You must be logged in to rate content!

6 minute read

Wheel Hub/Bearing DIY

Compliments of Eimer123 @ dodgeforum.com

2-26-2012

Tools needed

- Air impact (a must)

- 35mm socket

- 21mm socket

- Torch wrench (one that will go up to 185 Ft/lbs)

- Bearing grease

- Locktite

- PB blaster or any type of penetrating spray

- Bungee cord

- Wire clean up wheel

- Wire brush

- One big sledge hammer (like 20 lbs)

- Some type of torch (map/oxygen or acetylene torch)

- Replacement flange bolts if your old ones are as messed up as mine. Bolt part #06104259AA flange bolt specs 10.9 steel M14 1.50 pitch 50mm length

Step 1.

Jack up truck, put on jack stands, take wheels off

Insert key into ignition and turn to keep the steering from locking up

Step 2.

Remove caliper adapter bolts (2) that are on the back side of the knuckle

Use 21mm Socket and impact gun

Step 3.

Bungee cord the caliper up and out of the way. Avoid pinching the brake hose.

Step 4.

Remove rotor and set aside

Step 5.

Spray axle treads with PB Blaster and wire brush threads

Step 6.

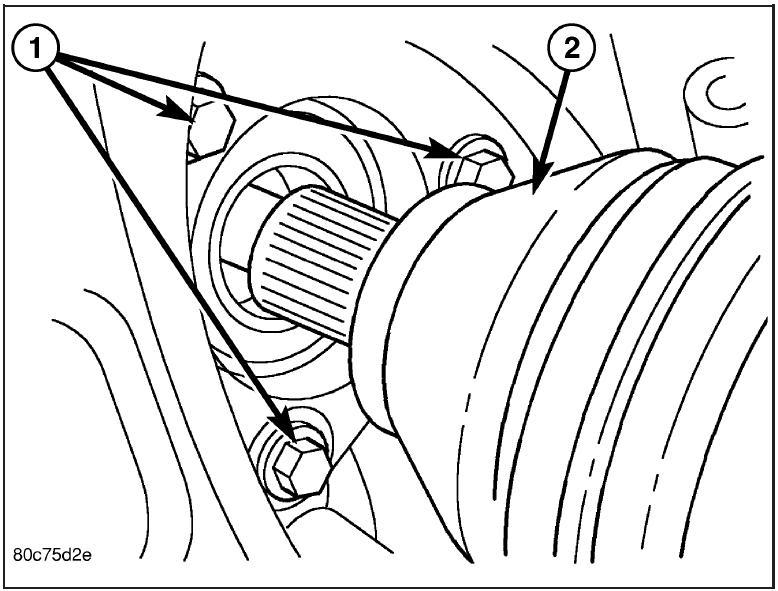

Remove axle nut (1) use 35mm Socket

Now for the fun fun fun part

Step 7.

If your bolts have been in as long as mine and rusted like no other you will need the torch for this step.

The wheel bearing is held in by (3) bolts on the back side of the knuckle. use a 21mm socket and impact gun

You will probably need to heat up the end of the bolts that stick out about 1/4" behind the wheel stud plate.

Step 8.

Once you have all three bolts out you will need to hammer the HECK out of the old wheel bearing until it gives in. (mine was rust welded on like no other) This is where the 20 lbs sledge hammer comes into play. Do not be gentle it will give in eventually and start to fall off. Make sure not to hit the axle splines with the wheel hub.

Step 9.

Remove the dust plate

Step 10.

Use wire brush and clean up the knuckle surface and inner mounting surfaces. (do not wire wheel the axle splines)

Step 11.

Use the bearing grease and put a light coat on the splines and the splines inside the new wheel bearings.

**EDIT** I have been told that it is a very good idea to put anti seize inside the knuckle and on the mounting face where the wheel hub touches the knuckle... Guess I will do that next time if I ever have to pull it apart again.

Step 12.

Slide the dust plate and new wheel hub into place (there is no specific position for the wheel hub, it is tri-consintric)

Put the bolts back in with locktite and torque down to 120 Ft/lbs

I found it easiest start the axle nut onto the threads to keep it from falling off while you try and get the bolts started. Make sure you have all three hub bolts installed before you tighten any one down. It is best to bring them in each a little at a time.

Step 13.

Put axle nut back on and tighten down as much as possible. (will torque later)

Step 14.

Reinstall brake caliper and bolts with locktite and torch to 130 Ft/lbs

Step 15.

Remove center cap from wheel and reinstall the wheels

Step 16.

Once the vehicle is back on the ground you will need to torque the axle nut to 185 Ft/lbs You need to do this when the wheels are back on because you have no other way to keep the axle from spinning besides using the trucks weight and friction of the tire.

Hope this helps someone. It is not that bad of a job. Best part is you do not need to remove the knuckle.

Total job time for me was 5 hours which included clean up. (I am sure I can do it a lot faster next time now that I know how to do it.

Shop wanted $160 a side. Thought I would save a few bucks and be able to do a write up.