You must be logged in to rate content!

5 minute(s) of a 210 minute read

7-26-2021

I've been a bit quiet getting the Cortina prepared for an MOT and tracking which takes a huge of time but has little to show for it!

being tight I purchased a pair of second hand headlamp rings that for some bizarre reason had been painted black, I figured I'd have a go at rubbing them down and polishing them up to see if I could get a shine on it and see how long they last! I'm rather happy with the results.

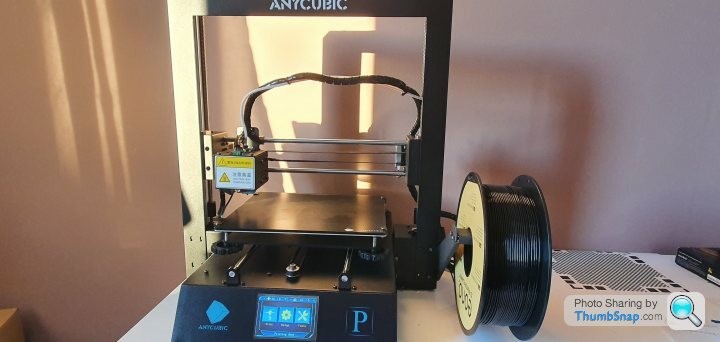

I made a decision to sell the lathe as I was struggling to open the doors fully so after a problematic set of bay bidders it has gone and it's freed up space and put some cash in my pocket! One thing I did buy was a 3D printer which is fascinating to use and watch. I do a lot of CAD work but I design for fabrication/ manufacture so I'm used to drawing something that is then cut/ welded/ machined etc whereas with a printer I am literally drawing the item as I want it which is a little different!

The first test was a functional M10 thread without cutting a thread myself, again I use the CAD library on Inventor that generates fasteners as drawing threads would normally take up file space. The great thing is that it worked with no issues.

8-16-2021

I'd like to say I've been busy but it seems as though the last 5% to get the Cortina ready for the road and functional is giving me a real kicking!

The main reason I purchased the printer a few weeks ago was to start making brackets and the one I had in mind was for a coolant catch bottle.

Currently (and for the last 50 years) the Cortina has relied on it's big headed radiator to act as a suitable overflow should the water get hot and expand it'll just stay there and it's extra capacity means that this is seldom used. If you get it too hot and the coolant has nowhere to go the cap will go under pressure and open a vent pipe that takes boiling water from under the radiator cap, along a pipe to the inner wing and then disperse it over the drivers front wheel/ brake!

Whilst this is a rarity I don't need to make these brakes any less effective than they already are!

I like the look of the alcohol bottles because I'm a child and have seen people use these instead of their header tanks so I don't think seldom used version will be an issue.

I chose Chambord because the bottle looks like the Holy hand grenade from Monty Python's quest for the holy grail - as I said, I'm a child!

Being a design engineer and smart arse I modelled it all on CAD and rendered it because reasons...

after 7 hours of printing I had this. I used PETG as it'll withstand a hotter temperature and has better impact resistance than PLA.

Usually with these projects I've seen people just run the hose into the bottle and call it a day, I wanted to not only retain the cap but also make it look like it's not half finished. I drilled the cap and used 1/4" bsp fittings with the top bung being drilled to allow gasses to pass and not explode the bottle like a grenade!

I'm happy with the result and how it looks, I know it won't draw the coolant once it retracts when cooled but for how little it will be used I'm fine with unscrewing the cap and manually putting it back into the radiator once cold.

Comments

Great work mate! Loved the taillights and fins on these cortinas. Remind me of the old type 34 VWs.

Posted by MPower on 10/31/20 @ 3:15:41 AM

Thank you! I had never made that connection before, you're right!

Posted by Jim_builds on 11/16/20 @ 2:29:18 PM

Thank you Steve I appreciate the support, it feels like a lifetime since I did a lot of the work! Hopefully I'll be back on the road early next year so I can finally put some miles on her.

Posted by Jim_builds on 10/26/20 @ 12:08:47 PM

Beautiful Cortina! Looks like a lot of work but you did a bang up job! Glad you saved this one!

Posted by stevegolf on 10/22/20 @ 11:06:39 PM

Thanks for all the photos! Such a cool car!

Posted by Diggymart on 11/12/23 @ 10:55:36 PM