You must be logged in to rate content!

9 minute(s) of a 241 minute read

2-4-2017

Today i started by finishing the cooling system, after i connected all the coolant lines i decided to do a pressure test before i fill the system with coolant, started with the hand pump but i wasn't getting any pressure rise so i grabbed a nitrous bottle and a regulator and connected it, there where many loose hose clamps, i had to remove the battery tray to access some of them and after an hour tightening every hose clamp, the system was holding 1 bar of pressure without leaks so i filled the system up with G12 coolent and i had a leak, that is really strange, holds air but leaks liquids, decided to leave it, it should stop, after that i mounted the intercooler and radiator support, after that mounted the fans and passenger side headlight left the drivers side one because i need access to the wiring there, then i reinstall the battery tray, you can see all the space available in front of the engine now, it should make for easy timing belt replacement, more to come.

2-7-2017

To my knowledge the shafts between gearbox and transfer case is the weak point, that's what failed on my car, the gearbox internals are same as any 405 BE3 gearbox only the casting is different to be able to bolt the transfer case to it, the transfer case is different for the mi16 as it contains the viscous coupling, base models are 50% front and 50%back and had the option to lock the transfer case via actuator motor, and some base models had the ability to lock the rear diff also with a cable and actuator motor, the mi16x4 got the torsen diff, others had open diff, the series 2 with 4x4 are much more rare, there was the 405 T16 which future the same 4WD system as the mi16x4, but with more power from the turbocharged cast iron block 2 liter engine there are about 1000 T16 made, as for interchangeability between parts the shaft from the gearbox is the same on all 405 4x4 but the shaft in the transfer case is only interchangeable between mi16x4 and T16, the base models with 4x4 system are less prone to breaking those part because they have less power and smaller tires, there's specialist on the net that make parts they claim can make the 4wd system bulletproof, but they are out of my price range, if you are looking for the ultimate 405 to import, it would be 405T16 made in 1996, the 1995 car have electrical issues, problems with the hydraulic clutch and driveshaft failure, is a driving machine i've owned many 405's and can tell you that the 4WD cars feel much more solid, the fwd models are let down by the rear suspension is harsh on small bumps and seam to bounce and lose grip easy when hitting a crack in the road or rail tracks, the 4wd have hydraulic rear suspension no torsion bars no shock absorbers, the 4wd have incredible grip at any speed, i've put in half turn of steering lock at 160 km/h to avoid an accident and the car responded like a champ, no understeer, no oversteer, that is the good ting, but it uses about 10-15% more fuel, i know this because i've driven my car with the same engine as 4wd and fwd, and it takes more effort to steer as a 4wd and is heavier, my measured 1350 kg with 1/4 tank of fuel. I'm going to post pictures of the shafts that failed on my car tomorrow.

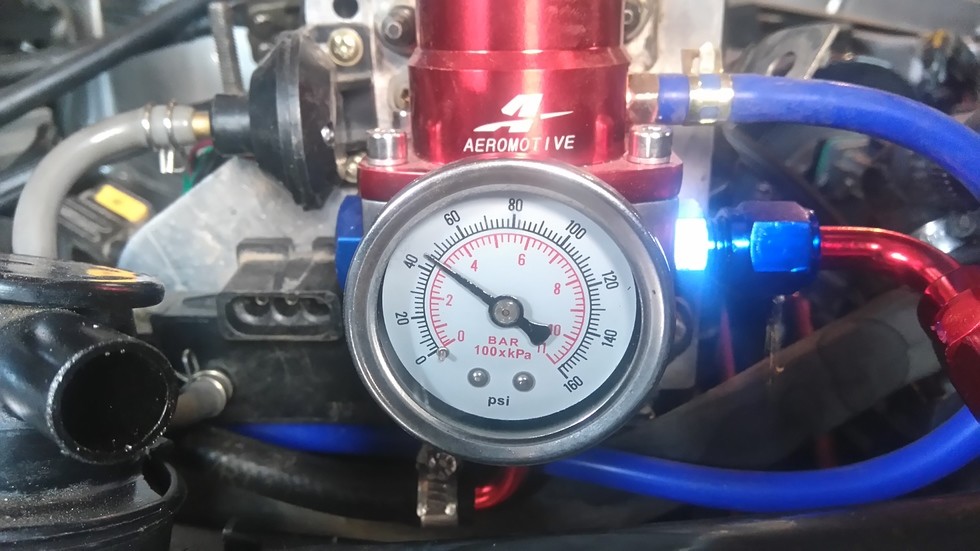

Today i spend couple of hours working on this project, i put couple of liters of fresh fuel and tested the system, has couple of leaks, so i went underneath tighten up couple of clamps and span half an hours tying back all the wires hoses hydraulic lines, after that i tested both fuel pumps and set the fuel pressure to 3 bar, i've had problems with fuel leaks on this car of and on ever since i have it, after the i started on the exhaust, installed the pieces the i mocked up before and it seems i'll have to move couple of them and make all new mounting points, more to come.

2-8-2017

Today i spend couple of hours working on this project, i put couple of liters of fresh fuel and tested the system, has couple of leaks, so i went underneath tighten up couple of clamps and span half an hours tying back all the wires hoses hydraulic lines, after that i tested both fuel pumps and set the fuel pressure to 3 bar, i've had problems with fuel leaks on this car of and on ever since i have it, after the i started on the exhaust, installed the pieces the i mocked up before and it seems i'll have to move couple of them and make all new mounting points, more to come.

2-9-2017

Today i had only a few hours to spend on this project, because of that i started with the brake power booster vacuum hose, then started with the main power cables and as always some of them are an inch short so i cut them back and crimp a piece copper pipe and will solder it later, i plan to do some more work tonight so i may write one more update today.

2-11-2017

Yesterday and today i did some more wiring and decided to try starting the engine, first had trouble with the battery and attached starter box and a charger, then the engine fired for a second, and died, then started to lock up, so i hot wire the second fuel pump and could hear what sounds like fuel is running inside the engine, so i'm thinking a fuel injector is leaking also the fuel system is not holding the pressure, letter today i'll remove the fuel rali and see whats what, more to come.

It's official the Mi16 runs, pull the fuel rail and injector number 4 is stuck open and is spraying full cone, good thing i have 6 injector so i just swapped it and the car fired up on the first crank, there was a lot of fuel already in the engine, the tachometer doesn't work for some reason but more Important the clutch works, press on the brakes and in gear letting the clutch it is stalling the engine, this is great news, i couldn't imagine having to remove the engine again to do something with the clutch, more to come.

2-13-2017

Last couple of days i've been working on the exhaust, started by mounting the rear part that i've already welded, it just needs hangers welded to it, so i made couple hangers from 8mm round rod, and from there continued installing and mounting the rest of the system, had to cut couple of new pieces to be able to move the muffler not to melt the CV boot, then i removed the entire system and started to weld all the pieces together, taking photos underneath is hard and they don't came out good so i took only couple, more to come.

2-15-2017

Today i spend couple of hours welding the exhaust, it was much harder than i thought, welding old rusty new, thin and thick pipes wasn't as easy as all new pieces, then i weld 3 bungs, 2 for oxygen sensors, one for exhaust temp, then i grounded the worst of the welds and painted the whole exhaust with high temp exhaust paint, more to come.