You must be logged in to rate content!

12 minute read

Upper HVAC Led Conversion

Compliments of adrst2.3 @ focusfanatics.com

11-11-2012

THIS MOD LIKE ALL MODS MUST BE DONE WITH EXTREME CAUTION,I AM NOT RESPONSIBLE FOR FAILED ATTEMPTS!!!

IF YOUR NOT GOOD AT WIRING AND SOLDER CONSULT A PROFESSIONAL FOR THIS MOD!!!

this mod will not work if you have a euro black face w/orange defrost image!/

this mod will work for usdm svt/st and all other focus upper hvacs of the following years 01-07

Do it yourself time approximately 4hrs

Tools needed:

solder iron with a clean tip

1/8th in heatshrink

a lighter for heatshrink

dremal

dremal bit #192

4 in of black wire,red wire

spool of solder or a tube of solder

tube of silicone

glue gun with glue stick

2 spare glue sticks(if needed)

11 leds of your choice

4 resistors 560ohm or 680ohm depending on leds used.

i dont know how many people have done this but when i started i figured out the easiest way for me to do the upper hvac without breaking my neck and

spending over an hour trying to shave the hvac down to the green crap,

there are 3 layers the first layer is a thick milky white(not all are like this as you can see in the lower pic but there all the same in thickness) section about 3/16's thick the second layer which is the green layer is super thin so when you get here you have to slow down.

this is what i did i took a dremal just like the founder of this mod did(member on FJ )but i went a bit further with the mod giving the fact that his way took over an hour of dremaling the hvac and complete numbness of the neck.

im pretty sure this is the reason people wont do this mod.

anyway my method took me less then 20 minutes and left the hvac spotless.

as you can see in the pic below

basically with this mod you can do your hvac in any led color available and get the true led color thru the faceplate without any green film to ruin your day

ok so this is what you gotta do,

you have to grind in a ''c'' shape all around the back heres an hvac images to give you an idea of what im talking about.

you absolutely must use a dremal bit.this is the part number needed dremal bit #192.

this bit should be available at any hardware store

on to the mod,

as you dremal the outer"c" shape you must grind in a 90 degree angle to get around the images you must do this for both sides of each dial the inner ring and the outer.becarefull as you dremal down to where you get the milky white layer and the thin green layer as you get to this point.you need to be super carefull and slow because you will dremal thru the third layer which is the hvac face!

so what you have to do here is dremal slow until you see bits and pieces of the green layer opening up and showing the black face,

as you go around the"c" shape try to make as many sweeping back and forth cuts into the green layer as you can to expose the black layer once you do this stop and do the inner side where the button would pop thru and basically follow the same above procedure.

now once you do this for both sides of the dials you can pry the rest of the plastic off using a thin flat screw driver(becarefull not to perforate the face!.if the plastic doesnt come up dont force it just dremal some more.)

now most but not all the green film will come off so to remove this use laquer thinner.DO NOT SAND!!.this layer is extremely sensative and you will burn a hole thru it and ruin your hvac.

you can use other chemicals at your discretion but the best one i used without any side effects was laquer thinner.(use a cotton swab and dab thinner on it.

use a sweeping motion to remove green film.do this until the image is white.

you can use a flashlight to check for perfection

now on to the lighting part

for leds that use 2.0v-2.2v which would be the following colors(red,orange,yellow,green

you need to wire them in a series of three and with 680ohm1/2watt resistors.

leds that use 3.3v which will be the following colors(true green,blue,white,uv/purple)

will use 560 ohm 1/4watt resistors als wired in series of 3

like this (negative side of led1 will stay untouched,positive sideof led1 will link up to negative side of led2,postive of led2 will link up to negative side of led3 and positive side of led3 will stay untouched this side will get the resistor soldered in.to secure the leds to the hvac and to ease the wiring of them use a dab of hot glue and secure the leds to rear of the hvac side,glue them right on the image that is going to be lit.do not use SUPER GLUE!!!!,DO NOT USE EPOXY!!!

you will do this to all the leds for the upper hvac

you will use a total of 11 leds for the upper hvac

once you wire them all as stated above you will need to take all the resistor ends and solder them to 1 single wire(this wire will be your positive side used to hook up to the rear of the hvac cluster.

instruction is the same for the ground.

now once you wire your leds. you must absolutely double check your leds and observe the polarity side once you do this.apply 12V to them if they light up go on to the next step.if the leds dont lite up...double check for bad solder,missed polarity side on leds(make sure you placed leds on the hvac exacally as instructed above when you hot glued them),check for bad resistors(highly unlikely)but possible

,blown led,no 12v going to led mod etc..

next step is to secure your leds from shorting out and spreading the light evenly thru the hvac dial's

use heat shrink tubing at the end of the wires used for polarity going to the rear hvac then use a tube of clear automotive silicon and fill the cut out of the hvac.the best way to do this is if you used the tip provided with the silicon tube so you can (baist)the hvac and fill the holes around the leds and to leave a clean professional look.

it should look like this after the silicon injection

silicon used.

this silicon once curred will not smell it goes on clear and spreads the light perfectly.

PLEASE DO NOT CUT CORNERS AND USE HOT GLUE FOR THIS PART OF MOD.

HOT GLUE WILL MELT IN HOT TEMP AND CAUSE A SHORT OR EVEN FIRE!!!

let the hvac cure for a couple of hours or let fully cure for a couple of days

once this is done its time to wire them to the rear havc and complete your mod

if you notice the inside of the back hvac assembly there are 2 exposed holes to the right underneath the second to last socket here you will heat up each exposed hole and place some solder int it once you do that take each wire and do the same ad solder to the tips of the wire once this is done place the ground wire to the right side hole as you use your solder iron to melt the solder once you place the wire in the solder.remove the iron an let the solder cool the wire in place.you will do this for the other side as well.

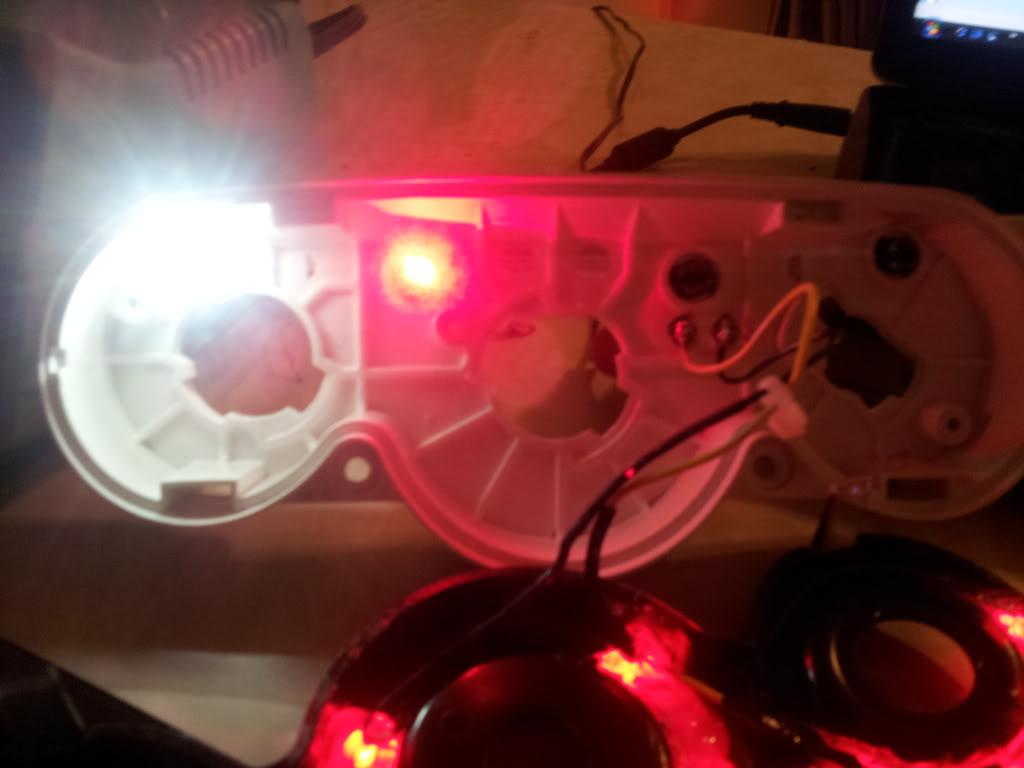

heres a pic before wiring in the face

after wiring in the face

observe the polarity left hand side(yellow wire-positive), right hand side (black wire-negative)

at this point your done just clip both hvac sides together and enjoy your awesome mod!!!

your hvac depending on the color should look like this...

image was darkened to try to get the blue on film,my cam sucks but the hvac lights up perfect with the other mod i did which will be put up tomorrow

heres a pic of the temp side.

what about the temp side why isnt it so bright?

that mod will be explained tomorrow.

hope this helps all you do it yourself guys!!!!

this is a continuation on my version of the upper hvac led conversion mod

last night i left off on the temp side lighting mod

this side requires no cutting or modification of the hvac but it will require skill and patience to do....so get ready and hear we go

time for mod is about 5minutes for experienced people and about 20 for

people who are new to soldering

i used the existing sockets and installed ultra bright white leds to make the temp side lite up as well as the rest of the hvac after modification but this can also be done for non modified hvac face plates.

first i removed the pins from the sockets like this...

then i soldered a left over wire end from the leds i used for the hvac(whoohoo recycling!!!) on to 1 of the socket ends like this...

once that was done i soldered the resistor to the other socket end

like this...

now if youve made it this far and are fustrated dont give up the modification of the socket is almost done but...theres more fustration to come,lol.jk.

once you solder both ends to ether socket end pop them into the socket

like this....

once you do this do not remove the extra wire coming off the resistor.

you will do this last.

now that you have done all of the above all you need to do is place the smd led between the pins and solder it.

the polarity side of the smd leds is the flat part of the smd not the notched side,you will solder this side(flat side of smd)to the resistor side of the socket like this...

once you do this all you have to do is tack the other side and your done.

test your led with an outside 12v power sourch or plug it in to the hvac

the resistor side will go on the lower connection of the socket assembly.

if you install it wrong you will see that it doesnt lite up just reverse the socket and it should lite.

do not take to long to observe the lite output because the led will blow.

do a quick check and proceed.

once your done your custom hvac should look like this....

now what i did when i did my hvac red was i installed a red led using the same proceeder above on the socket thats second to last of the left side and i used the white smd to lite up the blue side of the temp dial and thats how i got a nice even look

this is how it looks with the face off using the red led and the smd...

for blue hvacs i used a blue led for the blue side and the white smd for the red side of the temp dial.you might need to bend the smd alittle to the left so its not so bright on the blue leds in the center dial but it wont be much.

now once your done with the socket you can fill it with hot glue or silicone but that would be optional since the socket keeds everything secure.

you might be wondering why i used an led versus a smd for the other socket.

well my reason is the smd is realy bright and will bleed out into the other hvac color so to even it out i used the led since its not as bright as the smd

and just placed it were necessary to get the perfect lighting to that side.

enjoy guys!!!! theres more to come.