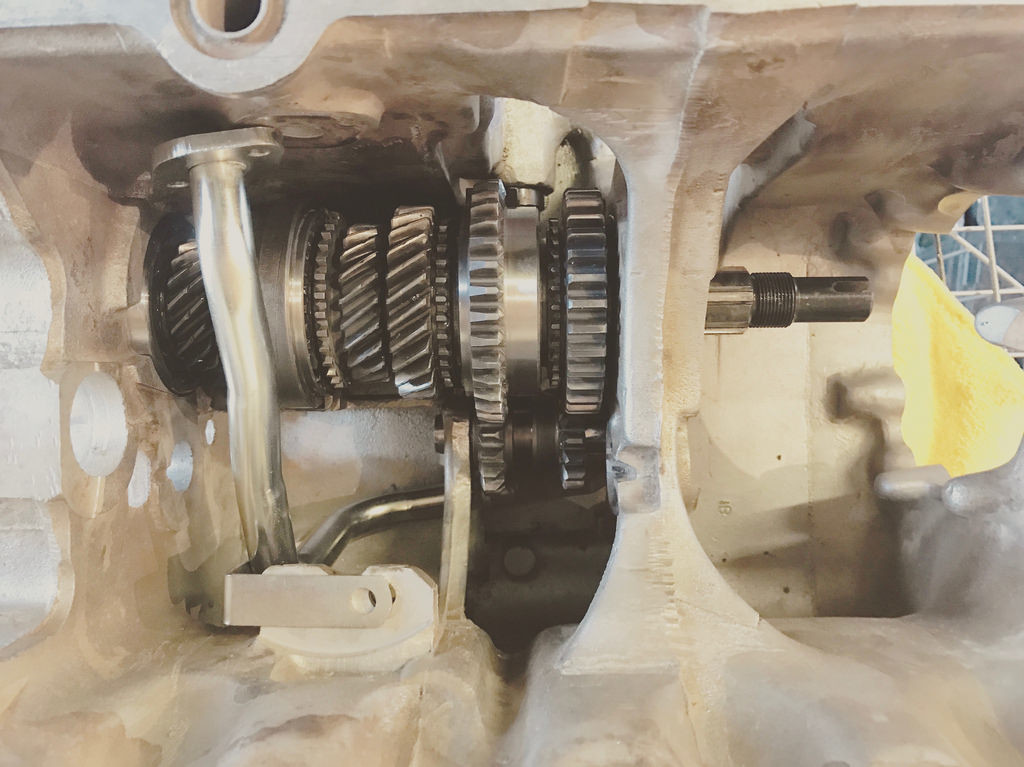

And in the box with just the lay shaft assembly to go in. I should note that the central oil pickup hasn't been bolted in until the layshaft is in. Should see a reduction in oil starvation in right hand turns like the standard oil pickup suffers from.

Got as far as fitting the new main bearings at either end of the main shaft

Need circlip pliers to permanently locate the main bearing at the other end of the main shaft, so if I get that first thing tomorrow it should be possible to get it all rebuilt by end of the day.[/size]

As I need the gearbox covers and plates done, I got stuck into them today.

These are a couple of blanking plates after media blasting. Can clearly see why I'm getting rid of the hammerite and going to powder coat instead. These weren't even in the line of fire for stone chips etc. Hammerite = *******.

Speedo drive housing, diff cover, blanking plates, thermostat cover and spacer plate and finally the oil filter housing all blasted and then powdered up ready for curing.

Not the best photo as it looks like they are pretty rough but in reality they are smooth and uniformly coated. Clear coats to go on tomorrow which will add a nice level of sheen. Ultimately these are going to be replaced with anodised billet versions when funds allow, so I'm not overly fussed by them but still want them to match the rest of the silver parts in the engine bay.

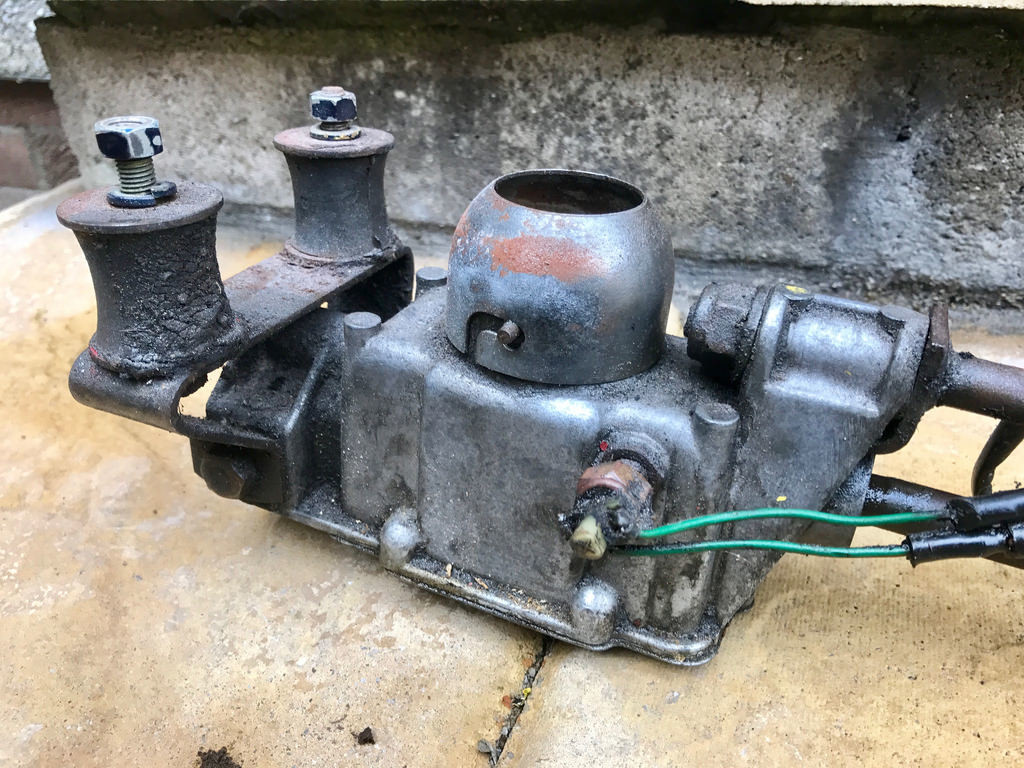

In order to fully test the gearbox once it is built up, i need a gear linkage. So whilst I was waiting for the above to cure, I took my spare linkage (from an old scrapper I broke with Greigzy years ago) and started to dismantle it to get it into powder as well. As you can see, its a bit minging and covered in oil from a previous leak.

Surprisingly enough, the internals weren't in bad condition and will just need a clean up and regrets going forwards. Just need to fire the two roll pins so i can get the shafts separated from the selector and get them coated black and the housing silver.

Ran out of high temp masking tape today so that puts a stop to powder coating until i can get some more. Still satisfying to eat away at the long list of jobs I have for the car. Hopefully get to spend a bit of money on it in time as well as I've managed to get a job again after being unemployed for the last three months.

Comments

I LOVE Mini Coopers. Wow fantastic detail / photos here!

Posted by Diggymart on 1/22/19 @ 4:17:19 PM

Congrats BOTW what a beauty!

Posted by Diggymart on 2/6/19 @ 3:15:15 PM