You must be logged in to rate content!

7 minute(s) of a 96 minute read

1-16-2009

Jibberjive's RS6 Build Log

Compliments of jibberjive @ audiworld.com

3-16-2009

Here's the setup I'm working on and it should be done within the next little bit. I'll update this first post with new pics as it progresses. This is by no means a complete list and I'll get more thorough later.

Engine:

- Custom Exhaust Manifolds - Agtronic Motorsport

- 3" V-band Downpipes, Inlets and Turbos modified by Agtronic Motorsport

- Garrett GT2860-707160-7's and oil/coolant lines - SMS Performance

- TiAL MV-S 38mm V-band wastegates - SMS Performance

- eurojet "Kugel" grenade diverter valve - eurojet racing

- Supertech Intake and Dual Exhaust Valve Springs/Titanium Retainers/Inconel Exhaust Valves, 1mm Oversize High Temp Stainless Intake Valves, Phoenlic spacers - Issam@034

- Bosch 044 drop-in - Issam@034

- Integrated Engineering Rods - Pete@Integrated

- Custom E85 tune - Greg@SSP

- 82lb Siemens Injectors, Bosch F5DPOR plugs, 85mm MAF - Greg@SSP

- Clutch Masters Stage 4 FX400 6-puck w/ WMS Steel Flywheel - Wicked Motorsports (WMS)

- ARD Bipipes - ARDesign

- ER SMIC's

- SDR X-1 Intake and RS4 accordian

- Ebay silicone tubes

- 2.8 heads w/ 2.8 cams

- RS4 headgaskets

- Big EFK - VAST

- 034 Track Density Engine/Tranny Mounts, Phoenlic Spacers, Apikol Rear Diff Mount - Issam@034

- Zeitronix Wideband

- JHM Hallman in-cabin MBC, SS, Shifter Linkage, Delrin Bushing - JHM

- 150 amp 14.8 volt upgraded Alternator "Ultranator" - [email protected]

Interior:

- RS4 shift ****

- B6 Ultrasport steering wheel and TT airbag

- Carbon fiber interior trim - Carbonetiks

- AWE new vent boost gauge

- Pioneer AVIC-f90bt

- Critical Mass UL12's

- Powerbass XA-3000d

Exterior:

- Sport Mirrors (or maybe something crazy[ ])

])

- RS4 grill

- 20% Suntek Carbon Series Tint

- Depo E-codes

- 55W DDM HID Kit

- Carbon fiber engine covers (and maybe a couple other parts)

This list is only new stuff that I'm adding. Pics:

Turbos Garrett 2860-7's (unmodified)

TiAL MV-S Wastegates

034 Track Density motor/tranny mounts, Apikol rear diff mount, poly mount for DTS

Integrated Engineering Rods w/ ARP bolts

eurojet "Kugel" diverter valves

2.8 Heads

ARD Bipipes

Ebay silicone pipes

ER SMIC's

SDR X-1 Intake

VAST EFK and tidbits

JHM Hallman In-cabin adjustable MBC

Sport mirrors

RS4 grill

Depo E-codes

DDM 55w H7 HID kit

RS4 Shift ****

B6 S-line steering wheel w/ TT airbag

Pioneer AVIC-f90bt

CM UL12's

Powerbass XA-3000D

What my front room looked like

Stage 2+ preliminary baseline dyno (enriching and pulling timing with bad EGT)

One of many new tools

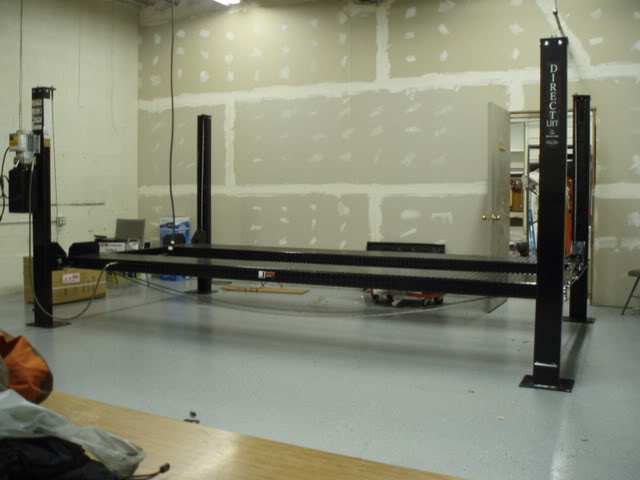

My shop that I've been cleaning out, prepping, painting and outfitting for the past little bit

New 4 post lift!

Pops helping assemble lift

Almost assembled

1/9/09

Well I finally got the lift fully assembled last weekend

And took a final shot of the car before I started taking some parts out

Great build nice detail!

Posted by Diggymart on 2/27/19 @ 2:48:23 PM